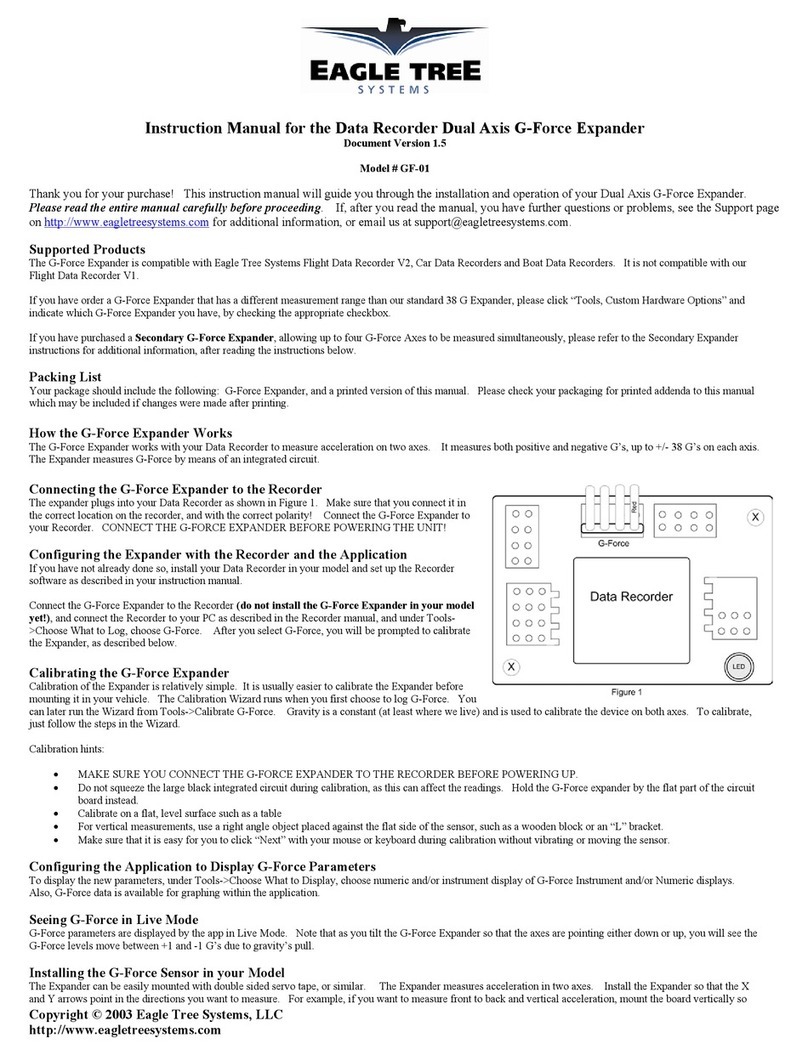

Connecting the Electric Expander to Your Battery

To measure current the hall effects current sensor ring can be installed around either the positive or negative wire leading from your battery to your

speed controller. It works through the wire’s insulation, and hence no cutting of the wire is necessary. It can be installed facing either direction, as it

is not polarized.

The alligator clip is for measuring battery pack voltage. It should be attached to an exposed part of the positive (normally red) battery wire or

terminal between the battery and the speed controller. It must be in direct electrical contact with the positive battery wire. Alternatively, the

alligator clip can be removed and soldered to the wire leading to the ESC for a more permanent installation.

If an easily removable installation is desired, one convenient way to do this is to have a removable wire “section” with Deansor other plugs on either

end (male/female). Both the current and voltage leads of the Electric Expander can attach to this wire section (the alligator clip is normally cut off

and the voltage wire soldered), and the section can be removed easily from the model when electric measurement is not desired.

ESCs with isolation between BEC/Throttle ground and Main Battery Ground

Note that there must be electrical conductivity between the ground wire of your main battery and the Recorder’s internal ground, for voltage

measurement to work correctly. Normally, when the Recorder is connected to your receiver via one or more of the Recorder’s servo connections,

the ground wire of the ESC’s BEC/Throttle output results in the correct grounding.

However, some ESCs isolate battery ground

from the ESC/BEC throttle output ground.

The easiest way to tell if there is ground

isolation is, with everything disconnected

from your ESC, to measure the resistance

between the main battery negative input of

the ESC, and the BEC/Throttle ground wire.

If the resistance is greater than an ohm or

two, there is isolation.

In these cases, for the Recorder to measure

voltage correctly, the recorder’s ground

must be connected to the ground of the

battery to be measured.

There are two ways to do this:

a) RECOMMENDED: Disconnect

all connections between your

Receiver (including BEC/Throttle

output of the ESC) and your

Recorder, and power the recorder

from a separate small battery. Then, connect a small ground wire between one of the Recorder’s servo ground pins, and the negative lead

of the battery being measured, as shown in Figure 2. Note that the resulting connections should not bypass the ESC’s isolation between

the BEC/Throttle ground and the ground of the battery being measured, since the BEC/Throttle ground is NOT connected to the recorder.

Note that servo position logging will not be possible in this scenario.

b) If you want to continue to power the Recorder from the ESC’s BEC output or the battery you are using to power the Receiver (and to be

able to log servo positions), you will need to leave the servo connections from the Receiver to the Recorder connected, AND you will need

to connect the small wire between the between one of the Recorder’s servo ground pins, and the negative lead of the battery being

measured, as shown in Figure 2. CAUTION! This configuration causes the internal ESC isolation to be bypassed. While the vast

majority of the customers who have done this with our equipment have not reported any problems, we have had one report of two

different high powered ESC’s which may have been damaged by performing this connection. Therefore, we strongly recommend

contacting the ESC manufacturer or consulting the ESC manual to ensure that connecting the ground of the ESC’s throttle output

and the main battery ground together will not cause a problem with that particular ESC, before proceeding. Bypassing the ESC

isolation is done at your own risk!

If your ESC has isolation, and you don’t understand how to set up the recorder in this configuration, don’t hesitate to visit the “Support” page of our

website for information about how to contact us with your issue.

Configuring the Expander with the Recorder and the Application

If you have not already done so, install your Data Recorder in your model and set up the Recorder software as described in your instruction manual.

Zeroing the Current Sensor for First Time Use

Some ESCs, servos, etc., can draw a large constant current when the systems are powered up. Therefore, it is good to set the zero current reference

with your new Electric Expander. To do this, simply connect the Electric Expander to your Recorder, and connect the Recorder to USB, but make

sure there is no current draw through the ring current sensor (don’t connect a battery pack to the ESC). Then, in the Windows Application, click