2ZSM 560 | Version 1.01

Imprint

Product identification

Cylinder Sanding Machine Item number

ZSM 560 5903560

ZSM 560 Vario 5903565

Manufacturer

Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Fax: 0049 (0) 951 96555 - 55

Internet: www.holzstar.de

Information on the operating instructions

Original operating instructions

Edition: 21.12.2020

Version: 1.01

Language: English

Author: MS/FL

Copyright information

Copyright © 2020 Stürmer Maschinen GmbH, Hallstadt,

Germany.

The contents of this operating manual are the sole

property of Stürmer Maschinen GmbH.

Passing on as well as duplication of this document, utili-

zation and communication of its contents are forbidden,

as far as not expressly permitted. Any infringement will

result in compensation for damages.

Technical changes and errors excepted.

Contents

1 Introduction .................................................... 3

1.1 Copyright ............................................................ 3

1.2 Customer service................................................ 3

1.3 Limitation of liability............................................. 3

2 Safety .............................................................. 3

2.1 Symbol explanation ............................................ 3

2.2 Obligations of the operating company ................ 4

2.3 Qualification of personnel ................................... 5

2.4 Personal protective equipment ........................... 5

2.5 Safety labels at the Cylinder Sanding Machine .. 6

2.6 Safety devices .................................................... 6

2.7 General safety instructions ................................. 6

3 Intended use ................................................... 7

3.1 Foreseeable misuse ........................................... 7

3.2 Residual risks ..................................................... 7

4 Technical Data ................................................ 8

4.1 Table .................................................................. 8

4.2 Type plate........................................................... 8

5 Scope of delivery ........................................... 8

6 Accessories .................................................... 8

7 Transport, Packaging, Storage ..................... 9

7.1 Delivery and Transport ....................................... 9

7.2 Packaging........................................................... 9

7.3 Storage ............................................................... 9

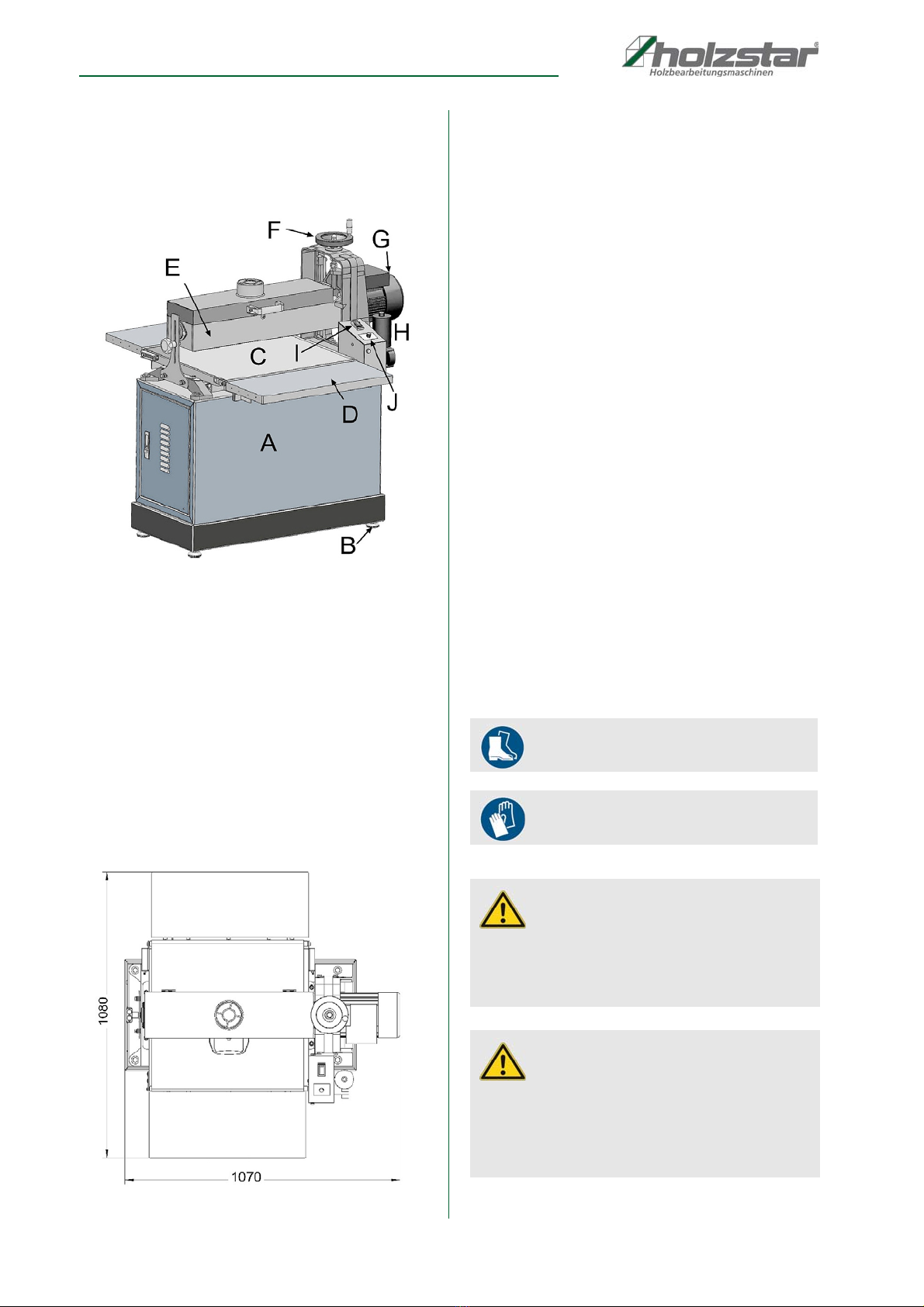

8 Description of the device ............................ 10

8.1 Space requirement ........................................... 10

9 Set up and connection................................. 10

9.1 Requirements for the installation site................ 10

10 Setting up the Cylinder Sanding Machine .. 10

10.1 Electrical connection...................................... 12

11 Commissioning .......................................... 12

11.1 Test run.......................................................... 12

12 Operation .................................................... 13

12.1 Notes on operation ........................................ 13

12.2 Starting the machine..................................... 13

12.3 Set feed rate .................................................. 14

12.4 Adjust height adjustment ............................... 14

12.5 Grinding process............................................ 14

12.6 Workflow....................................................... 15

13 Adjustment and setup work ...................... 15

13.1 Grinding belt change...................................... 15

13.2 Sandpaper cleaning....................................... 16

13.3 Adjustment of the pressure roller................... 17

13.4 Setting the height stop................................... 17

13.5 Adjusting the guide rails................................. 18

13.6 Align feed belt to grinding drum ..................... 18

14 Care, maintenance and repair................... 19

14.1 Cleaning......................................................... 19

14.2 Regular check and maintenance ................... 19

14.3 Replacing the feed belt .................................. 20

14.4 Tensioning the feed belt ................................ 21

14.5 Installation grinding rollers (Accessories) ...... 22

15 Disposal, recycling of old equipment ...... 22

15.1 Decommission ............................................... 22

15.2 Disposal of electrical equipment.................... 22

15.3 Disposal of lubricants..................................... 22

15.4 Disposal via municipal collection points......... 22

16 Troubleshooting ......................................... 23

17 Spare parts ................................................. 25

17.1 Ordering spare parts....................................... 25

17.2 Spare parts drawing....................................... 26

18 Electrical circuit diagrams ........................ 30

18.1 Electrical circuit diagram ZSM 560 ................ 30

18.2 Electrical circuit diagram ZSM 560 VARIO .... 30

19 EC - Declaration of Conformity ................. 31