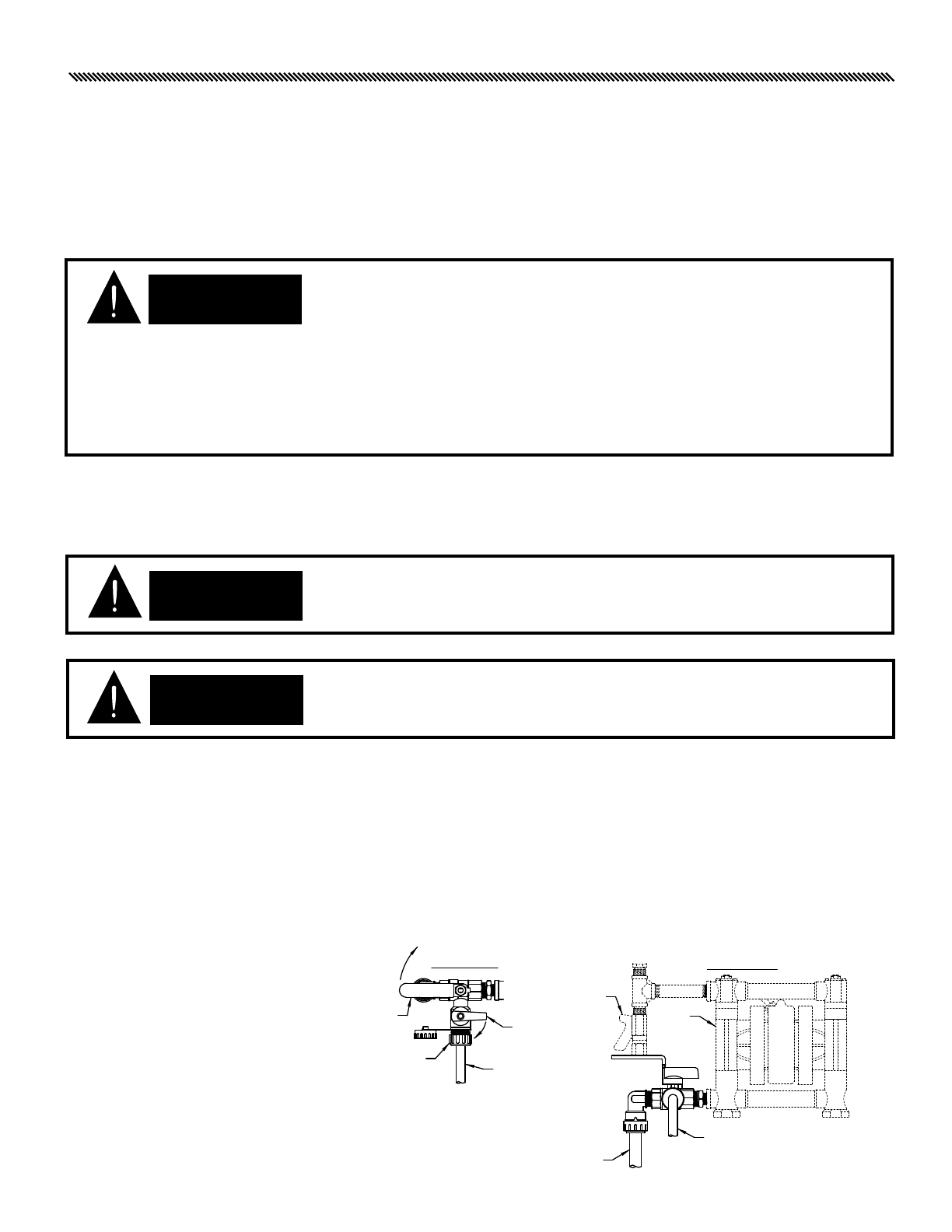

TOXIC FLUID HAZARD

Hazardous fluid or toxic fumes can cause serious

injury or death if splashed in the eyes or on the skin,

inhaled, or swallowed

• Know the specific hazards of the fluid you are

using.

• Store hazardous fluid in an approved container. Dispose of haz-

ardous fluid according to all local state and national guidelines.

• Always wear protective eyewear, gloves, clothing, and respira-

tor as recommended by the fluid and solvent manufacture.

• Pipe and dispose of the exhaust air safely, away from people,

animals, and food handing areas. If the diaphragm fails, the fluid

is exhausted along with the air. See Air Exhaust Ventilation in

the separated pump manual 308-553.

FIRE OR EXPLOSION HAZARD -

Improper grounding, poor ventilation, open flames,

or sparks can cause a hazardous condition and

result in a fire or explosion and serious injury.

• If there is any static sparking or you feel an elec-

tric shock while using the equipment stop pumping

immediately. Do not use the equipment until you identify and

correct the problem.

• Provide fresh air ventilation to avoid the buildup of flammable

fumes from solvents or the fluid being pumped.

• Pipe and dispose of the exhaust air safely, away from all

sources of ignition. If the diaphragm fails, the fluid is exhausted

along with the air.

• Keep the work area free of debris, including solvent, rags, and

gasoline.

• Electrically disconnect all equipment in the work area.

• Extinguish all open flames or pilot lights in the work area.

• Do not smoke in the work area.

• Do not turn on or off any light switch in the work area while

operating or if fumes are present.

• Do not operated a gasoline engine in the work area.

EQUIPMENT MISUSE HAZARDEQUIPMENT MISUSE HAZARD

3

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

• This equipment is for professional use only.

• Read all instruction manuals, tags and labels before operating the equipment.

• Use the equipment only for its intended purpose. If you are not sure, call Duro Dyne’s Technical Service

department at 1-800-899-3876

• Do not alter or modify this equipment.

• Check equipment daily. Repair or replace worn or damaged parts immediately.

• Do not exceed the maximum working pressure of the lowest rated component in your system. This equipment

has a 100 psi (7 bar) maximum working pressure at 100 psi (7 bar) maximum incoming air pressure.

• Use fluids and solvents which are compatible with the equipment wetted parts. Refer to the Technical Data

section of all equipment manuals. Read the fluid and solvent manufacturer’s warnings.

• Do not use hoses to pull equipment.

• Route hoses away from traffic areas, sharp edges, and hot surfaces. Do not expose hoses to temperatures

above 82°C (180°F) or below -40°C (-40°F).

• Wear hearing protection when operating this equipment.

• Do not lift pressurized equipment.

• Comply with all applicable local, state, and national fire, electrical, and safety regulations.

TECHNICAL DATATECHNICAL DATA

Wetted Parts

Pump……....... ……...............Acetal/Teflon*

Spray Gun...… ……...............Stainless/Aluminum

Fluid Hoses….……................Nylon

Surge Tank…..……....……......Nylon

Fluid Regulator

Fittings

235-366…….............Acetal, Carbon Steel

Tubling……......……......……....Nylon

Maximum Fluid Working Pressure….. 100 psi (7 bar)

Maximum Operating Range…........... 15-100 psi (1-7 bar)

Pump Air Inlet Size..........................1/4 npt (f)

Pump Fluid Inlet and Outlet Size.......3/8 npt (f)

*Sound Data

Pump sound level at 100 psi (7 bar), full flow….

…………………………………………..…..85 dB(A)

Pump sound level at 70 psi (4.8 bar)

1 gpm (3.8 lpm…………………………..78 dB(A)

Operating Temperature Range; 40° to 150°F (4.4°-65.5° C)

*Tested to CAGI-PNEUROP-1969