EARTHSTONE OVENS PRE-ASSEMBLED INSTALLATION INSTRUCTIONS--- ETL LISTED

4

A. INSTALLATION PROCEDURES

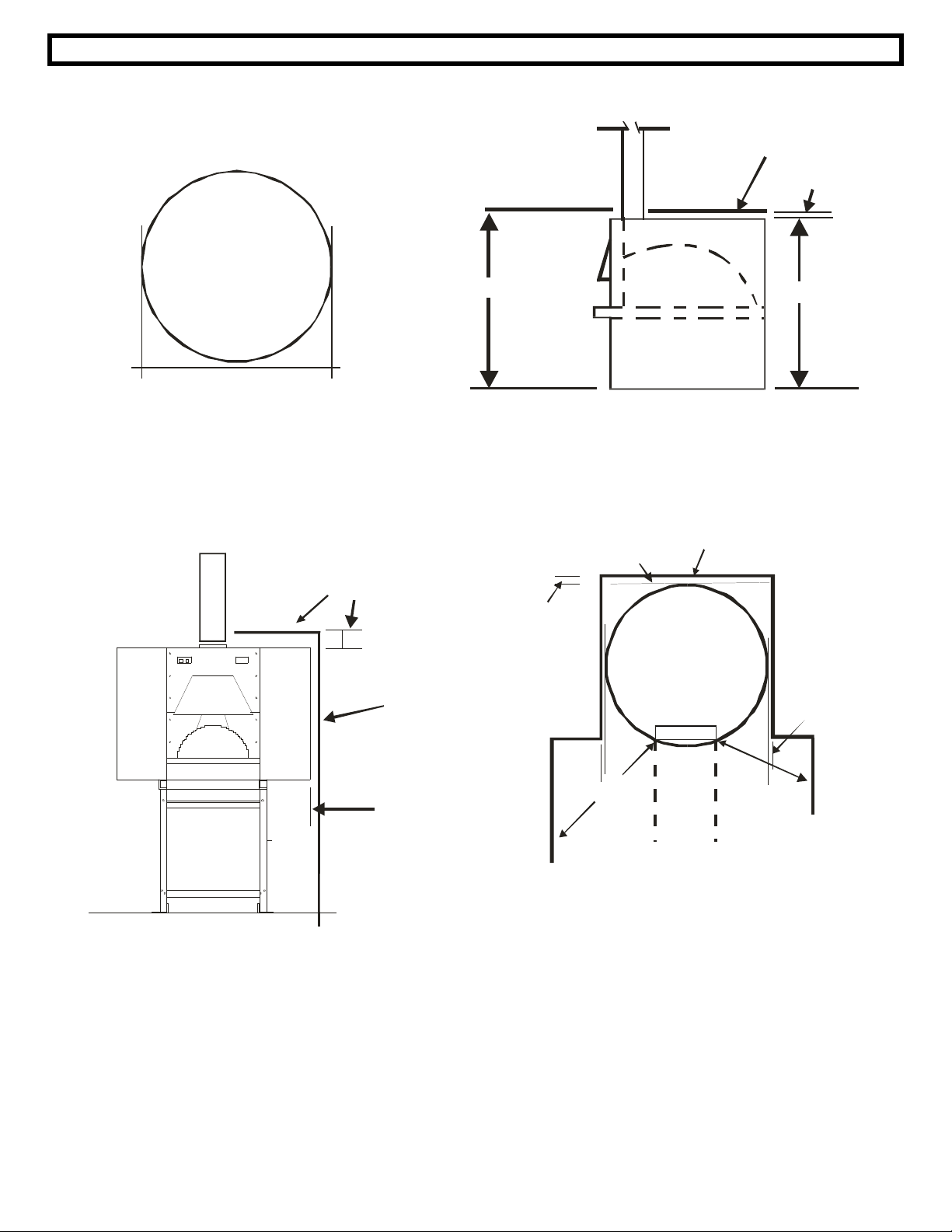

1. Mark an outline on the floor of the location desired. This is to assure that you have adequate

space. Refer to Fig. 1, pg. 6.

2. Check that there is adequate clearance at the ceiling for the hood. There must be a minimum of 3

inches of clearance between the top of the oven and the surface of the drywall above. (Refer to

Fig. 2 & 3 pg. 6)

3. It is recommended to use non combustible framing. If combustibles are near oven check that

there is a minimum clearance of 1 inch to any adjacent sidewall construction containing

combustibles. Any adjacent combustible sidewalls which projects beyond the front of the oven

opening must be a minimum of 48 inches, measured from the side of the oven opening closest

to the wall to the surface of the wall. (Refer to Fig. 4, pg. 6). If the distance is less than 48 inches

a wall shield must be mounted on the wall. Refer to the U.L. listed wall shield installation

instructions for the allowable clearance reduction.

Any adjacent combustible floor which projects in front of the oven opening must be a minimum

of 30 inches away from each side of the door opening and 36 inch from the front of the door

opening.

WARNING: DO NOT PACK REQUIRED AIR SPACES WITH INSULATION OR OTHER

MATERIALS

A minimum of 3 inches must be maintained between any combustibles and the top of the

metal covering over the oven enclosure. Refer to Fig 2 & 3 pg. 6.

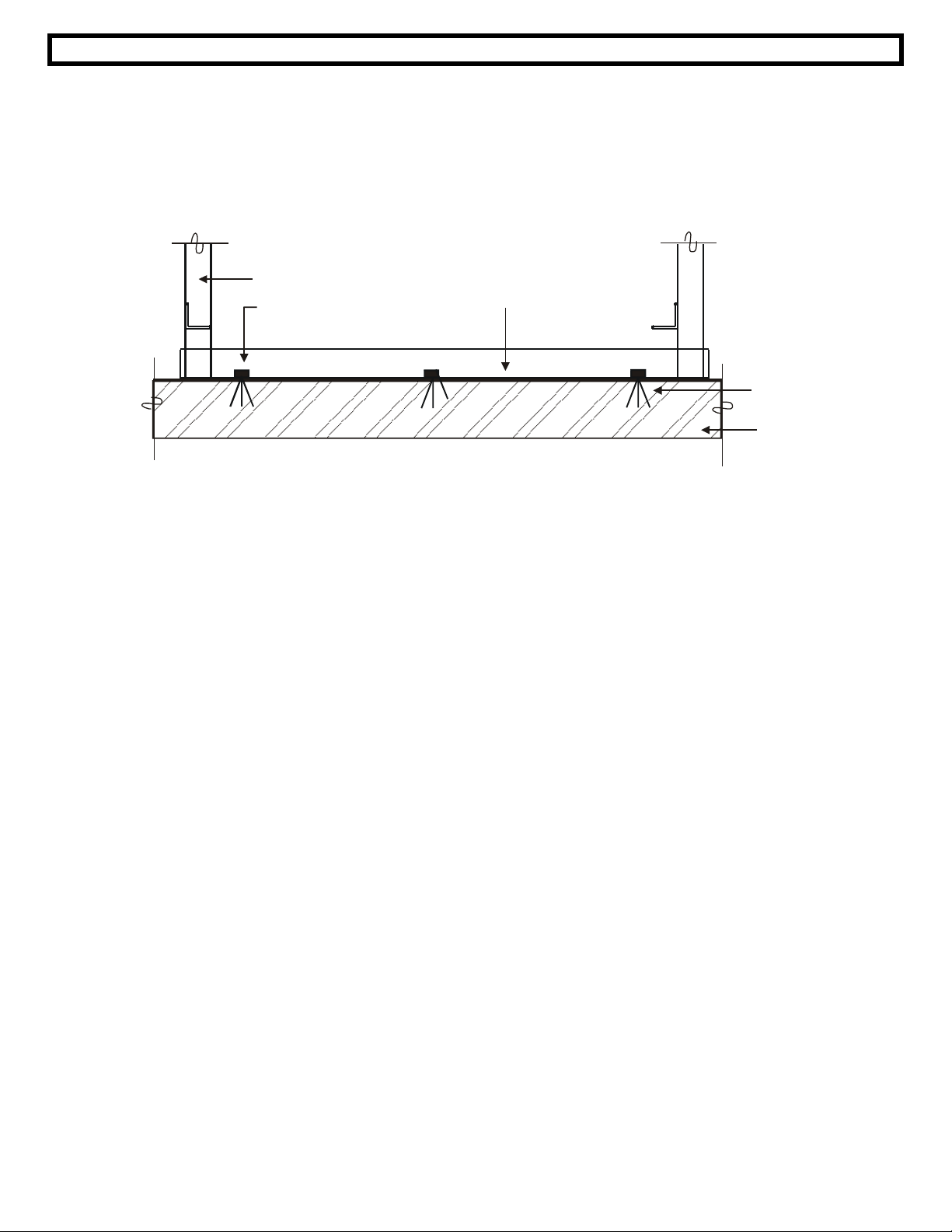

4. Once the oven is in the desired position, drill holes for the anchor bolts (Min 3 inches deep) using

the base plates as a guide. Insert ramset red heads to fasten oven base plates to concrete floor.

(Fig 17-A pg. 7)

5. The outside surface of the oven enclosure may be faced with non-combustible facing

material if desired. This might include but not limited to: Brick, Ceramic tiles, Stainless

steel, Marble or any other decorative metals. DO NOT FACE WITH COMBUSTIBLE

MATERIALS OR USE COMBUSTIBLE ADHESIVES. Allow for access to top of the

oven for servicing.

NOTE: FOR HEALTH DEPARTMENT REQUIREMENTS ANY 1-INCH AIR GAP

ADJACENT TO A COMBUSTIBLE WALL MUST BE SEALED WITH A NON

COMBUSTIBLE STRIP. i.e. ALUMINUM, STAINLESS STEEL OF TILE.

B. VENTING APPLICATION

A U.L. LISTED GREASE DUCT/BUILDING HEATING APPLIANCE CHIMNEY INSTALLATION (DIRECT

VENTING). PLEASE CONFIRM WITH THE LOCAL BUILDING DEPT. BEFORE BEGINNING

INSTALLATION OF THE OVEN. IT IS NEVER APPROPRIATE TO USE “CLASS A” OR “B VENT” IN ANY

PART OF THE EXHAUST SYSTEM. EXHAUST SYSTEMS SERVING SOLID-FUEL EQUIPMENT MAY

NOT BE COMBINED WITH EXHAUST SYSTEMS SERVING OTHER (NON-SOLID FUEL) COOKING

EQUIPMENT

Important: Chases should be made of non-combustible materials.