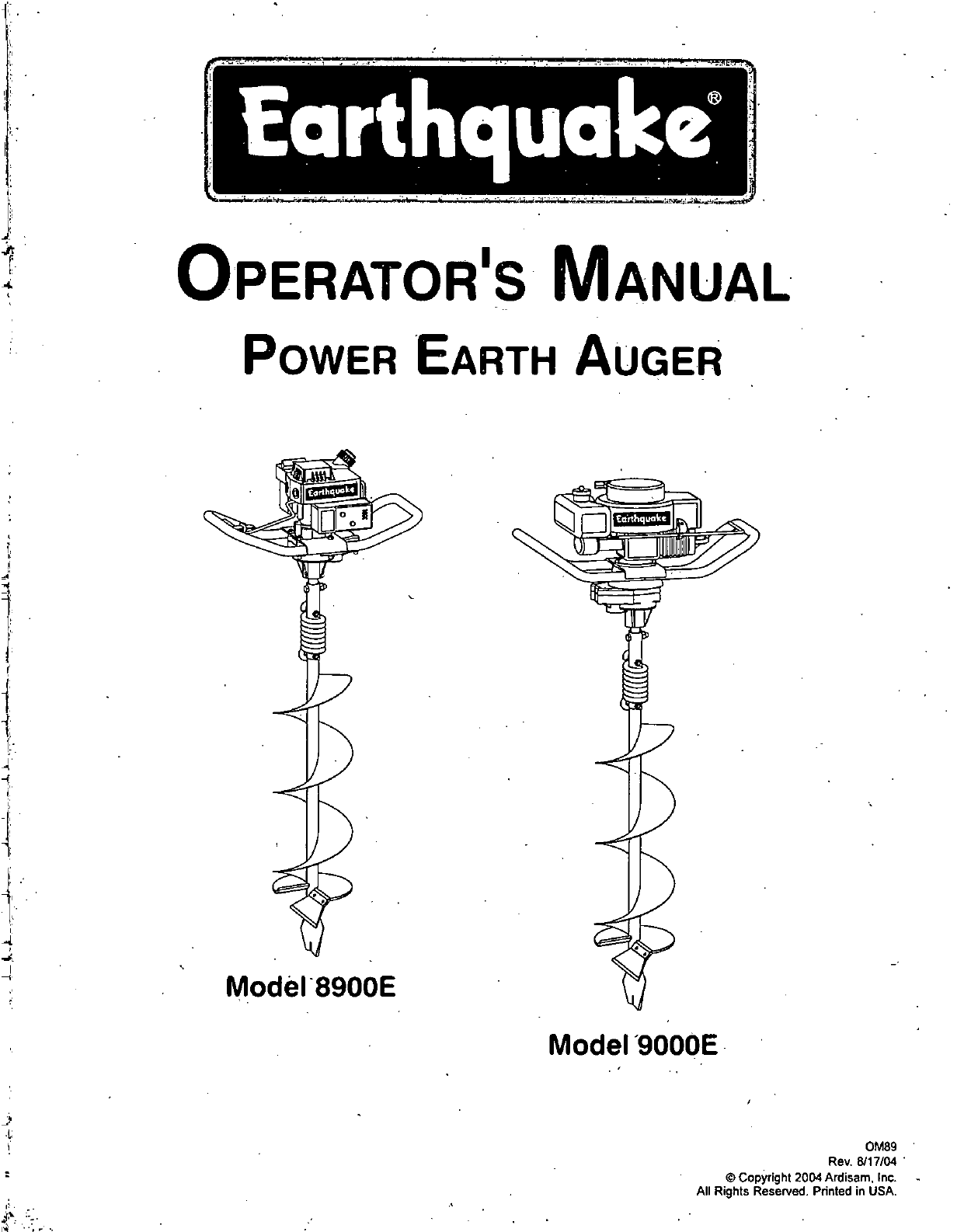

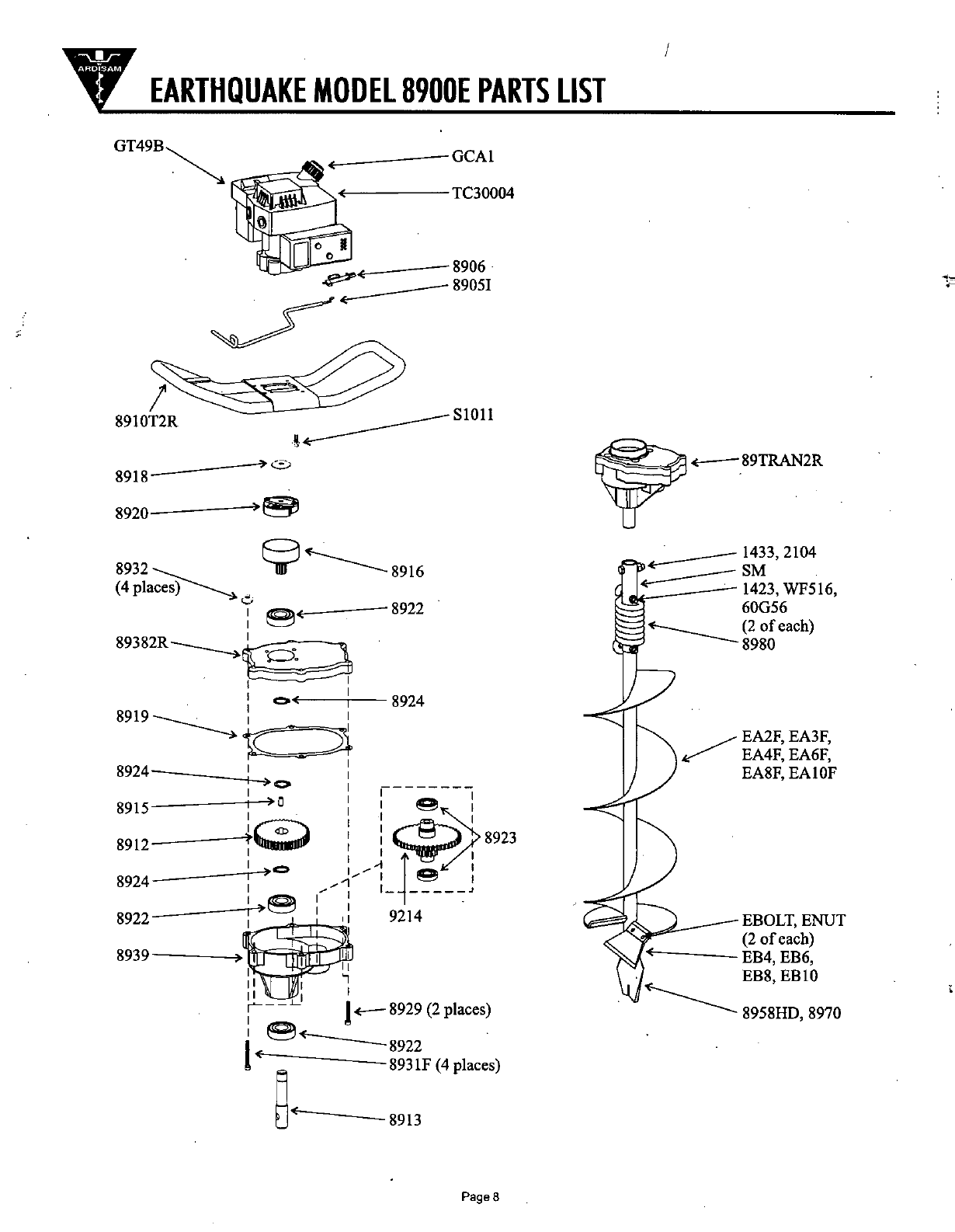

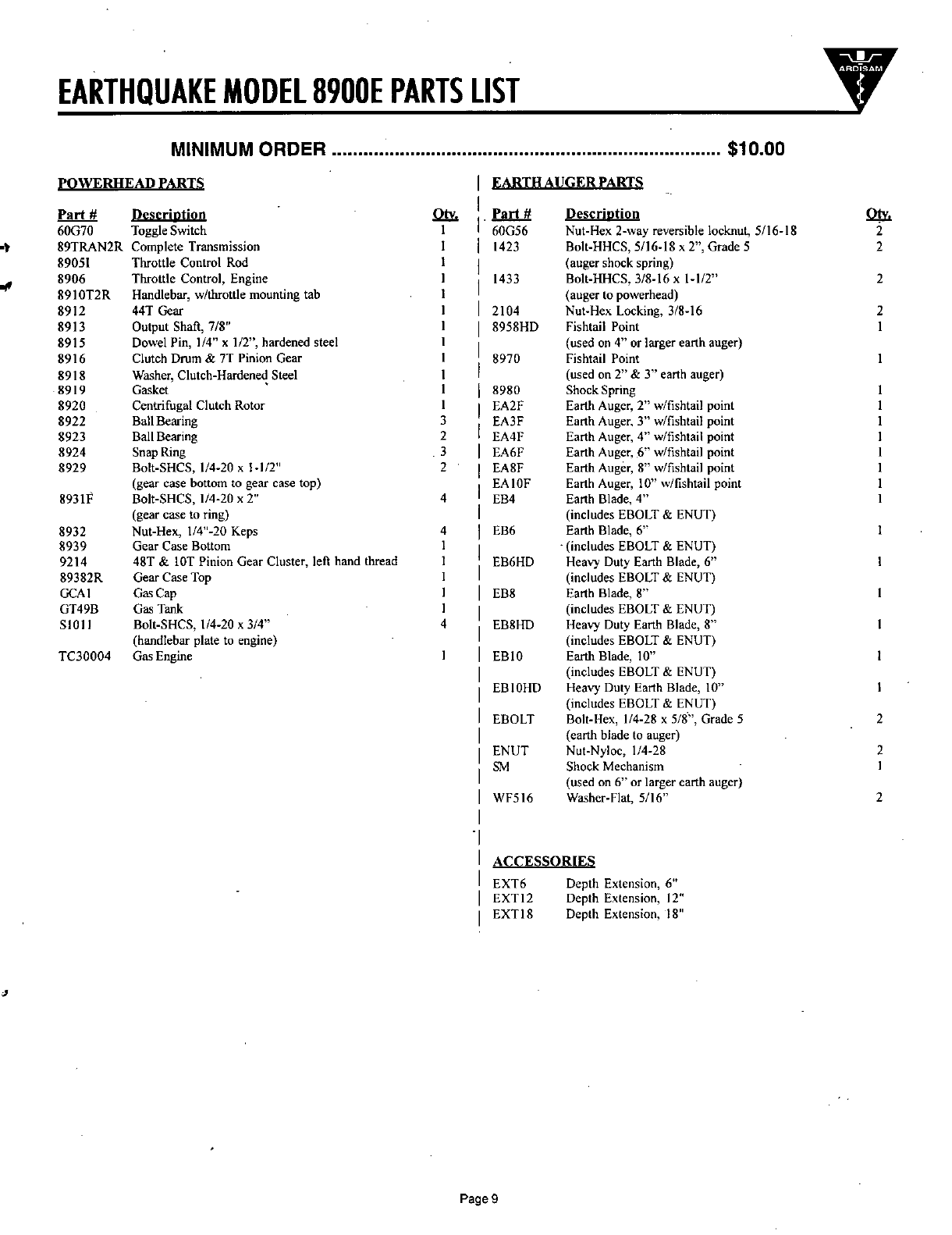

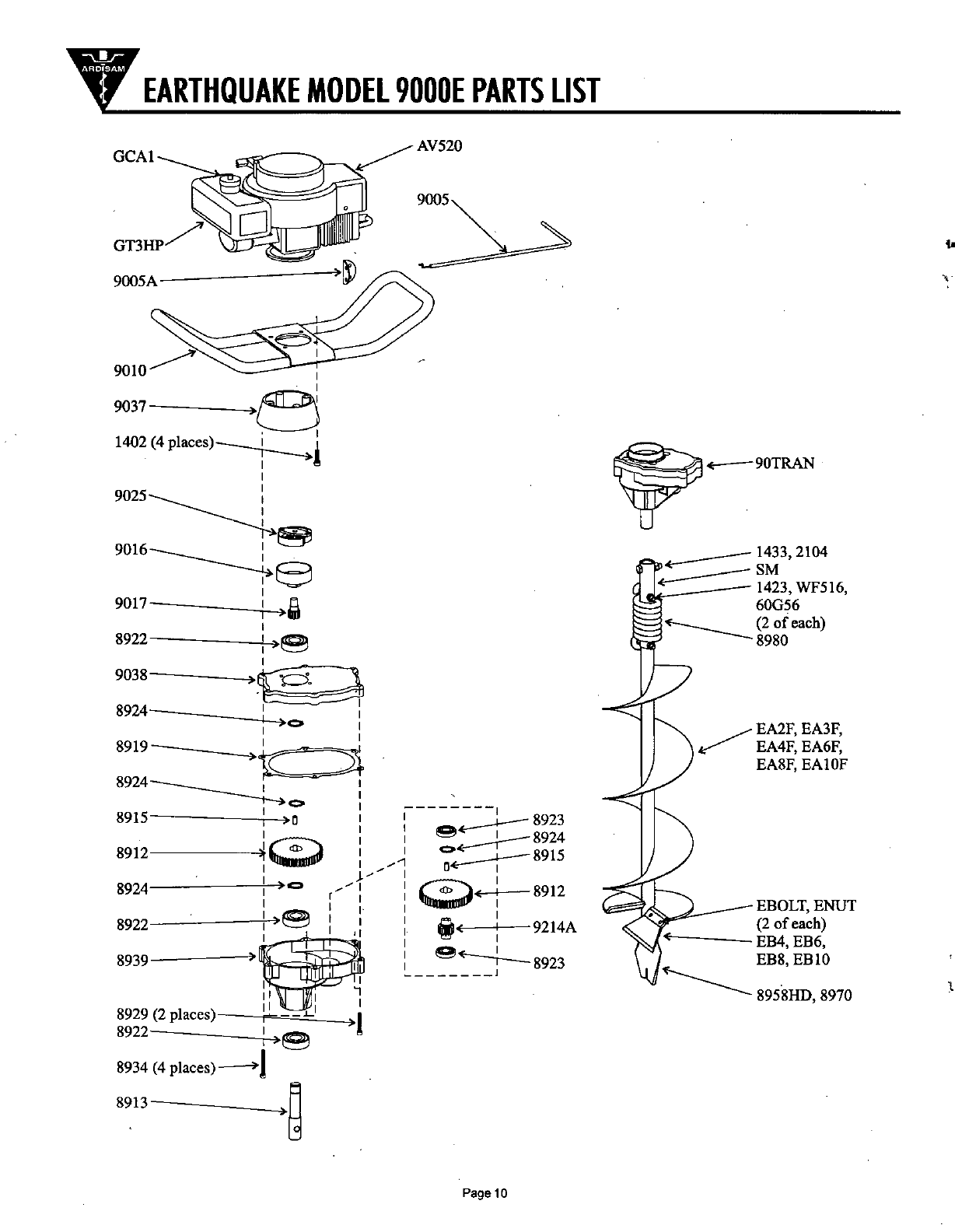

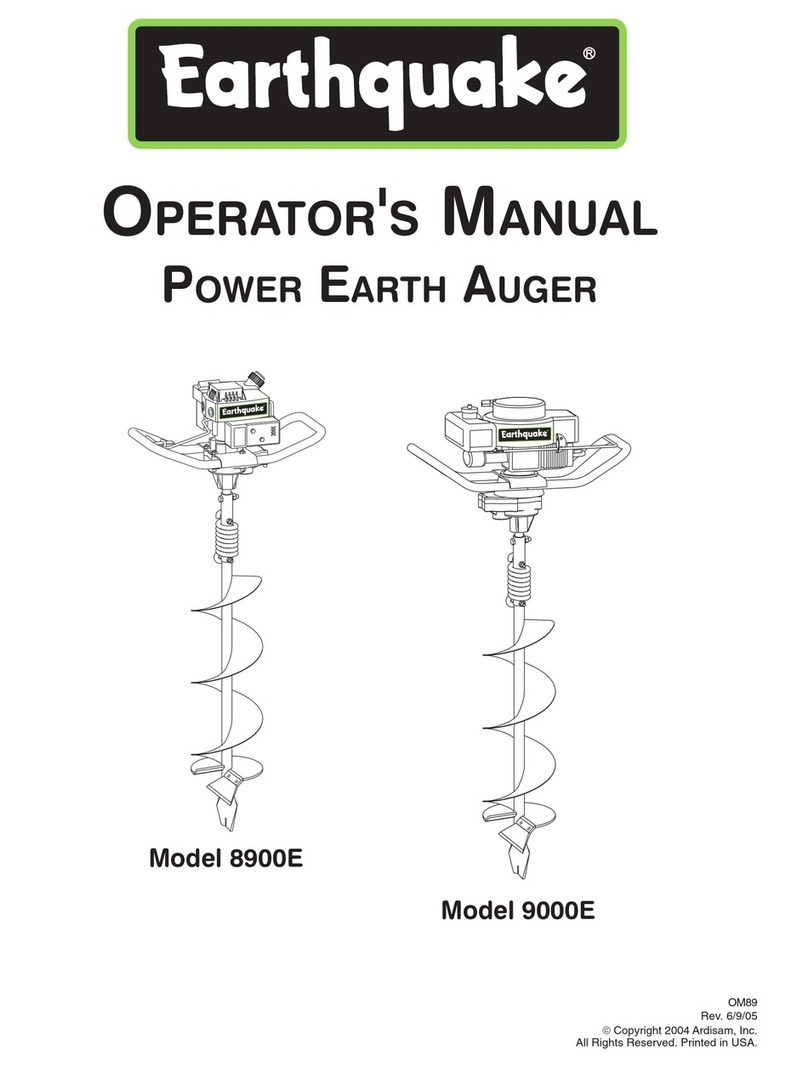

EarthQuake 8900E User manual

Other EarthQuake Lawn And Garden Equipment manuals

EarthQuake

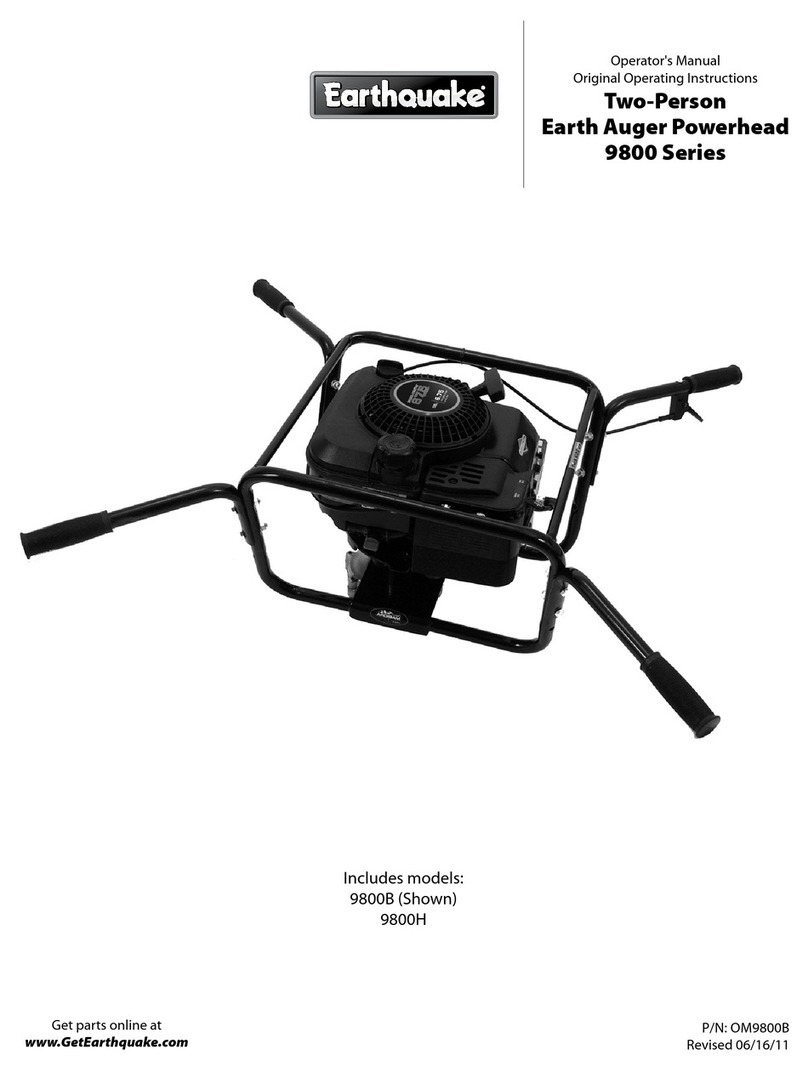

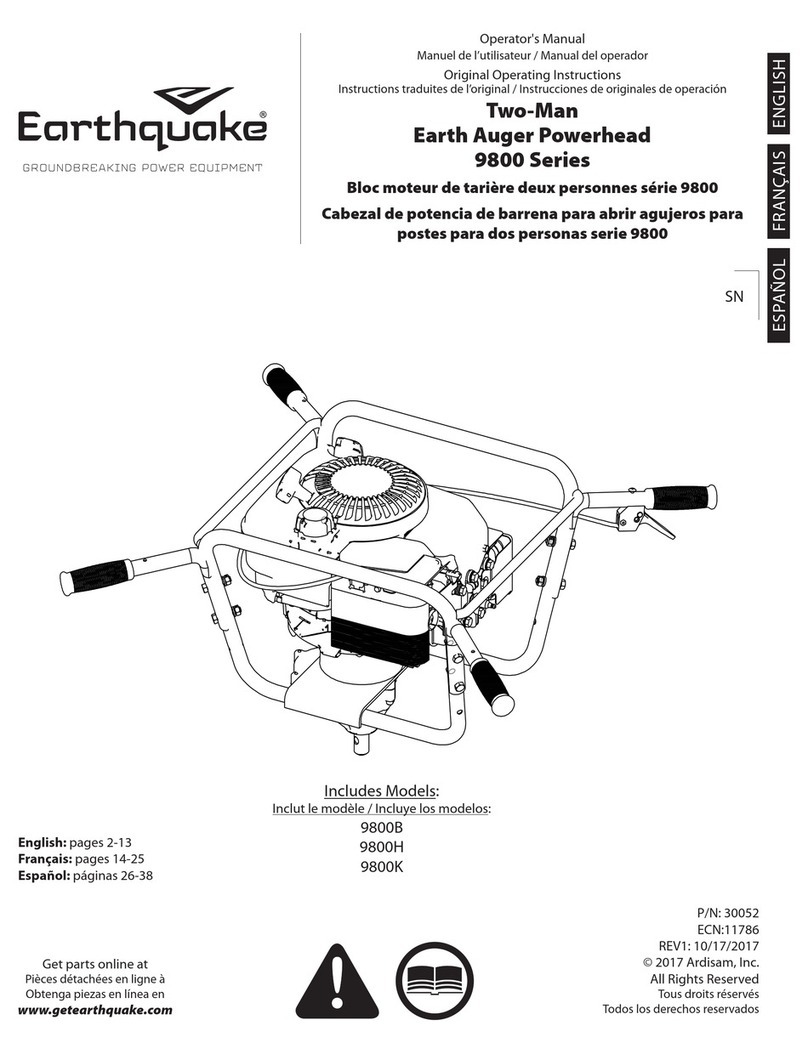

EarthQuake 9800KC User manual

EarthQuake

EarthQuake 9800 Series User manual

EarthQuake

EarthQuake Earthquake 8900 User manual

EarthQuake

EarthQuake 9800B User manual

EarthQuake

EarthQuake 9800B User manual

EarthQuake

EarthQuake 9800 Series User manual

EarthQuake

EarthQuake 9800H User manual

EarthQuake

EarthQuake E43 earth auger powerhead User manual

EarthQuake

EarthQuake 5040 User manual

EarthQuake

EarthQuake 9800 Series User manual

EarthQuake

EarthQuake E43 earth auger powerhead User manual

EarthQuake

EarthQuake 8900E User manual

EarthQuake

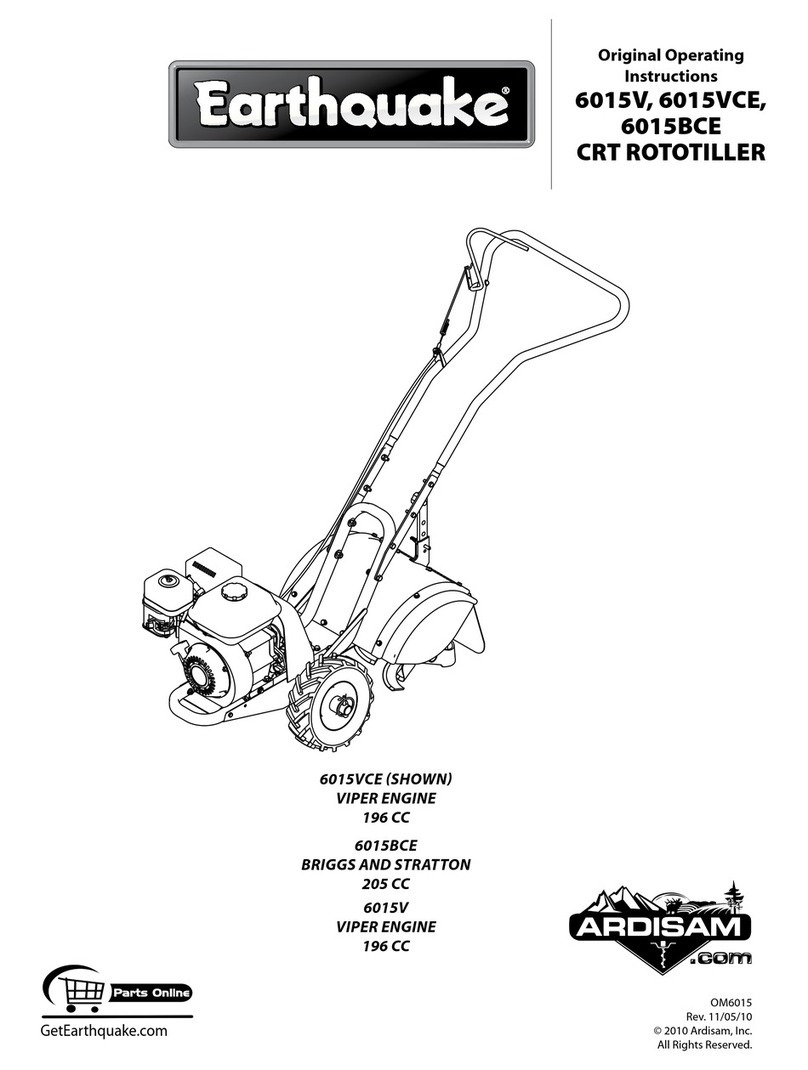

EarthQuake 6015V User manual

EarthQuake

EarthQuake Dually 10310 User manual

EarthQuake

EarthQuake 9800 Series User manual

EarthQuake

EarthQuake 9800 Series User manual

EarthQuake

EarthQuake MC25 User manual

EarthQuake

EarthQuake 23275 User manual

Popular Lawn And Garden Equipment manuals by other brands

Sunforce

Sunforce SOLAR user manual

GARDEN OF EDEN

GARDEN OF EDEN 55627 user manual

Goizper Group

Goizper Group MATABI POLMINOR instruction manual

Rain Bird

Rain Bird 11000 Series Operation & maintenance manual

Cub Cadet

Cub Cadet BB 230 brochure

EXTOL PREMIUM

EXTOL PREMIUM 8891590 Translation of the original user manual

Vertex

Vertex 1/3 HP Maintenance instructions

GHE

GHE AeroFlo 80 manual

Land Pride

Land Pride Post Hole Diggers HD25 Operator's manual

Yazoo/Kees

Yazoo/Kees Z9 Commercial Collection System Z9A Operator's & parts manual

Premier designs

Premier designs WindGarden 26829 Assembly instructions

Snapper

Snapper 1691351 installation instructions