AUTOMATIC

Page 6

Troubleshooting

Problem Cause Solution

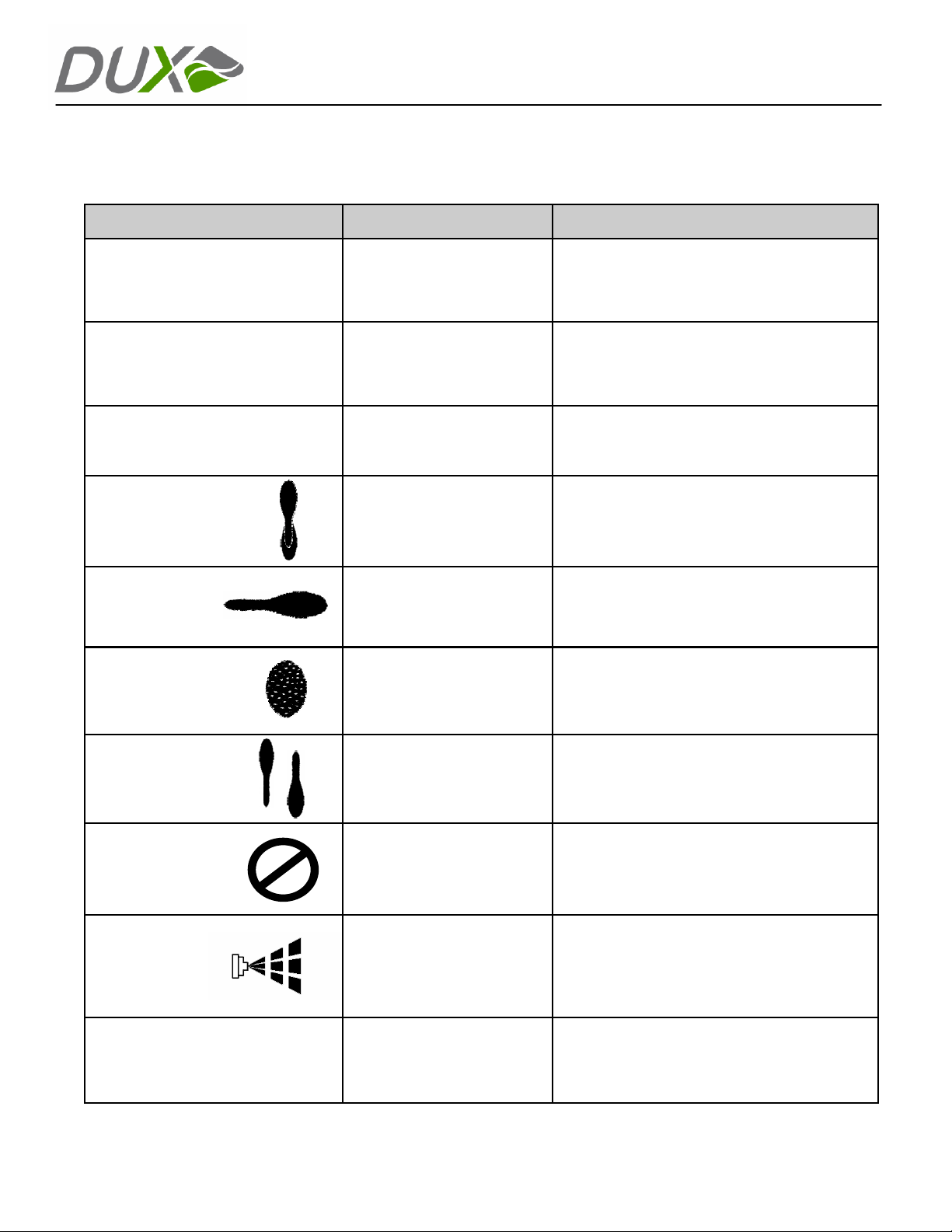

Coating leakage

out of tip of spray gun Needle packing is too tight

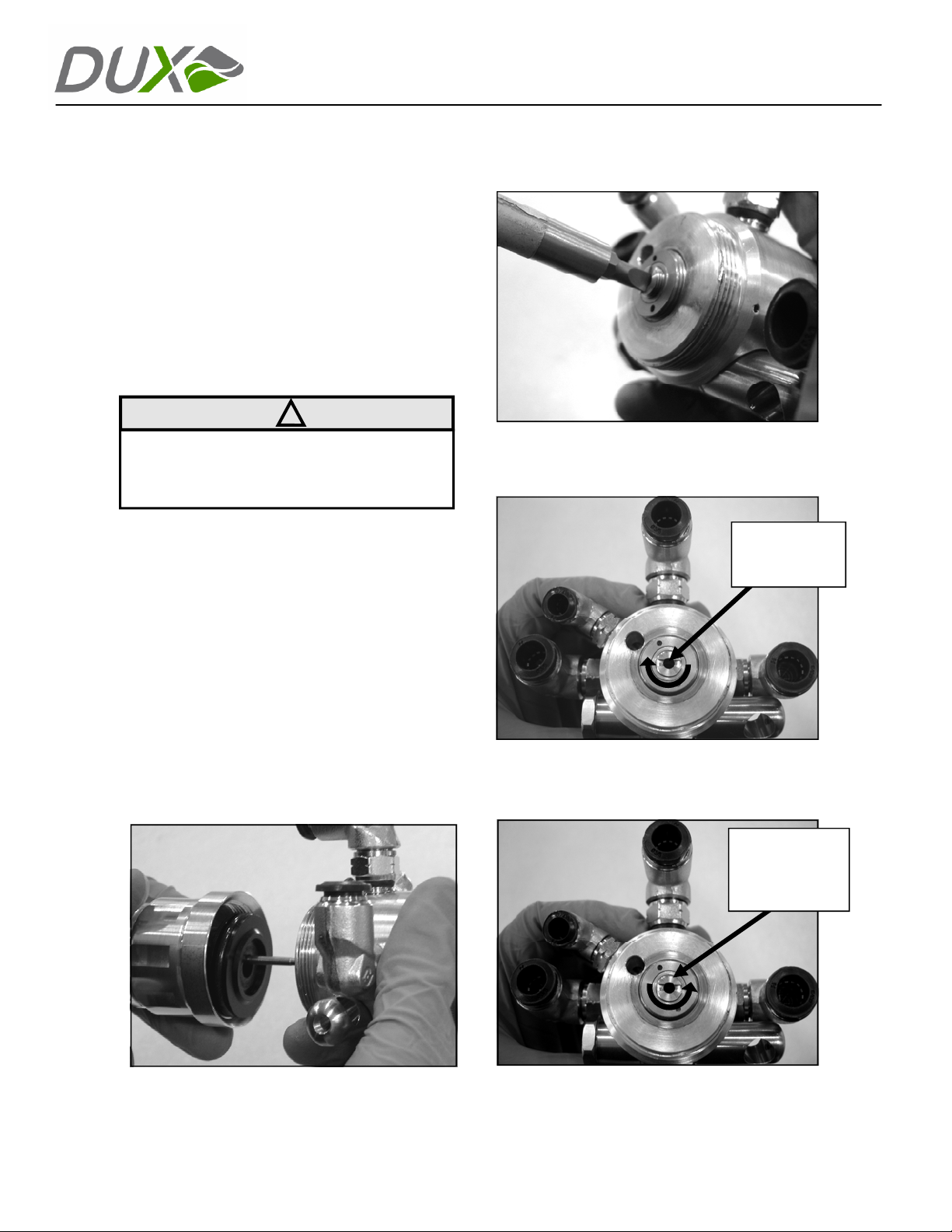

1. Remove triggering assembly

2. Insert screwdriver into rear of spray gun

3. Turn fluid seal nut counter-clockwise 1/4 turn (refer

to page 9 for packing adjustment)

4. Lubricate needle and reinstall

Coating leakage out of rear of

spray gun or drain hole Needle packing is too loose

1. Remove triggering assembly

2. Insert screwdriver into rear of spray gun

3. Turn fluid seal nut clockwise 1/4 turn (refer to page

9 for packing adjustment)

4. Lubricate needle and reinstall

Spray gun does not trigger 1. Insufficient triggering air

2. Piston binding

1. Increase triggering air pressure

Note: Do not exceed 50 psi

2. Remove triggering assembly. Remove trigger piston

and lubricate o-ring. Reinstall

Split pattern 1. Air pressure too high

2. Fluid flow too low

1. Reduce atomizing air pressure

2. Turn fluid control knob counter-clockwise

Note: if fluid flow is still insufficient after adjusting,

replace fluid tip with next largest size

Heavy right or

left side pattern Dirty or damaged air

cap/holes

Clean air cap

Note: Do not use metal tools to clean air cap

Note: If problem persists after cleaning, replace air cap

“Orange peel” or

Heavy pattern

1. Air pressure is too low

2. Spray gun is too close to

working

surface

3. Fluid flow is too high

1. Increase atomizing air pressure

2. Ensure proper distance from surface

is achieved, normally 6-10” from surface

3. Adjust fluid control knob clockwise to

decrease fluid flow

Heavy top or bottom

pattern 1. Air cap dirty or damaged

2. Fluid tip dirty or damaged

1. Clean air cap

Note: Do not use metal tools to clean air cap

2. Clean fluid tip

Note: If problem persists after cleaning replace

air cap or fluid tip

Will not spray

1. Insufficient air pressure

2. Insufficient fluid flow

3. Fluid too heavy for current

setup

1. Check atomizing air and triggering air pressures

and increase if necessary

2. Adjust fluid control knob counter-clockwise to

increase fluid flow

3. Thin coating and/or change fluid tip to next largest

size

Spray gun

sputtering

1. Damaged fluid tip

2. Loose fluid tip

3. Dried material in fluid tip/

needle

4. Fluid source empty/low

5. Needle packing too loose

1. Remove and inspect for damage

2. Ensure fluid tip is tight

3. Flush with solvent

4. Check coating and refill if necessary

5. See solution: (coating leakage out of rear of gun)

Spray pattern starved or dry

1. Air pressure too high

2. Fluid adjustment too low

3. Spray too far from working

surface

1. Reduce atomizing air pressure

2. Adjust fluid control knob counter-clockwise until

desired results are achieved

3. Ensure proper distance from surface is achieved,

normally 6-10”

For customer service call 888.389.2732