DESCRIPTION

Monitor and control temperature for heating and cooling applica-

tions with the Series TS2 Digital Temperature Switch. The Series

TS2 offers twelve programmable functions to customize the unit to

fit application requirements. Use the 15(5) Amp SPDT relay output

to drive a motor, compressor, or fan. Designed with the OEM in

mind, the TS2 offers the ability to configure multiple units with the

touch of a button.

Programming multiple units is quick and easy. Simply program one

switch with the desired parameter settings and connect the config-

uration key (sold separately) to the back of the unit. Press the but-

ton on the configuration key and download the parameter settings.

Connect the key to the other switches to upload the stored settings

with the push of a button.

The TS2 features set point adjustments, static defrost timing, com-

pressor mean time, hysteresis, and ambient probe adjustment.

Security protection is offered using a password code. The Series

TS2 Digital Temperature Switches are designed to operate with PTC

(1000Ω@ 25°C) probes sold separately.

INSTALLATION

The thermostat must be installed by authorized professionals. It

should be located in a place free of vibrations, impacts, water and

corrosive gases.

A hole measuring 71 x 29 mm must be cut in the panel where the

thermostat is to be fitted (apply silicone to make it leaktight). Then,

the fixing cups must be fitted, sliding them onto the thermostat until

secure. Do not force tightening of the screw if the U-brackets are

used. The connections must be covered with the rear cover for this.

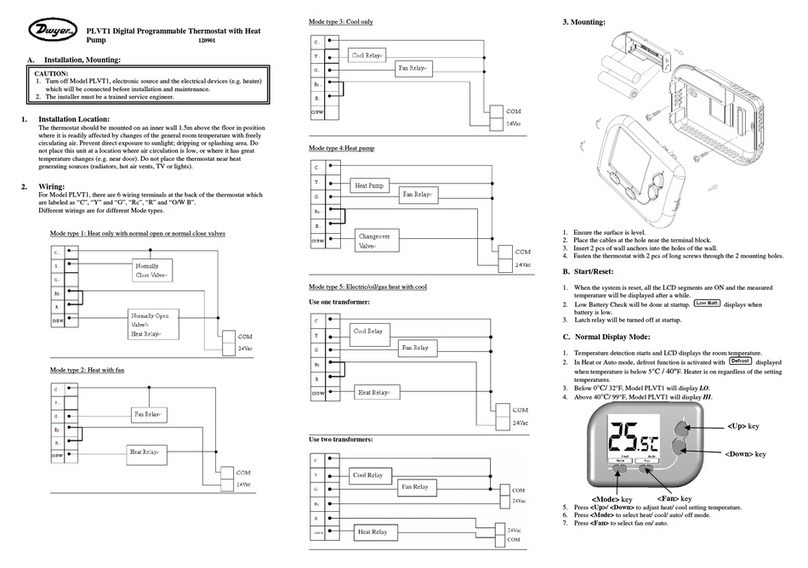

WIRING INSTRUCTIONS

Avoid installing the probe’s cables in proximity with any power

cable. If the length of the probe cables measures more than 100

meters, a recalibration adjustment must be made (parameter P1).

FRONT OPERATION

PUSH BUTTONS

Pushing SET once gives access to the SP. Pushing for 8

seconds gives way to the requested code. After entering

the correct code, all parameters are accessible. This but-

ton alternates between text parameters and their value. It

validates the modified parameters. When pressed with

DOWN, it exits parameter programming.

Pressing this arrow allows the user to go to the next

parameter or increase the value viewed on the display.

When pressed for 8 seconds, it activates or deactivates

defrosting.

Pressing this arrow allows the user to go to the previous

parameter or decreases the value viewed on the display.

When pressed for 8 seconds, it activates or deactivates the

continuous cooling cycle. When pressed simultaneously

with SET, it exits the programming mode.

PROGRAMMING PARAMETERS

Access only to Set Point SP (without code protection):

•Press and release SET. SP text appears on the display.

•Press SET again. The real value is shown on the display.

•Modify the value using the UP and DOWN keys.

•Press SET and DOWN to quit programming, or wait 1 minute for

Series TS2- Digital Temperature Switch

Specifications - Installation and Operating Instructions

Bulletin T-TS2

SPECIFICATIONS

Probe Range: -58 to 302°F (-50° to 150°C).

Input: PTC thermistor 1000Ω@ 25°C.

Output: 15A PTC SPDT relay @ 250 VAC resistive, 5A inductive.

Horsepower Rating (HP): 3/4 HP.

Control Type: ON/OFF.

Power Requirements: 110 VAC.

Accuracy: ±1°C.

Display: 3-digit, Red, 1/2˝ digits.

Resolution: ±1 digit.

Memory Backup: Nonvolatile memory.

Ambient Operating Temperature: 14 to 158°F (-10 to 70°C).

Storage Temperature: -4 to 176°F (-20° to 80°C).

Weight: 2.3 oz (65 g).

Front Panel Rating: IP64.

Agency Approvals: CE, URc, UR.

250 VAC 15(5)A 30 LRA

Power

Supply OUTPUT

789

10 11

12

Probe Input

t°

(3.000)

(1.338)

(2.375)

(1.100)

T-TS2 12/8/06 10:03 AM Page 1