321240

Instruc)on Manua

Duren Too s

www.duren.co.uk

8 NEVER yank the plug from the socket with the power lead. Never expose to heat, oil, water or sharp

edges.

9DO NOT use this appliance with wet hands or your feet.

10 DO NOT allow children to use or play with this tool or enter the work area.

11 DO NOT store this tool in a place that is within reach or accessible to children or unauthorised

persons.

12 Store this tool in a dry and secure location.

13 DO NOT open or tamper with any part of this tool. Cleaning of

the spraygun is permitted but repairs can and must only be

carried out by an authorised service centre.

14 A WAYS spray in a well ventilated area.

15 A WAYS wear an approved respirator when using this machine.

16 DO NOT spray at animals, plants, other persons or their

property under any circumstance.

17 A WAYS keep you work area clean and tidy. Untidy work areas are a

hazard to yourself and others.

18 A WAYS maintain a stable, secure and comfortable posture when working with this tool. Always avoid

stretching and over reaching.

19 Avoid using a platform or hop up when using this tool.

20 A WAYS stand on a stable, dry, non-slip surface and wear protective footwear when using this tool.

21 Always wear or use the relevant PPE, protective footwear, appropriate gloves, ear defenders,

respirator and eye protection must always be worn. Do not wear loose clothing, rings or jewellery and

tie long hair back.

22 Unauthorised persons and children should not be allowed near the work area or to use the tool and

should not be left alone with it.

23 All visitors should be made aware of the tool and the hazards relating to it, including but not limited to;

A: The potentially hazardous nature of the paint material and implications of contact with

skin, eyes, clothing and the breathing of vapours.

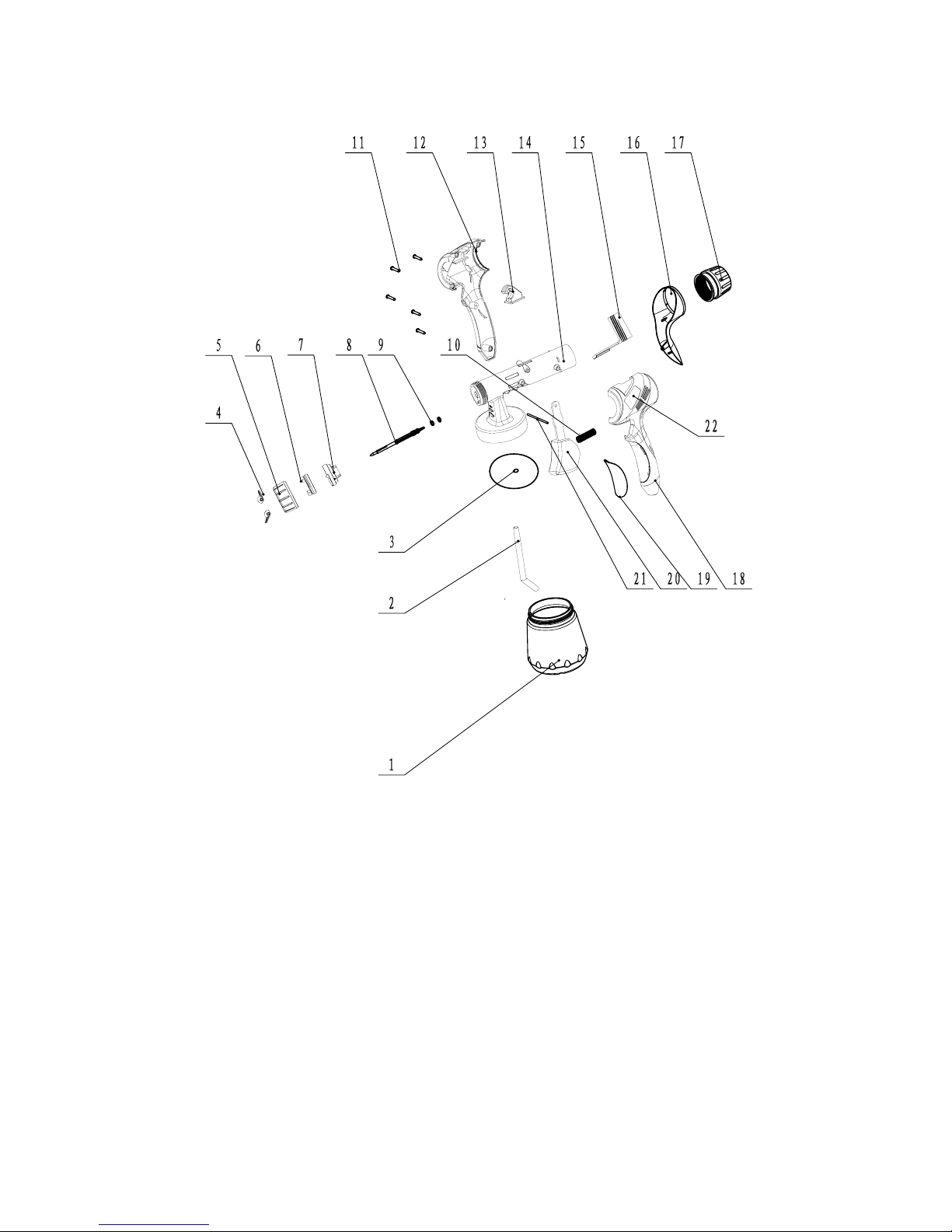

B: Trailing electrical cables and the risk of electrical shock.

C: Slippery surfaces and mess caused by over spray, accidental discharge and spillages.

D: The risk of accidental discharge.

E: Avoidance of freshly painted surfaces or workpieces.

24 DO NOT hold the workpiece with your hands. Always use clamps or a vice for the best and safest

results.

25 Ensure that adequate air ventilation and fume extraction is installed in the spraying area if indoors

and that it is in good working order.

26 If painting outdoors, ensure that over spray is not falling on private property such as cars, bikes, drive

ways, windows, etc. and that there is not entry of paint material into watercourses and irrigation

ditches.

27 Disconnect tool when changing accessories or filling paint cup.

28 Switch tool off when moving to a new position.

29 Make sure that you have enough slack in the power cord to enable unimpeded movement. Use an

approved and PAT tested extension cable if required.

30 If using an extension lead outside, ensure that it is one approved for outdoor use.

31 BE AWARE OF YOUR SURROUNDINGS. Other persons activities may have potentially lethal

implications for you. ikewise, make sure that others around you are aware of your presence and

activities and that your own actions are not impeding or harming those around you.

32 DO NOT use this tool if parts are missing or damaged. Doing so will invalidate the warranty and may

cause yourself or others harm.

33 Use only approved service or replacement parts. Not doing so will invalidate the warranty and may

cause yourself or others harm.

34 DO NOT use incompatible accessories or attachments. Doing so will invalidate the warranty.

35 DO NOT attempt to use this tool for any job or purpose outside of its design parameters and

capabilites. Doing so will invalidate the warranty.

36 Repairs carried out by unauthorised repair agents will invalidate the warranty unless you have been

given specific permission by Duren Tools on a case by case basis only.

37 Do not use this tools whilst under the influence of drugs, alcohol or intoxicating medication.

38 Do not spray at or near and naked flame or any source of ignition.

39 DO NOT spray any material without first consulting a Material Safety Data Sheet. If one

is not available it is advised that you source an alternative material.