Obviously the racks must be assembled and installed

prior to installation of the batteries. Instructions for the

rack assembly are contained in a separate pamphlet

received with the racks.

The batteries are rated at 77° F (25° C). Operation at

cooler temperatures will decrease the operating time.

Operation at elevated temperatures will decrease the

overall life of the battery. There is a 50% life reduction

for each 15° F above 77° F.

Required Installation Tools & Equipment

Preparation for System Installation

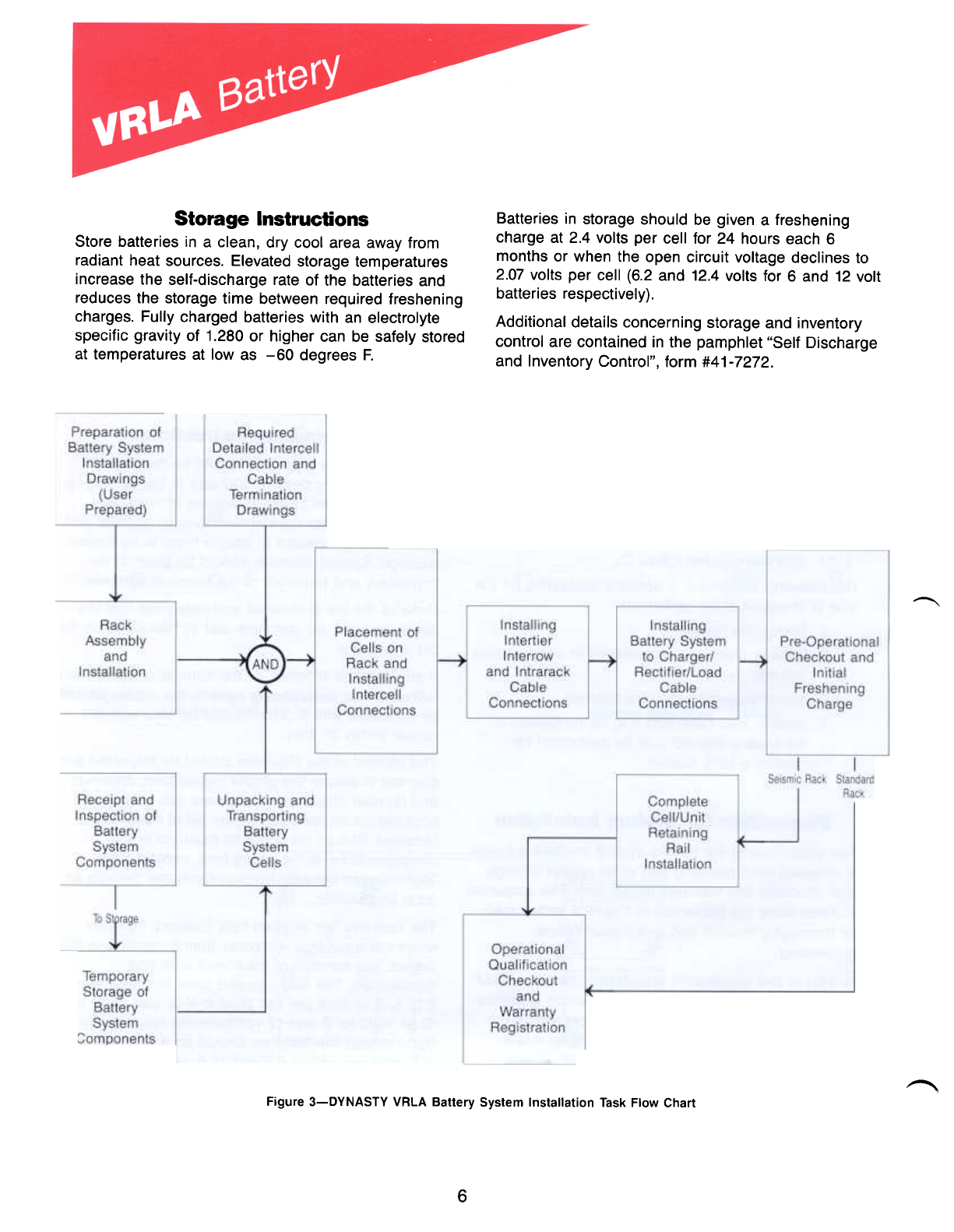

The installation of the battery system involves a series

of activities from planning and initial receipt through

final checkout and warranty registration. The sequence

of these tasks are presented in Figure 3 and should

be thoroughly studied and understood before

proceeding.

Receiving Instructions

Upon receipt the shipment should be thoroughly

inspected for any physical damage to the packaging

and to assure the proper quantities of items are

received. The packages should then be opened and

the batteries inspected to assure there is no hidden

damage. Special attention should be given to the

containers and terminals of the received batteries.

Refer to the bill of material and determine that the

items received are complete and as described on the

bill of material.

If any damage is noted, or the number of packages is

different from the shipping papers, the carrier should

be contacted and a claim should be filed with the

carrier within 10 days.

The content of the shipment should be inspected and

counted to assure the proper instructions, drawings

and number of batteries, hardware kits, cables and

accessories as identified on the bill of material are

received. Should the count be incorrect or the

components be of the wrong type, contact C&D

Technologies Dynasty Division Customer Service as

soon as possible.

The batteries are shipped fully charged, however

some self-discharge will occur during transit and the

degree is a function of the transit time and

temperature. The fully charged open circuit voltage is

2.12 to 2.14 volts per cell (6.36 to 6.42 and 12.72 to

12.84 VDC for 6 and 12 volt batteries respectively).

Upon receipt the batteries should be a minimum of

2.07 volts per cell or 6.2 and 12.4 volts for 6 and 12

volt batteries respectively. If at these minimum

voltages the batteries should be recharged as soon as

possible. If at or below 2 volts per cell (6 and 12 volts)

the batteries should not be used and the vendor

should be contacted immediately.

~

As part of this preparation activity the installer should

develop a system schematic diagram which identifies

how the individual batteries are to be placed on the

rack, interconnected and numbered. Figure 4 is a

schematic for a typical system of 30 each 12 volt

batteries on a single 3 tier rack while Figure 5 is a

schematic for a typical string of 40 each 12 volt

batteries on two each 3 tier racks. The cabling

received with the system presumes a specific rack

and installation configuration.

5

At a minimum, the following tools and equipment are

required to install the DYNASTY VRLA battery.

1.Digital voltmeter.

2. Socket wrench, insulated.

3. Torque wrench calibrated in inch-pounds.

4. Box end wrench, insulated.

5. Battery lifting equipment (handles) and fork lift

to lift pallets of batteries.

6. Rubber gloves.

7. Full face shield.

8. Plastic apron.

9. Potable eyewash.

10. Spill kit.

11. Fire extinguisher (class C).

The following equipment is optional depending on the

type of checkout to be performed.

1. Micro-ohm meter.

2. Battery resistance, impediance or conductance

test set.

3. 100 amp momentary load test set.

4. System load bank (DC if to be performed at

the battery and AC if to be performed by

loading a UPS output).