Contents:

Safety ............................................................................................................................. 7

Explanation of Symbols ................................................................................................ 8

Introduction ................................................................................................................... 9

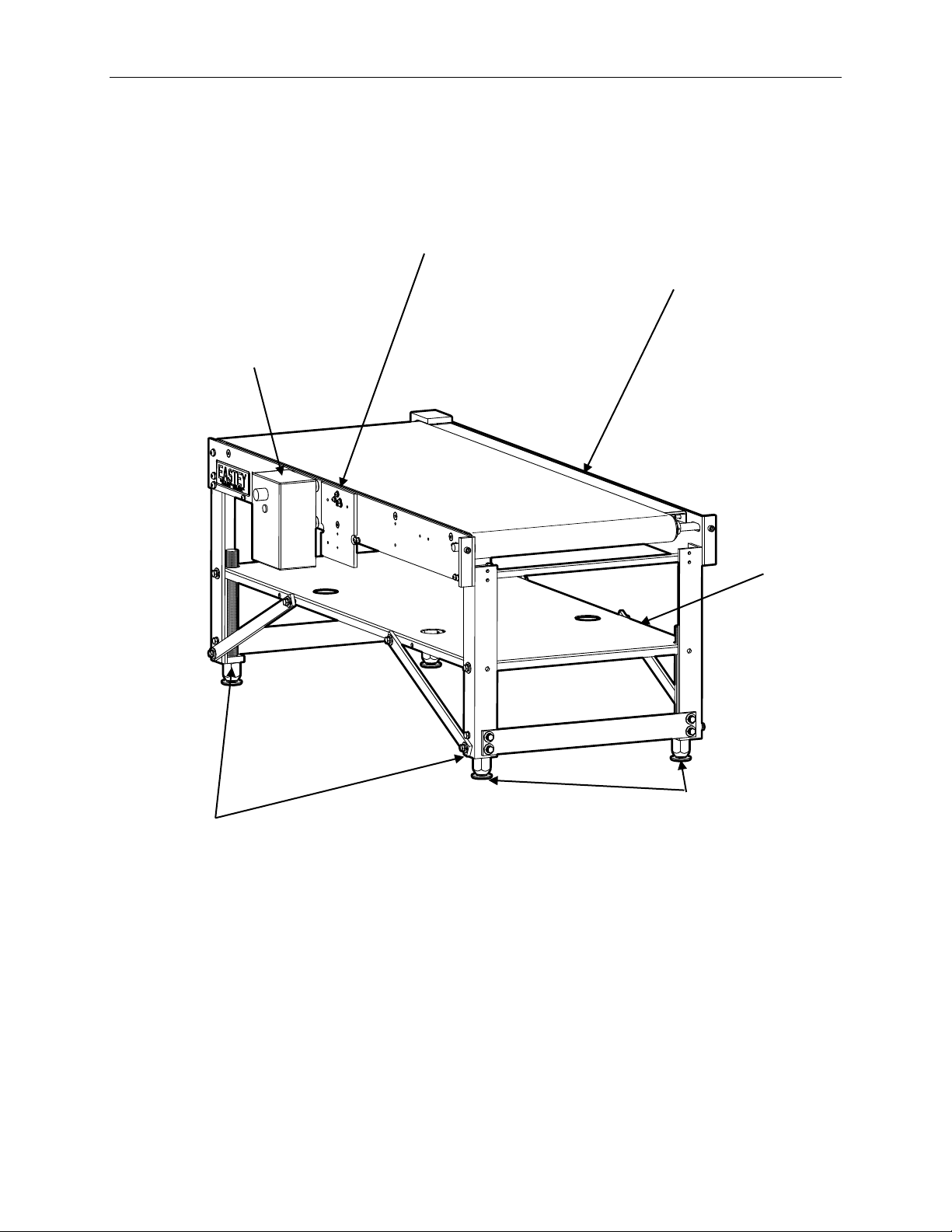

Eastey EC Series Variable Speed Conveyor Overview................................................ 9

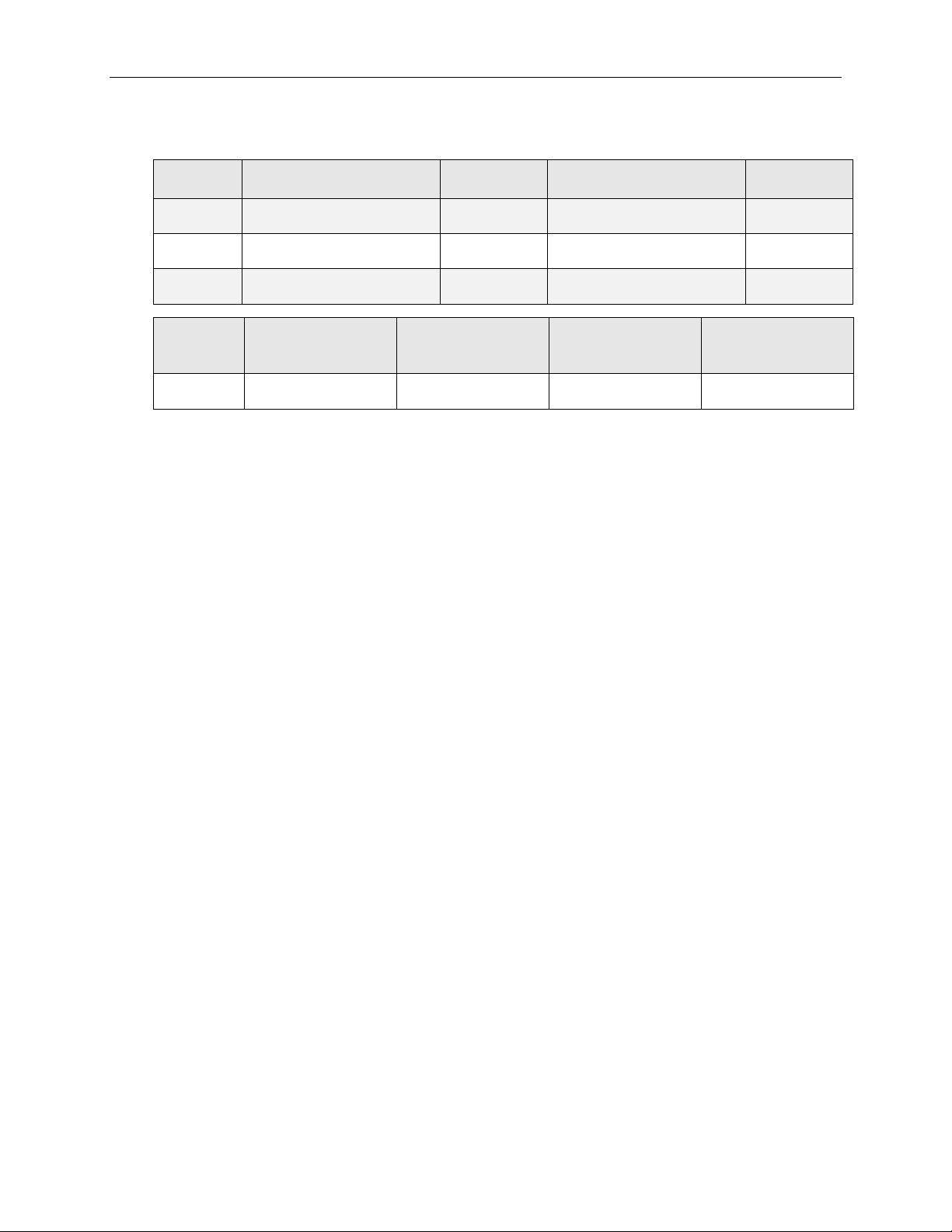

Specifications ............................................................................................................. 10

Dimensions................................................................................................................. 12

Installation ................................................................................................................... 13

Optional Casters......................................................................................................... 13

Move Conveyor into Operating Location .................................................................... 13

Height Adjustment and Leveling................................................................................. 13

Location Requirements............................................................................................... 16

Mounting the Ink Jet Printer........................................................................................ 17

Guide Rail Assembly and Installation (C0000501 or C0000511)................................ 18

Operation ..................................................................................................................... 19

Power ......................................................................................................................... 19

Control Box................................................................................................................. 20

Adjustments ................................................................................................................ 21

Height Adjustment and Leveling................................................................................. 21

Conveyor Tension Adjustment .................................................................................... 23

Advanced Speed and Control Function Adjustment ................................................... 24

Maintenance ................................................................................................................ 27

Cleaning the Belt ........................................................................................................ 27

Changing the Belt ....................................................................................................... 27

Troubleshooting.......................................................................................................... 29

Parts List...................................................................................................................... 32

Conveyor — EC1248, EC1848 & EC2472 ................................................................. 32

Option / Accessory Kits — EC1248, EC1848 & EC2472............................................ 34

Appendix A: Electrical Schematic ............................................................................. 35

Warranty Statement .................................................................................................... 36

Customer Support....................................................................................................... 38