SERVICE INFORMATION CS-3000

CS-3400

8

2-3 Adjusting carburettor

1. Start engine and warm it up well for 2 -3 minutes

with cycle of 5 seconds at WOT (Wide Open Throttle)

and 10 seconds at idling.

2. Using 2.5 mm wide blade screw driver, adjust L

mixture needle to obtain maximum idle speed.

3.

Set idle speed to 4,200 r/min

by turning idle adjust

screw (in the range of 4,100 to 4,300 r/min allowable).

4. Turn L mixture needle anticlockwise to reduce

engine idle speed 1,000 r/min to set idle speed in

the range of 3,100 to 3,300 r/min.

NOTE : Engine speed must be allowed to stabilize

a minimum of 20 seconds after each adjustment of

L mixture needle to assure accurate tachometer

readings.

5. Turn H mixture needle anticlockwise at WOT until

engine speed drops less than 10,000 r/min.

6.Adjust WOT engine speed in the range of 10,500

to 11,500 r/min byturning H mixture needleclockwise.

NOTE : Do not run engine at high speed without

load longer than 5 seconds, or engine damage may

occur.

7.

If the engine speed at WOT is above 12,000 r/min

,

adjust H mixture needle anticlockwise and set

maximum engine speed at less than 12,000 r/min.

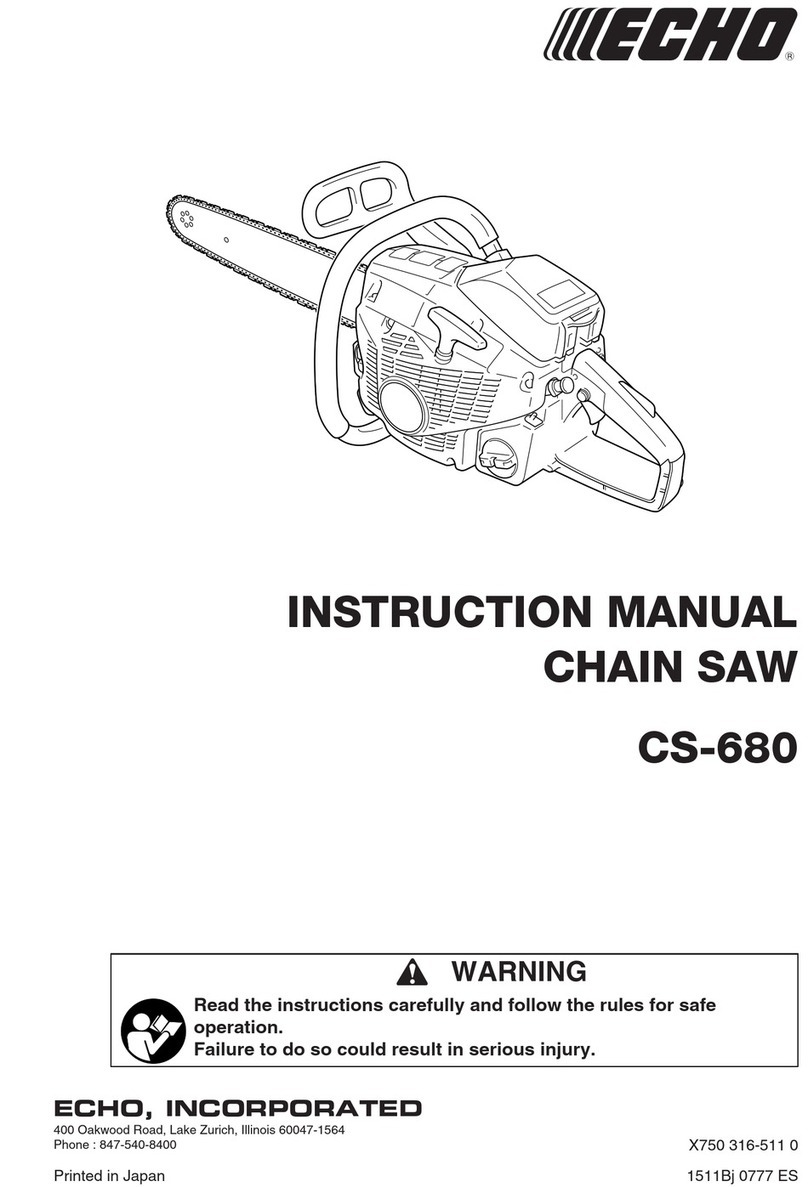

8. After adjusting carburettor, put the limiter cap on

the tip of 2.5 mm wood screw and install the caps

on L and H mixture needles.

NOTE : Align the limiter cap tabs (A) with locating

slots (B) in extended housing of carburettor.

9. Tap the respective limiter caps in as shown.

10.Start engine again and make it sure engine runs

at idle speed in the range of 2,700 to 3,500 r/min

and at WOT engine speed in the range of 9,000 to

12,000 r/min.Also make it sure chain would not turn

at engine idle speed and suitable acceleration.

NOTE : Initial carburettor setting (Idle adjust screw,

L and H mixture needles) shown here is to start the

engine after restoration or carburettor change. Idle

adjust screw, L and H needles turn for designated

engine revolution through procedures indicated here

may vary.As long as idle and WOT engine speed is

set in given range, variance would be ignorable.

idle adjust screw

H

L

(B)

(B)

(A)

(A)