Combines Root Cyclone™ technology

with a core separator - an extra

cyclonic stage between the outer and

inner cyclones - to separate particles

as small as 0.5 micron from the

airow.

Features and benets

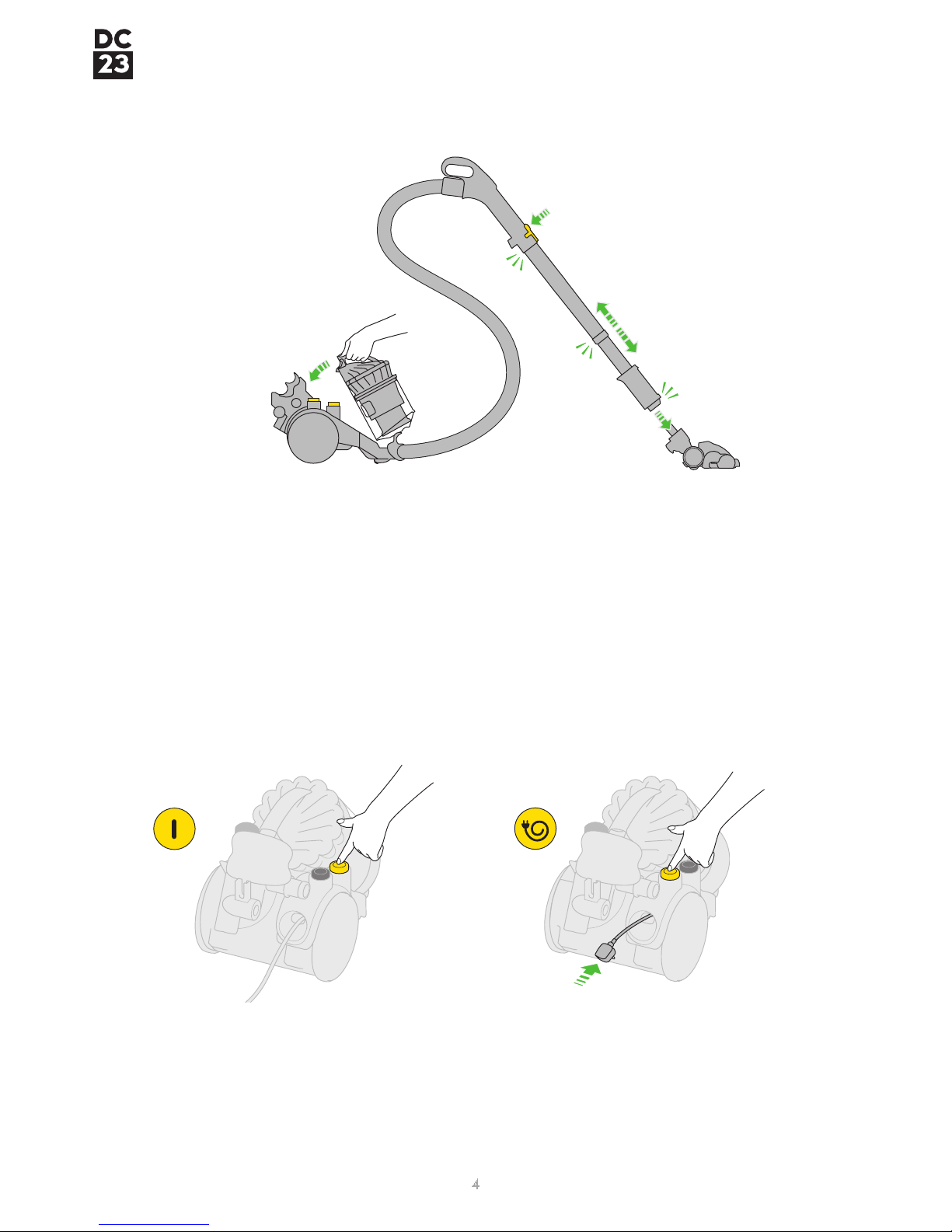

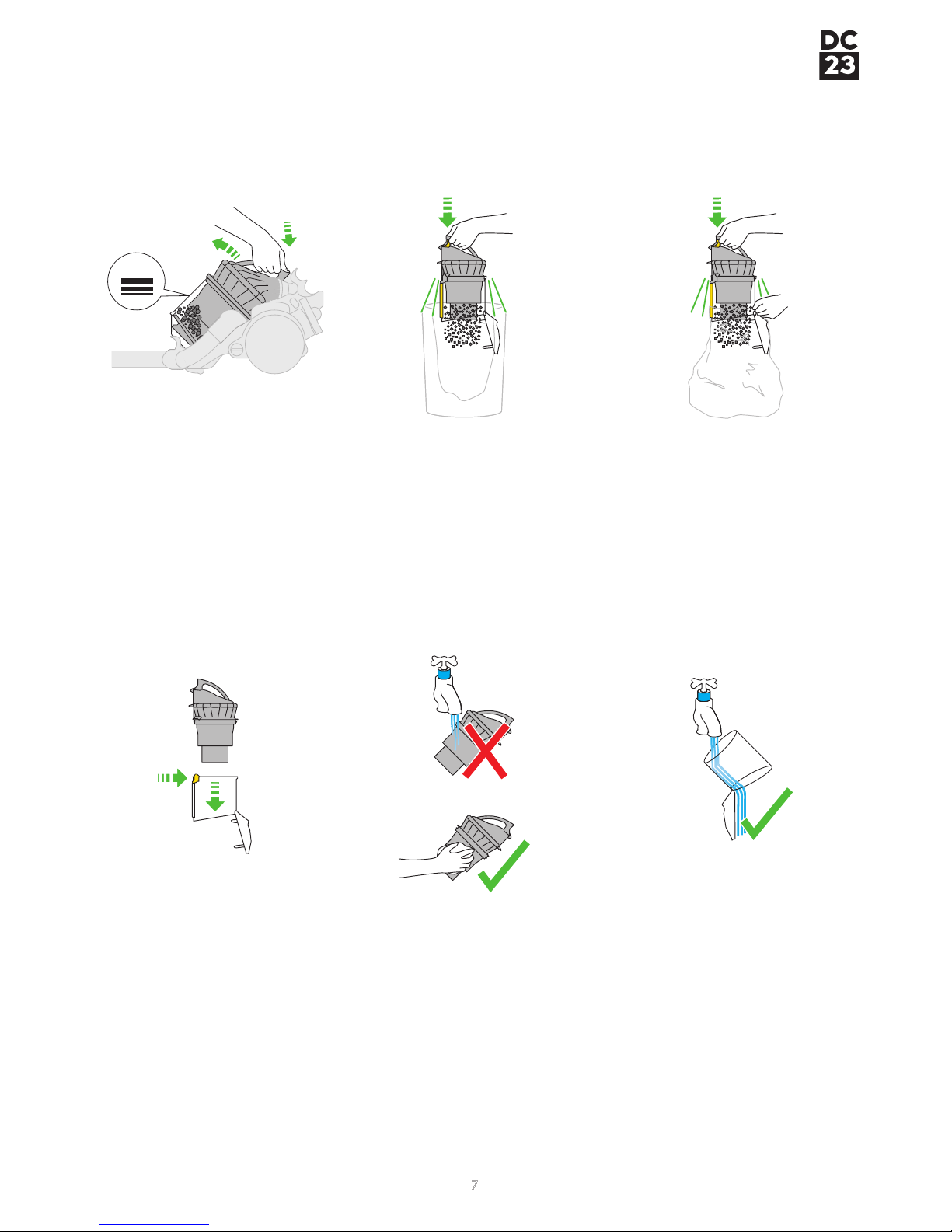

Hygienic bin emptying

No need to touch the dirt just

push the button.

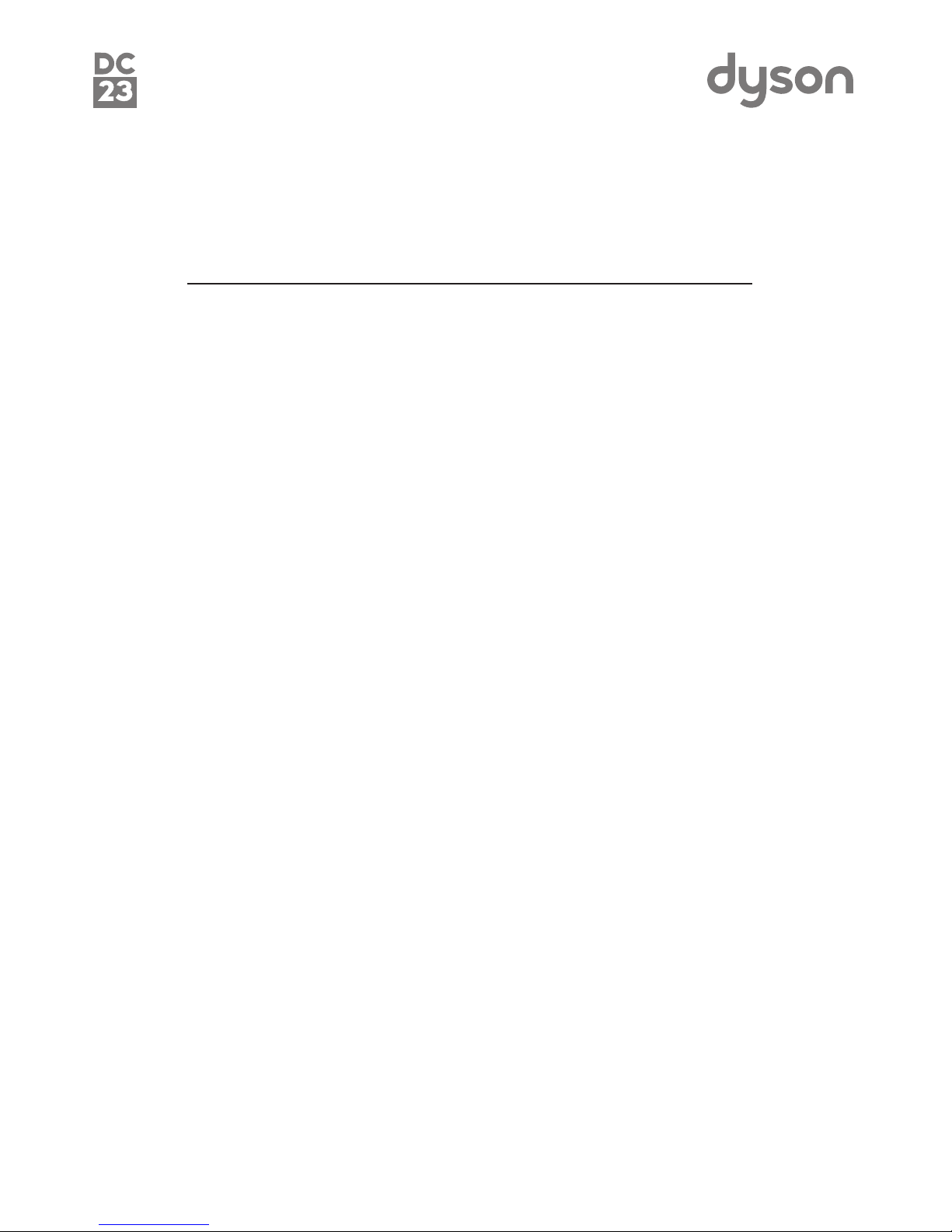

Telescope Wrap system

Hose and wand compress and

wrap for easy storage.

Low prole contact head

Enables more thorough cleaning

under furniture and appliances.

The full-size cylinder with hygienic bin emptying

Root Cyclone technology™ + core separator

Doesn’t lose suction and captures more microscopic dust than any other.

Cleaner exhaust air

Air expelled from a Dyson has up to 150 times less mould and bacteria than the

air you breathe.

Lifetime HEPA lter

Ideal for allergy sufferers.

*More airwatts

An extra 100 airwatts. Allows a bigger cleaner head for cleaning larger spaces.

*Longer cable

An extra 0.5 metres of cable. Clean a wider area without unplugging.

*Bigger bin

An extra 0.8 litres of bin capacity, so you don’t have to empty it so often.

*Compared to DC22

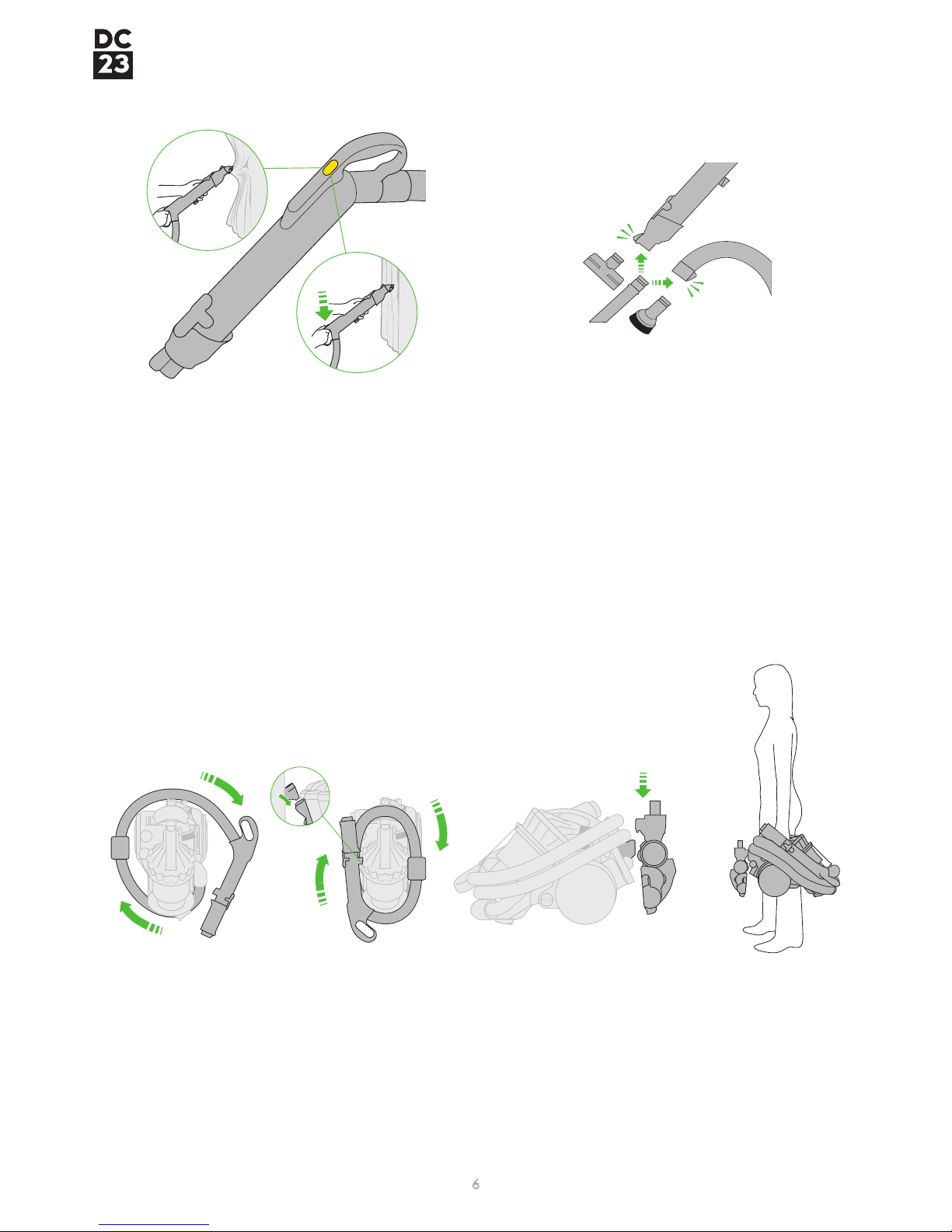

Sits on the stairs

Follows you up the stairs as you

clean them.

Shroud

core separator

root cyclone

Doesn’t lose suction and captures

more microscopic dust.