P/N 35 84 70

W-1012-2EN Hydr Propulsion Pumps CC 102/102C/122/122C 3

Contents Page

Contents, Notes ............................................................................................................. 3

Safety Regulations ...................................................................................................... 4-5

General dismantling ....................................................................................................... 6

General reassembly ....................................................................................................... 7

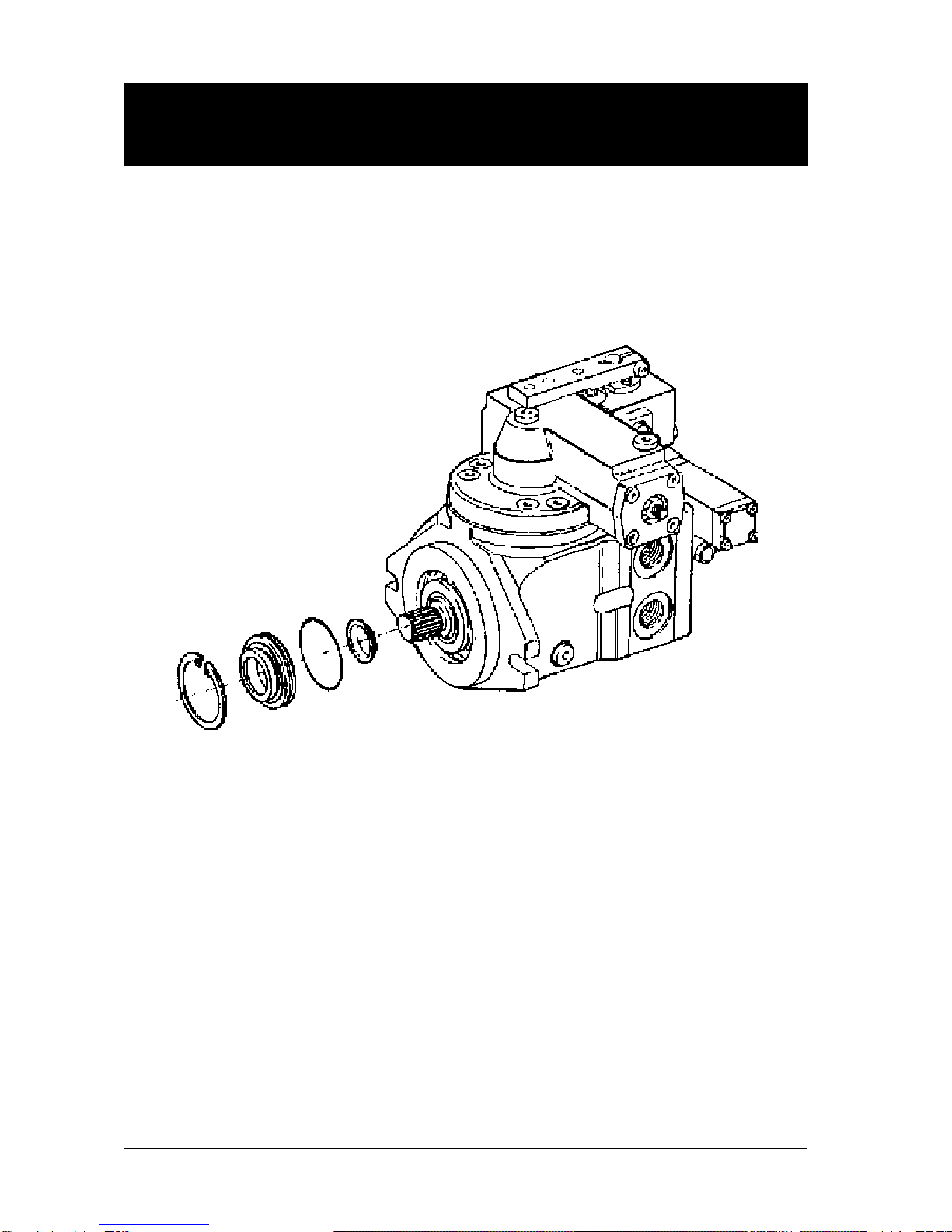

Sealing of the drive shaft................................................................................................ 8

Sealing of the high pressure valve ............................................................................... 10

Sealing of the charge pressure valve ........................................................................... 11

Sealing of the control device ........................................................................................ 12

Control device HW ....................................................................................................... 14

Dismantling the pump................................................................................................... 15

Inspection notes ........................................................................................................... 28

Pump assembly............................................................................................................ 30

Tightening torques ....................................................................................................... 37

Adjustment instructions - Mechanical "zero position" ................................................... 38

Adjustment instructions - Hydraulic "zero position" ...................................................... 39

Adjustment instructions - High pressure valve ............................................................ 40

Adjustment instructions - Low pressure valve (Charge pressure) ................................ 41

Contents

Notes

Notes

.........................................................................................................................................

.........................................................................................................................................

.........................................................................................................................................

.........................................................................................................................................

.........................................................................................................................................

.........................................................................................................................................

.........................................................................................................................................

.........................................................................................................................................

.........................................................................................................................................

.........................................................................................................................................