WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orreproductiveharm.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

YoumaycontactT orodirectlyatwww.Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorT oroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure1),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

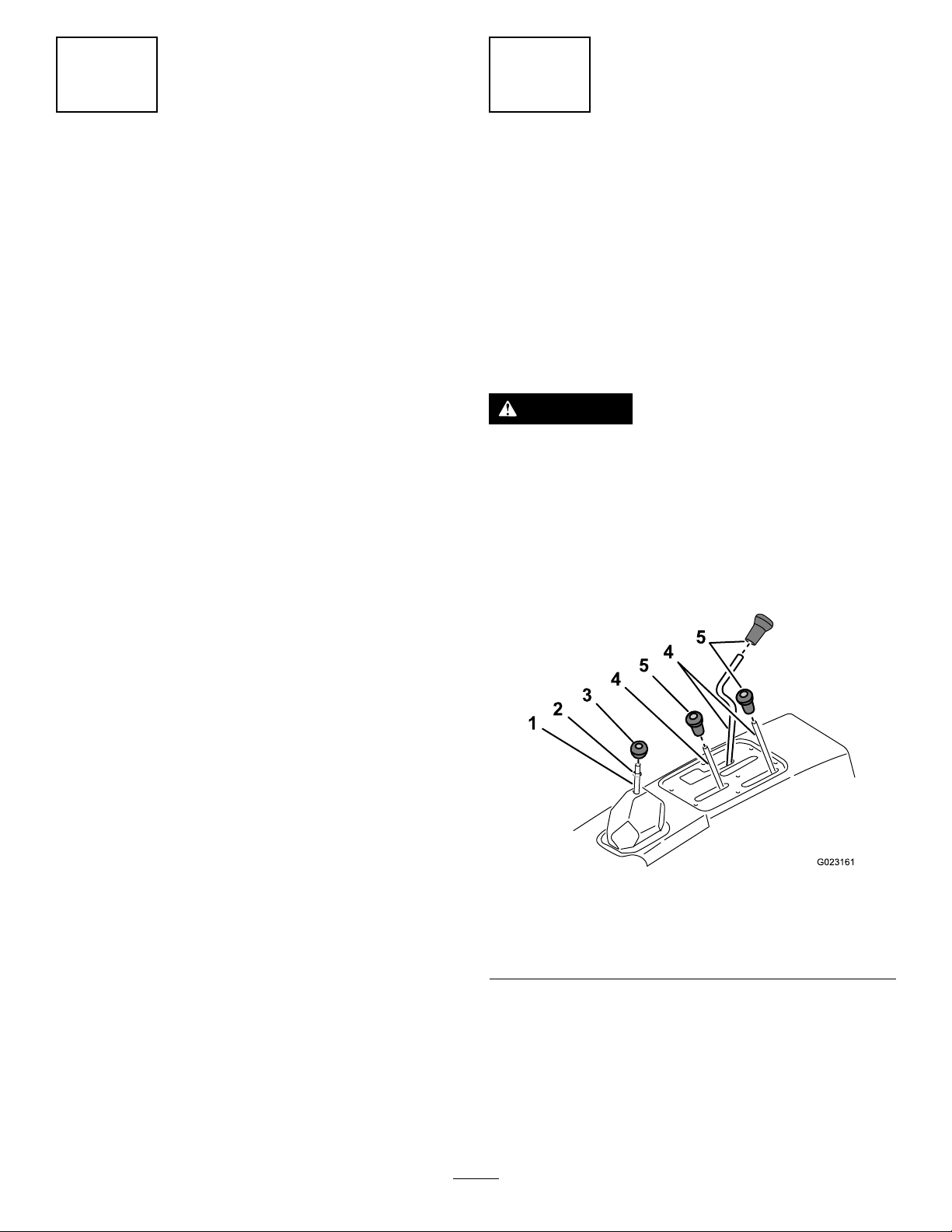

g000502

Figure1

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................3

BeforeOperating................................................3

WhileOperating..................................................3

Maintenance.......................................................3

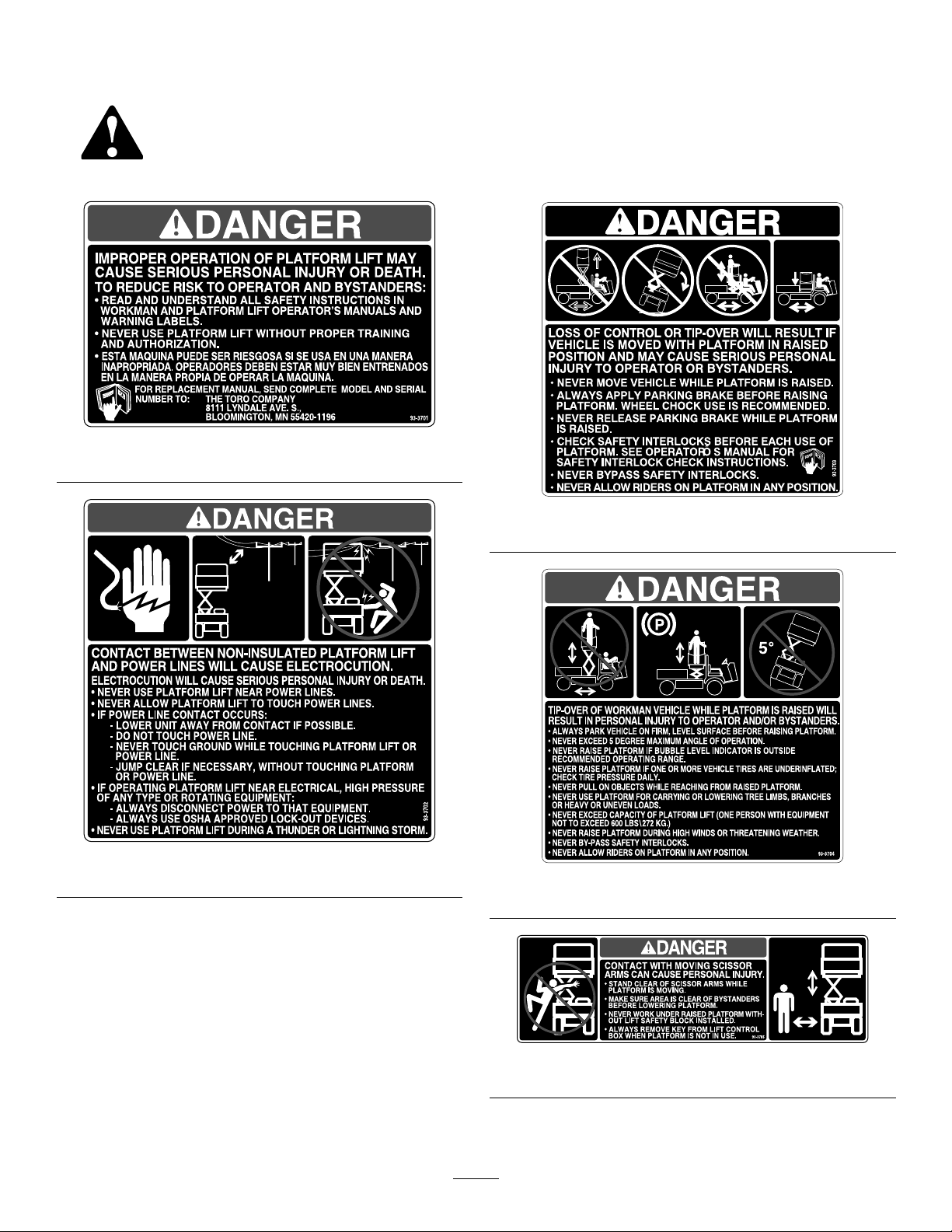

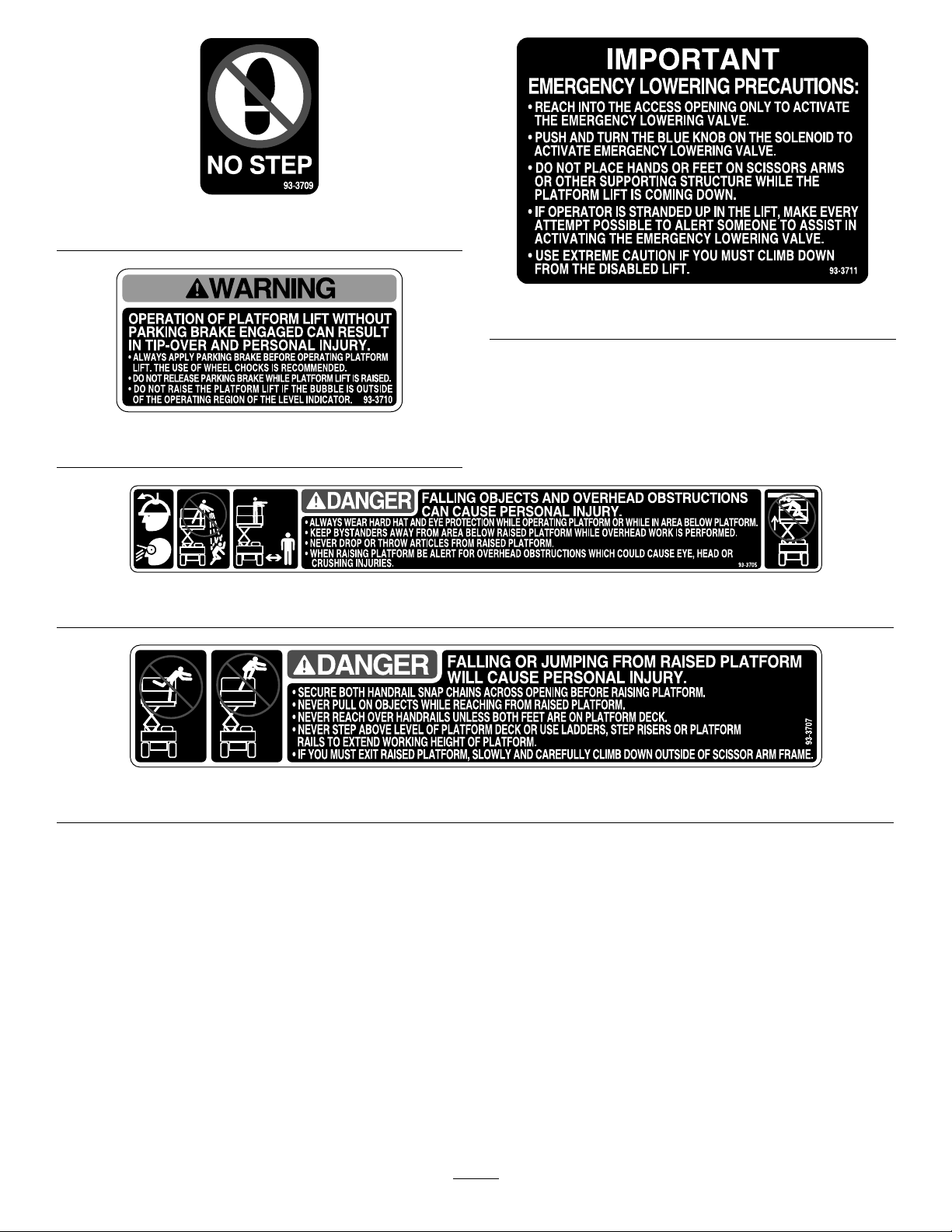

SafetyandInstructionalDecals..........................4

Setup........................................................................6

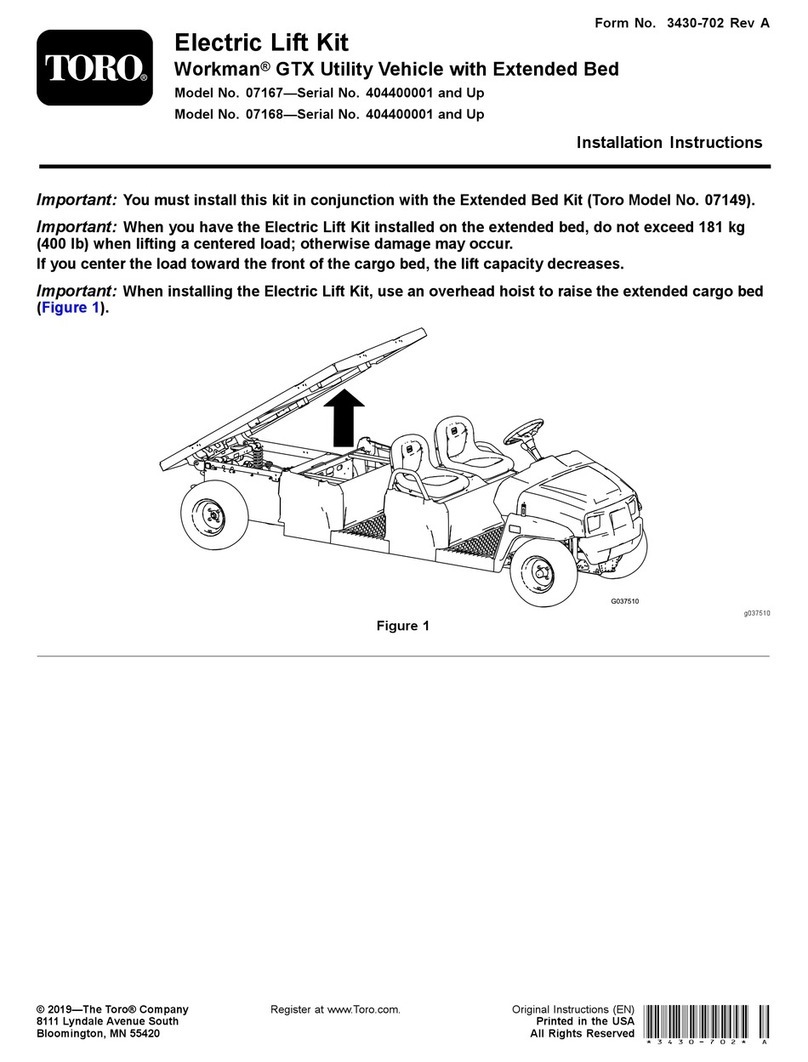

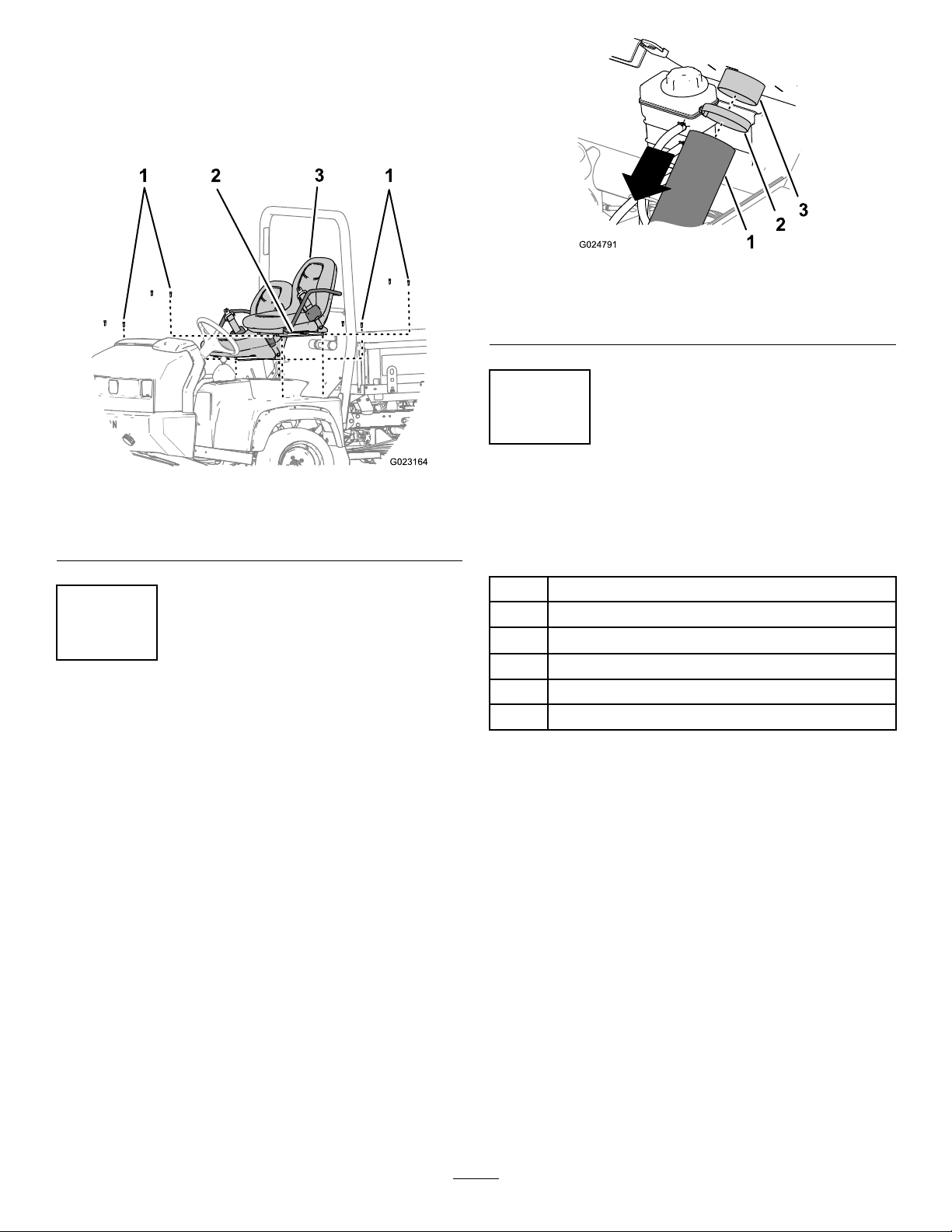

1PreparingtoInstalltheKit................................7

2RemovingtheCenterConsole,Seat

Shroud,andSeatAssemblies.........................7

3RemovingtheCVTCoolingDuct

(HDX-Autoonly)..............................................9

4InstallingtheMainWireHarnessand

Relays.............................................................9

5MountingtheParkingBrakeSwitch................10

6MountingtheRearLevelSwitch.....................12

7InstallingtheHood,ROPSShieldShroud,

Seats,SeatShroud,ConsoleCover

Plates,andCVTIntakeHose(HDX-Auto

only)..............................................................13

8MountingtheLiftontotheMachineFrame

......................................................................13

9ConnectingtheWireHarnessandBattery

......................................................................14

10MountingtheBubbleLevelIndicator.............15

11InstallingtheDecals.....................................16

ProductOverview...................................................17

Controls...........................................................17

Operation................................................................18

CheckingtheOilLevel......................................18

CheckingtheTirePressure...............................18

EngagingSafetyLocks.....................................18

OperatingtheLift..............................................19

OperatingTips.................................................21

Maintenance...........................................................22

CheckingtheSafetyCircuits.............................22

MaintainingtheBattery.....................................23

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved