SapIP –IRT Instruction Manual 1/23/2017

2.2 SAPIP-IRT Specifications

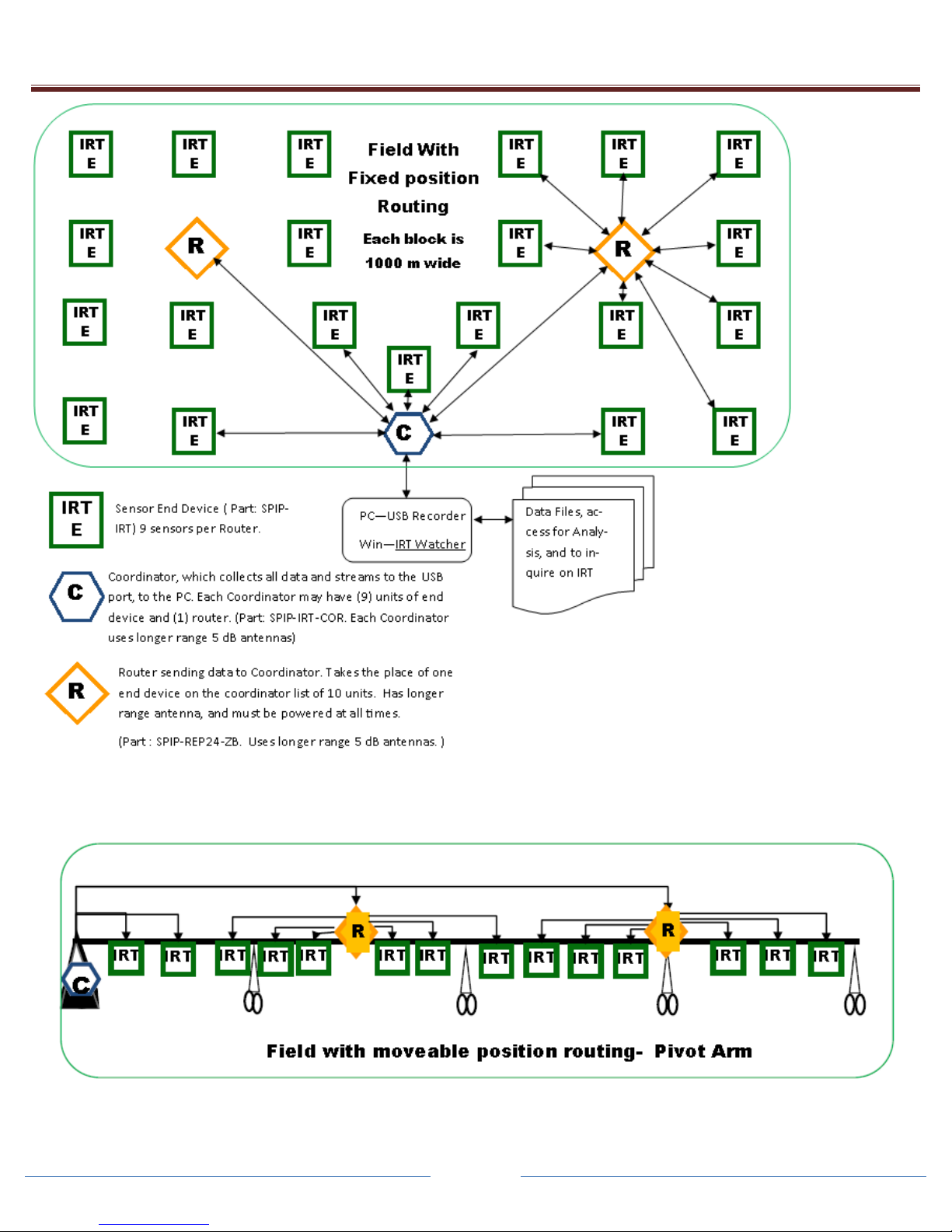

2.2.1 Data Collection –RF Network

-Samples are taken continuously every 10 seconds, accumulated and then averaged. This

average value is then sent by radio at 1, 5, 10, 15, 30 or 60 minute intervals. The averaging

accumulator is then reset.

-Settings are defined upon order from Dynamax. These settings are normally set in the factory,

but are changeable in the field using the IRT watcher program.

Protocol:

-Open Protocol: Data can be encrypted, coded, and read by any manufactured Zigbee device or

gateway.

-The Dynamax preferred network is the Digi International Zigbee network.

-

-Adjacent Zigbee networks have settings for their respective network ID’s to discriminate

different signals.

oNotes on Open: We have found that a variety of manufacturers have implemented the

“open” Zigbee protocol, however that does not mean that each will find the specific

node you may purchase without programming. For example a Texas Instruments (TI)

Zigbee may be quite difficult to program to talk to a Digi device, since the TI device

may need a significant development tool to program it to accept a setting we have

chosen for the Digi Device.

-In our Zigbee Format: We have chosen the Digi International since the tools, and supporting

coordinator hardware is complete and fully supported with Windows software tools. Settings

for the groups of agricultural networks that are close together requiring Pan and in some cases

channel assignments to avoid interruption. Our application engineers and technicians are very

familiar and can program your network to satisfy any requirement.

2.2.2 Output

-Sensor output is a packet transmission which contains a time tick, serial number, battery voltage

target IR temperature (+/- 0.01 degrees Celsius resolution), and sensor body temperature. Each

item is separated by a comma and the last character is a carriage return. i.e. “1, 17, 5.1, +32.70,

+24.80/cr”

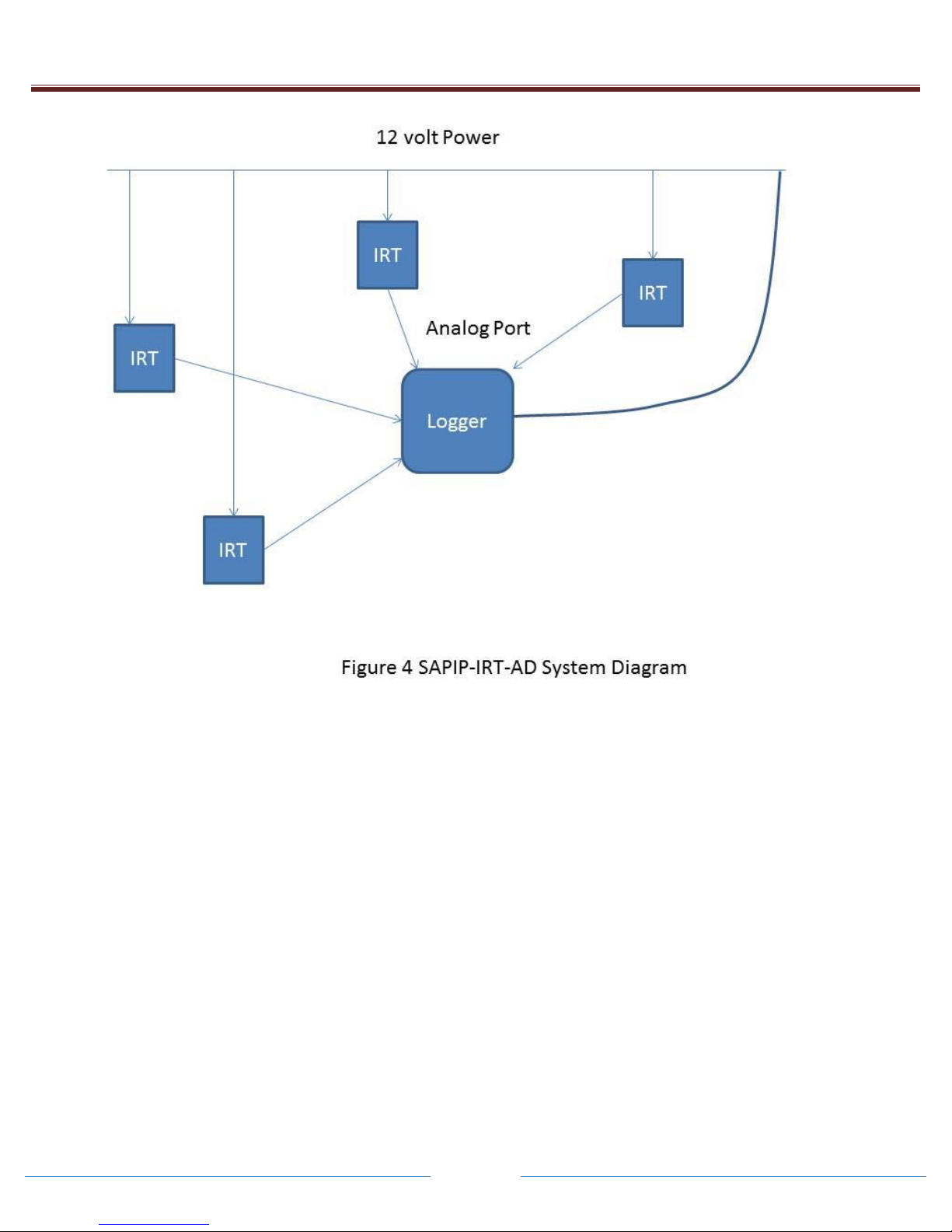

2.3SAPIP-IRT-AD analog specifications

2.3.1 Data Collection Analog output

-Samples are taken continuously every 10 seconds, accumulated then averaged. This average

value is then updated on the analog output port at 1, 5, 10, 15, 30 or 60 minute intervals. The

averaging accumulator is then reset.

-Settings are defined upon order from Dynamax. These settings are normally set in the factory,

but are changeable in the field using the IRT watcher program.