ISO 9001: 2015 quality management systems. It was

published by the International Organization for

Standardization. And we base on quality management

principles: (1) Customer focus (2) Leadership

(3) Involvement of people (4) Process approach

(5) System approach to management (6) Continual

improvement (7) Factual approach to decision making (8) Mutually beneficial supplier

relationships.

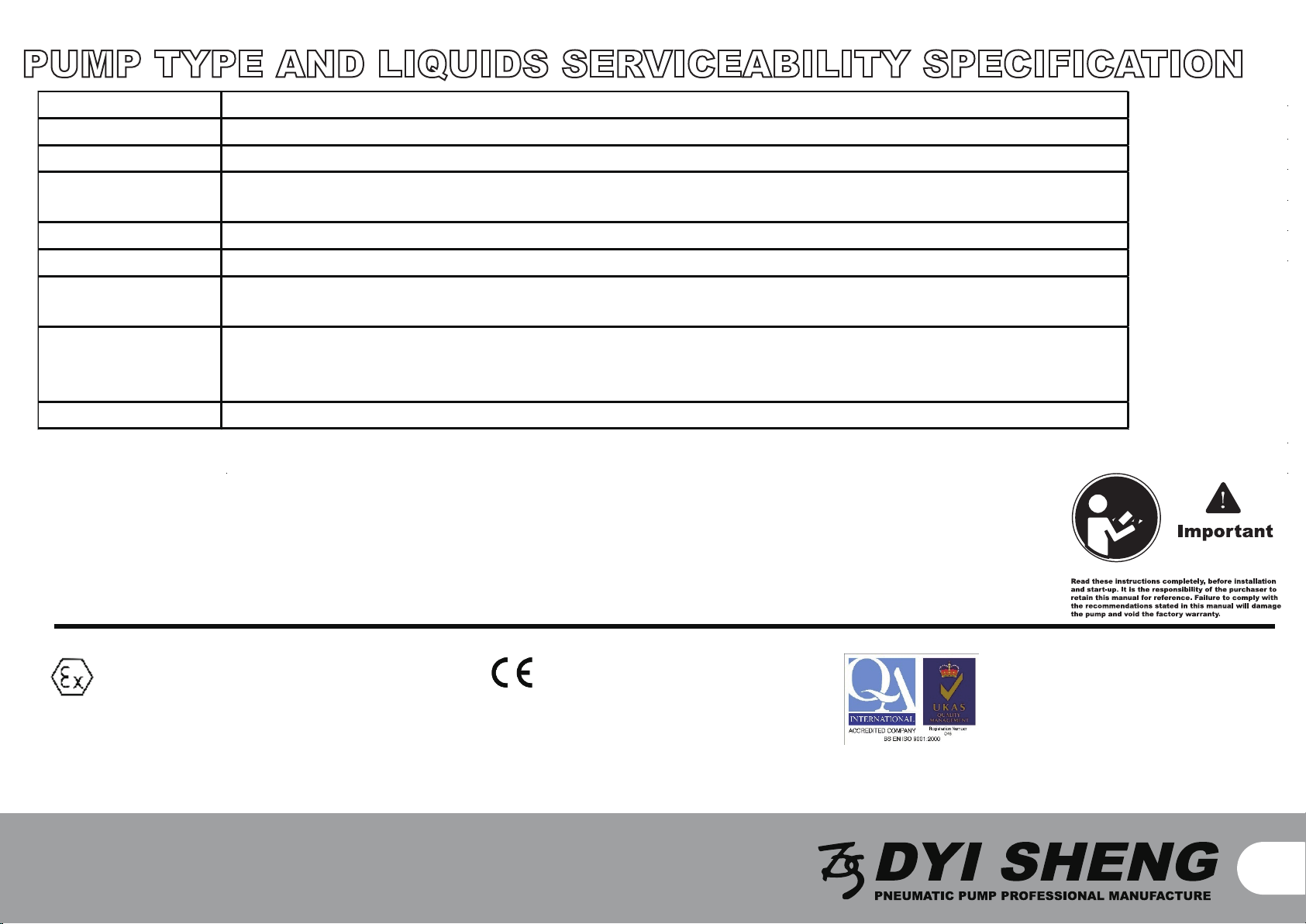

PUMP TYPE AND LIQUIDS SERVICEABILITY SPECIFICATION

3

Pump Type Liquids Serviceability

DSXX-AAX-UXXX-X Paint, Solvent, Ink, Glue, Pulp, Heavy Oil, Toluene, Benzene

DSXX-AAX-TXXX-X Hight temperature liquid, Resin, Metal Scrap Soluon, Gasoline, Xylene, Acetone

DSXX-AAX-OXXX-X

Mud, Sludge, Waste Water, Lubricaon Oil, Motor Oil, Cung Oil, Turbine Oil, Methyl Alcohol, Release Agent,

Casng Fluid

DSXX-PXX-OXXX-X Seawater, Hydrogen Peroxide Soluon, Acid and Alkali, Floats the Clean Water

DSXX-PXX-TXXX-X Inferior Sodium Nitrite, Hydrochloric Acid, Aqua Regia, Phosphoric Acid, Boric Acid, Liquid Medicine

DSXX-SXX-UXXX-X

Glycol, Alcohol, Sodium Hydroxide, Nitric Acid, Carbonic Acid, Fruit Acid, Enzyme, Sodium Nitrate, Ethanol, Citric Acid,

Wastewater, Liquid Causc Soda, Methyl Alcohol, Isopropyl Alcohol, Glycol

DSXX-SAX-TXXS-X

Polyvinyl Chloride, Ammonia, Asphalt, Sulfuric Acid, Chromic Acid, Electroplate Soluon, High Temperature Sauce,

Chili Sauce, Coal Oil, Volale Oil, Carrier Oil, Immiscible Fluids, Freezing Mixture, Degreasing Agent, Methylene

Chloride, Jam, Juice, Acec Acid, Leavan, Slops, Balsam, Olive Oil, Defoamer

※

DSXX-SAX-OXSO-X Glaze, Poery Clay Thick Liquid, Bolivian Filament

Note:

◆Depending on the density, temperature, concentration, and fluid production of the liquid, it may not be usable.

◆If it is used for the abrasive fluid, please make sure wear-resisting property.

◆Please inquiry with us directly about other liquids, if this information is above-unmentioned.

◆Please see the type-specification comparison.

◆Please inquiry to us about the type-specification noted “※” advance.

II 2 GD c IIB T4~T5

II (Explosive atmospheres, like flammable gases or dust.)

2 ( Protection level: exist it during operation, in explosive gas>10~1000hrs )

GD ( Dangerous source: gas, dust) c ( Explosion-proof structure: Construction safety)

IIB (Explosion-proof electrical equipment classification: B )

T4~T5 ( Temperature level: the highest surface temperature is below 100℃~135℃.)

CE marking is a certification mark that indicates

conformitywith health, safety, and environmental

protection standardsfor products sold within the

European Economic Area (EEA). The CE marking is also found

on products sold outside the EEA that have been manufactured

to EEA standards.