GAS CONNECTIONS

Installation Personnel: Che k all onne tions and fittings on valves and tubing supplied as a part of this unit to

make sure they did not ome loose during shipment. A manual gas valve should be provided upstream within 6

feet of the applian e for shutting the gas off during servi ing. A ground joint union should be provided between

the house plumbing and the gas inlet to the applian e. A gas pressure regulator has been provided as a part of

this applian e. It is fa tory pre-set for natural gas and is field adjustable for liquid propane gas. All plumbing

should be lean and free of burrs and metal hips. All pipe onne tions should be made using a pipe joint

ompound resistant to the a tion of LP gases. A drip TEE must be used to olle t any moisture or dirt in the

gas. Upon ompleting the installation of this applian e, all the gas onne tions must be he ked for gas leaks.

Use a solution of liquid dishwashing soap and water to he k for leaks.

This installation must onform with lo al odes, or in the absen e of lo al odes with the National Fuel Gas Code

ANSI Z223.1/NFPA-54, National Gas and Propane Installation Code, and CSA-B149.1 as appli able.

The applian e and its individual shutoff valve must be dis onne ted from the gas supply piping system during

any pressure testing of that system at test pressures in ex ess of 1/2 psig (3.45 kPa). The applian e must be

isolated from the gas supply piping system by losing it’s individual manual shutoff valve during any pressure

testing of the gas supply piping system at test pressures equal to or less than 1/2 psig (3.45 kPa).

Provisions for proper air supply must be taken into a ount when installing the unit. Care should be taken so as

not to obstru t the area in front, under or in rear of the unit. DO NOT PLACE BACK OF THE UNIT CLOSER THAN

6˝ (153mm) TO A WALL OR OTHER SURFACES. The applian e shall be lo ated with respe t to other equipment

so it will have adequate learan es for servi ing and proper operation.

This unit is supplied with four (4) adjusta le feet, which must e installed prior to operation. Four (4)

threaded openings are provided on bottom of the unit to a ept the threaded portion of the feet. S rew in the

feet and tighten them se urely. During operation, he k the feet every sixty (60) days to assure that they are

tight. Failure to use the feet will void warranty and ould ause unsafe onditions.

Note: Appliance must e installed under a ventilation hood.

3

INSTALLATION/OPERATING INSTRUCTIONS

Gas Charbroilers

(continued on Page 4)

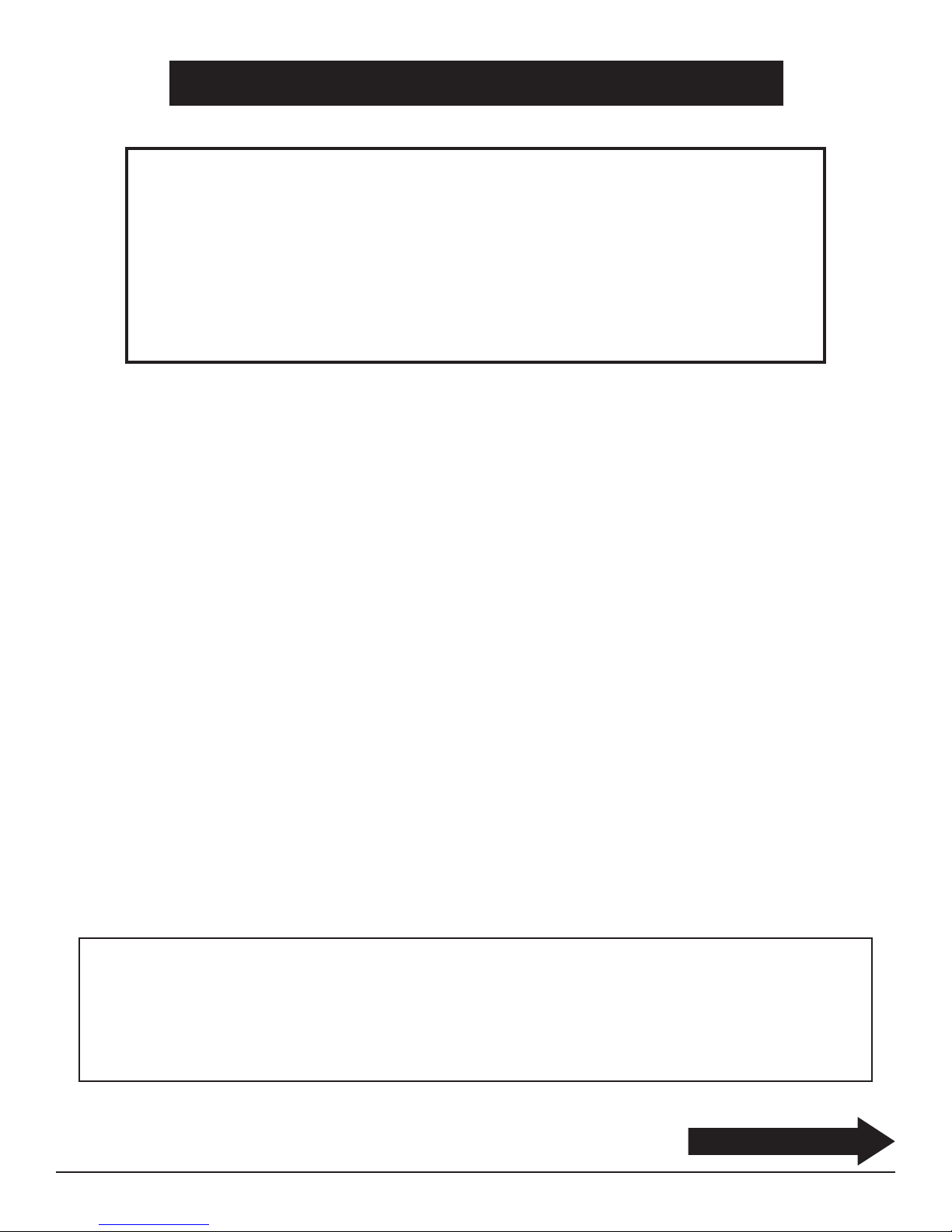

SERIES ORIFICE DRILL SIZE / EAGLE PART # INCHES IN WATER COLUMN

NATURAL LP NATURAL LP

CLCHRB 32 / 336254 50 / 336007 6˝ 10˝

CLCHRBL 39 / 361984 51 / 360322 6˝ 10˝

GAS ORIFICE INFORMATION

ORIFICE SIZE ORIFICE SIZE REQUIRED AT OTHER ELEVATIONS

AT SEA LEVEL 2000 ft 3000 ft 4000 ft 5000 ft 9000 ft

32 33 34 35 35 38

39 40 41 41 42 44

41 42 42 42 43 45

50 51 51 51 51 53

51 51 52 52 52 53

52 52 53 53 53 54

60 64 64 65 65 67

67 68 68 68 69 70

73 73 77 77 78 78

77 77 77 77 78 78

1.55mm 54 54 54 54 55