-6

10)The chargershouldbepacked properlyifnot used forlongtime.

Belowisthecharging procedure:

·TurnOffThePowerOfTheWholeVehicle

1)When it’snon-onboardcharger, one setofbatteries, the process isasfollows:

a)Connect chargertoDC receptacleon the vehicle;

b)Connect thechargertoACpower;

c)Turnonthecharger

d)Turnoffthe chargerwhen thebatteriesarefullycharged,disconnectthechargerfromACpowerfirst, then

disconnect the chargerwithACreceptacle;

2)When it’snon-onboardcharger, twosetsofbatteries, the process isasfollows:

a)Disconnect the twoDC receptaclesunderthe driver’sseat, refertoleft picture;

b)Connect thechargerstotheDC receptacles, onechargertoonereceptacles;

c)Connect the chargerstoACpower;

d)Turnon the chargers;

e)Turnoffthe chargerswhen the batteriesarefullycharged,disconnectthechargerswithACpowerfirst,

then disconnectthechargerswithDC receptacles;

f)Connect thetwoDC receptaclesunderthe driver’sseat.

3)When it’sonboard(build-in)charger(s), no matterthereisone set ortwosetsofbatteries, theprocess isas

follows:

a)Connect thecharger(s)withACpower;

b)Turnon the charger(s);

c)Turnoffthe charger(s)when the batteriesarefullycharged, disconnect the charger(s)withACpower;

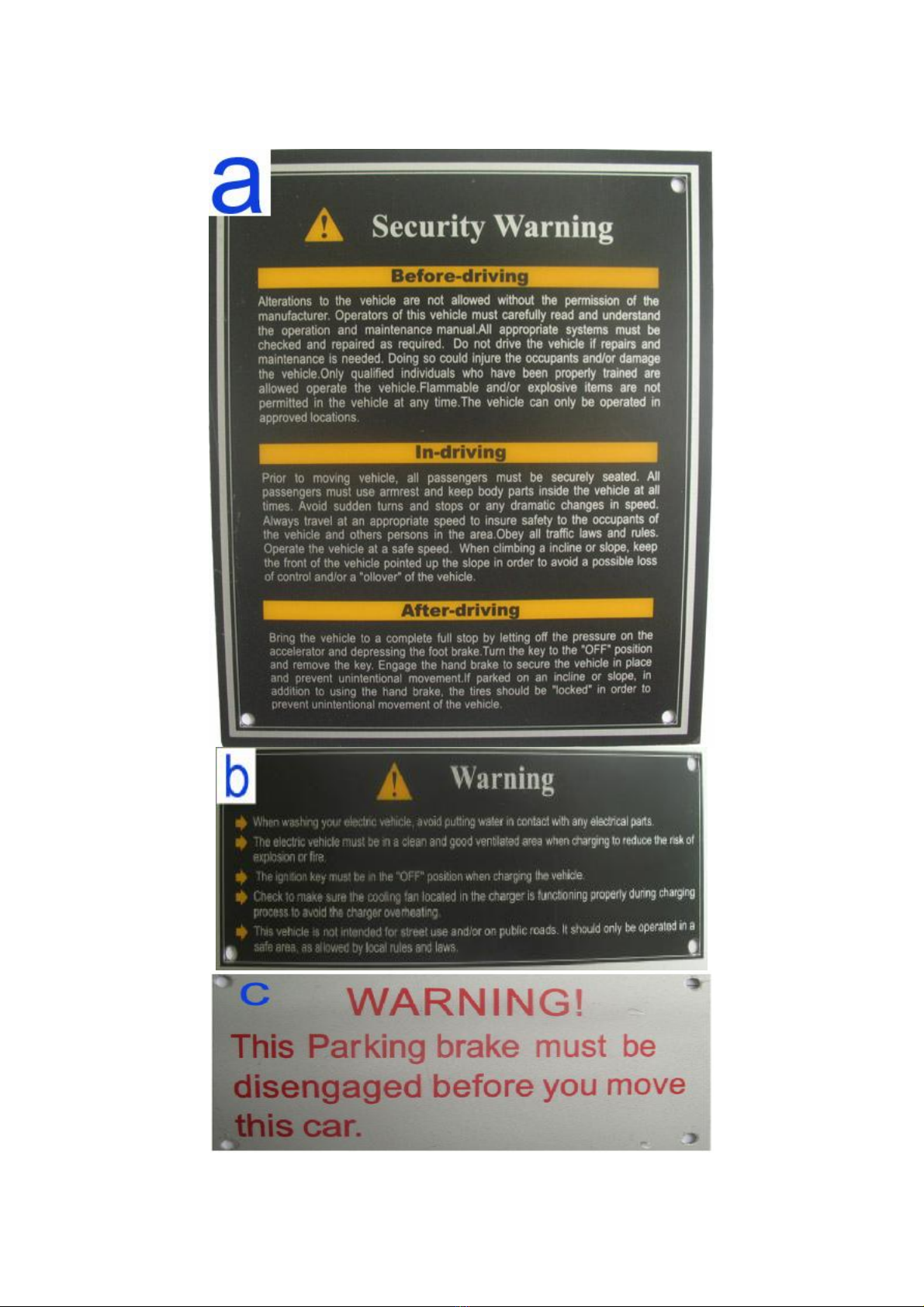

6. RulesforSafe Operation

The drivershouldhaveagood knowledgeofthe operation systemofthe vehicleand itsfeatures;meanwhile

followthe rulesforsafeoperation.

W

W

Wa

a

ar

r

rn

n

ni

iin

n

ng

g

g:

:

:

lDrivethe vehicleoffroad unless it isallowed.

lThevehiclecannotbeover-loaded,otherwisethe motorwill bedamaged,the vehiclewill losecontrol

and itslifewillbeshortened.

lUnqualified personsareprohibited todrivethe vehicle.

lMakesurethisvehiclerunsinitsrated climbingability.

lDon’t overtakeothervehiclesat crossroad, inblind area orinotherdangerouszone.

WHILEOPERATING THEVEHICLE

lKeepyourentirebodyinsidethevehicle, keepseatedandholdingonwhilethe vehicleismoving.

lDonot start thevehicleuntil all occupantsaresecurelyseated.