ECB E10.14000.45 L-EUF User manual

Operation Manual

for the authorized specialist

Dual-fuel Burner

E 10... L-EUF

06/2006 102.885.8162

2

Inhalt

Overview Important Information Warranty Product Description .......................................... 3

Technische Daten ................................................................................................. 4

Dimensioned Drawings ......................................................................................... 5

Start-up Mode Oil Operating Mode General Safety Functions .............................. 6

Fuel-air Compound Control ................................................................................... 7

Hydraulic diagram L-E... / GL-E... Burner E 10 ..................................................... 8

Hydraulic Valves and Instruments Group .............................................................. 9

Start-up Burner Head Settings .......................................................................................... 10

Installation Mounting to Boiler Electrical Connection Presetting ........................................... 11

Boiler Lining ........................................................................................................ 12

Burner GL/L-EUF ................................................................................................ 12

Oil Connection Oil Pressure Control (Feed) ........................................................ 13

Nozzle rod linkage 32 - EH ................................................................................. 14

Start-up Return Nozzle Rod RDG 1250 ............................................................................ 17

Nozzle selection „Sonic“ ...................................................................................... 18

Checking Procedure ............................................................................................ 19

Adjusting Instructions Air Flow Rate Adjusting Procedure ..................................................................... 20

Elektronic Burner Control with Electronic Compound Controller ......................... 21

Flame Detecting System Type FLW 05 .............................................................. 22

Servomotor Type SAD 15.0 ................................................................................ 23

Electrical Actuator STM 40 .................................................................................. 24

Starting the BCS, Etamatic, VMS/FMS Electronic Compound Controller ........... 25

Adjusting Instructions Oil Pressure Switch Air Pressure Switch ........................................................... 26

Overview Flame monitor ..................................................................................................... 27

Flame monitor ..................................................................................................... 28

Fan Impeller ........................................................................................................ 32

Service Instructions Maintenance Burner ............................................................................................ 33

Exhaust Gas Test ................................................................................................ 35

Trouble Shooting Instructions ............................................................................. 36

Operating Trouble ............................................................................................... 38

System Diagram .................................................................................................. 39

Product description Brenner E10.12000/14000 L-EUF ....................................................................... 40

Overview

3

Overview

Important Information

Warranty

Product Description

Important information

The burners of type E 10... L-EUF have

been designed for the combustion of

heavy fuel oil. The burners should be

installed and taken into operation care-

fully by qualified personnel. The work

should be done in accordance with the

applicable regulations and guidelines.

Only a duly authorized specialist should

be entrusted with the installation of the

gas system.

Any repair work on monitors, limiters

and automatic furnace controllers and

on the other safety facilities are allowed

to be done on the single items only by

the manufacturers themselves or spe-

cialists authorized by them.

Original parts should only be exchan-

ged by a duly qualified specialist.

Standards and regulations

The following standards should be

observed in the interest of a safe, easy-

on-the-environment and energy-saving

operation of the burner:

EN267/

DIN4787

Oil Atomizing Bur-

ners

VDE 0116 Electrical Equipment

of Furnaces

According to DIN 4755 the user must be

instructed in the operation of the fur-

nace system.

For the installation of an oil furnace sys-

tem, care should be taken to observe

DIN 4755, TRbF (Technical Regulation

on Combustible Liquids) and the local

furnace construction regulations appli-

cable in the country.

Place of installation

The burner must not be operated in

rooms containing corrosive vapours

(e.g. spray, perchloroethylene, hydro-

carbon tetrachloride, solvent, etc.) and

tending to heavy dust formation and

only up to 60% relativ air humidity.

Adequate ventilation must be provided

at the place of installation of the furnace

system to ensure a reliable supply with

combustion air.

Maintenance

The furnace system should be serviced

at least once a year by an authorized

specialist. It is recommended to con-

clude a maintenance agreement to this

effect.

Warranty

Manufacturer will not accept any war-

ranty if the operating instructions have

not been duly observed in the start-up

and maintenance of the burner and

damages have been caused by impro-

per installation, incorrect adjustment,

unauthorized interference or operating

errors.

Product description

The burners of type E10...L-EUF have

been designed as oil-burner for the

combustion of heavy fuel oil according

to DIN 51603-1.

They are fitted with a free-flame burner

head as a system to ensure low-NOx

combustion.

The burners are equipped with combu-

stion air fan and air pressure switch with

test key, air box with actuator for the air

dampers, oil pressure-atomizer with

high-pressure oil pump, nozzle rod,

return nozzle, and oil hydraulic system

(with pressure switches, valves and

control shaft), pressure hoses, electrical

ignition system for the oil operating

mode.

The burners are designed for operation

with electronic compound control.

4

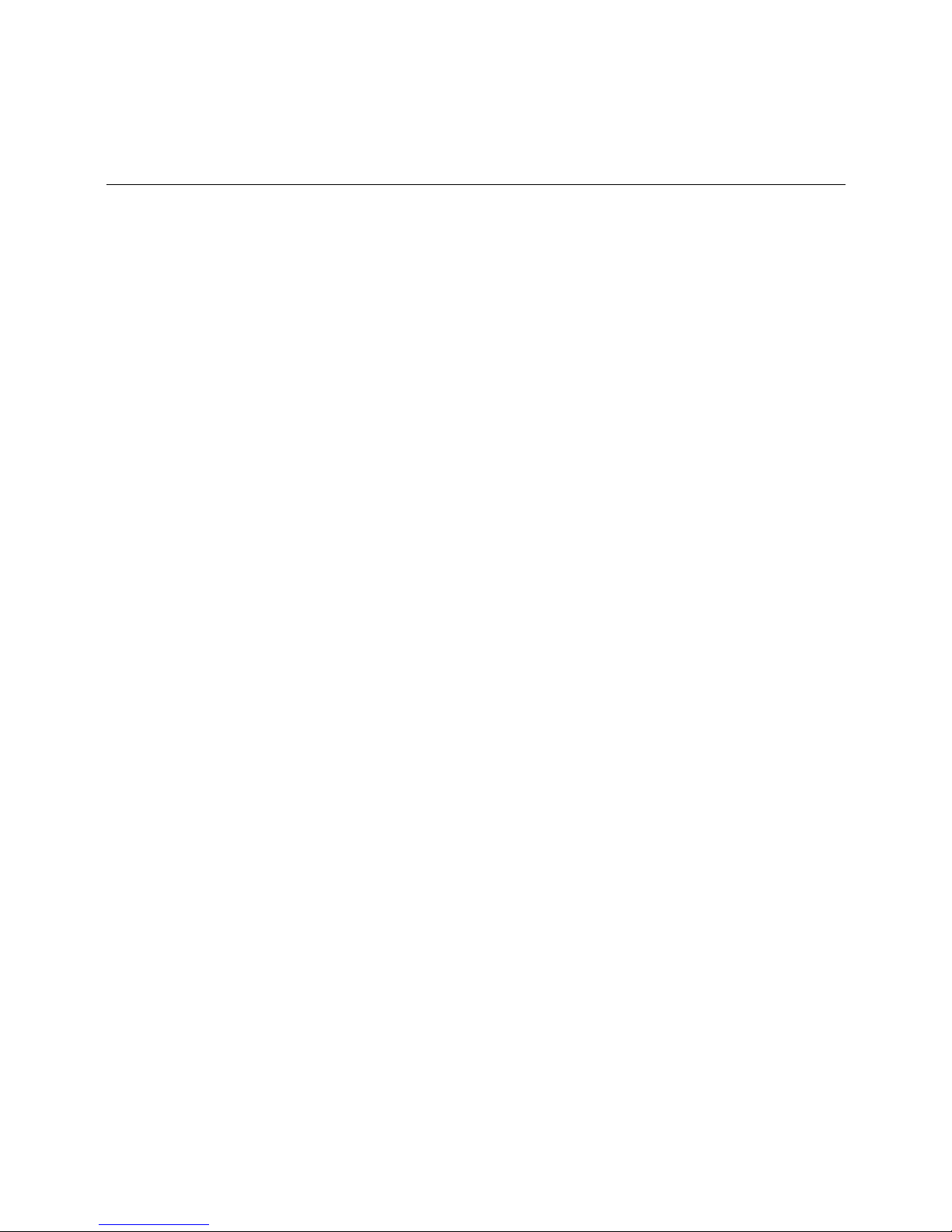

Technische Daten

Gas-Gebläsebrenner

E 10.12000/14000 G-EU2

LowNoxmitDeltaBrennkopf

Technical Data

Gas/light oil Forced Draught Burner

E10.12000/14000 L-EUF

Stand: 20.10.2005

Market Launch E10.14000 L-EUF Available not yet defined

Burner weight Approx . 650 kg plus 100 kg for transport rack

CE-Conformity No CE-Confirmity, Equipment for heat generator, Single audit necessary (see

manufacturer declaration), Homologation according European directives planned for

2006

Acoustic Emission - Sound Pressure < 97 dBA (average value on enveloping surface at 1 m distance)

Max. temperature of operating material max. 60°C (including impact from heat radiation)

Flame length max. at 3% O25,9 m 6,4 m

Flame Diameter

(depends on NOx requirements)

1,3 - 1,6 m 1,4 - 1,75 m

Protection Class IP40, IP54 as option

NOx-Emissionen Emission Class 3 according EN267

Oil operation: 120-200 mg/kWh (0% O2 acc. EN267)

Detailed values on request

Oil connection High pressure pump 30 bar mounted on burner

approx. 2700 l/h; 4,0 kW approx. 4000 l/h; 5,5 kW

Fan motor 400/690 V, 50/60 Hz, 2950/3550 U/min, IP55

37 kW 45 kW

Operation Type Continuously modulating

Electronic Air-Fuel-Compound-Control

Automatic Firing Device

Etamatik OEM or BCS 300 on burner

Alternative electronic burner controls in separate cabinet

Fuels Fuel Oil EL

Max. control ratio

(FQ=frequency converter for motor)

1:3,5 bei Fuel oil EL 1:3,5 for Fuel oil EL

Deviating values on request

Low NOx with Free-Flame Combustion Technology

Electronic Fuel-Air-Control

E10.12000.37 L-EUF E10.14000.45 L-EUF

Combustion Power Output Fuel Oil EL: 1500 - 12.000 kW Fuel Oil EL: 1750 - 14.000 kW

Boiler Furnace Pressure According line of operation field and 10 mbars less.

Deviating values on request.

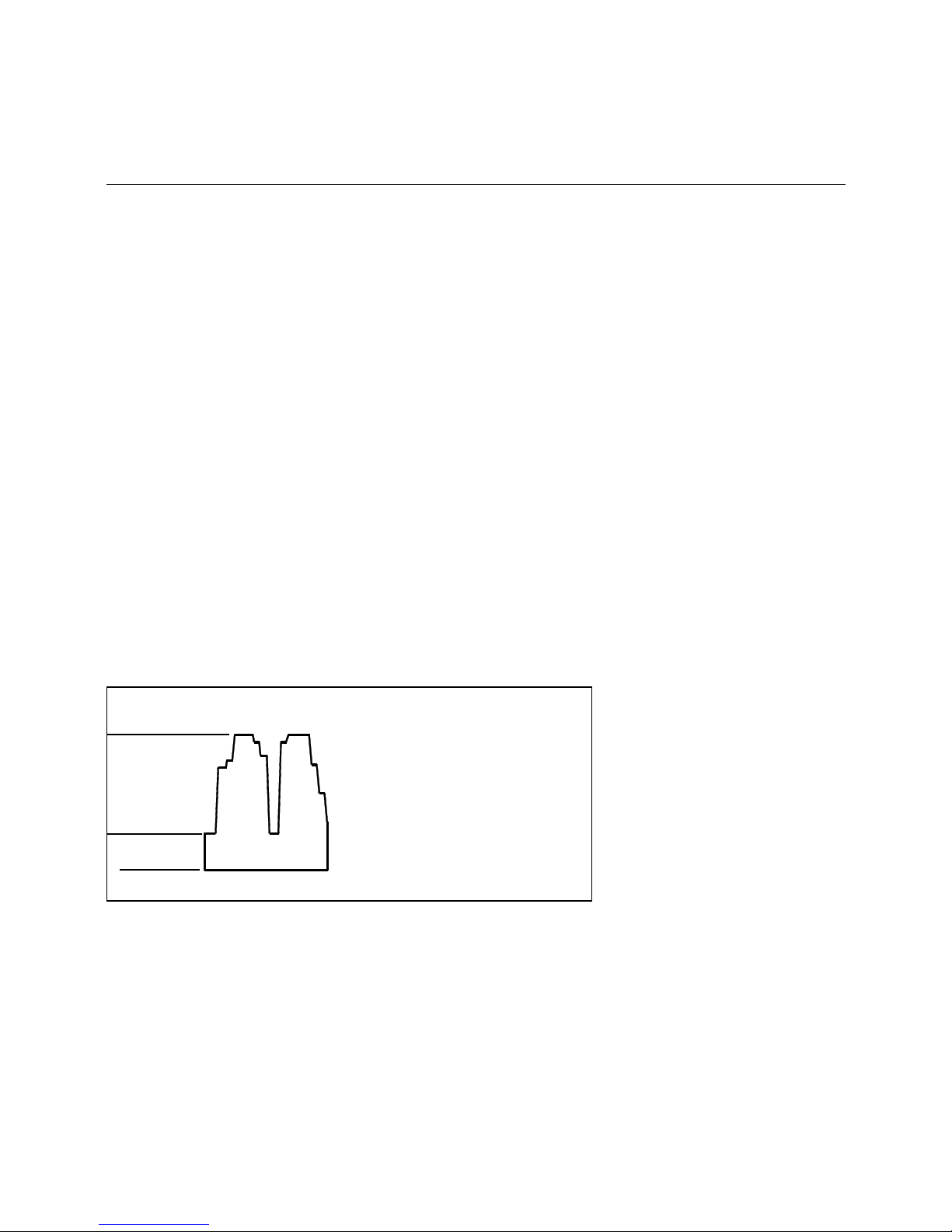

Operation Fields E10 L-EUF according EN 267

0

5

10

15

20

25

30

35

40

0123456789101112131415

Combustion Power Output [MW]

Boiler Furnace Pressure [mbar]

E10.14000.45 L-EUF E10.14000.45 L-EUF with FQ E10.12000.37 L-EUF

5

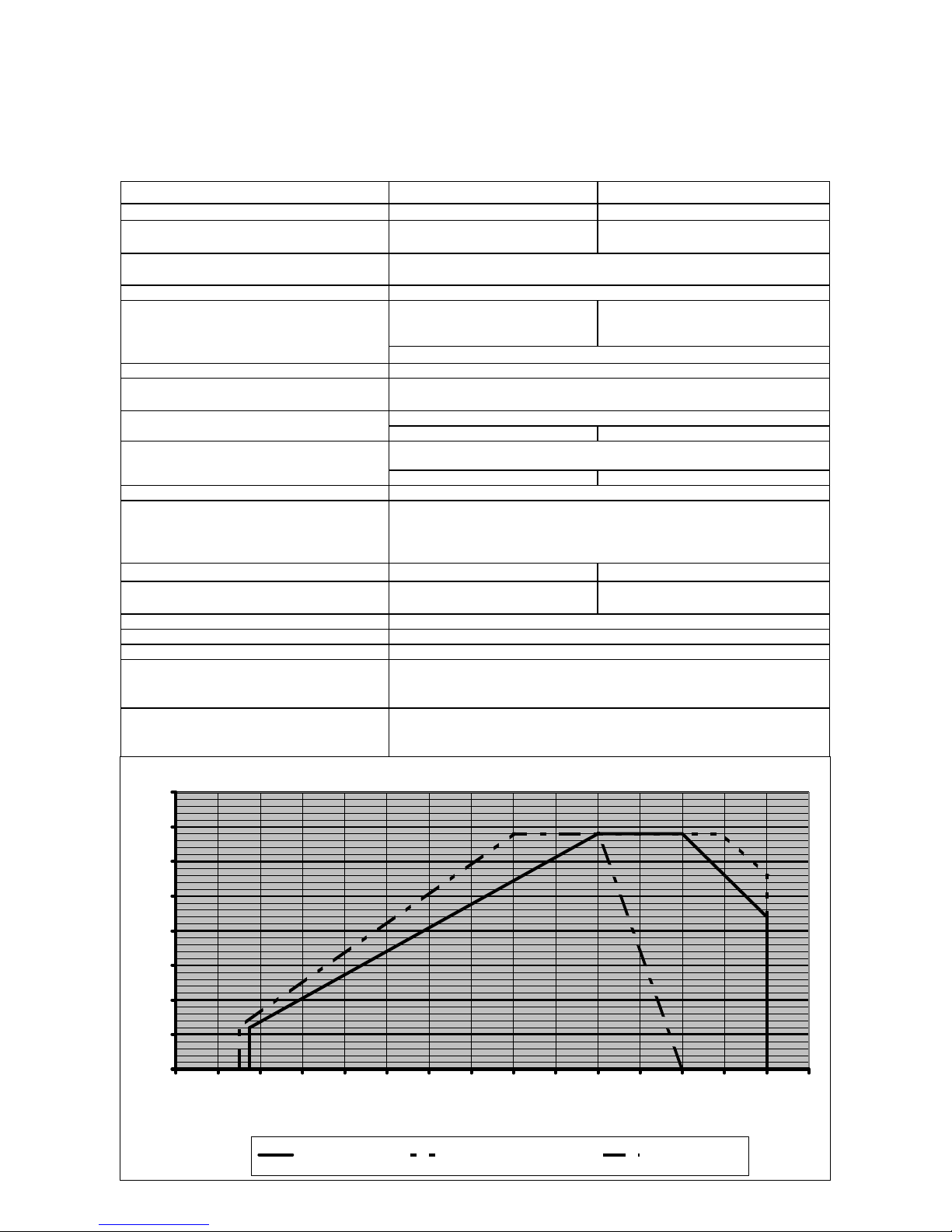

Overview

Dimensioned Drawings

EK 10... L-EUF

EK 10...L-EUF

The cover of motor is

removable in case of ope-

ning boiler door for revi-

sion

Drilling Template

Motor with disassembled protection grid

The air intake box can be rotated in

steps of 22,5 °C, the swivelling function,

however, is then not functional.

Note: In pecial cases, the air

intake box can be mounted in a

way that the opening shows to

another direction. The dimen-

sioned drawing will the differ

slightly.

6

Operation

Start-up Mode

Oil Operating Mode

General Safety Functions

Start-up mode

As soon as the furnace system is requi-

red to supply heat the burner control cir-

cuit will close and the program be

started. After the program has run down

the burner will start.

The air damper is closed when the

burner is out of operation.

The automatic furnace controller con-

trols and monitors the starting function.

The electric actuator opens the closed

air damper to its full-load position so

that the burner will sweep the furnace

compartment and exhaust ports at the

required air flow rates. Shortly after the

pre-ventilation process has been star-

ted the lack-of-air cut-out must change

over to operating position within a cer-

tain time, i.e. the minimum air pressure

setting must be reached and maintained

until the burner is turned off. At the end

of the specified pre-ventilation time the

air damper will be moved into its partial-

load position. This operation will be fol-

lowed by the pre-ignition procedure and

the oil feed start.

The solenoid valves will open and thus

allow the pressurized oil to flow to the

nozzle and to the return line. The oil will

be atomized, mixed with the combustion

air and ignited.

A safety period is provided to allow the

flame to develop a proper and steady

pattern. On the termination of the safety

period, a flame signal must have been

received by the automatic furnace con-

troller via the flame monitor and remain

on until the regular shut-off. The start-

up program of the burner has now been

completed.

Oil operating mode

After flame formation, the burner will

shortly remain in the separately set igni-

tion load, and is then run to minimum

output. Then the oil feed will start for

load regulation. The load regulator will

now control the burner automatically

between its partial-load and full-load

stages.

Depending on the heat rate required the

servomotor will via the controller be

given an "open" or "close" signal and

thus increase or decrease the oil and air

flow rates.

This compound control concept will vary

the position of the oil control valve and

air damper and thus adjust the oil flow

rate in relation to the air flow rate.

The stepless control will allow the bur-

ner to be operated at any desired stage

between its partial-load and full-load

positions. The air damper will be closed

when the burner is out of operation and

will thus prevent cold air flowing through

the burner chamber, heat exchanger

and chimney. The interior cooling los-

ses will be greatly minimized.

General safety functions

In case a flame does not develop when

starting the burner (fuel release) the bur-

ner will shut off at the end of the safety

period (shut-off on trouble). A shut-off on

trouble will also occur in the case of flame

failure during operation, air flow failure

during the pre-ventilation phase and pres-

sure failure during the whole period of bur-

ner operation. Any failure of the flame

signal at the end of the safety period and a

flame signal during the pre-ventilation

phase (external light control) will result in

a shut-off on trouble with the automatic

furnace controller being lokked. Die Stö-

rung wird am Display der elektronischen

Regelung und/oder wenn vorhanden

einer Störmeldelampe angezeigt.The

trouble is indicated by the trouble signal

lamp lighting up. The automatic furnace

controller can be unlocked immediately

after a shut-off on trouble by pressing the

unlocking key. The program unit will return

to its starting position and proceed with

the restart of the burner.

A voltage failure will result in a regular

shut-off of the burner. Upon voltage reco-

very there may be an automatic restart

unless another interlock is provided, e.g.

by the safety system. In any case of

trouble the fuel oil supply will be shut off

right away. The program unit will stop at

the same time causing also the trouble

location indicator to stop. The symbols will

indicate the kind of trouble.

When using the burner control system

type BCS all operational and fault messa-

ges may be indicated in plain text on an

optionally available operating and display

module.

When using the Etamatik/VMS/FMS

system, the display is located directly on

the control system, which is incorporated

in the boiler switch cabinet. In the Etama-

tik OEM, the control system is located in

the electric module of the burner, and the

customer interface is also located on this

module or incorporated in the boiler switch

cabinet. In the Etamatik OEM, a pro-

gramming unit could be installed as an

alternative to the customer interface.

sregulierung

g

t

ile

EIN

e

AUS

s

tellung

Leistungsregulierung

EIN

Gasventile

Zündung

Startlast

Teillast

Freigabe

AUS

Betriebsstellung

Vollast

Zündung/Ventile

Pumpe

Teillast

EIN

Freigabe

Leistungsregulierung

Betriebsstellung

Vollast

AUS

Oil control steepless Gas control steepless

ON OFF ON OFF

Full load

Operating position

Load regulator

Release

Start load

Partial load

Ignition / gas valves

Full load

Operating position

Load regulator

Release

Partial load

Ignition/valves

Pump

7

Operation

Fuel-air Compound Control

Fuel-air compound control

This compound pneumatic control

system with precision-adjustment capa-

bility has been designed to allow the

fuel and air flow rates to be steadily

varied in sliding mode for an adjustment

of the fuel-air ratio over the whole con-

trol range.

In the stepless control mode the load

will be controlled at any point within the

control range depending on the heat

demand.

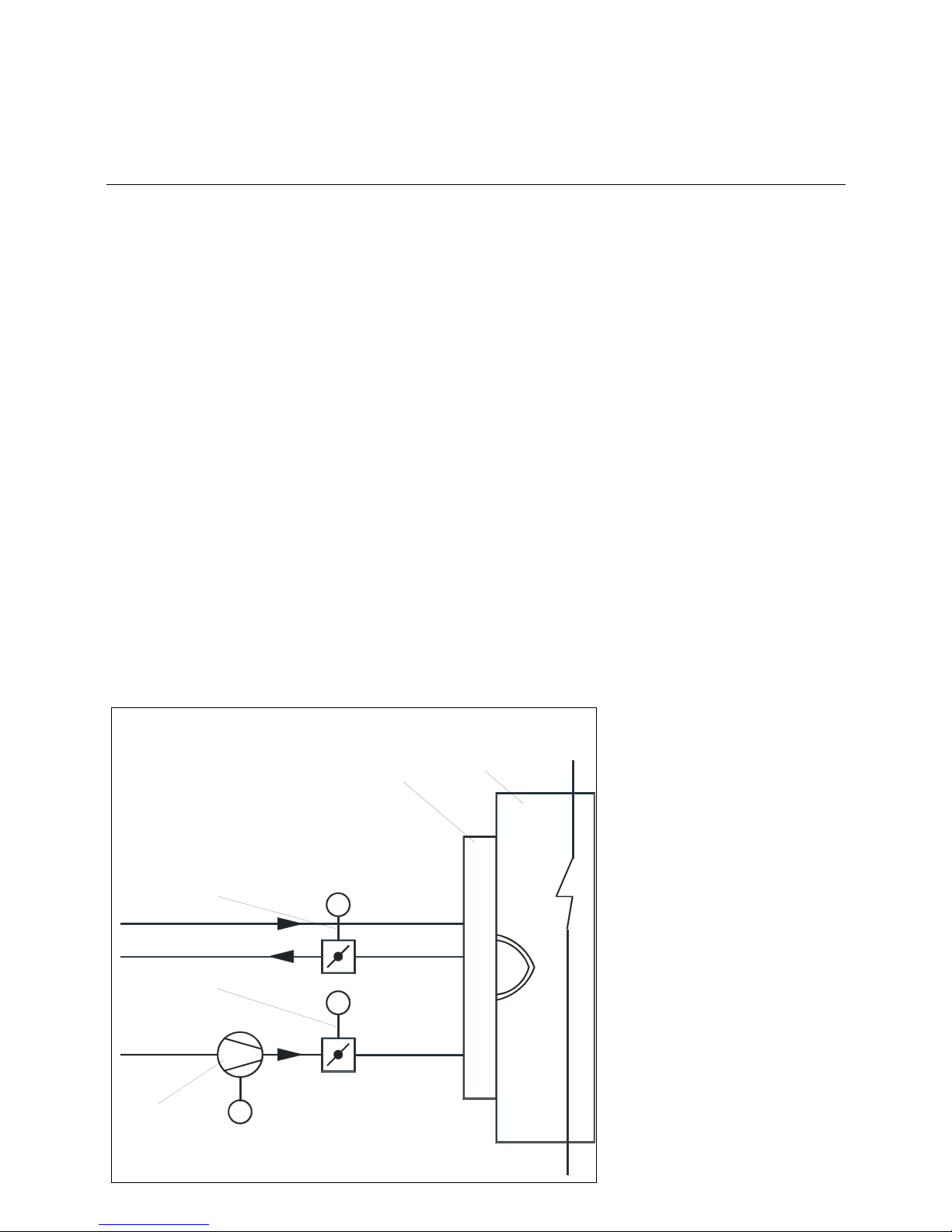

Electronic compound control:

The air box includes an actuator for

operating the air damper. The oil control

valve incorporates an actuator for adju-

sting the return oil flow rate and thus the

output of the burner.

The actuators for the air and fuel flow

control will be operated depending on

output by the electronic compound con-

trol which will move them into the pro-

grammed positions.

4

Luft

M

M

Öl

Öl

RL

VL

1a

1b

M

3

2

Oil feed

Oil return

Air

Electronic compound control

1a Oil control valve with actuator

1b Air dampers with actuators

2Burner

3Boiler

4 Combustion air fan

8

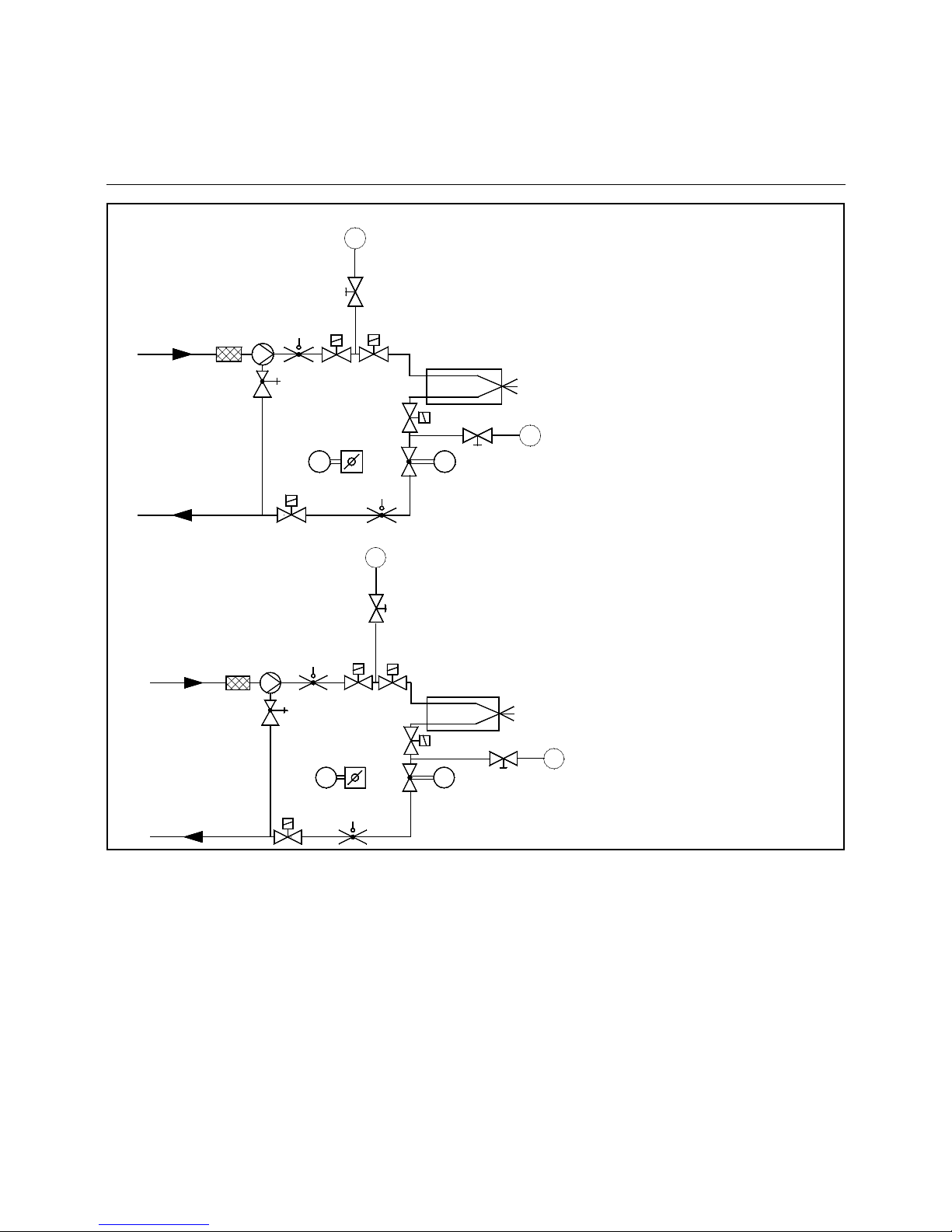

Hydraulic diagramm

120 Air damper

143 pressure gauge option

175 Filter

176 Pump

178 Feed solenoid valve

180 Nozzle rod

181 Return solenoid valve

184 Output control valve

187a Pressure regulating valve

(integrated in pump)

311 Return oil pressure switch

312 Feed oil pressure switch

349 Actuator

In case of TRD 604/72 hr control

items (pos. 311, 312) need to be

tested according to „special construc-

tion design“ or must be installed twice.

312

RL

181

175

187 a

VL

176

311

178

178

M M

120

184

349

349

180

181

PI

143

PI

143

Hydraulic diagram -DIN / EN

RL

175

187 a

VL 176

311

312 178

178

181

180

181

M184

120

M349349

PI

143

PI

143

Hydraulic diagram -TRD 604/72 h

9

Operation

Hydraulic Valves and Instruments Group

The hydraulic valves and instruments

group is an integrated concept that

combines several functions of the

hydraulic systems of burners. Its modu-

lar construction makes it possible to

meet a wide range of requirements and

conditions of installation.

Depending on the level of equipment of

the hydraulic system, oil pressure swit-

ches and pressure gauges (3) may be

installed in the supply and return pipes

of the basic module (1). The solenoid

valve in the supply pipe is of servo-assi-

sted type while the return valve is

directly controlled. The solenoids of the

two valves are electrically connected in

series which will prevent one of the val-

ves being opened alone if any of the

solenoids is defective. For the replace-

ment of the solenoid valves during

maintenance work it should be ensured

that the right valve type is installed in

the correct direction of mounting. For

mounting the solenoid valve in the sup-

ply pipe (type 321F2523) it must be

ensured that the direction of flow shown

be a stamped arrow on the valve flange

is the same as the direction of flow of

the oil (from the pump to the nozzle

rod). The solenoid valve in the return

pipe (type 121 F2523) is marked with a

stamped arrow opposite to the direction

of the oil flow from the nozzle rod back

to the pump.The volume flow control

valve installed in the return pipe con-

sists of a bush pressed into the hydrau-

lic valves and instruments group and

locked against torsion and a control

shaft. As the control shaft is turned, the

contoured configuration of the bush and

shaft will change the open cross section

for the oil flowing back and thus vary the

oil return flow rate. Control shafts with

different control contour parameters are

available for adjustment to various oil

nozzle sizes. This concept ensures that

an excellent control characteristic and a

wide control range can be covered for a

great variety of applications. The control

contour parameter is affixed to the con-

trol shaft by means of an electric mar-

ker. The current position of the control

shaft is indicated by the position dis-

play. From the "min." mark (low load of

burner) the control shaft will turn clock-

wise to the "max." mark (full load of bur-

ner). If the control shaft has been

removed during maintenance work care

should be taken when reinstalling it to

ensure the right mounting position of

the control contour by observing the

centre punch mark on the shaft end

face. In the low load position (min.) the

centre punch mark will in any case point

up (12 o'clock position - see figure).

If the hydraulic valves and instruments

group is used in conjunction with nozzle

rods not approved as safety shut-off

valve according to EN 264, an exten-

sion module (2) is available which

incorporates an additional solenoid

valve each in the supply and return

pipes. The extension module is atta-

ched directly to the basic module. The

modules are sealed against each other

by O-rings.

Metal hoses are used for connection

between the hydraulic valves and

instruments group and the nozzle rod.

The hose lines must be protected

against exterior mechanical damage.

The hoses must be positioned and

mounted in accordance with the appli-

cable technical standards. For the

installation care must be taken not to

introduce torsional or buckling stresses

neither by the mounting procedure nor

by movements at a later stage. Speci-

fied bending radii of the hoses must not

be changed.

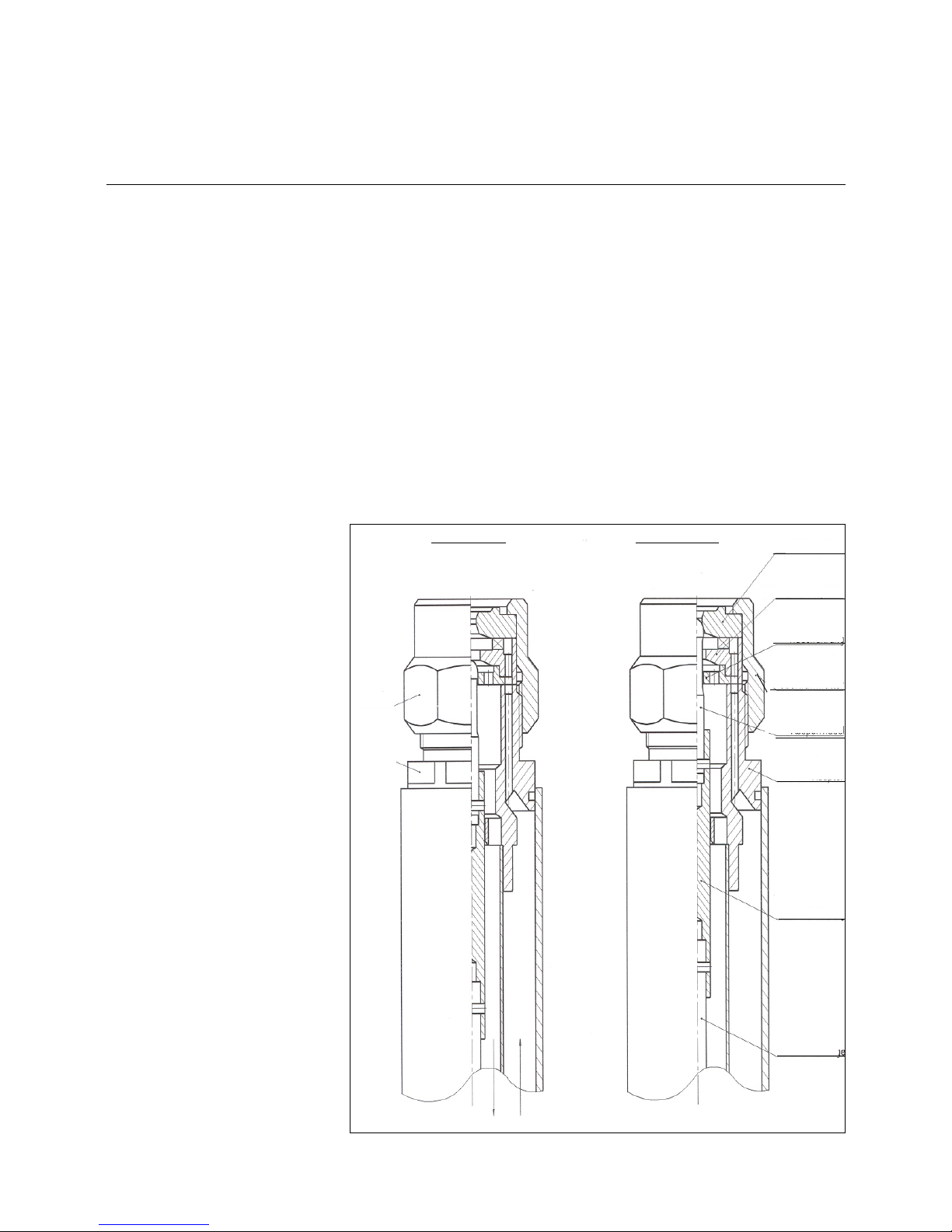

Basic module

Extension module

Control shaft installation

Complete hydraulic valves and

Instruments group

3

1

2

10

E 10.1200 L-EUF

Start-up

Burner Head Settings

E 10... L-EUF

11

Installation

Mounting to Boiler

Electrical Connection

Presetting

Adjustment electrical ignition

oil firing operation

Burner plate with gasket strip

Check before burner installation

Check the mixing unit for correct set-

ting; see dimensioned drawing.

Burner head settings

The settings mentioned are factory set-

tings.

They are understood to be recommen-

ded values and may be readjusted

according to burner system conditions,

exhaust gas analysis and combustion

characteristics.

- Set the ignition electrodes according

to the sketch.

- Check the burner pipe mounting

according to Section “Boiler lining for

burners” and the boiler manufacturer’s

specifications.

Electric connection:

The electric connection including all

installation materials as well as joints

and earth terminals must be made in

accordance with the applicable regulati-

ons. For the electrical installation of the

burner reference should be made to the

circuit diagram of the furnace system.

The electric connection of the burner

and gas valves and instruments is allo-

wed to be entrusted to authorized spe-

cialists only.

Burner installation

For mounting the burner to the boiler

make sure the connection plate is pre-

pared in accordance with the dimensi-

ons given in the technical datasheets.

• Install the stud bolts in the connection

plate.

• Put the insulating base and burner in

place and fasten with bolts.

Arrangement of sealing tape on the

boiler

- Evenly stick on self-adhesive tape

according to Figure.

- Adapt the flat gasket by cutting to the

boreholes in the area of the four.

vertically arranged boiler fastening

holes.

- In case of butt joints make sure the

bordering is fitting closely

NOTE: For the installation of the con-

necting cables care must be taken to

provide cable loops of sufficient length

so that the boiler door and burner can

be swung out as required.

After the completion of the electric con-

nection work make a check of the wiring

of the burner electric system. This inclu-

des a check for the direction of rotation

of the burner motor (fan).

Boiler inspection glass cooling

For cooling and cleaning the boiler

inspection glass, a cooling line (e.g. a

hose) may be installed from the burner

to the inspection glass. A connection

piece is provided on the burner for this

purpose.

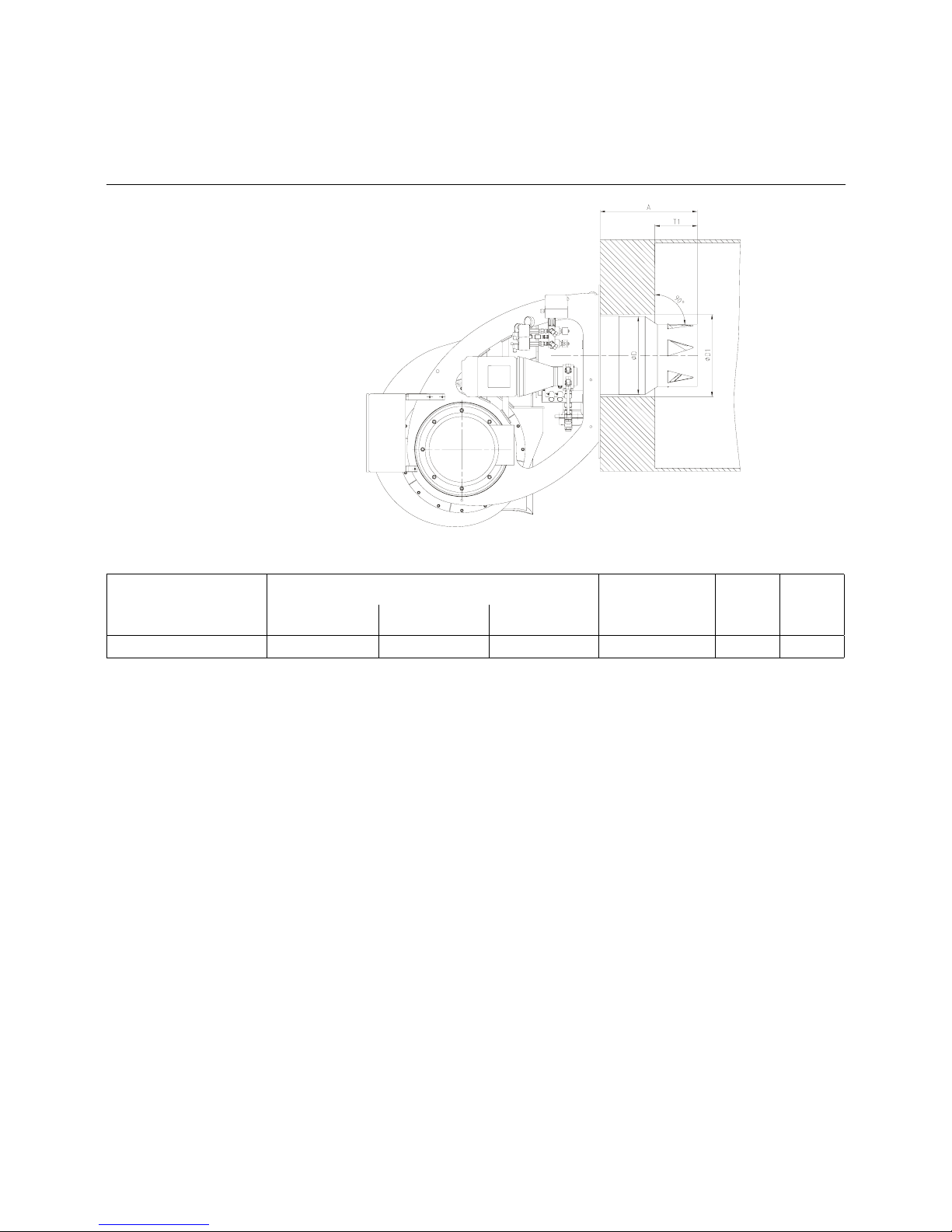

12

Installation

Boiler Lining

Burner GL/L-EUF

Boiler lining

The burner lining must be installed at

right angles to the burner tube.

Possible trimming work (bevelling, roun-

ding) as is required for reversing boi-

lers, for example, should done at a

diameter not below 70 % of the combu-

stion chamber diameter.

The space between the flame pipe of

the burner and the boiler lining should

be lined with heat resistant material,

such as Cerafelt.

This space is not allowed to be lined

with brickwork.

DF= Combustion chamber diameter

Burnertyp Dimension A Dimension T1 φ D φ D1

Standard 100 verl. 200 verl.

E 10 620 720 820 200 - 250 497 525

13

Installation

Oil Connection

Oil Pressure Control (Feed)

Oil connection

Hoses are used for connection to the oil

lines and stop valves. The hoses must

be installed according to the applicable

standards (relieved of tensile load, free

of distortion) to avoid kinking and

exclude the danger of breakage. Take

care when mounting the oil lines to

bring their ends as close to the burners

as possible and to arrange them in a

way that the boiler door and the burner

can be swung out without any obstruc-

tion.

Refer to the technical documentation for

the line dimensions for the feed and

return lines from the stop valves to the

tank.

Oil filter

A filter must be installed upstream of the

pump to protect the oil pressure pump

and the hydraulic system.

Installation options

• Two-line installation

(separate feed and return lines without

delivery pump)

• Ring line system

(with delivery pump and gas-air sepa-

rator)

Oil hose aplication area

Burner type DN length

[mm]

double sided

connection

bending radius

min. R [mm]

E 10 25 1500 R 1" 250

Instrument mounting

Prior to adjusting the burner make sure

to mount the test pressure gauges for

measuring the feed pressure (Item 2)

and return pressure (Item 1).

A vacuum gauge and pressure gauge

are mounted to the oil pump for measu-

ring the oil pressure.

NOTE: After the burner has been taken

into operation the gauges must be

removed again and the connections

sealed with suitable means. If the gau-

ges are mounted to remain on the bur-

ner they should be fitted with stop

valves.

Oil pressure control (feed)

The feed pressure is controlled by

means of the pressure regulator instal-

led in the pump and should be set at

approx. 25 to 30 bar depending on bur-

ner output and nozzle make. The pres-

sure regulator is operated by turning its

screw. Make sure to fill the pump with

oil prior to taking into operation.

Pump bleeding

Open the feed and return stop valves

and ensure the ring line (if any) is in

operation. Reduce the oil pressure at

the pressure regulating valve. Turn on

the pump by pressing the contactor.

Check the pump for proper direction of

rotation. Check for proper oil delivery

and absence of leaks in the hydraulic oil

system. For bleeding the pump open

the pressure gauge connection, for

example. When taking the burner into

operation proceed by gradually increa-

sing the pressure to operating level (25-

30 bar).

Checking the pressure (oil suction

pressure)

The maximum permissible vacuum is

0.2 bar. At higher vacuum levels the fuel

oil will tend to gas evolution which may

lead to operating trouble. In the ring line

mode of operation the pump oil pres-

sure is not allowed to exceed 5 bar.

1

2

14

General

The burner feed pipe 32-EH is particu-

larly suited for mounting to oil burners

and is designed for the operation of

return plate nozzles with needle shut-

off. The powerful spring of the driving

piston moves the shut-off needle into

closing position, thus always ensuring a

safe shut-off.

The driving piston is operated with oil

tapped from the supplied pipe, and its

opening function is controlled by the

solenoid valve of the hydraulic block.

The piston has a fixed travel.

The final position of the driving piston

can be checked hydraulically and incor-

porated into the control system of the

burner.

During the pre-ventilation of the burner,

the shut-off needle keeps the bore in

the nozzle plate closed and the oil circu-

lates in the feed pipe. When using

heavy fuel oil, the complete hydraulic

system is heated in the pre-scavenging

stage. When the solenoid is turned on,

or after a longer downtime, an imme-

diate atomizing and a perfect ignition

are ensured.

The burner feed pipe is suitable for sup-

ply pressures from 20 to 40bar and oil

temperatures up to 140°C. The ambient

temperature in the vicinity of the coil

should not exceed a temperature of

60°C.

SW 41

SW 41

SW 41

swirl chamber plate

e

adapter

mounting

rod

Needle open Neddle closed Nozzle plate

swivel nut

needle guidance

shut off needle

Nozzle rod linkage 32 - EH

Mounting the nozzle plates

The nozzle plate and the swirl chamber

plate should be installed according to

the attached sketch.

The sealing surfaces on the adapter, on

both sides of the swirl chamber plate

and on the nozzle plate must not be

damaged because this would endanger

the proper sealing. When sealing these

surfaces, never use material from other

manufacturers.

Remove the swivel nut from the feed

pipe, check that the needle guidance in

the swirl chamber plate is sliding pro-

perly over the needle head and place

the plates into the nut evenly in proper

position and proper sequence.

Now the nut together with the plates is

carefully placed over the needle and

tightened by hand as firm as possible.

The cap nut is firmly tightened with a

spanner. Spanner surfaces are provi-

ded on the adapter to counter with the

feed pipe when screwing down or off

the cap nut. These surfaces are desi-

gned for this purpose only!

15

Nozzle rod linkage 32 - EH

Connections

The connections on the block of the

feed pipe are identified as follows:

S Oil supply to the nozzle and to the

hydraulic system of the needle

actuation. A filter with a mesh size

smaller than 50 µm should be pre-

connected. The pressure should

be kept above 20bar.

MS Here, the supply pressure of the

nozzle is available. A pressure

gauge or a pressure sensor can

be connected to evaluate this

pressure.

R Oil return from the nozzle. A pres-

sure or a quantity governor can be

connected for fuel oil flow control.

MR Here the return pressure of the

nozzle is available. A pressure

gauge or a pressure sensor can

be connected to evaluate this

pressure.

L Oil return from the hydraulic

system of the needle actuation. In

principle, this oil should be allo-

wed to flow off without back pres-

sure. If this pipe is connected to a

ring main having a low overpres-

sure, it is essential to observe that

the pressure at connection „S“

must in any case be at least 20

bar higher than that pressure

which is applied at connection “L”.

Only then, the proper needle

function is ensured.

C Here, the switching pressure of

the needle piston is available. A

pressure gauge or a pressure

sensor can be connected to eva-

luate this pressure. The pressure

is lower than the pressure at con-

nection “S” when the needle is

closed and during the switching

procedure of the needle piston.

Only during the time while the

needle is fully open, there will be a

pressure that is as high as the

pressure at connection “S”. These

properties allow the final position

of the needle to be checked

hydraulically.

When selecting the screwed connec-

tions, make sure that the ducts in the

connecting block of the feed pipe can

not be covered, not even in part. Even a

partial covering of these ducts will result

in a malfunction of the feed pipe.

16

Nozzle rod linkage 32 - EH

Function

During the pre-scavenging stage, both

the external solenoid in the supply line

and the external quantity or pressure

governor in the return line are open.

The attached solenoid is de-energized

and the valve used for needle actuation

is closed, the spring-loaded rod thus

keeps the needle in the bore of the

nozzle plate at the front of the feed pipe

closed so that the oil cannot reach the

furnace chamber too early. The pres-

sure at connection “C” is 0 bar or equal

to the ring main pressure if the connec-

tion “L” has been connected to a ring

main. The oil circulates from connection

“S” via the swirl chamber plate in the

nozzle through the feed pipe to the con-

nection “R”, thus warming it up to opera-

ting temperature. (For heavy oil only)

Operating voltage and type of current

are indicated on the attached coil. The

moment the attached solenoid is turned

on, the oil is released for needle actua-

tion; the rod is withdrawn, and the

nozzle needle is opened. During the

short time where the piston moves from

closed to open needle position, the

pressure at connection “C” is always at

least 2bar lower than the pressure at

connection “S”. From the moment on

where the piston reaches its final posi-

tion and the needle is opened fully, a

pressure is applied at connection “C”

which is as high as the pressure at con-

nection “S”.

The interruption of the power supply to

the attached solenoid causes the

needle to be closed by means of the

spring. The oil outflow on the nozzle will

stop immediately.

The pressure at connection “C” will go

down to 0 bar or reaches again the

same level as in the ring main if connec-

tion “L” is connected with the ring main.

The circulation from connection “S” via

the swirl chamber plate to connection

“R” will still take place. The temperature

of the feed pipe is thus maintained.

Service

Normally, the burner feed pipe is

maintenance-free.

The only moving part in the feed pipe is

the rod linkage used for actuating the

needle with the piston. After a longer

period, the O-rings could be worn out.

For replacement, complete O-ring sets

are available.

17

Start-up

Return Nozzle Rod RDG 1250

Function description

The return nozzle rod RDG 1250 is for

return nozzle without integrated needle

valve and comes with M14 screw con-

nection (for example Sonic DZ 1000,

CBM M14).The locking mechanism

consisted of a slider with seal ring (Pos.

2 and 6) in the forward flow section and

a needle valve (Pos. 5) in the return

flow section, using the sliding rod con-

trol by a hydraulic control-piston system

located at the back of the nozzle rod.

The opening pressure of RDG 1250 is

about 3 bar in forward flow section or 13

to 20 bar in return flow section. When

the solenoid valves are open, the pres-

sure from the oil would retract the con-

trol-piston via the pressure channel

(Pos. 7) and then push open the slider .

Both the control-piston and sliding rod

with needle valve would remain open as

long as there is an existing oil pressure.

The same oil pressure would keep the

slider open. Under normal circum-

stances, both locking mechanisms

would open at the same time. The oil in

the forward flow section would exit

through the nozzle head to be mixed

with the air for combustion. The remai-

ning oil would be redirected through the

return holes of the nozzle back into the

return flow section of the nozzle rod

assembly. When it is not in operation,

the swirl plate in the nozzle head blocks

the return flow.The return oil flow rate

can be adjusted accordingly using a

pressure control valve If the pump pres-

sure is too low (<20 bar), thereby pre-

venting the control needle from opening

all the way, variations in throughput are

to be expected as the needle position

will affect the return oil flow.

Control-piston opening distance H is set

in the factory at 9mm. Any adjustment

at installation site is not necessary.

1

5

3

6

4

7

2

H

The Control piston

opens at ca. 13 bar;

Fully open at 20 bar.

Close at 10 bar.

1 Return Nozzle

2 Slider

3 Spring (Forward)

4 Sliding rod

5 Needle valve

6 Seal ring (Forward)

7 Pressure channel

Distance H = 9 mm

Forward

Valve

18

Start up

Nozzle selection „Sonic“

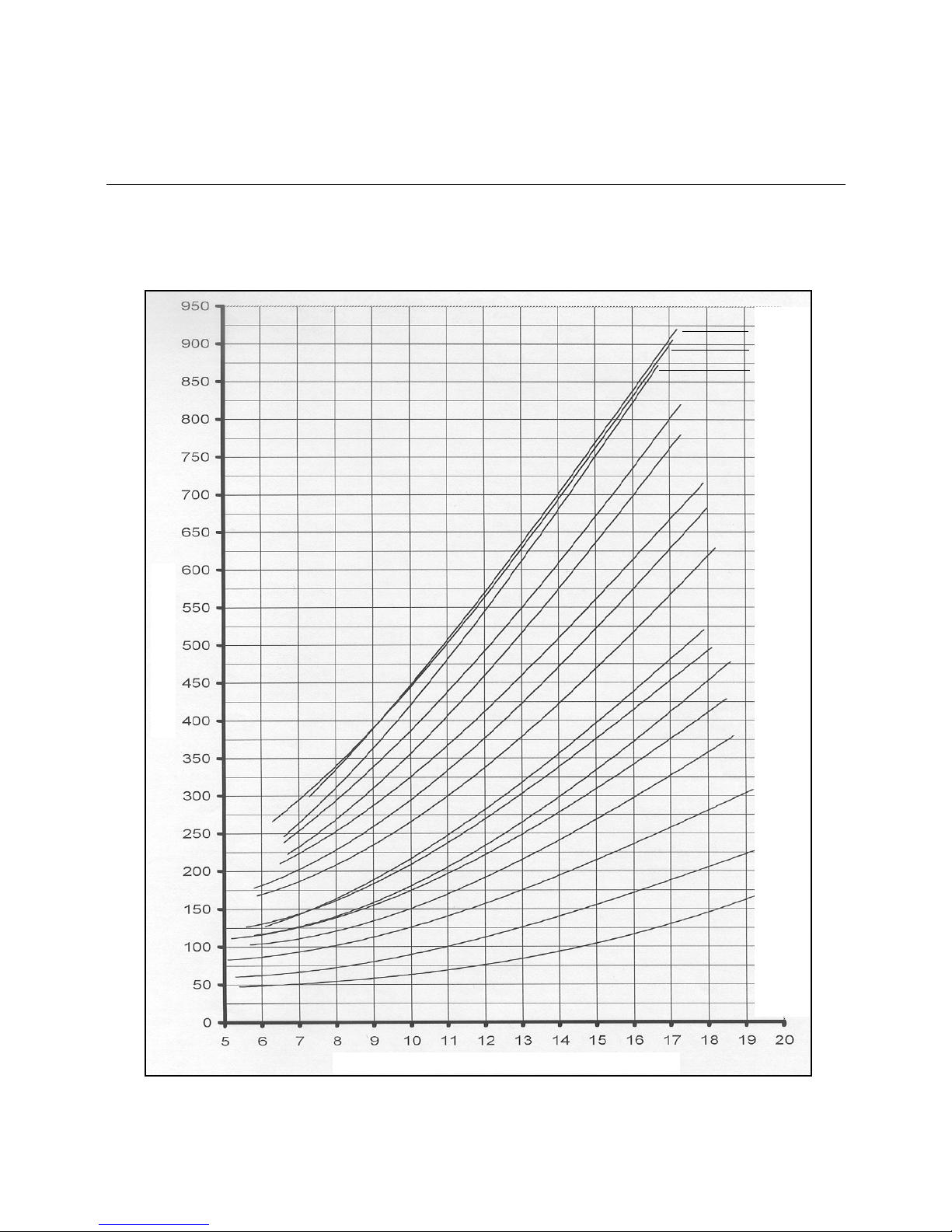

160 kg/h

240 kg/h

300 kg/h

350 kg/h

400 kg/h

450 kg/h

500 kg/h

550 kg/h

650 kg/h

700 kg/h

750 kg/h

800 kg/h

850 kg/h

900 kg/h

950 kg/h

1000 kg/h

Diagram - of Sonic-Spray return nozzle DZ 1000-60°

with controlled return

Light fuel Oil

Feed pressure 28bar

Return nozzles of the type Sonic-

Spray are available in different ratings

with an angle of spray of 45°, 60° or

80°.

The 45° nozzles are preferably used

for reversed-flow furnaces while the

60° and 80° nozzles are operated in

three-pass boilers and swirl-type

mixing installations, respectively.

Quantity Oil Nozzle [kg/h]

Return Pressure at the Hydraulicblock [bar]

19

Start-up

Checking Procedure

Check the following prior to the

initial operation of the boiler system:

• Take care to observe the operating

instructions supplied by the boiler

manufacturer. The boiler must be

mounted ready for operation.

• Ensure that the heating system is filled

with water to capacity.

• Check the complete system for correct

electrical wiring.

• Check the burner motor for correct

direction of rotation.

• Check for the proper setting of the

temperature and pressure controllers,

limiters, safety switches and electrical

limit switches.

• Bleed the fuel-carrying lines (make

sure they are free of air).

• Check tank, lines and oil pump are fil-

led with oil and correct oil nozzle is fit-

ted.

• Check the oil hydraulic system is free

of leaks.

• Check the exhaust gas ports are ope-

ned and adequate fresh air intake is

ensured.

• With burner in starting position check

that air damper is in „CLOSED“ posi-

tion.

• Check that automatic furnace control-

ler is unlocked and in its original posi-

tion.

Oil start-up

Open all shut-off valves of oil supply

system.

• Set fuel selector switch to its „Oil“ posi-

tion.

• Fill pump with oil.

• Mount pressure gauge in the feed line

and return line.

• Mount the pressure gauge for

checking the pump suction pressure.

Bleeding

Shortly start the burner and check for

proper direction of rotation. Bleed the oil

line and oil pump.

CAUTION: The hydraulic system has

been filled with test oil by the manufac-

turer. This may cause ignition trouble

when initially operating the system. To

protect the pump, the oil pressure con-

troller is factory-set at zero pressure.

When starting the burner take care to

increase the oil pressure slowly to the

operating level.

Prior to the initial fuel feed start

make a functional test of the burner

program flow:

Oil system:

• Open all shut-off valves of the oil sup-

ply system.

• The oil solenoid valve in the feed line

disconnect on the terminal strip (see

Circuit Diagram).

• Start burner and check program flow

for correct start-up sequence.

1. Fan starts.

2. Pre-ventilating damper.

3. Air pressure check.

4. Partial-load air damper.

5. Ignition.

6. Valves open (disconnected valve

remains closed).

7. Shut-off upon trouble after expiry

of safety period (see automatic

furnace controller).

• Reconnect the valve.

• Unlock the automatic furnace control-

ler.

20

Adjusting Instructions

Air Flow Rate Adjusting Procedure

Adjusting procedure

• Set the selector switch to its "Manual"

or "Hand" position.

Air flow rate adjustment

The air control curve of the compound

controller is factory-set so that the air

damper is closed in minimum position

and open in maximum position.

The combustion air flow rate required

for proper fuel combustion is controlled

by an electronic fuel-air compound con-

trol system over the full load range. A

check is made by analyzing the exhaust

gases.

For the gradual adjustment of the

load points (fuel flow rate, air flow

rate), a procedure should be used as

described in the operating instruc-

tions for the electronic compound

control system.

A fuel test should be made at each point

if possible.

This manual suits for next models

1

Table of contents

Popular Burner manuals by other brands

Dyna-Glo

Dyna-Glo DGH474CRN manual

Sime

Sime MACK 6 Installation, use and maintenance instructions

Unigas

Unigas N18 MANUAL FOR INSTALLATION, OPERATION AND MAINTENANCE

John Lewis

John Lewis 85330112 Pre-assembly preparation

Riello

Riello 826 T2 Installation, use and maintenance instructions

Meec tools

Meec tools 008484 operating instructions

YOKOI KIKAI KOSAKUSHO

YOKOI KIKAI KOSAKUSHO HOPE CJ-1 Handling manual

EcoSmart Fire

EcoSmart Fire Vision manual

baltur

baltur BT 40G instructions

CIB UNIGAS

CIB UNIGAS LMV5 Series Manual of installation - use - maintenance

Ekoterm

Ekoterm GP sc Series Installation, operation and maintenance manual

baltur

baltur BGN 60 LX Startup guide