E&I 350L User manual

The material contained in this document is the property of Electronics & Innovation Ltd., it is subject to

change without notice.

December 2015 Revision F

1

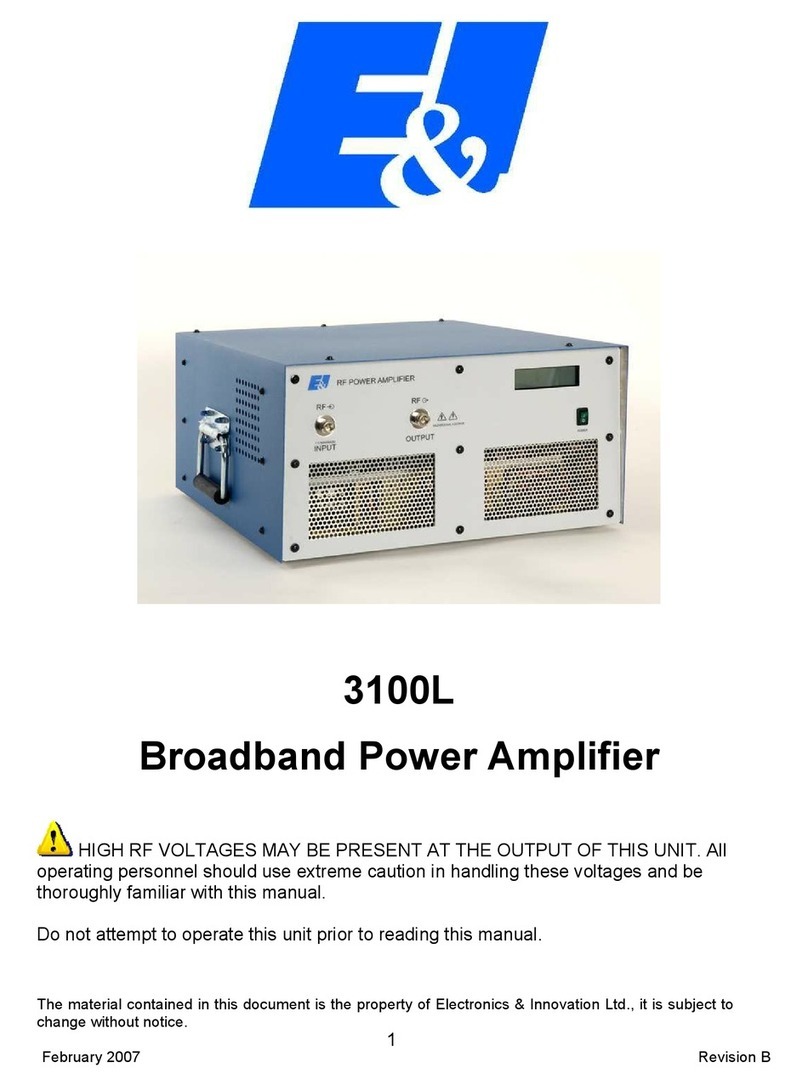

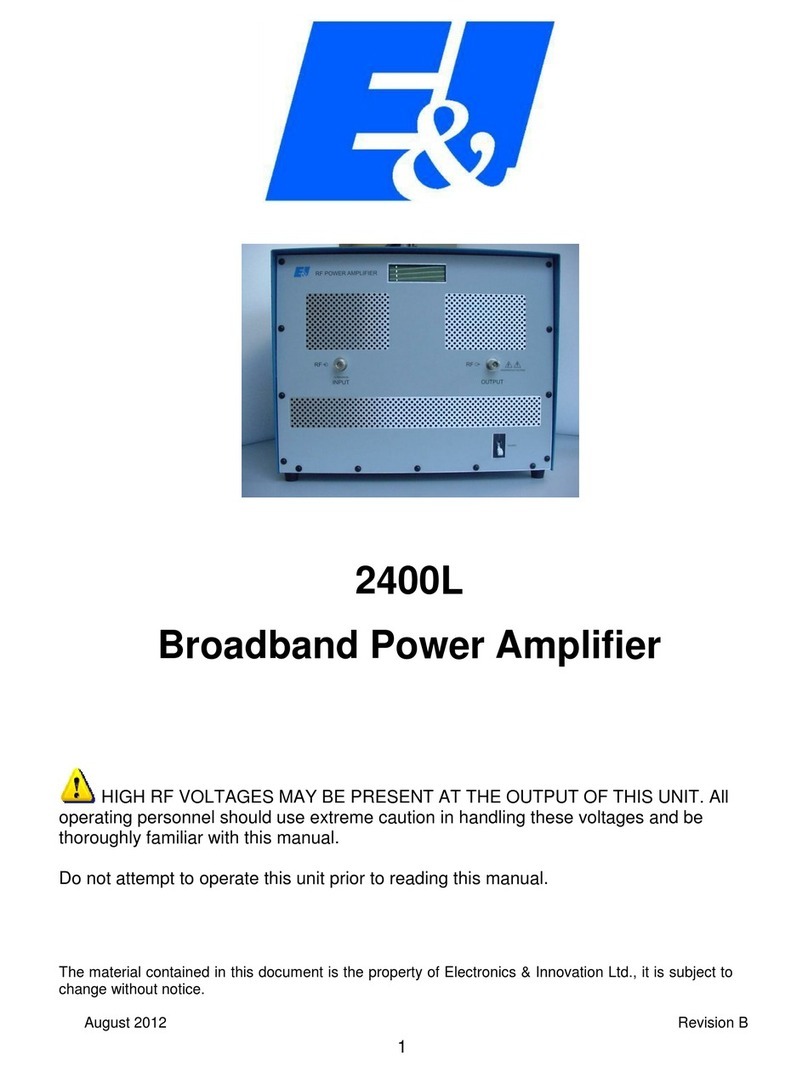

350L

Broadband Power Amplifier

HIGH RF VOLTAGES MAY BE PRESENT AT THE OUTPUT OF THIS UNIT. All

operating personnel should use extreme caution in handling these voltages and be

thoroughly familiar with this manual.

Do not attempt to operate this unit prior to reading this manual.

Warranty

The material contained in this document is the property of Electronics & Innovation Ltd., it is subject to

change without notice.

December 2015 Revision F

2

Electronics & Innovation Ltd., (hereafter E&I) warrants for the period of three years from

the date of original delivery, each unit to be free of defects in materials and workmanship.

For the period of 36 months E&I will, at its option, repair or replace defective parts so as

to render the unit fully operational such that it performs according to the original

specifications; free of charge to the original purchaser.

Should warranty service be required, the unit must be returned to E&I, freight cost to be

borne by the owner. If, in our opinion, the unit has been damaged by use outside the

limits prescribed in this manual or by accident, then the warranty shall not be honored. In

such a case E&I will provide an estimate for repair, assuming repair is possible and

provide a quote at standard service rates.

Contents

Chapter 1

General Information……………………………………………………………3

Chapter 2

Operation………………………………………………………………………..4

Chapter 3

Technical Information………………………………………………………….7

Chapter 4

Maintenance……………………………………………………………………8

Chapter 5

Safety……………………………………………………………………………12

The material contained in this document is the property of Electronics & Innovation Ltd., it is subject to

change without notice.

December 2015 Revision F

3

Chapter 1 Introduction

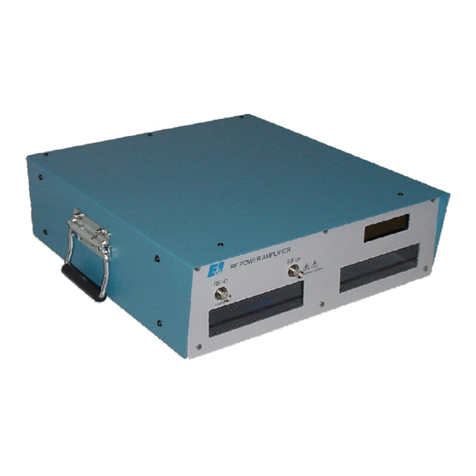

The 350L is a broadband solid state amplifier covering the frequency spectrum from 250

KHz to 150 MHz. It is rated at 50 watts of RF power with low harmonic and

intermodulation distortion. Over 100 watts of saturated power can be produced with

increased distortion products. A highly linear Class A design, the 350L will amplify inputs

of AM, FM, SSB, pulse and any complex modulation signals. The amplifier has 50 dB

gain it is unconditionally stable and will not oscillate even with mismatched load

impedance. It is protected against failure due to output load mismatch and/or overdrive.

RMS forward and reverse powers are monitored by a front panel meter. An integral power

supply permits operation from 115/230 single phase AC power.

1.2 INSTRUMENTATION IDENTIFICATION

Each amplifier is identified by a serial number tag on the back panel of the unit. Both the

model number and the serial number should be quoted to identify specific unit.

1.3 SPECIFICATIONS

Physical and electrical specifications are listed in Table 1-1 below

The material contained in this document is the property of Electronics & Innovation Ltd., it is

subject to change without notice.

December 2015 4 Revision F

Table 1-1. SPECIFICATIONS

FREQUENCY COVERAGE:

250 kHz to 150 MHz

GAIN:

50 dB min, ±1.5 variation

CLASS A LINEAR OUTPUT:

50 Watts P1dB

HARMONIC DISTORTION:

< -25 dBc @ 50 W

SATURATED RF POWER OUTPUT:

80W Min.

INPUT IMPEDANCE

50 ohms, VSWR, 1.5:1 Maximum

OUTPUT IMPEDANCE:

50 ohms, VSWR, 2:1 Maximum

STs STABILITY:

Continuous operation into any load or

source impedance

PROTECTION:

Unit will withstand a + 13dBm input

signal (1.0 Volts RMS) for all output load

conditions, without damage

POWER OUTPUT METER:

True RMS power detection. ±3% of full

scale accuracy

POWER REQUIREMENTS:

100 –240 VAC 47-63 Hz

SIZE:

(H x W x D)

7.5” x 9.5” x 12.5”

190.5 x 241 x 317.5 mm

WEIGHT:

18 lbs (9 Kg)

CONNECTORS:

N-Type

OPERATING TEMPERATURE:

0 –40 C

RACK MOUNTING:

Chapter 2 Operation

2.1 INTRODUCTION

The 350L RF amplifier is used to amplify the RF level of signal sources in the 250

KHz to 150 MHz range. No tuning or any other form of adjustment is required.

The 350L produces rated power output at its output connector, regardless of load

impedance. Any power reflected due to output load mismatch is absorbed in the

amplifier. Therefore, although the output impedance is 50 ohms (maximum

VSWR: 2:1), the amplifier will work into any load impedance.

The material contained in this document is the property of Electronics & Innovation Ltd., it is

subject to change without notice.

December 2015 5 Revision F

2.2 RACK INSTALLATION

This unit will accept optional Rack ears for mounting.

2.2.1 Mains Voltage

The unit accommodates AC line voltages from 100 TO 240 VAC 47 –63 Hz

2.3 OPERATION

A line cord is supplied to form a connection between the mains supply and the

rear of the unit. Plug this into AC input at the rear of the unit and the AC mains

outlet.

2.3.1 Proceed as follows:

(i) Ensure that there is at least 3” or 7.5 cm clearance at the rear of the

unit for air flow.

(ii) Ensure RF input voltage is not excessive

a. The 1 V rms indicated maximum input voltage is 5 times the level of

the input signal required to achieve maximum output. Input voltages

in excess of 2 volts peak may permanently damage the instrument.

(iii) Connect the output via a 50 ohm coaxial lead and BNC plug to the

load.

(iv) Connect the input signal via a 50 ohm coaxial lead and BNC plug to

the input connector.

2.3.2 Front Panel Display

The 350L front panel has a passive LCD display designed for simplicity and ease

of use. During initialization, the LCD shows the software revision. After the

amplifier is initialized, the LCD indicates Forward Power, Reflected Power, and

amplifier status (see figure 2.1).

Pf:___W Pr:___W

Status:________

Figure 2.1 : Front Panel Display

Where Pf refers to forward power, Pr refers to reverse power, and Status

indicates “OK” unless there is a fault condition, such as:

Overheat (heat-sink temperature is too high for reliable operation)

The material contained in this document is the property of Electronics & Innovation Ltd., it is

subject to change without notice.

December 2015 6 Revision F

PSU fault (internal fault in the main switching power supply)

In the event of a fault, the unit may be reset by either cycling the power. In the

case over an over temp fault, ensure that the air inlet and out let are unclogged

and unrestricted. If the fault persists, please contact Field Service.

2.3.3 RS 232 Interface

The 350L features a standard RS-232 serial interface suitable for connection to a

PC or host system. The communication protocol is extremely simple to facilitate

readback and control with readily available terminal programs such as

Hyperterm. The RS-232 link has the following parameters:

Baud rate: 19200

Data bits: 8

Parity: none

Stop bits: 1

Flow control: none

An example configuration using HyperTerminal on a PC is shown in figure 2.2.

Figure 2.2: Example RS-232 setup using Hyper Terminal

The material contained in this document is the property of Electronics & Innovation Ltd., it is

subject to change without notice.

December 2015 7 Revision F

In the default state, the RS-232 port will echo the same information sent to the

front panel LCD display, allowing a running datalog to be stored to disk using the

capture feature of the terminal program.

Single character commands can be sent to the amplifier to achieve the following:

"1" key enables telemetry (readback similar to LCD display) - this is the default

mode at power up

Custom commands and display lists can be implemented upon customer

request.

Chapter 3 Technical Description

3.1 GENERAL DESCRIPTION

The 350L is designed to amplify signals by 50 dB in the frequency band of 250

KHz to 150 MHz. The signal from the front panel N connector is fed via a length

of 50 ohm coaxial cable into the input of the driver amplifier module. The signal

from the input of the driver is coupled to the input of the MMIC front end. The

output signal of the MMIC is coupled to the gate of transistor Q1. The further

amplified signal appearing at the drain of Q1 is coupled to the input of Q2. This is

transformed to 50 and fed to the driver output port.

The driver output signal is fed through a length of coaxial cable to a two way

splitter and then to a four way hybrid splitter, to the individual power amplifier

modules. The output of each amplifier is then combined in a four way hybrid

combiner and the two modules are then combined in a two way.

The power amplifier output signal is then fed into a length of 50 ohm coaxial

cable to the RF bi-directional coupler. The output of the coupler is then fed

directly to the N connector on the front panel, this is the unit output.

The forward and reverse coupled ports of the bi-directional coupler are fed to the

RF detector which is situated on the main control board. The RF detector feeds a

voltage, which is representative of the true RMS power to the control board

proper. The control board in turn drives the front panel display.

The main power supply unit provides a 24 VDC 24 ampere source. It is a switch

mode power supply unit. The output feeds the PA and driver. The main power

supply also has a 5 VDC output which feeds the control board.

Block Diagram See Appendix A

The material contained in this document is the property of Electronics & Innovation Ltd., it is

subject to change without notice.

December 2015 8 Revision F

Chapter 4 Maintenance

4.1 INTRODUCTION

The E&I 350L RF amplifier requires no periodic maintenance. The instrument is

unconditionally stable and is fail-safe under all load conditions. Damage can only

be externally caused by the incorrect selection of the AC supply voltage or by an

input signal in excess of the specified 1 volt rms equivalent to a power level of

13dBm.

This chapter therefore, deals only with certain fundamental procedures for fault

location.

Performance limits quoted are for guidance only and should not be taken for

guaranteed performance specifications unless they are also quoted in the

Specification Section 1.2.

4.2 PERFORMANCE CHECKS

To determine the amplifier’s performance carry out the following procedure.

4.2.1 Initial Check

The following check can be made after repair and adjustments or

whenever the condition of the unit is in question.

a. Connect AC power supply. Switch on power and observe that the

display initializes.

b. Connect a sweep generator (HP 8601 or similar) capable of sweeping

the frequency range 250 KHz to 150 MHz, to the input connector.

c. Adjust the output level of the sweep generator so that a 50 ohm video

detector connected at the output of the unit will not be damaged by

excessive power output. (Reference section 4.4.1 for set up.)

d. Observe the gain versus frequency ripple on an oscilloscope calibrated

in decibels. The gain variation must be not more than +/- 1.5 dB over

the frequency range.

e. Connect a calorimetric power meter (HP434 or equivalent) through a

10 dB 200 watt attenuator to the output connector. Adjust the input CW

signal to any frequency between 250 kHz and 150 MHz for 40 watts

The material contained in this document is the property of Electronics & Innovation Ltd., it is

subject to change without notice.

December 2015 9 Revision F

output.

f. Observe the harmonic distortion of the output on a spectrum analyzer.

The harmonic components contributed by the amplifier should be

better than 20 dB down from the fundamental.

(a) If the above items are found to be outside of the specification, check

the spectral content of the input signal. If this is a pure signal then

the unit needs to be returned to the factory for service.

4.3.1 Measurement of Gain

1. Equipment Required (or equivalent):

a) Osilloscope - Tektronix T921

b) Sweep/Generator - HP8601A

c) Signal Generator - Exact Model 7060

d) 50 ohm Detector - Wavetek D151

e) Attenuator, 30 dB, 200 Watts Bird

Figure 4-1. Gain Measurement

30 dB Attenuator

RF

Detector

Sweep Generator

RF Output

Sweep

Signal

Trigger

250 KHz –150 MHz

Input

The material contained in this document is the property of Electronics & Innovation Ltd., it is

subject to change without notice.

December 2015 10 Revision F

2. Connect the equipment as shown in Figure 4-1, then proceed as follows:

a) Set the oscilloscope to DC, Time/cm to Ext. X, and gain to

l0mv/cm.

b) Set the sweep generator to the video sweep mode with the start

frequency at 250 kHz and the sweep width to 150 MHz.

c) Disconnect the 350L from the set-up and connect the

sweep/generator RF output directly to the 30 dB attenuator.

d) Adjust the output level of the sweep/generator for full vertical

deflection on the oscilloscope face.

e) Calibrate the scope face to show 3 dB in 1 dB steps by

attenuating the sweep/generator in 1 dB.

f) Return sweep/generator output level to full deflection. Rotate the

step attenuator (CCW) so that the output is reduced by 50 dB.

g) Reconnect the 350L into the test set-up of Figure 4-1.

h) Place the 350L power switch to the "ON" position.

i) Observe the gain versus frequency sweep on the oscilloscope.

The average gain should be greater 50 dB

The gain variation should be within the 3 dB as shown on the

oscilloscope.

4.4.2 Measurement of Harmonics

Figure 4-2.

1.) Equipment Required:

a) Sweep/Signal Generator

30 dB Attenuator

Sweep Generator

RF Output

250 KHz –150 MHz

Spectrum

Analyzer

Power

Meter

30 dB

coupler

The material contained in this document is the property of Electronics & Innovation Ltd., it is

subject to change without notice.

December 2015 11 Revision F

b) Calorimetric Power Meter HP434A

c) Spectrum Analyzer.

d) Attenuator (20dB)

e) Attenuator (30dB)

f) Coupler (30 dB)

2.) Connect the Equipment as shown in Figure 4-2, then

proceed as follows:

a) Adjust the signal generator to a CW center frequency of 250 kHz, for an

indicated output of 40 watts on the power meter.

b) Using the spectrum analyzer, check that the level of the carrier

harmonics is less than -20 dB with respect to the carrier while manually

scanning the frequency band of 250 KHz to 150 MHz. An indicated

power output of 50W should be maintained during this operation.

4.5 PACKAGING FOR RESHIPMENT

In the event of the equipment being returned for servicing it should be packed in

the original shipping carton and packing material. If this is not available, wrap the

instrument in heavy paper or plastic and place in a rigid outer box of wood,

fiberboard or very strong corrugated cardboard. Use ample soft packing to

prevent movement. Provide additional support for projecting parts to relieve

these of unnecessary shock. Close the carton securely and seal with durable

tape. Mark the shipping container FRAGILE to ensure careful handling.

Chapter 5 Safety:

Do not attempt to operate this unit with the cover removed. High AC and DC

voltages are present. The cover prevents against electrical shock due to AC line

voltages, high DC and RF fields. Further the cover provides part of the cooling

system design. Components, specifically on the RF driver board are prone to

over-heat and eventual failure if the unit is operated without the cover in place.

Ensure that the load is connected to the output prior to connecting the RF input

to the unit. This will prevent high voltages being present and exposed at the

output connector.

Only use the AC cord provided or equivalent.

Ensure that the mains outlet is properly grounded.

The material contained in this document is the property of Electronics & Innovation Ltd., it is

subject to change without notice.

December 2015 12 Revision F

Appendix A:

Page 1

350L Rev 1 Block Diagram

4 X Splitter

Gating

Board

Option

403

LA

TTL

Input

24

Volt

To Page 3

a

RF

IN

To Page

2

B - I

The material contained in this document is the property of Electronics & Innovation Ltd., it is

subject to change without notice.

December 2015 13 Revision F

Coupler

RF OUT

To Page 3 j

RF Detect

Page 2

350L Rev 1 Block Diagram

From Page

1

B - I

35

325

325

325

4 X Combiner

The material contained in this document is the property of Electronics & Innovation Ltd., it is

subject to change without notice.

December 2015 14 Revision F

AC

IN

Controller

To page 2 j

TTL

Control

Front Panel LCD

To Rear

Panel

RS232

SMPS 24 Volt

To page 1 a

Fans

Page 3

350L Rev 1 Block

Diagram

Line

Filter

10 Amp

Other E&I Amplifier manuals