NorthStar RIM Tach®1250 Instruction Manual

3 Dynapar (847) 662-2666 17 November 2008

Table of Contents

Chapter/Paragraph/Illustration Page

1 Introduction....................................................................................................................................... 4

1.0 Safety Summary................................................................................................................................... 4

1.1 General................................................................................................................................................. 5

1.2 Descriptions......................................................................................................................................... 5

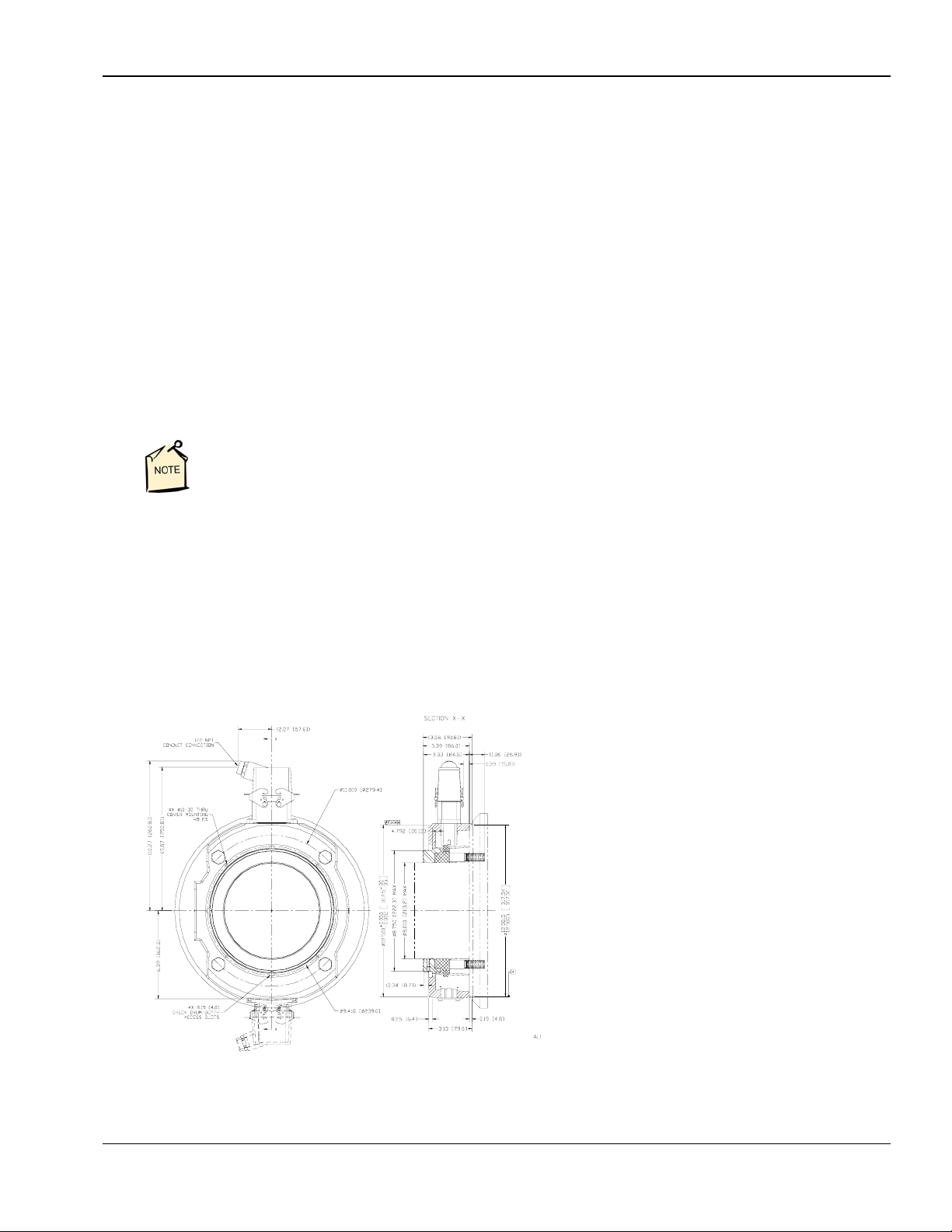

Figure 1: Small Thru-Shaft Enclosure ......................................................................................... 5

Figure 2: Specification Drawing.................................................................................................. 6

1.3 Specifications.............................................................................................................................................. 6

2 Installation......................................................................................................................................... 7

2.0 Inspection and Unpacking ................................................................................................................... 7

2.1 Painting Considerations....................................................................................................................... 7

2.2 Mechanical Installation........................................................................................................................ 7

Figure 3a: Large Thru-Shaft 1250............................................................................................... 7

Figure 3b: Large Thru-Shaft Assembly........................................................................................ 8

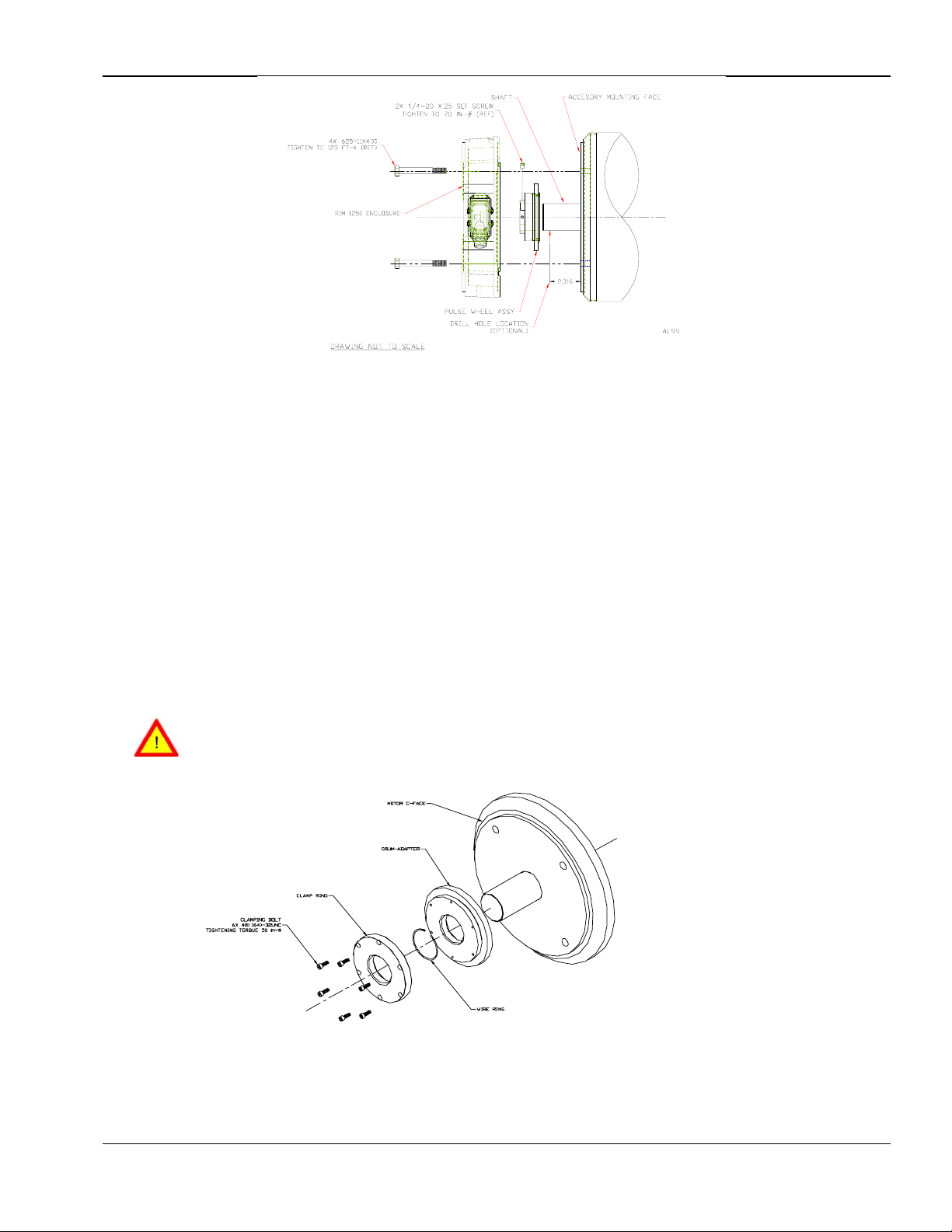

2.2.1 Motor Facing and Shaft ....................................................................................................................... 8

Figure 4: Typical 12.5 Inch Diameter Type C-Face Motor ......................................................... 9

2.2.2 Pulse Wheel Assembly for Small and Large Thru-Shaft..................................................................... 9

Figure 5: Pulse Wheel Assembly.................................................................................................. 10

2.2.3 High Slew Rate Wheels....................................................................................................................... 10

Figure 6: High Slew Rate Wheel.................................................................................................. 10

2.2.4 Enclosure Installation .......................................................................................................................... 11

2.2.5 Pulse Wheel Assembly Axial Position Adjustment............................................................................. 12

Figure 7: Pulse Wheel Alignment Check Using Straight Edge .................................................... 12

2.2.5.1 Optional Pulse Wheel Alignment Check............................................................................................. 12

Figure 8: Optional Pulse Wheel Alignment Check w/ Depth Gauge............................................ 12

2.2.6 Sensor Module Installation.................................................................................................................. 13

Figure 9: Sensor Module Installation........................................................................................... 13

2.3 Electrical Installation........................................................................................................................... 13

2.3.1 Quick Release Connector Hood Wiring .............................................................................................. 14

Figure 10: Quick Release Connector Installation........................................................................ 14

Methods and apparatus disclosed and described herein have been developed solely on company funds of Dynapar No government or other contractual

support or relationship whatsoever has existed which in any way affects or mitigates proprietary rights of Dynapar in these developments. Methods and

apparatus disclosed herein may be subject to U.S. Patents existing or applied for. Dynapar reserves the right to add, improve, modify, or withdraw functions,

design modifications, or products at any time without notice. Dynapar shall not be liable for errors contained herein or for incidental or consequential

damages in connection with furnishing, performance, or use of this material.