WARNING:

The 360° monitoring system is to be used as an auxiliary safety device. The vehicle operator

should be aware of his surrounding at all times! Please ensure you are familiar and comply

with local traffic and driving regulations.

CAUTION

Power

1. Supply DC 12/24V. Please check voltage before installing.

2. Please disconnect the power supply if not in use for a long period of time.

Safety

1.This ECU is design for indoor usage. To prevent from short circuit or being

shocked, please keep machine away from humid environments.

2.If any liquid or solid materials enter the machine, cut off the power

immediately. Please ask professional technicians to examine the unit before

it can be used again.

3.If any fault occurs, please ask a professional technician to examine or

contact your local distributor.

Installation location

1.Please install in a ventilated location to prevent the machine from overheating.

2.Keep the machine away from the radiator and exhaust area, or downpour, dust,

humidity, strong magnetic fields and places that will cause vibration or shock to

the machine.

Copyrighted

1.While recording please ensure you are familiar and comply with local traffic and

driving regulations.

2.Without approval from our company, any refit or adjustment will void warranty.

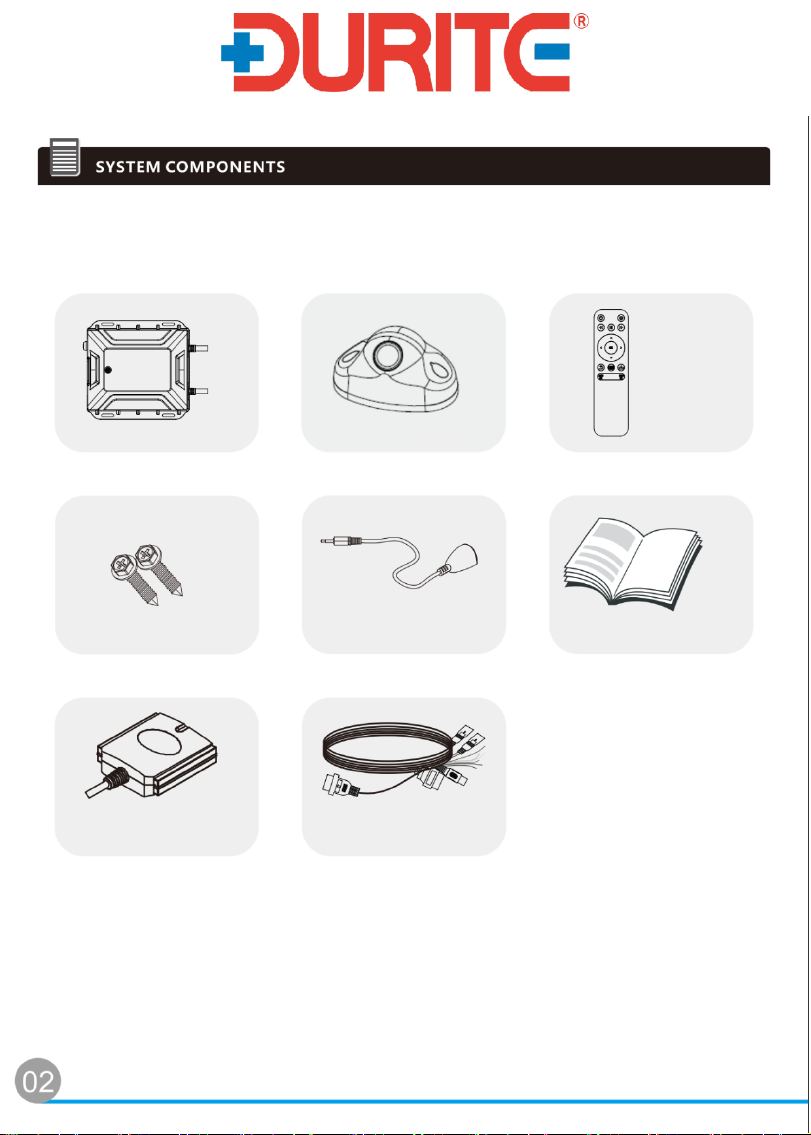

The around view monitoring system provides high resolution images, which are captured from four

AHD camera's installed around the vehicle. It combines the surrounding images of the vehicle into

a vehicle virtual 360° birds eye view image. The system assists the operator to visually identify

obstacles in all directions of vehicle, it covers the blind - spots where accidents often happen. The

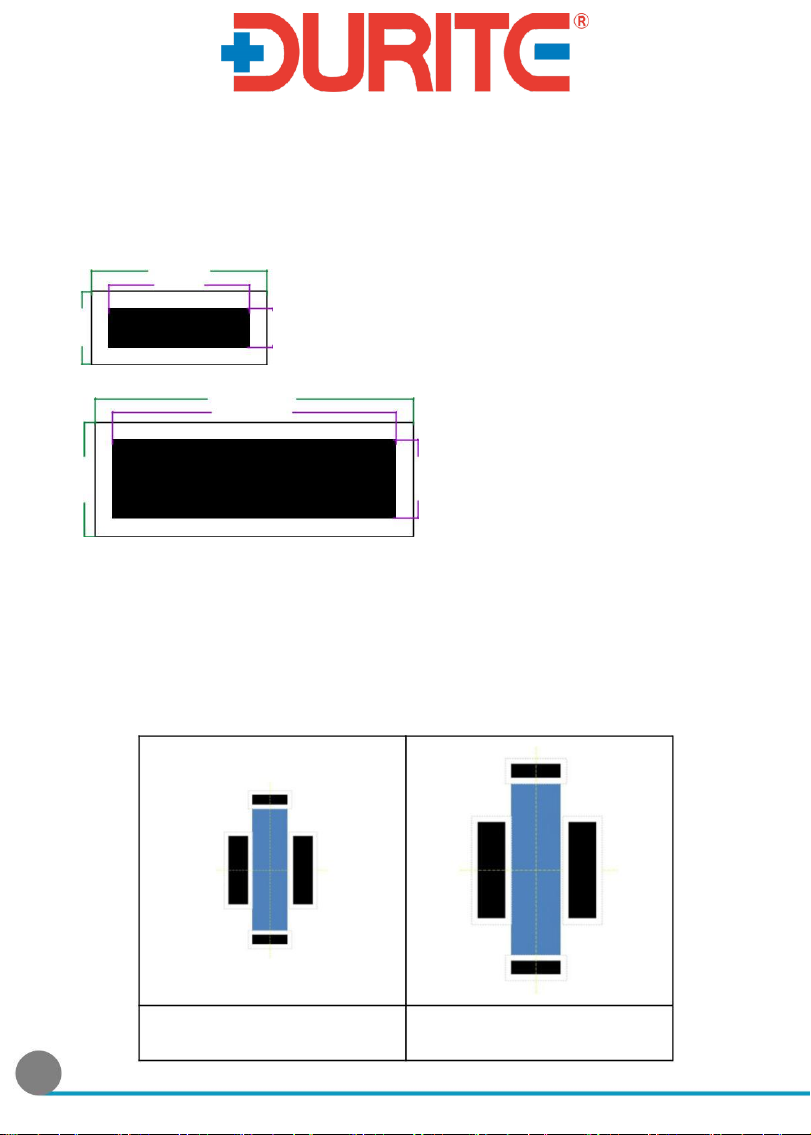

innovative 360° monitoring system simplifies the installation. All that is required are fixed dimension

mats, a small area and your vehicle dimensions to be input into the control box, the unit can auto

calibrate and will provide a 360° birds eye view image based on the values input.