5

WARNING

Besuretoprovide enough fresh air for combustion. Enough

airinsuresproper combustion and assures that no hazard

will develop due to the lack of oxygen.

You must provide for enough fresh air to assure proper combustion. The

fireintheboilerusesoxygen.Itmusthave acontinuoussupply.Theairin

a house contains only enough oxygen to supply the burner for a short

time.Outsideairmustenterthehousetoreplacethatusedbytheburner.

Studyfollowingexamples1and2todetermineyourfreshairrequirements.

EXAMPLE1:BoilerLocatedin UnconfinedSpace

An unconfined space is defined as a space whose volume is not less

than 50 cubic feet per 1,000 Btu per hour of the total input rating of all

appliances installed in that space.

If your boiler is in an open area (unpartitioned basement) in a

conventionalhouse,the air that leaksthroughthecracksaround doors

and windows will usually be adequate to provide air for combustion.

The doors should not fit tightly. Do not caulk the cracks around the

windows.

Equipmentlocatedinbuildingsofunusuallytightconstruction shall be

providedwithairforcombustion,ventilation,and dilution of flue gases

using the methods described in example 2B or shall be specially

engineered. The authority having jurisdiction must approve specially

engineeredinstallations.

EXAMPLE 2: Boiler Located in Confined Space

A. All Air from Inside the Building: The confined space shall be

providedwith two permanentopeningscommunicatingdirectly with

an additional room(s) of sufficient volume so that the combined

volume of all spaces meets the criteria for an unconfined space.

The total input of all gas utilization equipment installed in the

combinedspaceshall beconsidered in making this determination.

Each opening shall have a minimum free area of one square inch

per 1,000 Btu per hour of the total input rating of all gas utilization

equipment in the confined space, but not less that 100 square

inches. One opening shall be within 12 inches of the top and one

within 12 inches of the bottom of the enclosure. The minimum

dimension of air openings shall not be less than 3 inches.

B. All Air from Outdoors: The confined space shall communicate

withtheoutdoors in accordance withmethods1or2.Theminimum

dimension of air openings shall not be less than 3 in. Where ducts

are used, they shall be of the same cross-sectional area as the

free area of the openings to which they connect.

1.Twopermanent openings,onecommencing within 12 inchesof

the top. and one commencing within 12 inches of the bottom,

of the enclosure shall be provided. The openings shall

communicate directly, or by the ducts, with the outdoors or

spaces(crawlorattic)thatfreelycommunicatewiththeoutdoors.

a) Where directly communicating with the outdoors or where

communicating to the outdoors through vertical ducts. each

opening shall have a minimum free area of 1 sq. in. per 4000

Btuperhourof totalinputratingofallequipmentintheenclosure.

(See Figure 3B)

b)Where communicatingwiththe outdoorsthrough horizontalducts.

each opening shall have a minimum free area of 1 sq. in. per

2000 Btu per hour of total input rating of all equipment in the

enclosure. (See Figure 38.)

Fresh Air for Combustion

NOTE

Ifyouusea fireplace or a kitchen or bathroomexhaust fan,

you should install an outside air intake. These devices will

rob the boiler and water heater of combustion air.

2. One permanent opening commencing with 12 inches of

the top of the enclosure, shall be permitted where the

equipment has clearance of at least 1 inch from the sides

andbackand 6 inches from the frontof theappliance. The

opening shall directly communicate with the outdoors or

shall communicate through a vertical or horizontal duct to

the outdoors or spaces (crawl or attic) that freely

communicate with the outdoor, and shall have a minimun

free area of:

a) 1 sq. inch per 3000 Btu per hour of the tatal input of all

equipment located in the enclosure ( See Figure 4), and

b)Notless than the sum of the areas ofall ventconnectors

in theconfined space.

Provision for combustion and ventilation air must be in accordance with Section 5.3, Air for Combustion and Ventilation,

of the National Fuel Gas Code, ANSI Z223.1-latest revision, or applicable provisions of the local building codes.

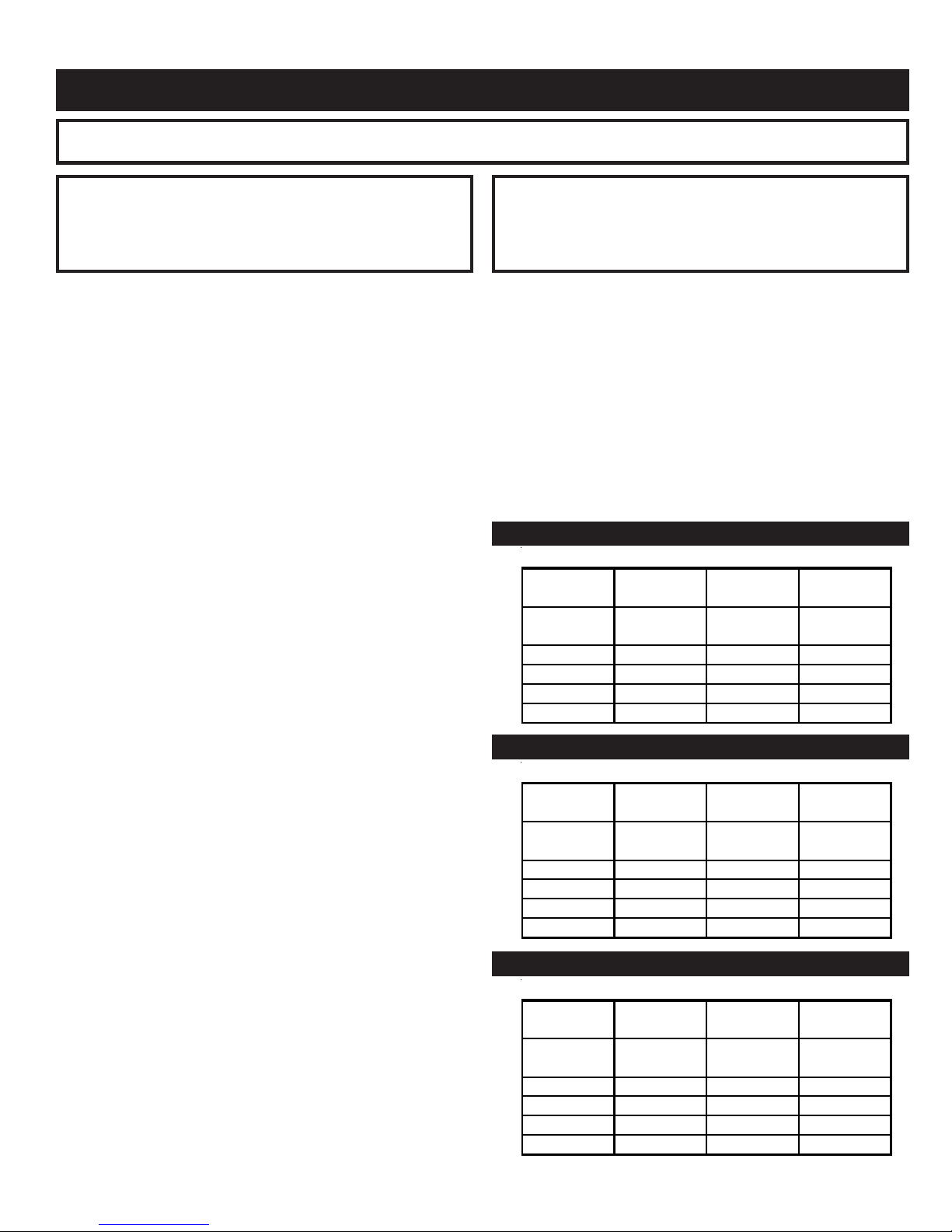

100% Free 75% Free 25% Free

Area Area Area

Fresh Air ¼" Wire Metal Wood

Duct Size Mesh Louvers Louvers

3" x 12" 144,000 108,000 36,000

8" x 8" 256,000 192,000 64,000

8" 12" 384,000 288,000 96,000

8½" x 16" 512,000 384,000 128,000

1 Square Inch per 4,000 Btuh

100% Free 75% Free 25% Free

Area Area Area

Fresh Air ¼" Wire Metal Wood

Duct Size Mesh Louvers Louvers

3" x 12" 72,000 54,000 18,000

8" x 8" 128,000 96,000 32,000

8" 12" 192,000 144,000 48,000

8½" x 16" 256,000 192,000 64,000

1 Square Inch per 2,000 Btuh

100% Free 75% Free 25% Free

Area Area Area

Fresh Air ¼" Wire Metal Wood

Duct Size Mesh Louvers Louvers

3" x 12" 108,000 81,000 27,000

8" x 8" 192,000 144,000 48,000

8" 12" 288,000 216,000 72,000

8½" x 16" 384,000 288,000 96,000

1 Square Inch per 3,000 Btuh

Figure 3A - FRESH AIR DUCT CAPACITIES (Btuh)

Figure 3B - FRESH AIR DUCT CAPACITIES (Btuh)

Figure 4 - FRESH AIR DUCT CAPACITIES (Btuh)