ECKELMANN Compact GLT 3010 User manual

Firmware: V2.18 / V--

26.10.2022

Docu 1.5

Operating instruction

Compact GLT 3010 / -GLT 5010

Freely programmable control

The series includes the following expansion stages: GLT 3010 / GLT 5010

Firmware: V2.18 / V--

26.10.2022

2/119

Eckelmann AG

Business Unit Refrigeration and Building Automation

Berliner Straße 161

65205 Wiesbaden

Germany

Telephone +49 611 7103-700

Fax +49 611 7103-133

www.eckelmann.de

Board of Management:

Chairman Dipl.-Wi.-Ing. Philipp Eckelmann,

Dipl.Ing. (FH), Dipl.-Ing. (FH) Volker Kugel,

Dr.-Ing. Marco Münchhof

Supervisory Board: Hubertus G. Krossa

Deputy Chairman of the Supervisory Board: Dr.-Ing. Gerd Eckelmann

Seat of the company Wiesbaden, district court Wiesbaden HRB 12636

Beforecommissioning and use, please check that this is the latest version of the document. With the publication

of a new version of the documentation, all previous versions lose their validity. The current operating manual

and information such as data sheets, more detailed documentation and FAQs are available for you on-line in

E°EDP (Eckelmann ° Electronic Documentation Platform) at

www.eckelmann.de/elds

You reach all relevant documents for this component directly using the QR code:

https://edp.eckelmann.de/edp/lds/_RdC4ujAibE

Information on safety and connection instructions are described in detail in chapter ”Industrialsafety notes”.

Copyright: All rights to any use whatever, utilisation, further development, forwarding and creation of copies

remain with the Eckelmann AG company. In particular, neither the contract partners of Eckelmann AG nor other

users have the right to distribute or market the IT programs/program parts or modified or edited versions

without express written permission. To some extent, names of products/goods or designations are protected for

the respective manufacturer (registered trademarks etc.); in any case, no guarantee is assumed for their free

availability/permission to use them. The information provided in the description is given independently of any

existing patent protection or other third-party rights.

Errors and technical modifications are expressly reserved.

Firmware: V2.18 / V--

26.10.2022

3/119

Table of Contents

1 Conventions............................................................................................................................................6

1.1 Warning signs, symbols and text formatting used in this manual....................................................6

1.2 Explanation of text formatting ..............................................................................................................7

2 Safety instructions .................................................................................................................................8

2.1 Disclaimer in the event of non-compliance .........................................................................................9

2.2 Requirements for the personnel ...........................................................................................................9

2.3 Intended Use.........................................................................................................................................10

2.4 Five safety rules according to DGUV Regulation 3...........................................................................10

2.5 Electrostatic-sensitive components and control components (ESD).............................................11

2.6 EGB - Richtlinien zur Handhabung.....................................................................................................11

2.7 Abbreviations Used..............................................................................................................................11

3 System design GLT x010 .....................................................................................................................12

3.1 Connections..........................................................................................................................................13

3.2 GLT x010 models..................................................................................................................................16

3.2.1 Number of data points ............................................................................................................................17

3.2.2 Synchronisation......................................................................................................................................17

3.2.3 Compatibility...........................................................................................................................................17

4 Tasks of the GLT x010..........................................................................................................................19

5 Functions of the GLT x010 and set-up ...............................................................................................20

5.1 Implementation.....................................................................................................................................20

5.2 Starting Characteristics.......................................................................................................................21

5.2.1 First Start................................................................................................................................................21

5.2.2 Restart....................................................................................................................................................21

5.3 Controller configuration ......................................................................................................................21

5.3.1 Measuring ranges of the Pt1000 sensor inputs......................................................................................23

5.3.2 Measuring ranges of the analogue inputs ..............................................................................................24

5.3.3 Measuring ranges of the analogue outputs............................................................................................26

5.3.4 Number of SIOX extension modules......................................................................................................27

5.3.5 System error messages .........................................................................................................................28

5.4 Process Image (PI) ...............................................................................................................................28

5.4.1 Feedback of the manual control level.....................................................................................................29

5.4.2 Pt1000 sensor inputs..............................................................................................................................31

5.4.3 Analogue inputs......................................................................................................................................32

5.4.4 Analogue outputs ...................................................................................................................................33

5.4.5 System Status ........................................................................................................................................34

5.4.5.1 Status of the CAN bus............................................................................................................................35

5.4.5.2 CAN bus address status.........................................................................................................................36

Firmware: V2.18 / V--

26.10.2022

4/119

5.4.5.3 Status of the SIOX 1..3 extension modules............................................................................................37

5.4.5.4 Status of the battery and DIP switches ..................................................................................................38

5.4.5.5 Status of the Life LED (life lamp)............................................................................................................39

6 Signal List .............................................................................................................................................40

6.1 Formal structure of the Signal List.....................................................................................................42

6.2 The Column Markers............................................................................................................................43

6.2.1 Marker $EA1 - Address according to IEC 61131-3.................................................................................44

6.2.2 Marker $EA2 - Variable identifier............................................................................................................46

6.2.3 Marker $REF - channel reference..........................................................................................................47

6.2.4 Marker $LDSW, $ARC, $ARCNR - LDSWin visualisation .....................................................................48

6.2.5 Marker $FTYP, $FTZ, $FN - Probes and sensors..................................................................................48

6.2.6 Marker $YMIN, $YMAX, $SM, $B, $E, $DEF.........................................................................................49

6.2.7 Marker $PRIO - Alarm priority ................................................................................................................50

7 Signal List Tool.....................................................................................................................................52

7.1 Starting the tool and settings..............................................................................................................54

7.2 Menu functions.....................................................................................................................................54

7.3 Error message examples.....................................................................................................................57

7.4 Changes of GLT 5010 compared to GLT 3010 ...................................................................................58

8 CODESYS..............................................................................................................................................59

8.1 Creation of the application using CODESYS.....................................................................................59

8.1.1 Target system settings............................................................................................................................61

8.2 Importing the application using CODESYS .......................................................................................63

8.2.1 Connection to development PC..............................................................................................................64

8.2.2 Compile project and load into DDC........................................................................................................66

8.2.3 Create boot project and start application................................................................................................67

9 Installation and start-up GLT x010 / SIOX ..........................................................................................68

9.1 DIN rail mounting .................................................................................................................................69

9.1.1 Mounting on the DIN rail.........................................................................................................................70

9.1.2 Removal from the DIN rail ......................................................................................................................71

9.1.3 Handhabung breiter COMBICON-Stecker .............................................................................................72

9.2 SIOX Extension Module .......................................................................................................................73

9.2.1 Connection of the SIOX modules to the base module ...........................................................................74

9.3 Default hardware settings ...................................................................................................................75

9.3.1 Settings using DIP switch S1 .................................................................................................................76

9.3.2 Setting the CAN bus address using decade switch S2 ..........................................................................78

9.3.3 Setting of the interfaces RS485/TTY using jumper J1 ...........................................................................79

9.3.4 Configuration of the analogue inputs and outputs..................................................................................80

9.3.5 Power supply..........................................................................................................................................81

Firmware: V2.18 / V--

26.10.2022

5/119

9.3.5.1 Status LEDs ...........................................................................................................................................82

9.4 Replacing the battery...........................................................................................................................83

9.5 Firmware Update ..................................................................................................................................85

9.5.1 Requirements for firmware update.........................................................................................................85

9.5.2 Update der aktuellen Firmware ..............................................................................................................86

10 Connection and terminal assignment GLT x010 / SIOX....................................................................89

10.1 Assignment of all inputs and outputs ................................................................................................89

10.2 Connections for 230 V AC (top) ..........................................................................................................90

10.2.1 Assignment of the 230 V AC power supply ............................................................................................91

10.2.2 Assignment of the digital inputs - 230 V AC / 24 V AC/DC.....................................................................92

10.2.2.1 Configuration of the digital inputs 230 V AC and 24 V AC/DC ...............................................................95

10.2.3 Assignment of the relay outputs - 230 V AC / 24 V AC/DC ....................................................................96

10.3 Connections for safety extra-low voltage (bottom) ..........................................................................99

10.3.1 Assignment of the analogue inputs ......................................................................................................100

10.3.2 Assignment of the analogue outputs....................................................................................................103

10.4 Connections for interfaces (on the side) .........................................................................................104

10.4.1 CAN Bus Assignment ...........................................................................................................................105

10.4.2 Assignment RS232 and TTY................................................................................................................106

10.4.3 Assignment RS485...............................................................................................................................107

10.4.3.1 Assignment Modbus Modules ..............................................................................................................108

10.4.4 Assignment SIOX .................................................................................................................................110

11 Manual / Automatic operating modes changeover ......................................................................... 111

12 Decommissioning and Disposal .......................................................................................................112

12.1 Decommissioning / Dismantling.......................................................................................................112

12.2 Disposal ..............................................................................................................................................112

13 Alarms and Messages GLT x010.......................................................................................................113

13.1 Message system.................................................................................................................................113

13.2 Structure of the messages ................................................................................................................113

13.3 Message types....................................................................................................................................114

13.4 Setting the priorities ..........................................................................................................................115

14 Technical Data GLT x010 / SIOX........................................................................................................116

14.1 Electrical Data GLT x010 / SIOX ........................................................................................................116

14.2 Mechanische Daten GLT x010...........................................................................................................118

14.3 Mechanical Data SIOX Extension Module........................................................................................118

15 Part numbers and accessories GLT x010 ........................................................................................119

Firmware: V2.18 / V--

26.10.2022

6/119

•

•

•

•

•

1 Conventions

1.1 Warning signs, symbols and text formatting used in this manual

Explanation of the warning signs, symbols and text formatting used in this operating and service manual:

DANGER

WARNING

CAUTION

*IfanyofthesesymbolsDANGER/WARNING/CAUTION is recognized, the user must refer to the operating

manual in order to understand the type of potential HAZARD and the required actions for avoiding the

HAZARD. Carefully observe all health and safety instructions and use particular caution in these situations.

Failure to observe the DANGER/WARNING/CAUTION symbols will cause injury (in the worst case,

severe injury or death) and/or damage to property!

ATTENTION

NOTICE

DANGER

Instructions with this symbol and/or the signal word DANGER warn the user of situations that will

cause severe injury or death if the specified instructions are not observed! *

WARNING

Instructions with this symbol and/or the signal word WARNING warn the user of situations that may

cause severe injury or death if the specified instructions are not observed! *

CAUTION

Instructions with this symbol and/or the signal word CAUTION warn the user of situations that may

cause moderate or minor injury if the specified instructions are not observed! *

ATTENTION

Instructions with this symbol and/or the signal word ATTENTION warn the user of situations that may

cause damage to property if the specified instructions are not observed! The ATTENTION symbol

highlights guidelines and regulations, instructions and proper working procedures that must be

particularly observed in order to prevent damage to and destruction of components or malfunctioning.

Failure to observe the ATTENTION symbol will cause damage to property!

NOTICE

Instructions with this symbol and/or the signal word NOTICE provide tips and useful additional

information.

Firmware: V2.18 / V--

26.10.2022

7/119

•

•

•

1.

2.

3.

4.

1.

2.

ELECTRIC SHOCK

Risk of fatal electric shock!

This symbol warns of danger from dangerous voltage with possible consequences such as severe injury and death. If this symbol

is seen, the user must refer to the operating manual in order to understand the type of potential HAZARD and the required actions

for avoiding the HAZARD. Carefully observe all health and safety instructions and use particular caution in these situations.

Failure to observe the WARNING symbol will cause injury (in the worst case, severe injury or death) and/or damage to

property!

ESD - Electrostatic-sensitive components and control components

DISPOSAL

Potential negative impact on people and the environment due to non-environmentally friendly disposal.

The strike-through dustbin symbol indicates the duty to dispose of items properly. Do not dispose of this product with other

domestic waste, see chapter Disposal. Please inform yourself about the local regulations for the separate disposal of electrical and

electronic products. The correct disposal of your old equipment protects people and the environment from possible negative

impact.

1.2 Explanation of text formatting

Safety instructions or hazard warnings are composed of four elements:

Thesymbol with text (e.g. for DANGER),

a concise description of the hazard and

a description of the possible consequences.

Where applicable, a catalogue with measures for avoiding the hazard.

For example:

A general instruction consists of two elements:

Thesymbol with text (including NOTICE, if applicable) and

the text of the instruction:

For example:

Risk of destruction of the control component / controller!

Electronic components and control components (e.g. circuit boards) are sensitive to electrostatic charges. Circuit boards may only

be replaced when the power supply is disconnected. Always hold circuit boards by the edges. The guidelines for the handling of

electrostatic-sensitive components and control components must be observed at all times.

Failure to observe the ESD symbol will cause damage to property!

Failure to observe the DISPOSAL symbol will cause damage to people and the environment!

DANGER

Warning of dangerous electrical voltage! Risk of fatal electric shock!

Beware of external voltage at the digital inputs and outputs! Connections/plug connectors of the device

may only be plugged in, removed and/or wired when no voltage is present.

NOTICE

The current operating manual is available online from the E°EDP (Eckelmann ° Electronic

Documentation Platform) at www.eckelmann.de/elds.

Firmware: V2.18 / V--

26.10.2022

8/119

•

•

•

•

•

•

•

•

•

•

•

•

2 Safety instructions

This operating manual is part of the device. It must be kept in the vicinity of the controller as well as for future

use so that it can be consulted when required. The operating manual must be available to the operating and

maintenance personnel at all times in order to avoid operating errors. The safety regulations, instructions and

information must be strictly observed and complied with. During repairs on the entire E*LDS system, the

accident prevention regulations and general safety regulations must be strictly complied with. Important

information (safety instructions and hazard warnings) are indicated by appropriate symbols, see chapter

Conventions. Follow these instructions in order to prevent accidents and danger to life and limb, as well as

damage to the E*LDS system!

Always observe the following information:

Workontheelectricalsystemmayonlybeperformedbyauthorised, skilled personnel (accordingtothe

definition of skilled persons in DIN/VDE 0105 and IEC364) while observing the applicable

- VDE regulations

-Localsafetyregulations

-Intended Use

-FivesafetyrulesaccordingtoDGUVRegulation3

-ESDmeasures

-Operatingmanuals

For safety reasons, the equipment must not be used for any applications other than described in the

operating manual and only for the intended use.

Before using the device, check whether it is suitable for your application with regard to its limit values.

The equipment must be installed in an electrically shielded area within the switch cabinet.

Before connecting the device, it must be checked whether the power supply is suitable for the device.

Coded connectors must be used, as there is a possibility of plugging in non-coded connectors in such a

way that there is a danger to life and limb!

Specified ambient conditions (e.g. humidity and temperature limits, see chapter Technical Data) must be

observed and complied with at all times to prevent malfunction.

Before switching on the device, check the correct wiring of the connections.

The device must never be operated without its housing. If the intended use requires opening the housing,

the control unit must be disconnected from the power supply before opening the housing.

Note the maximum load of the relay contacts, see chapter Technical Data.

Note that all supply lines from and to the device, particularly those of the CAN bus and Modbus, must be

shielded or installed sufficiently far away from live cables. This prevents faulty measurements and protects

the device against electrical interference via the analogue inputs. Connection in parallel of RC elements is

recommended for applications with critical environment.

Contact the supplier in the case of any malfunction.

DANGER

Warning of dangerous electrical voltage! Danger of electric shock!

Beware of external voltage at the digital inputs and outputs! Connections/plug connectors of the device

may only be plugged in, removed and/or wired when no voltage is present.

Firmware: V2.18 / V--

26.10.2022

9/119

2.1 Disclaimer in the event of non-compliance

These operating instructions contain information on the commissioning, function, operation and maintenance

ofthecontrolsandoftheassociatedcomponents.

2.2 Requirements for the personnel

Special technical knowledge is required for planning, programming, installation, putting into service and

maintenance work. This work may only be performed by skilled, specially trained personnel. The installation,

putting into service and maintenance personnel must have training that authorises them to perform

interventions in the system and the automation system. The planning and programming personnel must be

familiar with the safety concepts of automation technology. Working on electrical systems requires special

technical knowledge. Work on electrical systems may only be performed by instructed electrically skilled

persons or under the guidance or supervision of such persons. The applicable regulations (e.g. DIN EN 60204,

EN 50178, DGUV Regulation 3, DIN-VDE 0100/0113) must be observed. The operating personnel must be

instructed in how to handle the system / machine and the controller and must be familiar with the operating

instructions.

ATTENTION

Warning of damage to goods!

In our experience, the transmission of fault messages is not yet functional during the putting into

service (no internet connection, no telephone line installed, etc.). It is strongly recommended in such

cases to monitor the controller via the CAN bus using a system centre, a store computer or an operator

terminal and to enable the transmission of fault messages, for example using a GSM modem via a

mobile telephone system. In standalone operation, or as an alternative to monitoring via system

centre / store computer / operator terminal, an available alarm contact on the controller must be used

to enable the transmission of fault messages via a telephone network.

For more information, refer to E*LDS basics, safety instructions, CAN bus & Modbus.

Observance of these operating instructions is a prerequisite for safe and trouble-free operation.

Firmware: V2.18 / V--

26.10.2022

10/119

•

•

•

•

•

•

•

•

•

•

•

•

•

2.3 Intended Use

The controller GLT x010 must be used exclusively as a freely programmable controller for building automation

and for the automation of commercial and industrial refrigeration systems. It is used to receive digital and

analogue signals from sensors and output them to actuators, forward them to higher-level controllers and/or

process the signals. The controller is designed for a working environment that is compliant with protection class

IP20.Therearefingerprotectionandprotectionagainstsolidforeignbodies≥12.5mm,butnoprotection

against water.

The following use is not permitted:

in wet or dusty environments

in potentially explosive atmospheres

in aircraft, rail vehicles and ships

in medical devices and facilities

in devices and systems that are used for military purposes

for the realisation of safety functions, e.g. safe stop

Read the safety instructions and the instructions for installation and putting into service, operation and

maintenance. THEN start the commissioning and/or operation of the machine / system.

The safety and functionality of the machine / system are only guaranteed for this intended application.

Never use the machine / system, its components, control components or parts for any other purpose.

The system must not be put into operation until conformity with the applicable EU Directives has been

established for the entire system.

2.4 Five safety rules according to DGUV Regulation 3

The following rules must be strictly observed!

1.Disconnect:The entire system to be worked on must be disconnected from the power supply at all poles.

2. Secure against reconnection: Attach information signs to the disconnected operating equipment stating:

What has been disconnected.

Reason for the disconnection.

Name of the person who made the disconnection.

Reconnection must be prevented using a suitable lock (e.g. padlock).

3. Prove dead (authorised skilled personnel only):

Check voltmeter just before use.

Prove dead on all poles at the disconnection point.

Prove dead on all poles at the work area.

4. Ground and short-circuit:Allelectricalpartsattheworkareamust be grounded and then short-

circuited.

5. Cover or block off adjacent live parts:Ifthereisliveequipmentadjacenttotheworkarea,itmustbe

covered using appropriate materials (e.g. insulation blankets / plates).

DANGER

Warning of dangerous electrical voltage! Warning of dangerous electrical voltage! Danger of

electric shock!

Beware of a possible external power supply! BEFORE connecting and disconnecting it must be

checked that no voltage is present at the controller! Connections/plug connectors of the device may

only be plugged in, removed and/or wired when no voltage is present.

Firmware: V2.18 / V--

26.10.2022

11/119

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

2.5 Electrostatic-sensitive components and control components (ESD)

All electrostatic-sensitive components and control components (referred to as "ESD" below) are labelled with

the warning sign shown. Electrostatic charges arise from friction of insulating materials (e.g. floor covering,

items of clothing made of synthetic fibres etc.). Even small charges can result in damage to or destruction of

components. Such damage is not always immediately noticeable; in some cases, it does not lead to failure until

after a certain operating time.

2.6 EGB - Richtlinien zur Handhabung

Transport and store ESDs only in the protective packaging provided.

Avoid materials that may produce electrostatic discharge, for example

Plastic containers and table tops

Synthetic fibre clothing

Plastic-soled shoes

Plastic file covers

Styrofoam packaging

Computer monitors, etc.

Preferably wear the following:

Cotton work clothes

ESD shoes with conductive soles or leather soles

Use the following:

Conductive flooring

ESD workstations equipped with suitable tools (grounded soldering guns, antistatic wrist straps, etc.)

Conductive ESD bags, conductive plastic containers, IC tubes or cartons lined with conductive foam

Containers and worktops made of wood, metal or conductive plastics or paper bags

2.7 Abbreviations Used

DGUV Regulation 3 - Accident Prevention Regulation for Electrical Systems and Equipment

(previously: BGV A3-Employer’sLiabilityAssociationRegulationforOccupationalHealthandSafety)

DINDeutschesInstitutfürNormunge.V.(GermanStandardisationInstitute)

E°EDP/EDP Electronic Documentation Platform of Eckelmann AG

ESDElectrostatic-SensitiveDevice

ESDElectro-staticdischarge(ElectroSensitiveDevices)

IECInternationalElectricCommittee

VDEVerbandderElektrotechnikElektronikInformationstechnike.V.(GermanAssociationforElectrical,

Electronic and Information Technologies)

ATTENTION

Risk of destruction of the control component / controller! Electronic components

and control components (e.g. circuit boards) are sensitive to electrostatic

charges.Therefore, the guidelines for handling electrostatic-sensitive components and

control components must be strictly observed.

Firmware: V2.18 / V--

26.10.2022

12/119

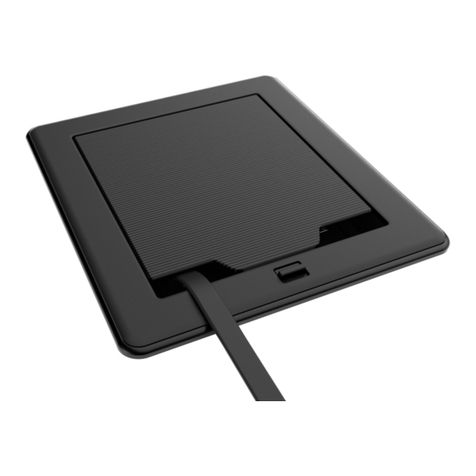

3 System design GLT x010

Base module GLT 3010 / GLT 5010

The freely programmable Compact GLT x010 is available in the GLT 3010 and GLT 5010 versions. They have

the same hardware, they only differ in their firmware, see chapter GLT x010 models. The base module consists

of an analogue input/output module (lower board) and a digital input/output module (upper board). The

interfaces for communication are located on the left side, for details see chapter Connections. The controller is

a modular design and can be extended with a maximum of 3 SIOX extension modules, see chapter SIOX

Extension Module.

SIOX Extension Module

The controller can be programmed with the programming system CODESYS according to IEC61131-3 and

operated and parametrised with the LDSWin PC software.

Firmware: V2.18 / V--

26.10.2022

13/119

•

•

•

3.1 Connections

Base module connections

Top view - for details, see Connectionsfor230VAC(top)

Digital inputs

23 x input 230 V AC / 24 V AC/DC

Relay outputs

6 x normally open contact 230 V AC

4 x changeover contact 230 V AC

Bottom view - for details, see Connections for safety extra-low voltage (bottom)

Analogue Inputs / Outputs

2xPt1000input-4-wirePt1000temperaturesensorconnection

13 x Pt1000 input - 2-wire Pt1000 temperature sensor connection

7 x input / 4-20 mA (0..10 V) - e.g. valve feedback; CO2sensor; flow / pressure sensor

4xoutput/0-10V(4..20mA)-e.g.continuousvalveactuators;connectionofaspeedcontrollerforspeed-

controlled motors

Firmware: V2.18 / V--

26.10.2022

14/119

•

•

Side view - for details, see Connections for interfaces (on the side)

Interfaces

CAN bus: Communication in the E*LDS system

RS232: Interface for firmware update

RS485: Modbus RTU

TTY:currentlywithoutfunction

SIOX OUT: connection for data transfer to the SIOX extension modules

SIOX Supply

power supply for SIOX extension modules

Firmware: V2.18 / V--

26.10.2022

15/119

•

•

•

•

SIOX extension module connections

Top view - for details, see Connectionsfor230VAC(top)

Digital inputs

12 x input 230 V AC / 24 V AC/DC

Relay outputs

6 x normally open contact 230 V AC

4 x changeover contact 230 V AC

Side view - for details, see Connections for interfaces (on the side)

Interfaces

SIOX IN: connection for data transfer to the base module

SIOX OUT: connection for data transfer to the SIOX extension modules

SIOX Supply

power supply for SIOX extension modules

The detailed device and terminal assignments of the controller GLT 3010 E are listed in the chapter

Connection and terminal assignment GLT x010 / SIOX.

Firmware: V2.18 / V--

26.10.2022

16/119

•

•

•

•

3.2 GLT x010 models

The GLT 3010 and the GLT 5010 only differ in their firmware. The main features are:

Compared to the GLT 3010, the GLT 5010 can embed the GLT channel configuration "glt.cfg" (data point

description) in the user application running on it. Compared to the GLT 3010, there is no longer a separate

"glt.cfg" file that has to be manually imported into the system centre. In addition, the Virtus 5 can then manage

more data points per GLT 5010.

The current procedure for importing the GLT-3010 configuration is to import it into the system centre via

LDSWin. This currently results in the following disadvantages:

The GLT configuration "glt.cfg" contains all data points about all GLT 3010 controllers that are in the system.

The GLT 3010 controllers can also be located in different maintenance groups, e.g. in the "building

management system" group and in the "refrigeration" group for heat recovery. In the case of any change, it

must be ensured that the corresponding Signal Lists for all maintenance groups have been merged before

importing.

In the case of any change in the CODESYS project of the GLT 3010 and the possibly resulting changes in

the data points, it must currently be ensured that the corresponding GLT configuration is also available in

the system centre or is imported subsequently. If this is not the case, then incorrect or implausible actual

and setpoint values are displayed in LDSWin because the GLT configuration does not match the CODESYS

project of the GLT 3010.

The new concept envisages that the GLT channel configuration is embedded in the CODESYS project of the

controller.

TheconcepthasbeenimplementedintheVirtus5seriessystemcentreandGLT5010,formoredetailsabout

these aspects, see chapter Compatibility. The hardware of the GLT 3010 controller is not affected, i.e. a GLT

3010 controller can be transformed into a GLT 5010 controller via a firmware upgrade. The following are

created from the EXCEL Signal List with the GLT channels for a DDC using the Signal List Tool

the files of the PLC code for the CODESYS project and

file of the GLT channel configuration (glt.cfg)

The GLT channel configuration is then integrated into the CODESYS project and is stored in the controller after

import. The GLT channel configuration is then transmitted via CAN bus to the system centre and is stored there.

When a connection is established, LDSWin retrieves all available GLT configurations and displays them in the

usualway.

Firmware: V2.18 / V--

26.10.2022

17/119

•

•

•

3.2.1 Number of data points

A maximum of 4 controllers of the type GLT x010 can be used system-wide in the E*LDS system.

GLT 3010:

The system centre can manage a total of 600 data points system-wide (150 per controller) and archive a

maximum of 255 data points.

GLT 5010:

The system centre can manage a total of 2000 data points system-wide (500 per controller) and archive a

maximum of 1020 data points (255 per controller).

3.2.2 Synchronisation

In this chapter, the aspects of synchronisation of the GLT channel configurations of the GLT 5010 and the

system centre will be covered.

Synchronisation from the perspective of the system centre

In the case of a first start or a restart of the system centre, the system centre will query the GLT channel

configuration of all existing GLT 5010 controllers in the field and persist if necessary.

Synchronisation from the perspective of the GLT 5010

In the case of a restart of the GLT 5010 or a change in the GLT channel configuration in the GLT 5010, the GLT

5010 sends its GLT channel configuration to the system centre automatically.

3.2.3 Compatibility

The new functionality is already integrated in the Virtus 5 series and GLT 5010. A suitable LDSWin version that

supports the necessary functionalities is required for this. A system centre in the CI 4000 series can be

converted into an equivalent system centre in the CI 5000 series by purchasing an upgrade.

New installation

Due to the larger data volumes, the Virtus 5 series will no longer support the CAN BUS PC adapter

("Netporty") in the future.

In the case of new installations with a system centre in the CI 5000 series, GLT 5010 controllers must

be used in order to be able to use the concept with the separate GLT configurations.

Firmware: V2.18 / V--

26.10.2022

18/119

•

•

•

Existing installations

In the case of existing installations with an installed system centre CI 4x00, it is not possible to use GLT 5010

controllers. The separation of GLT configurations is not supported in the CI 4000 series and GLT 3010. Also, in

the case of replacement of a defective GLT 3010 controller, it must be replaced by a GLT 3010 controller again.

Backward compatibility

The two concepts are mutually interlocked in the system centre of the CI 5000 series; mixed operation is not

possible. The support of the concept of separate GLT configurations is exclusively implemented in the system

centre of the CI 5000 series, i.e. depending on the connected components, either the old previous GLT concept

or the new GLT concept with separation of the GLT configurations is supported. The rules for interlocking are

defined as follows:

If an "old" GLT configuration is stored in the system centre, then the old, previous GLT concept is active.

If a GLT 5010 controller is active on the CAN bus and no "old" GLT configuration has been imported into the

system centre, then the new GLT concept is active.

If a GLT 5010 controller is active on the CAN bus and the component is managed as a participant in the

system centre, it is no longer possible to import the "old" GLT channel configuration into the system centre

via LDSWin.

Nevertheless, if mixed operation of the GLT 5010 controller and GLT 3010 controller takes place, then this is

escalated accordingly via system messages in the system centre; there is - for the components of the variant

that was added later - only "node guarding" (participant monitoring on the CAN bus) of the components.

The rules mentioned below should be understood analogously. If other parameters or indicators are

more suitable for detection, these can be selected after consultation.

Firmware: V2.18 / V--

26.10.2022

19/119

•

•

•

•

•

•

•

•

•

•

•

•

4 Tasks of the GLT x010

The controller GLT x010 is a freely programmable DDC (Direct Digital Control) according to IEC 61131-3. IEC

61131-3 includes the following languages:

Abbreviation Description Note

STL Statement List Text: A sequence of mnemonics and operators like in assembler

LAD Ladder Logic Graphic: Resembles an electrical wiring diagram lying on its side

FBD Function Block Diagram Graphic: Reminiscent of logic plans

SFC Sequential Function Chart Graphic: Sequence chains comparable with Petri nets

ST Structured Text Text: A high level language with the syntax of PASCAL

The programming environment used is CODESYS from 3S1) which is supplied with standard libraries. These

contain ready-made modules such as PID controllers, timers, counters, triggers, flip-flops, mathematical

modules, etc. With CODESYS, almost object-oriented programming with declaration of types and the use of

individual types in any number of independent instances is possible.

CODESYS has yet another powerful language that complements IEC 61131-3:

Abbreviation Description Note

CFC Continuous Function Chart. Free

graphical function block diagram editor.

The graphical function blocks can be freely arranged in the editor as in

an RI Flowchart. Feedbacks are allowed.

1): Protected trademark, see bibliography.

For individual control applications, e.g. in the field of refrigeration and building automation, the following

functions can be realised with the controller in combination with Virtus 5 and LDSWin:

Control functions

Regulation functions

Fault reporting

Fault archiving

Monitoring functions

Archiving functions

These functions depend on the individual programming of the controller.

Applications (examples)

Monitoring of safety equipment

Controls and regulation of heating circuits with monitoring of pumps and valves

Weather management

Hot water preparation, especially via heat recovery

Individual heat pump control systems

Integration of third party controllers via Modbus RTU

Firmware: V2.18 / V--

26.10.2022

20/119

5 Functions of the GLT x010 and set-up

5.1 Implementation

The freely programmable controller is shipped from the factory without application functions. There is no

application loaded. All relay outputs are switched off. In contrast, the inputs are constantly read in even when

the application is missing or stopped. The values can be visualised with LDSWin.

If the application is missing or stopped, the life lamp (life LED) on the lower circuit board lights intermittently

(periodically on for approx. 3 s and off for 0.3 s).

Only the firmware that has the following functions is installed at the factory:

1. Install firmware - with and without applications

A function that allows installing a new firmware via the serial interface RS232. There are two versions of the

software installed on delivery:

a. Firmware without application

b. Firmware with application

2. Provision of the interfaces for CODESYS

a. RS232 - only for the CODESYS programming system

b. RS485 - only for Modbus RTU

c. CAN bus - only for the E*LDS system

d. EEPROM - for the non-volatile saving of setpoints

e. real-time clock

3. Cycle control and management of the process image (PI)

The procedure for installing a new firmware with or without applications is identical to that of a firmware

update.

1.

2.

The following must be ensured when starting up:

The desired CODESYS application has been loaded into the controller.

All manual control switches have been set to a position that is appropriate for the process, see

chapter Manual / Automatic operating modes changeover.

This manual suits for next models

1

Table of contents