10 11

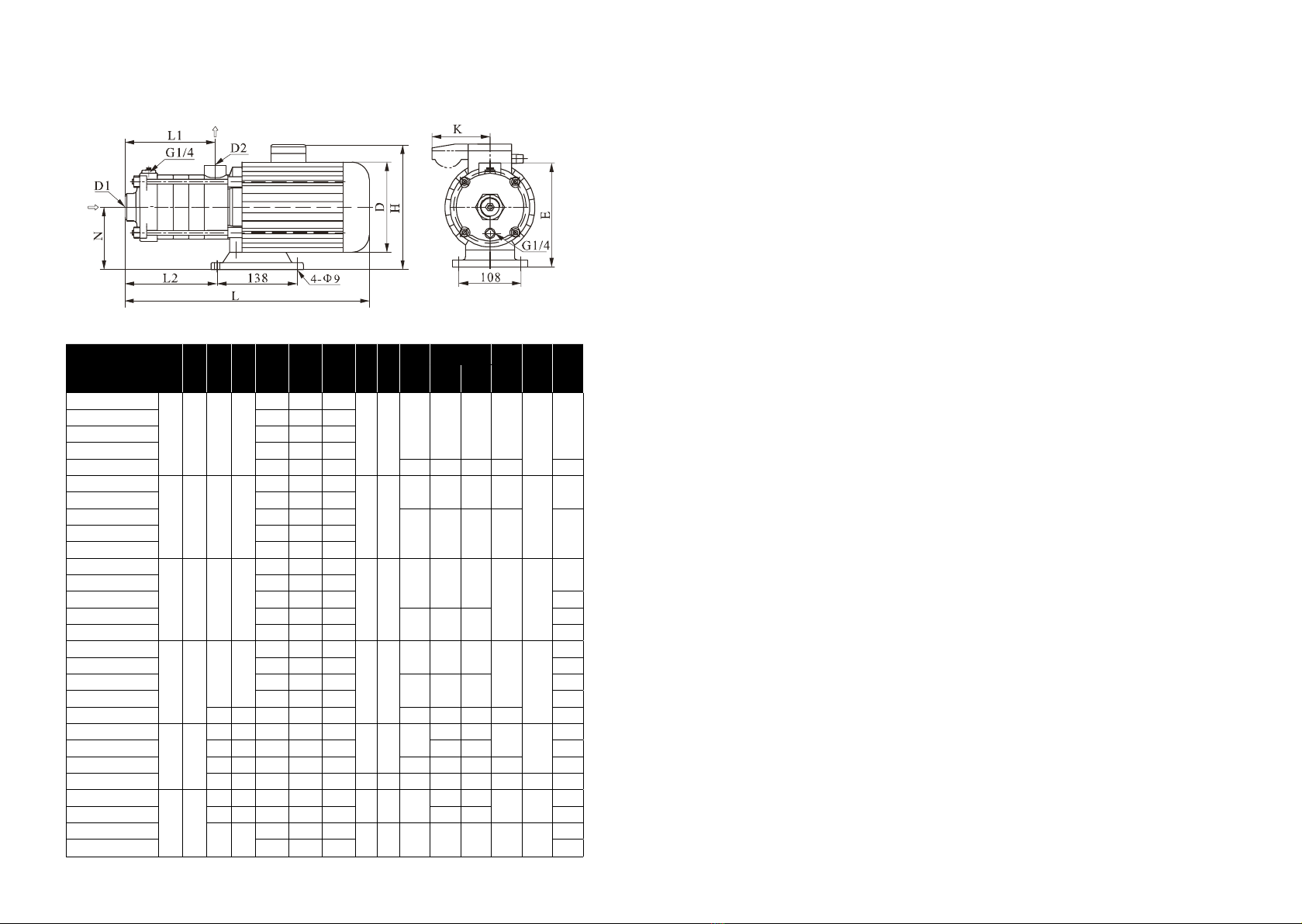

3. HF, HX, HN dimensions (mm)

Model D1 D2 N E L L1 L2 L3 d D

H K

M

weight

Three

phase

Single

phase

Single

phase Kg

HF, HX, HN 2-20

G1 G1 110 182

305 84 87

138 9145 215 230 96 108 15

HF, HX, HN 2-30 323 102 105

HF, HX, HN 2-40 341 120 123

HF, HX, HN 2-50 359 138 141

HF, HX, HN 2-60 422 156 159 170 225 245 100 17

HF, HX, HN 4-20

G1¼ G1 110 182

329 102 105

138 9

145 215 230 96

108

15

HF, HX, HN 4-30 356 129 132

HF, HX, HN 4-40 416 156 162

170 225 245 100 17HF, HX, HN 4-50 455 183 188

HF, HX, HN 4-60 482 210 213

HF, HX, HN 8-10

G1½ G1¼ 118 228

395 108 126

138 9

170 230 265

100 108

20

HF, HX, HN 8-20 395 108 126

HF, HX, HN 8-30 425 138 156 25

HF, HX, HN 8-40 490 168 186 180 240 270 28

HF, HX, HN 8-50 520 198 216 30

HF, HX, HN 12-10

G1½ G1½ 118 268

395 108 126

138 9

170 230 265

100 108

20

HF, HX, HN 12-20 395 108 126 21

HF, HX, HN 12-30 460 138 156 180 240 270 25

HF, HX, HN 12-40 490 168 186 29

HF, HX, HN 12-50 126 240 555 198 216 195 270 / / 34

HF, HX, HN 16-10

G2 G2

117 227 423 126 151

138 9180 230 265 100 108

18

HF, HX, HN 16-20 118 228 455 126 151 240 270 27

HF, HX, HN 16-30 130 240 561 171 196 195 270 / / 33

HF, HX, HN 16-40 120 230 621 216 340 140 12 220 270 / / 190 41

HF, HX, HN 20-10

G2 G2

117 227 423 126 151 138 9180 230 265 100 108 18

HF, HX, HN 20-20 118 228 455 126 151 240 270 27

HF, HX, HN 20-30 120 230 576 171 294 140 12 220 270 / / 190 41

HF, HX, HN 20-40 621 216 340 44

V. START-up, OpERATION AND MAINTENANCE

Caution: It is prohibited to run without liquid, which will damage mechanical

seal and sliding bearing.

1. Do not start the pump until it has been filled with water or liquid fully.

· Fill water in pump in inverse pouring system.

Close the pump outlet valve, release air vent screw on the pump head, and open the

inlet valve slowly until stable water flows from the air vent screw.

Then fasten the screw.

· Fill water in pump when liquid level is lower than pump. Before installing,

pump and pipes must be filled with liquid fully and air vented.

2. Check the rotary direction

Switch on the power supply and view the rotary direction by viewing the

motor fan. From the motor end, pump shall run counter-clockwise.

3.Check before pump start-up

· Check whether the pump is fixed securely.

· Check whether pump is filled with water fully and check whether liquid

can flow freely.

· Check whether the voltage of power supply is stable.

· Check whether it turns correctly.

· To make sure all pipe lines are connected tightly and can supply water

normally.

· The valves in the inlet pipe line are completely opened.

· The outlet valve shall be opened slowly after the pump is started up.

· Check the operation pressure if pressure meter is installed.

· Check all the controls for normal operation. If the pump is controlled

by pressure switch, check and adjust the starting pressure and stopping pressure.

Check the full load current to make sure it not surpasses the max allowed

current.

4. Frequency of pump starts

· Pump should not be started too frequently. It is suggested pump shall

not be started more than 100 times per hour if the motor power is less or equal

to 4kW. When motor power is big than 4kW, pump shall not be started

more than 20 times in one hour.

· Suggestion: When pump running, flow should be controlled at the range

of 0.5-1.3 times of rated flow.

· There should be no noise when pump running. If there is something

wrong, stop pump and check it and repair.