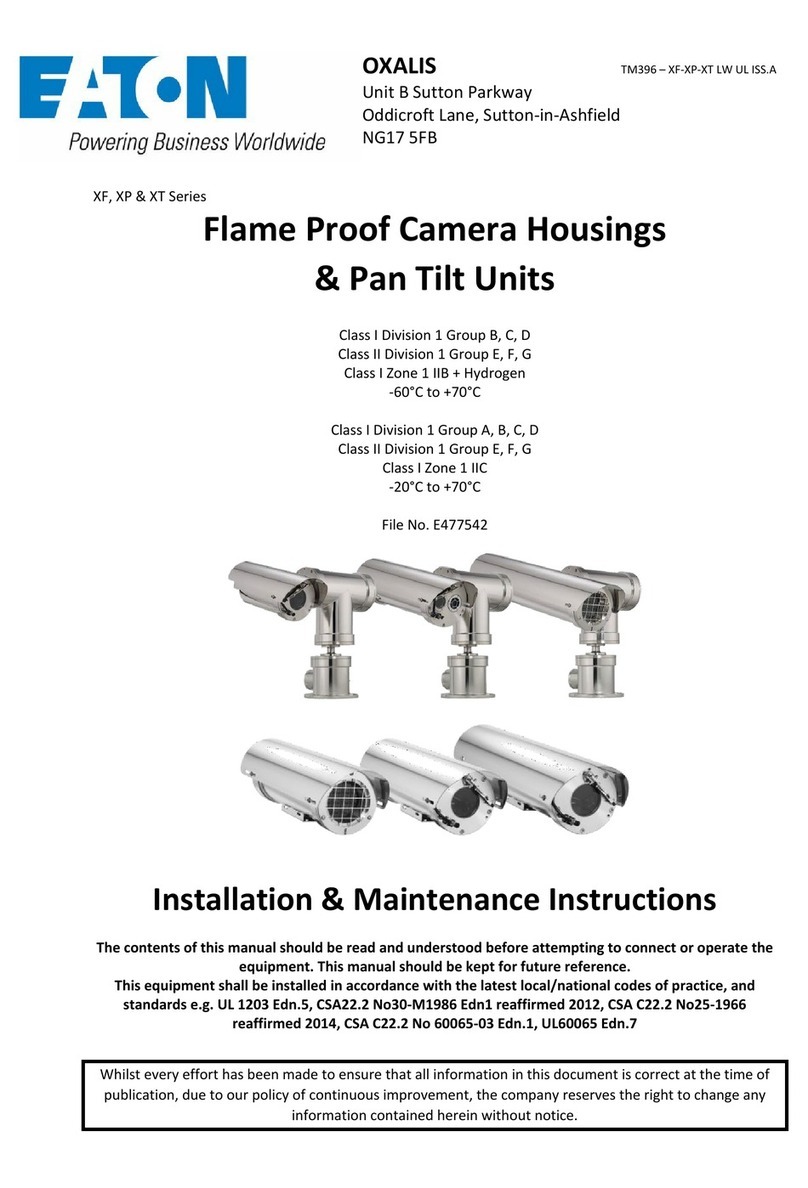

Installation & Maintenance Instructions

1.0 General

1.1 Important Safeguards and Warnings, refer also to Section 7.0 & Annex A

This symbol indicates that there are important operating and maintenance instructions

in the literature accompanying this unit.

Prior to installation and use of this product, observe the following warnings.

1. Installation and servicing should only be carried out by qualified service personnel

and in accordance with all local/national codes of practice and standards e.g.

EN60079-14 2014 and IEC 60079-14:2013 no modification to the certified

product allowed.

2. It is essential that provision is made for overload, short circuit and earth fault

protection for this equipment. Therefore, we recommend that a double pole,

mains rated, miniature circuit breaker rated to the max power consumption of

the unit, must be incorporated in the electrical installation of the power supply

to this product.

3. A readily accessible disconnection device shall be incorporated in the electrical

installation wiring, to provide all pole isolation of the supply to the equipment.

4. Only use tools and replacement parts supplied or recommended by EATON. This

unit does not contain any user serviceable parts.

5. Care must be taken to ensure selection of suitable cables connecting to these

units. (See Special Conditions for safe Use in the Certified Annex for cable

selection.)

6. The equipment is designed to satisfy the requirements of Clause 1.2.7 of the

Essential Health and Safety Requirements ANNEX II of ATEX Directive

2014/34/EU.

7. Be aware that aggressive substances may require extra protection of the

equipment to maintain its integrity and explosion protection.

8. The equipment may need additional means of protection if it is to be installed in

locations where it may be exposed to excessive external stresses e.g.

vibration, heat, impact and damage.

9. Any repairs or replacement parts must be done by the manufacturer or an

approved repair agent.

10. Due to the weight of the units, correct planning and equipment must be used

when unpacking and installing. When handling the XP and XT units, the correct

lifting points must be adhered to (see section 3.1.2 for safe lifting points.)

11. For systems fitted with integral Fiber Optic transmitters, the label coding

includes the lettering “op pr” after Ex d, denoting that the enclosure employs

the type of protection

for protected optical radiation, type of protection “op pr” according to clause

5.1 of EN60079-28:2015. Please refer to Special Conditions for Safe Use.

12. When batteries are fitted to electronic equipment they must be removed and

are not to be replaced.

WARNING: DO NOT OPEN WHEN ENERGISED

OR WHEN AN EXPLOSIVE ATMOSPHERE IS

PRESENT.

CLEAN WITH DAMP CLOTH.

This symbol indicates that dangerous voltage constituting a risk of electric shock may

be present within this unit.