P/N: 974155 | Rev: 091316 | ECO: 46774

www.dynisco.com

From lab to production,

providing a window into the process

-3-

sealscrewandadjustpotentiometeruntildesiredoutputisachieved.

Replacesealscrewwhencomplete.

mAunitshaveavarietyofonboardZeroAdjustmentstypes(based

onconfiguration),i.e.potentiometer,pushbuttons,andHALLEffect

Switches.

oForunitswithpotentiometers,removesealscrewandadjust

potentiometeruntildesiredoutputisachieved.Replacesealscrew

whencomplete.

oForunitswithpushbuttons,removesealscrew,usinga2mmorsmaller

AllenKey,depresspushbuttonfor½sec,releasepushbuttonfor½sec,

depresspushbuttonfor½secandrelease.Replacesealscrewwhen

complete.

oForunitswithHALLEffectSwitches,unthreadzeroscrewfromendplate,

depressscrew,releasescrew,depressscrew,releasescrewandreturn

screwinendplate(failuretoreturnthescrewonunitswithHALLEffects

Switcheswillcausetheunittogointofailsafe).

DYNISCOVERTEXQUICKSTARTSETUPGUIDEUTILIZINGHARTCOMMUNICATOR

ThissectiononlyappliestomAHARTunits.

1. Followsteps1through5fromDYNISCOVERTEXQUICKSTARTSETUPGUIDE.

2. ConnectHARTHandheldtotheloop.

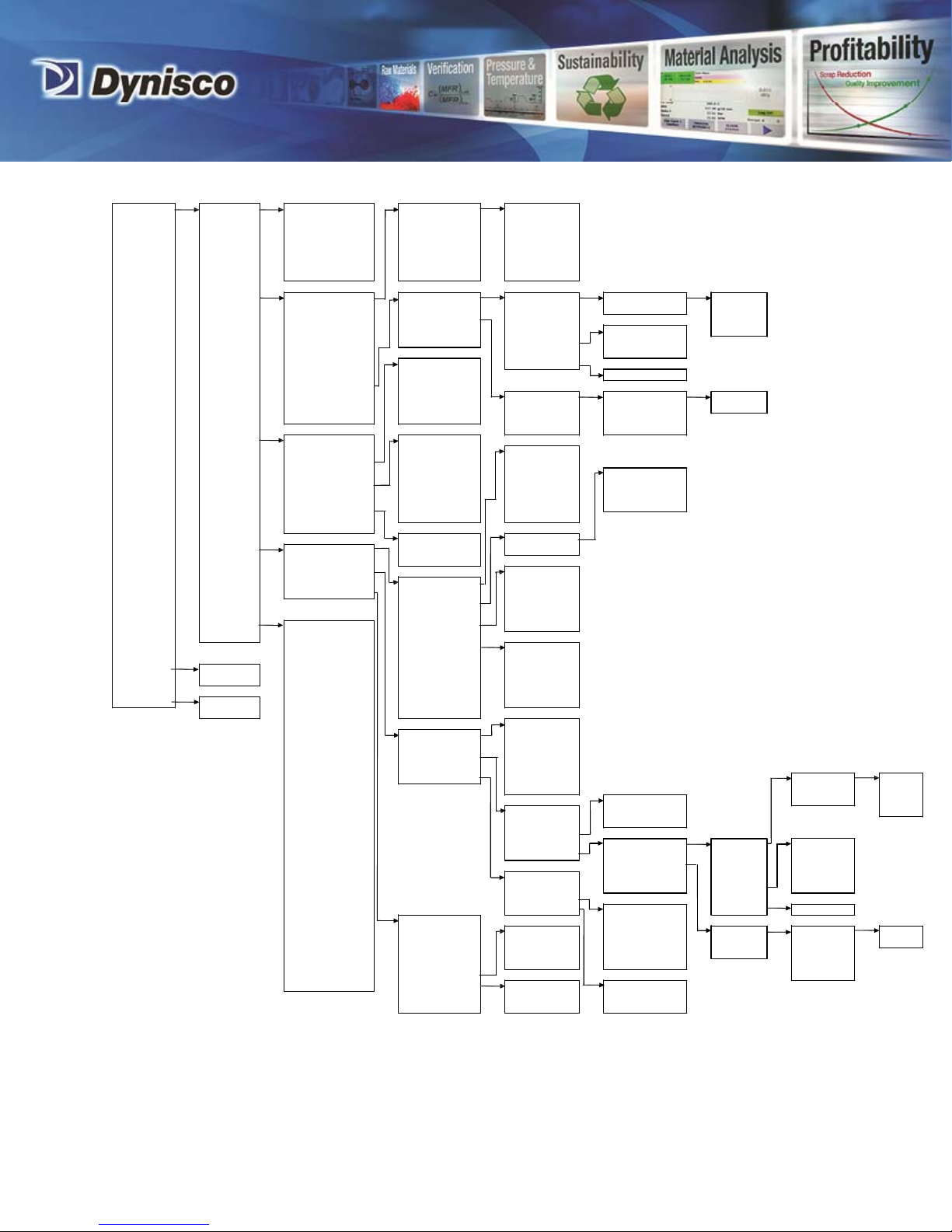

3. PowerontheHARTHandheld.SeeHARTCommandtreeonthefollowingpagefor

reference.

4. FromtheMainMenu:

a. EnterTag(QuickKey1,3,1).

b. Setpressureunits(QuickKey1,3,2),ifrequired.

c. SetURV(QuickKey1,3,3,2)ifoutputturndown(rescaling),isrequired.

d. PerformZeroTrim(QuickKey1,2,5,1,3,1)

5. Verifyloopoutputiszero(4mA).

6. RemoveHARTHandheldfromtheloop.