-

SAFETY

INSTRUCTIONS

AND

PRECAUTIONS

• SafetyInstructions

When a gas

leak

is

found

or

suspected:

-

Turn

off tfle gas valve

of

the boirer

and

other appliances which operate with gas.

-Shut off the oven, cooker

and

similar appliances

to

put their flame out.

-Do

not light match, lighter etc.

and

put cigarette out.

-Allow

fresh

air into the room

by

opening doors

and

windows.

-Do nottouch the electrical appliances' switches

and

plugs.

-

Turn

off gas supply

at

the gas meter.

-Do not

use

telephones

in

the environment where a gas leak

is

suspected.

-Call your qualified person as soon as possible.

~

Do not

place

and

use flammable

and

explosive liquid or materials around the boiler.

~

Keep soap

and

water solution

away

from electrical connections during cleaning, gas

leak

test etc.

~

Do not

block

air vents, openings

made

in

the walls of the room, which provide

fresh

air to

the installation room.

~

Do not lay the

LPG

container down.

~

Open flued gas combination boilers are

equipped

with combustion products discharge

safety

device

(TTB

sensor).

Combustion products discharge safety

device

shall not

be

put out

of operation.

In

case

of

the replacement

of

the defective safety devices, only the original

parts

may

be

used.

• Water Systems &

Gas

SupplyUne

~

Before installation

of

the boiler, the water

systems

(CH

and

DHW

circuit)

and

gas supply line

must

be

completed

in

accordance

with the relevant regulations

and

standarts

by

user.

• Gas

Type

Conversion

~

The

appliance

should

be

purchased

depending

on operating gas type.

In

case

of

a

demanding

gas type conversion,

this

is

made

with charge.

~

Gas type conversion from

LPG

to natural gas or from natural gas

to

LPG

must

be

carry out

only

by

qualified person. After gas type conversion, gas leak

test

must

be

performed

by

qualified

person.

~

Maximum pressure regulator must

be

sealed

and

the self-adhesive conversion label must

be

placed

on

the boiler after gas type conversion.

•Installation

~

The

boiler must

be

installed

in

accordance

with national

and

local requirements, gas safety

regulations, relevant standarts

and

this

manual

by

qualified installer.

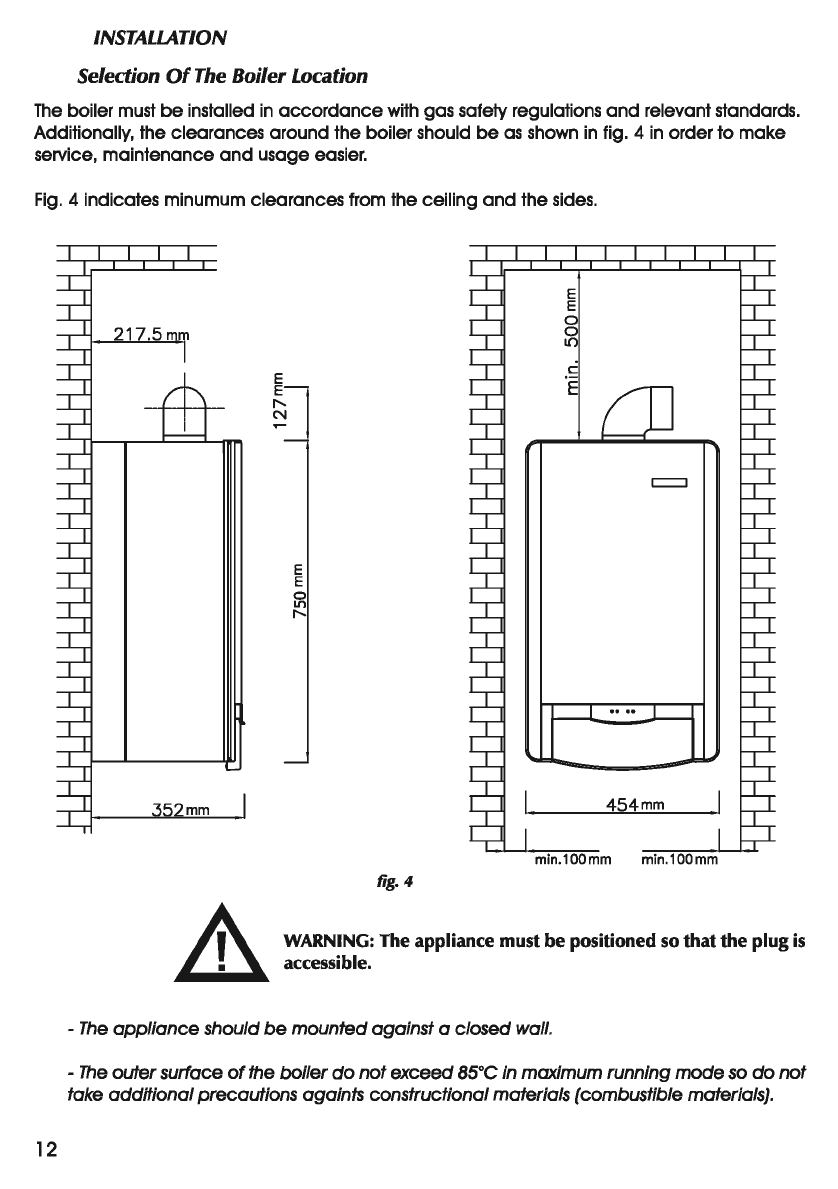

~The

appliance

should

be

mounted against a closed wall.

~

The

appliance

must

be

positioned

so

that the plug

is

accessible.

~

The

appliance

should not

be

positioned having a direct

contact

to

steam or gases.

~

Any

change

of

flue position must not

be

made

without consulting qualified person.

~

The

flue ducts must

be

fitted to a

approved

chimney for

open

flue boilers.

•

Boiler

Start-up

~

Boiler start-up must

be

performed certainly

by

qualified person.

~

Gas type (natural

gaS/LPG),

gas supply pressure (mbar), maximum

DHW

operating water

presure (bar)

and

electricity supply voltage M

data

which are detailed on the information

plate must

be

suitable with mains supply conditions.

This

is

checked

by

qualified person.

~

After boiler start-up, you should request information

about

operating the boiler

and

safety

precautions from qualified person.

•

Operating

The

Boiler

And

Maintenance

~

Read carefully instructions

and

precautions

in

this

manuel against wrong usage which causes

unsafe conditions.

~The

boilershould

be

checked

and

serviced for general maintenanceoncea year. Maintenance

and

service operations must

be

carried out only

by

qualified person.

~

Only a

damp

cloth should

be

used for cleaning the outer surface of the boiler

and

then the

surfaces should

be

dried completely. Do not

use

chemical subtances or solutions which cause

rust

and

scratches

in

your

appliance.

4