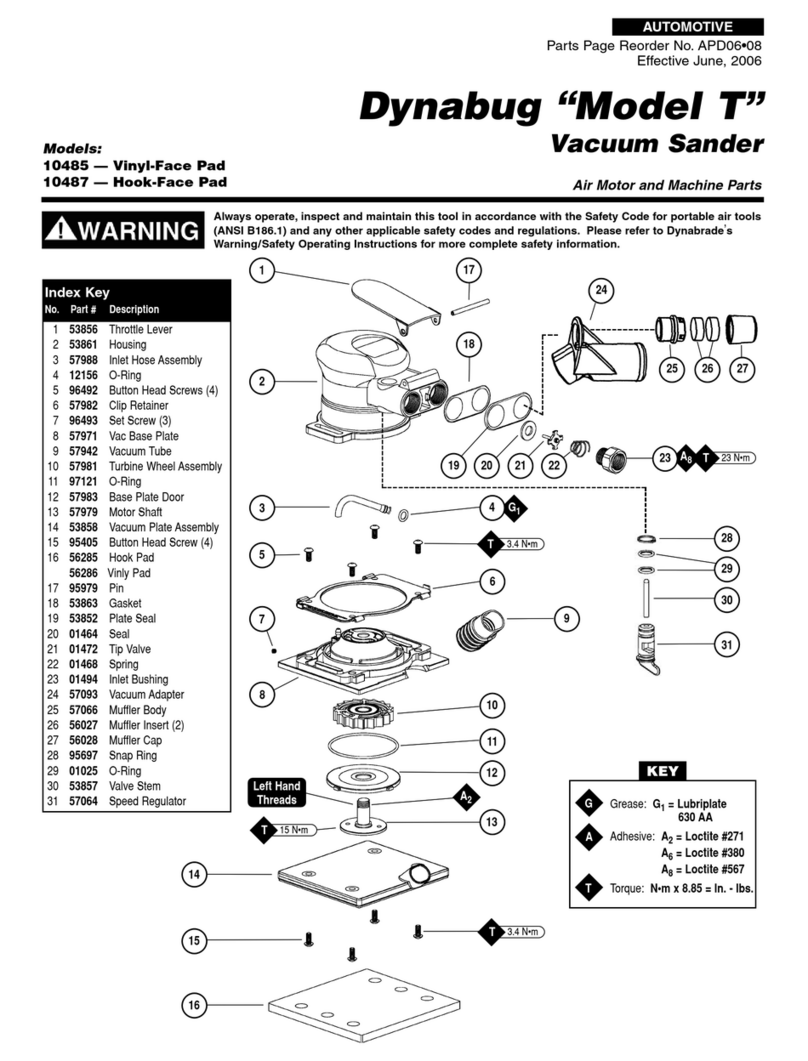

Dynabrade 4657971919 User manual

Other Dynabrade Sander manuals

Dynabrade

Dynabrade Dynorbital-Spirit 21000 User manual

Dynabrade

Dynabrade 50304 User manual

Dynabrade

Dynabrade 48520 Guide

Dynabrade

Dynabrade 57800 User manual

Dynabrade

Dynabrade 48500 Guide

Dynabrade

Dynabrade Dynorbital-Spirit 21000 Manual

Dynabrade

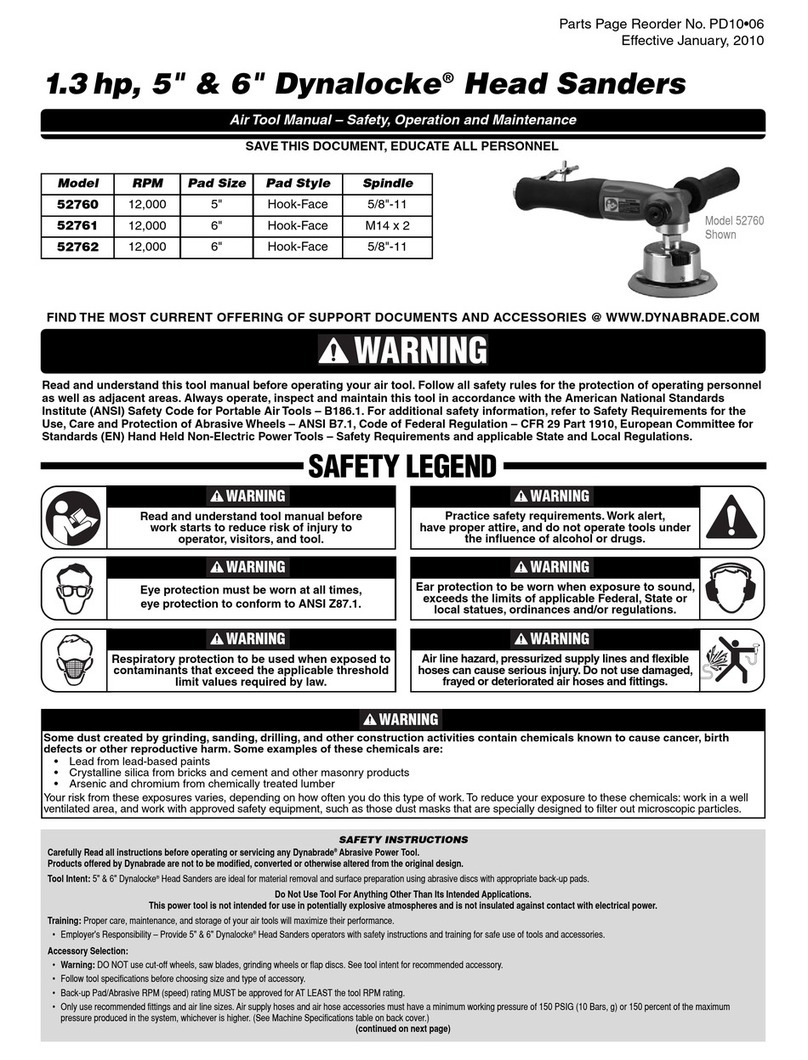

Dynabrade Dynalocke 52760 Guide

Dynabrade

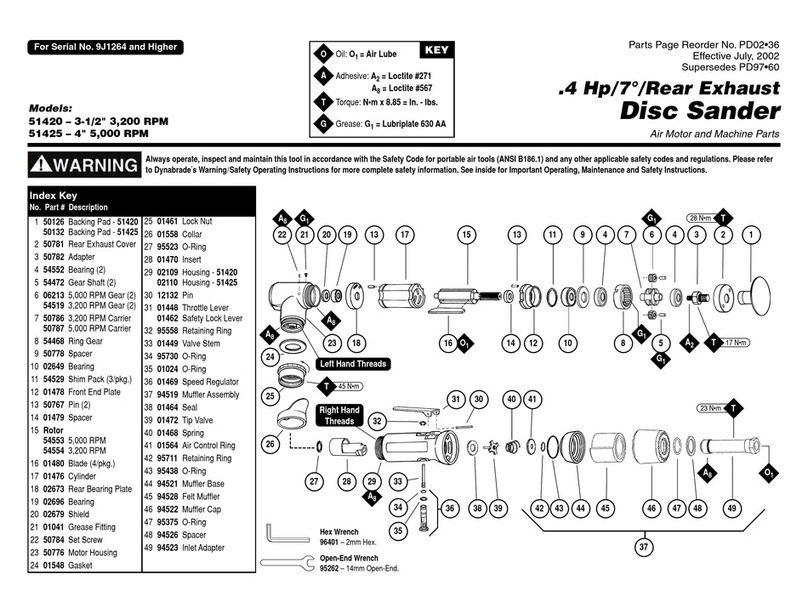

Dynabrade 51420 User manual

Dynabrade

Dynabrade 52413 Installation instructions

Dynabrade

Dynabrade Dynorbital-Spirit 21000 User manual

Dynabrade

Dynabrade 300CE Guide

Dynabrade

Dynabrade 57900 Guide

Dynabrade

Dynabrade Mini-Dynorbital Silver Supreme 69500 Guide

Dynabrade

Dynabrade 53521 Guide

Dynabrade

Dynabrade Dynabug II 58500 Guide

Dynabrade

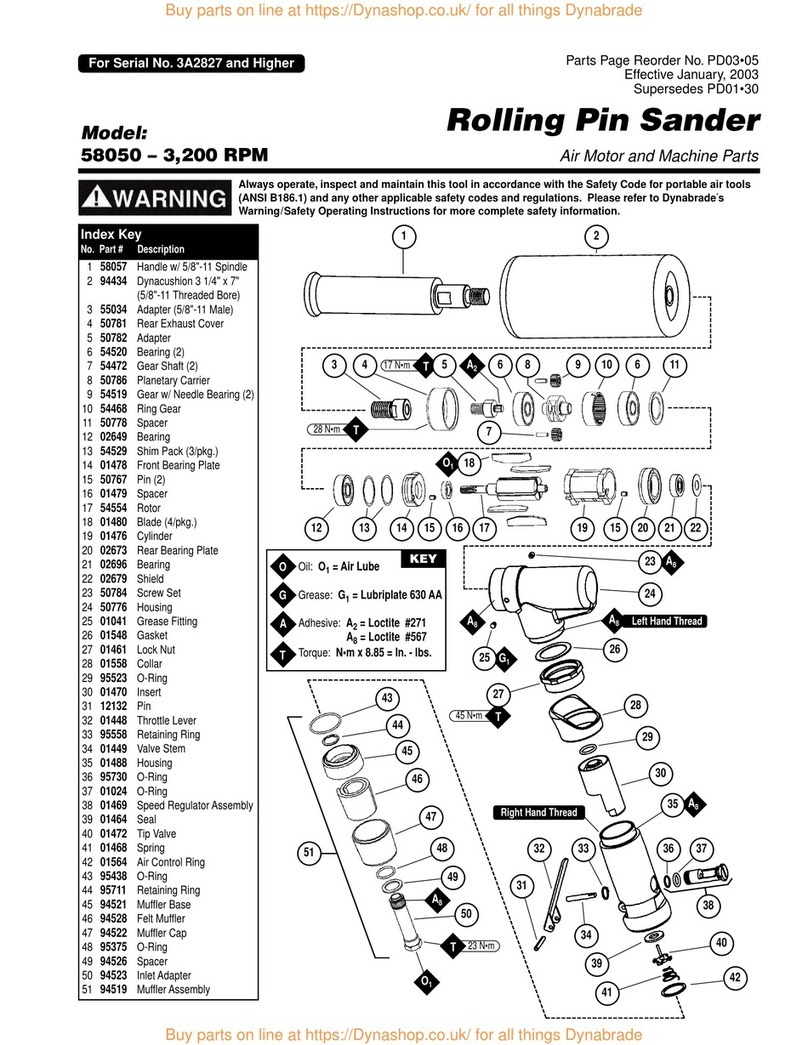

Dynabrade 58050 Installation instructions

Dynabrade

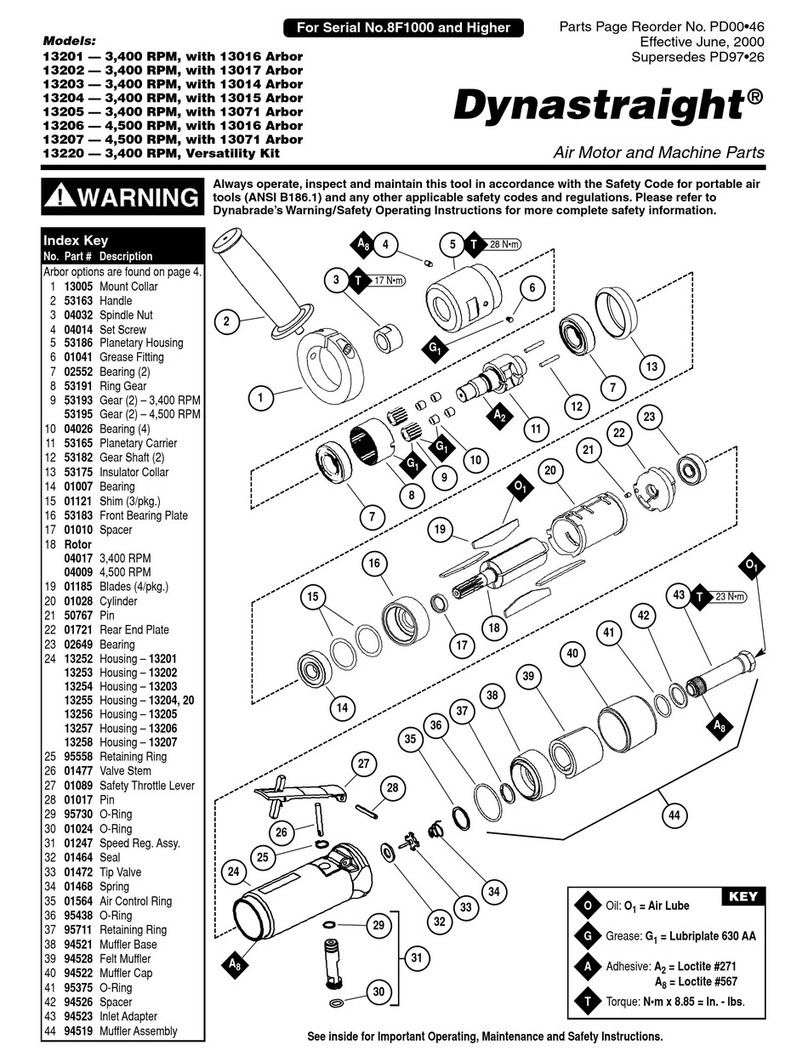

Dynabrade Dynastraight 13201 User guide

Dynabrade

Dynabrade Dynangle 14200 User manual

Dynabrade

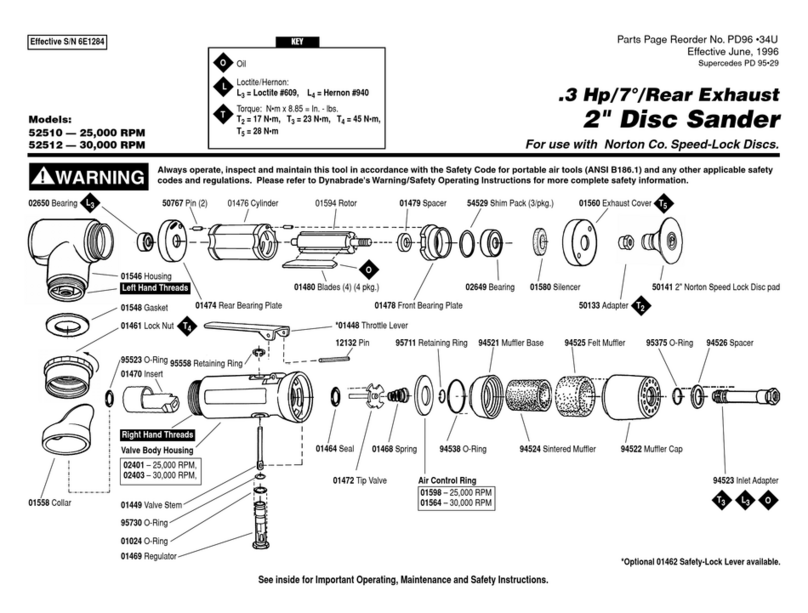

Dynabrade 52510 User manual

Dynabrade

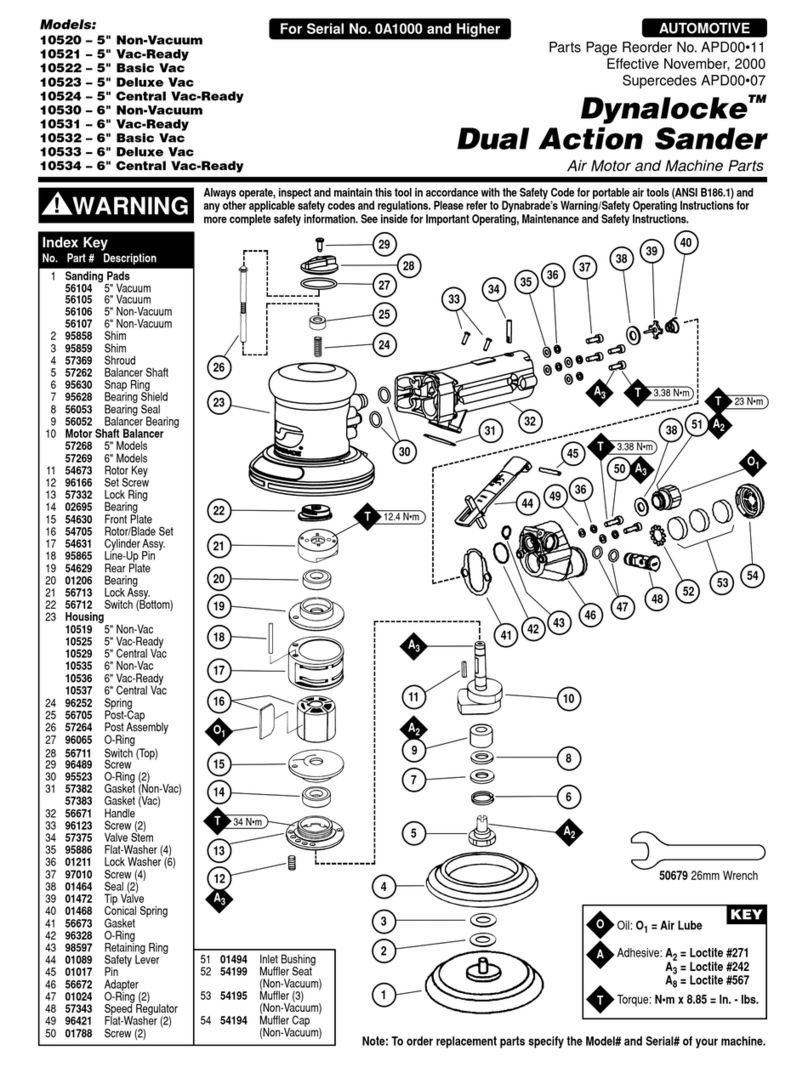

Dynabrade Dynalocke 10520 User manual