3 … 16

Printed in Germany • Rösler Druck • Edition 02.08 • Nr. 240 164

Overview

• Microprocessor-based electronics

• Installation in housing to IP20

• Connection system with RAST 5 and

RAST 2.5 plug-in connectors

• 24 VDC/25 mA power supply for

powering external current level

converters

• Selectable input for power actuator

signals either as voltage input of

0...10 V/2...10 V or as current input

of 0...20 mA/4...20 mA.

• 0...10 V/2...10 V output

• 0...20 mA/4...20 mA output

• Integrated eBUS connection

• “Four-wire eBUS” connection (TTL

level) for connecting automatic burner

control systems without fully integra-

ted eBUS connection

• Connection for external display unit

for instrument parameterising

DLU 02 Dungs power converter for coupling controllers and DDC systems with eBUS-compatible auto-

matic burner control systems

The Dungs DLU 02 power converter has the following functions:

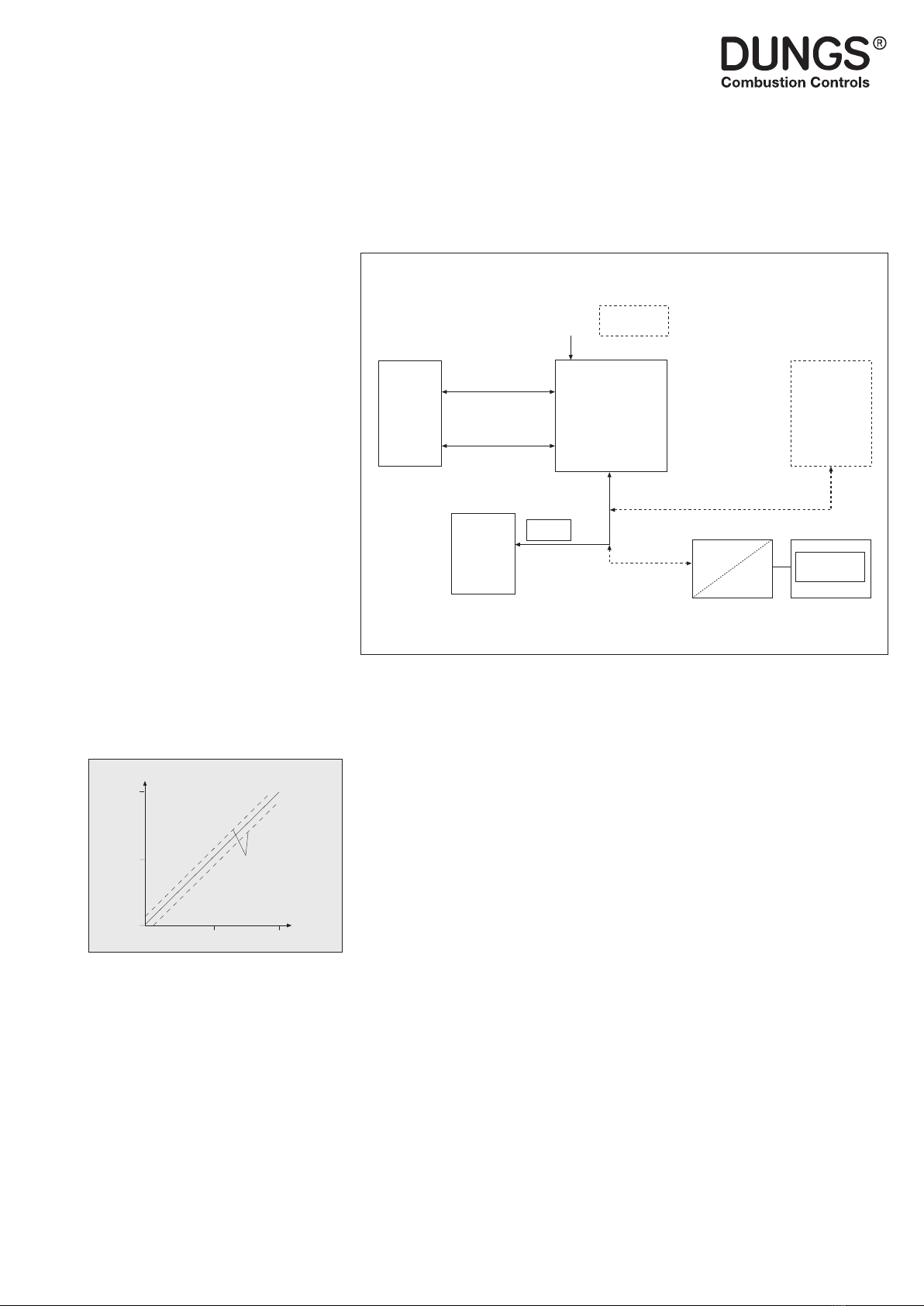

Schematic Diagram

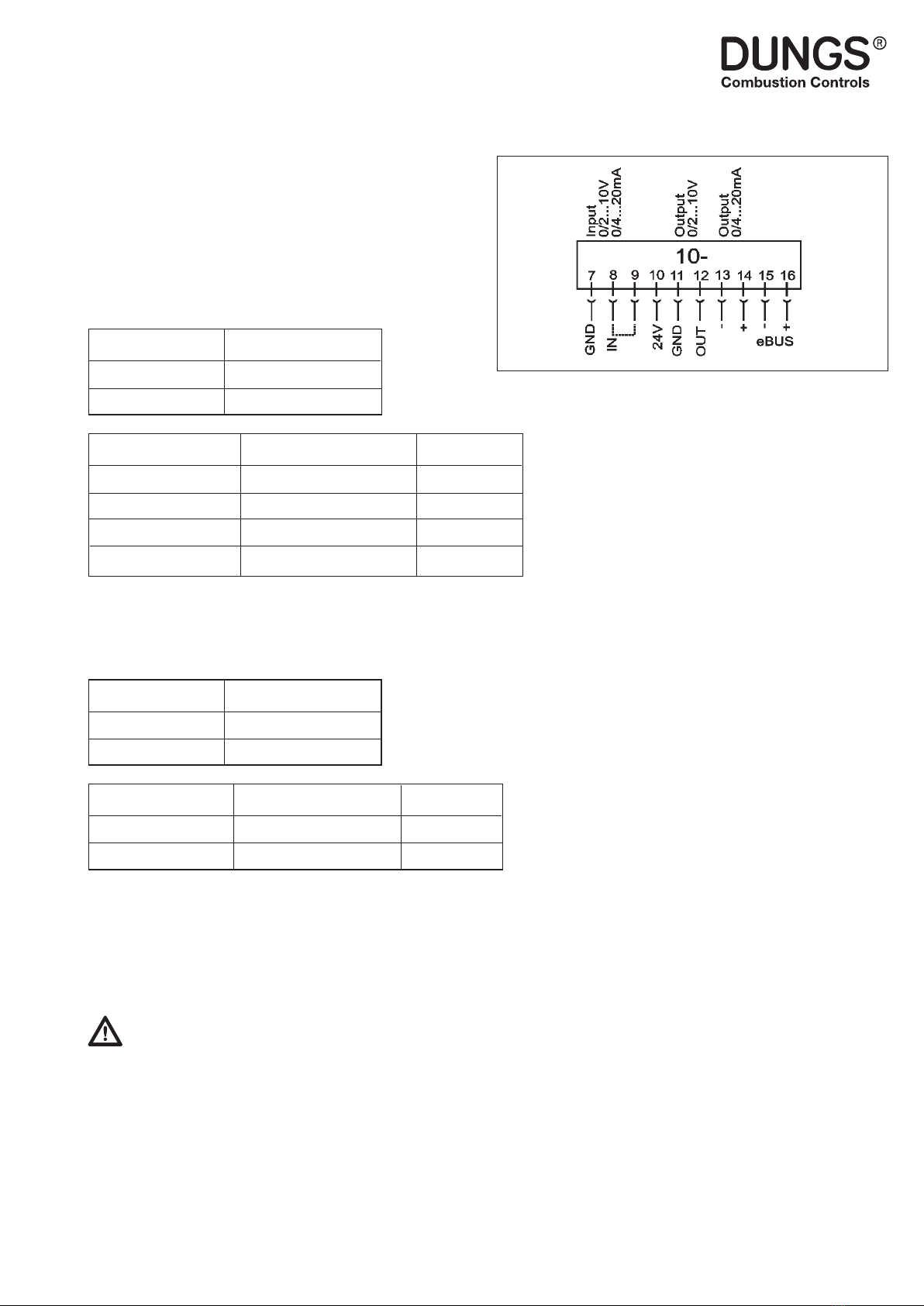

Voltage/current input

Input for controlling the modulation of a

connected MPA series automatic bur-

ner control system using eBUS.

The voltage input converts the 0...10 V

voltage to a modulation depth of 0...100

% and sends this via the eBUS to a

connected automatic burner control

system. The voltage input can be used

as a current input by placing a jumper

between terminals 8 and 9. This current

input can be switched from 0..20 mA

to 4...20 mA using a software switch.

Negligible changes to the input para-

meter are not transmitted immediately.

Changes which are smaller than the

hysteresis

(+/- 5 % of the end value) are transmit-

ted after one minute.

Voltage/current input

The DLU 02 supplies the modulation

depth sent by the MPA as an analogue

output variable. A modulation depth

of 100 % (10 V) means 100 % power

whereas a modulation depth of 0 % (0 V)

indicates that burner is running at mini-

mum power. The modulation depth can

be measured as a current signal (0...20

mA) using the current output. This out-

put can be adjusted to 4...20 mA using

a software switch. As the output signals

of the voltage and current outputs are

internally linked, the voltage output also

switches from 0...10 V to 2...10 V.

Power supply output

There is a power supply of 24 VDC for

powering external modules (such as

level converters). This supply has a load

capacity of max. 25 mA.

eBUS interface

The DLU 02 has a fully-functional

eBUS interface. An eBUS supply with

a constant current of 20 mA and SYN

character generator are integrated.

0 %

50 %

100 %

Modulation depth

0 V

0/4 mA

5 V

0/4 mA

10 V

0/4 mA

Input

Hysteresis

“Four-wire eBUS” connection

To connect the DLU 02 to automatic

burner control systems which are only

equipped with a “four-wire eBUS”

interface (e.g. MPA22), the DLU 02

is also tted with such an interface.

Both devices can be interconnected

using a special connecting cable

without the need for a special MPA/

eBUS adapter.

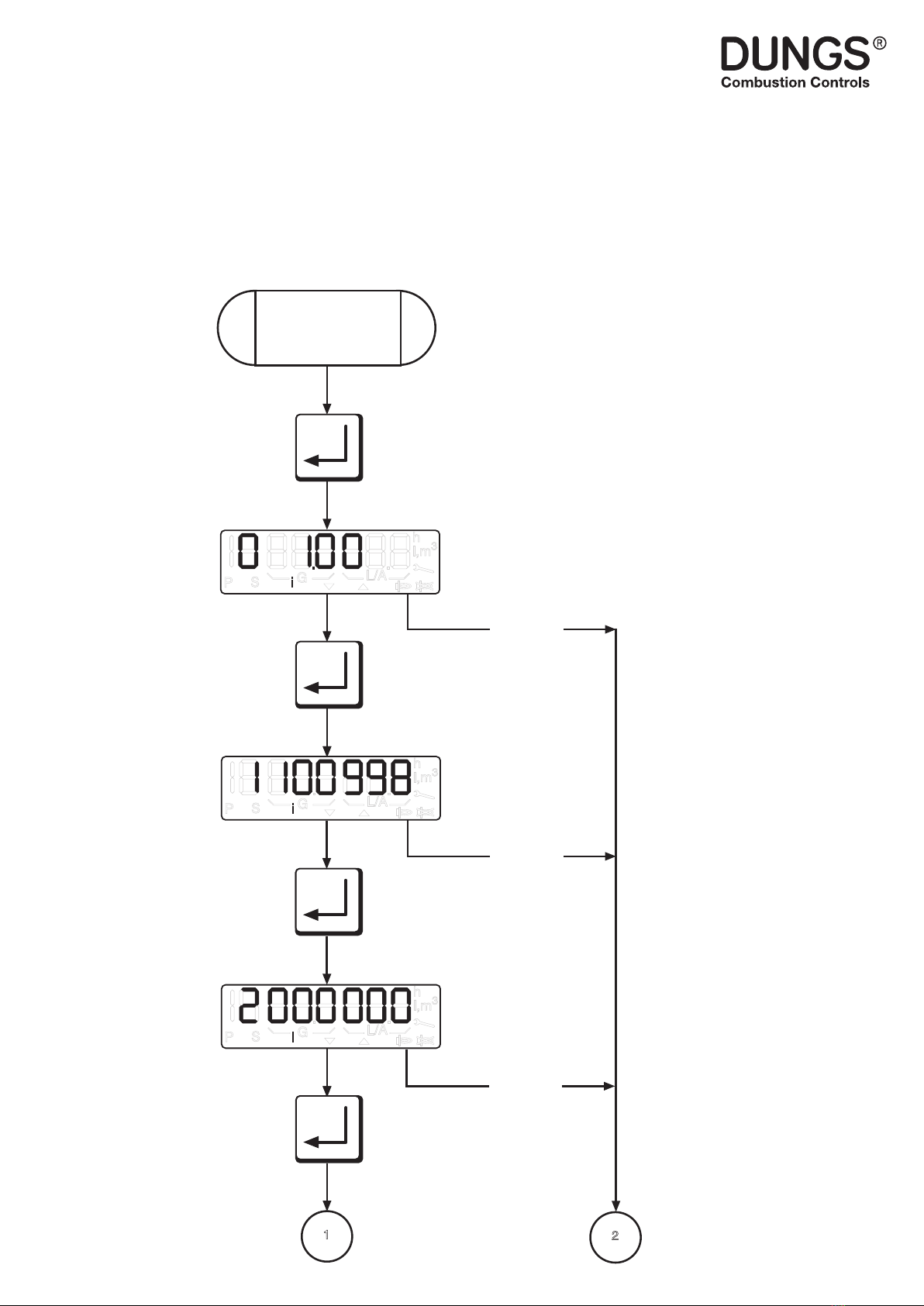

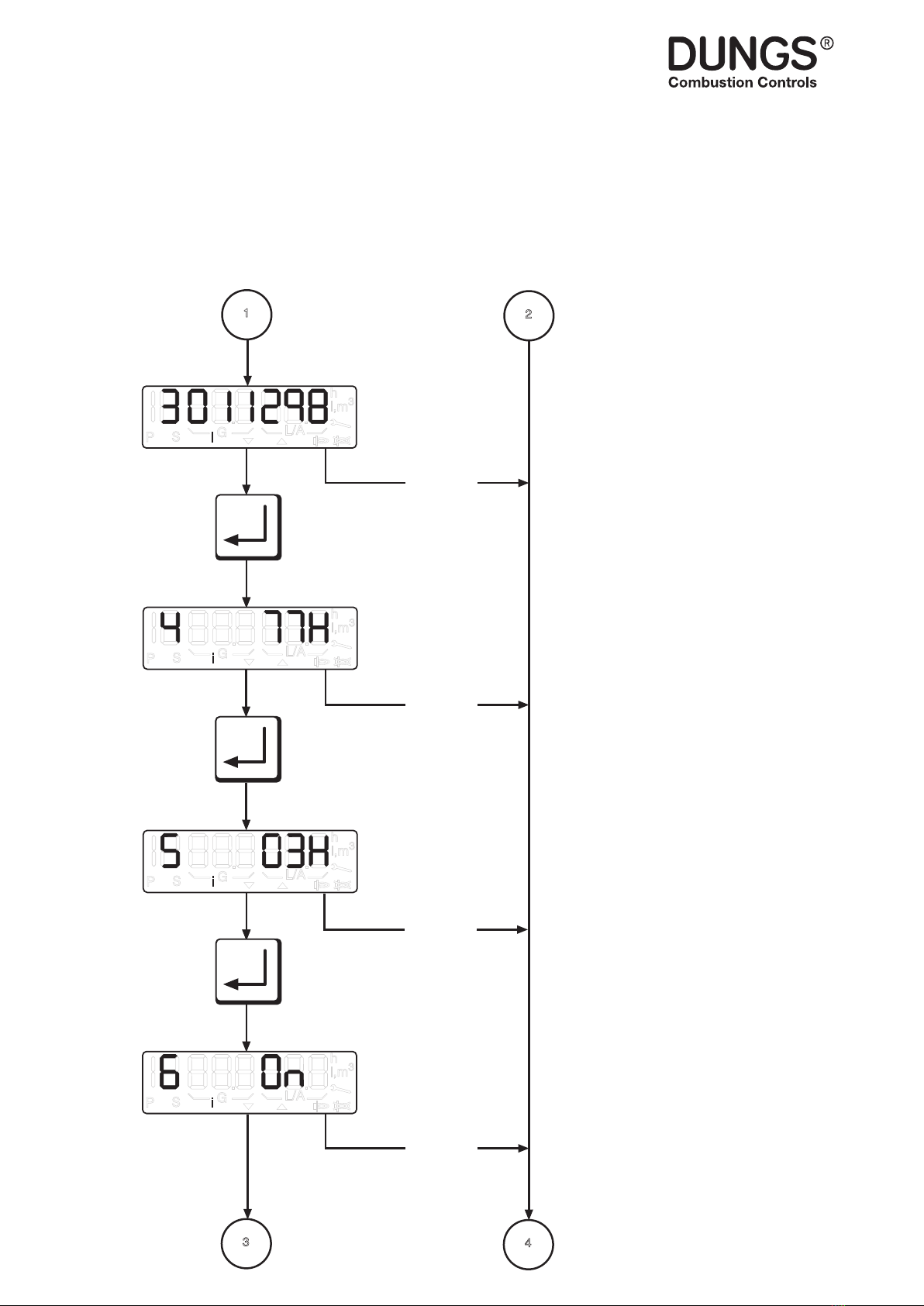

Connection for external display

unit

The DLU 02 is parameterised using

an external display unit which is not

required for operation. The display unit

is a special accessory.

Alternatively, you have the option

of parameterising the DLU02 with

MPA-Vision.

DLU 02

power

converter

PC with

MPA-Vision MV5

eBUS

PC adapter

Automatic

burner control

system

eBUS

Regulator

Analogue control variable

0...10 V, 0...20 mA

or 4...20 mA

Analogue return signal

0...10 V, 0...20 mA

or 4...20 mA

Display

Mains

Other eBUS-

subscriber