Norac UC5 Topcon X30 User manual

Other manuals for UC5 Topcon X30

55

Table of contents

Other Norac Paint Sprayer manuals

Norac

Norac UC4.5 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4+ User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4+ User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4+ User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC 4.5 Hagie STS10 User manual

Norac

Norac UC4.5 User manual

Popular Paint Sprayer manuals by other brands

Earlex

Earlex spraystation hv1900kr Operating instructions manual

Bareknuckle

Bareknuckle Welterweight APS Operating Instruction and Safety Manual

HARDER & STEENBECK

HARDER & STEENBECK Colanm Instructions for use

Fimco

Fimco LG-40-SS Assembly / operation instructions / parts

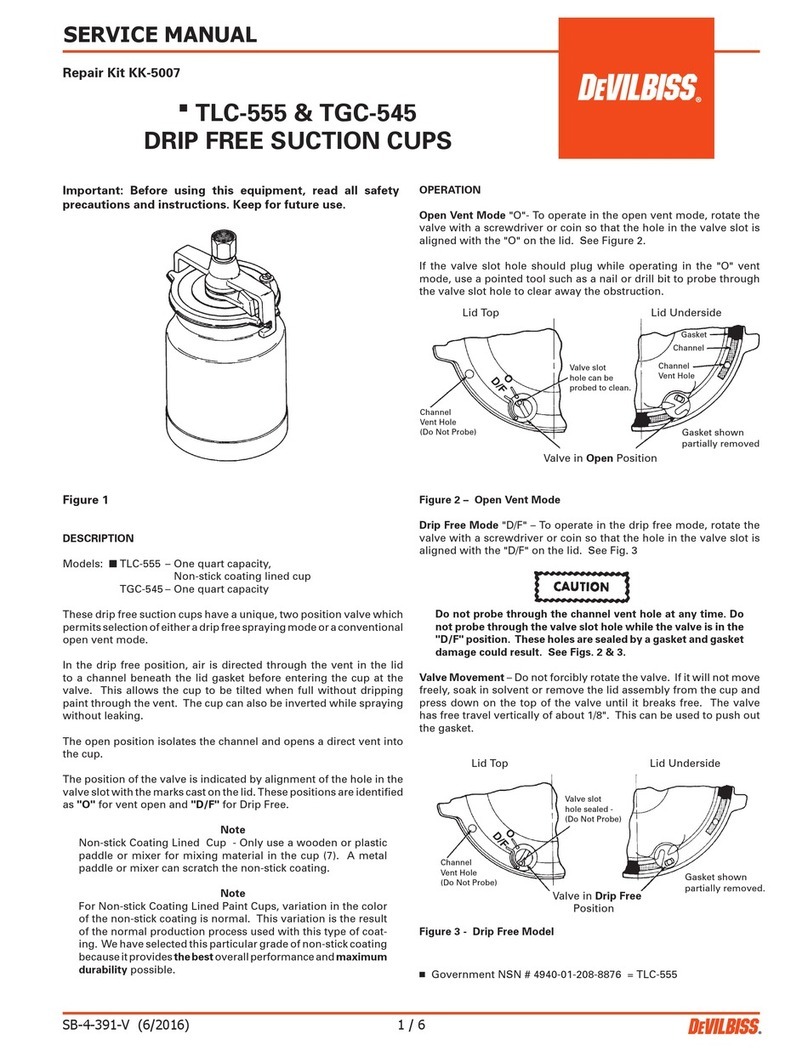

DeVilbiss

DeVilbiss TLC-555 Service manual

Krautzberger

Krautzberger Perfekt 4 operating instructions