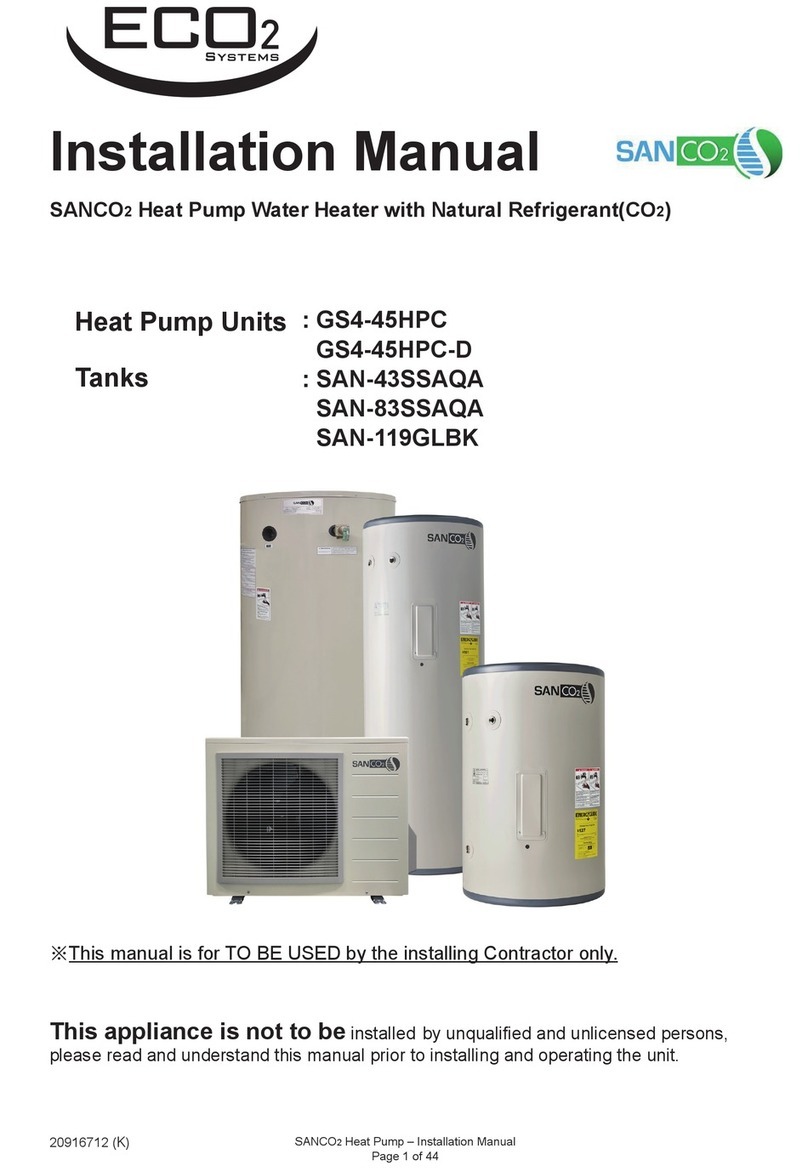

ECO2 Systems SANCO2 SAN-43SSAQA User manual

SANCO2Heat Pump – Owner’s Manual

Page 1 of 28

Sanden Heat Pump –Installation Manual

Page 1 of 40

.

Page title

Covering model numbers for residence

Heat Pump Unit GS3-45HPA-US

This appliance is not to be installed by unqualified and unlicensed persons,

please read and understand this manual prior to installing and operating the unit.

※This manual is for TO BE USED

by the installing Contractor

only.

20916702 (K)

Sanden Heat Pump –Owner’s Manual

Page 1 of 24

Page title

Covering model numbers for residence

Heat Pump Unit GS3-45HPA-US

This appliance is not to be installed by unqualified and

unlicensed persons, please read and understand this manual

prior to installing and operating the unit.

OOwwnneerr’’ss mmaannuuaall

Owner’s Manual

SANCO2Heat Pump Water Heater with Natural Refrigerant(CO2)

Heat Pump Units

Tanks

: GS4-45HPC

GS4-45HPC-D

: SAN-43SSAQA

SAN-83SSAQA

SAN-119GLBK

This appliance is not to be used by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge,

unless they have been given supervision or instruction.

Children being supervised not to play with the appliance.

This appliance is not to be installed by unqualied and

unlicensed persons, please read and understand this manual

prior to installing and operating the unit.

SANCO2Heat Pump – Owner’s Manual

Page 2 of 28

PATENTS

This water heater may be protected by one or more patents or registered designs in the name of ECO2 System LLC

TRADE MARKS

® Registered trademark of ECO2 Systems LLC

Note: Every care has been taken to ensure accuracy in preparation of this publication.

No liability can be accepted for any consequences that may arise as a result of its application.

Contents

Page title …………………………………………………………………………………………………… 1

Contents …………………………………………………………………………………………………… 2

Introduction………………………………………………………………………………………………… 3

How It Works……………………………………………………………………………………………… 3

Installation Details ……………………………………………………………………………………… 8

Trouble Shooting Guide …………………………………………………………………………… 9

Error Codes ……………………………………………………………………………………………… 10

Filling the System & Bleeding Air ……………………………………………………………… 11

Mains Power/Electrical Installation …………………………………………………………… 12

Electrical Connections ……………………………………………………………………………… 12

How to Connect Main Power …………………………………………………………………… 13

How to Connect Thermistor Cable …………………………………………………………… 14

Standard System Operation ……………………………………………………………………… 14

System Operation If Connected to Dry Contact ………………………………………… 15

Water Supply Quality ………………………………………………………………………………… 16

Technical Data …………………………………………………………………………………………… 17

Warranty Policy ………………………………………………………………………………………… 19

Registration for Warranty …………………………………………………………………………… 24

Memo ………………………………………………………………………………………………………… 25

SANCO2Heat Pump – Owner’s Manual

Page 3 of 28

Sanden Heat Pump – Owner’s Manual

Page 3 of 20

Introduction

The Sanden Heat Pump Water Heater System has been designed using the latest

refrigeration technology to remove the heat from the air to heat water. The refrigerant we

use is CO

2

which does not contribute to global warming so it allows us to help keep a clean

healthy earth for future generations.

We have also considered the power requirement. By using CO

2

as the refrigerant we have

produced one of the most energy efficient units currently available. It’s even more efficient

when connected to off-peak power

and the noise level is so low it will operate

unobtrusively throughout the night.

How it works

The Heat Pump Water Heater System heats water by transferring the heat from the

surrounding air to the water using a refrigerant. The refrigerant is heated by a heat

exchanger that absorbs heat from the surrounding air (Figure 1).

Figure 1: Heat Pump Water Heater System

Note: Operating conditions may vary depending on the type of off-peak tariff that is

available in your area. The unit must have a minimum of 5 hours continuous power

available at all time to allow the unit to operate without affecting reliability.

63

Sanden Heat Pump –Owner’s Manual

Page 3 of 24

Introduction

The Sanden Sanco2 Heat Pump Water Heater System has been designed using the latest

refrigeration technology to remove the heat from the air to heat water. The refrigerant used

is CO2 which does not contribute to global warming so it allows us to help keep a clean

healthy earth for future generations.

We have also considered the power requirement. By using CO2 as the refrigerant, we have

produced one of the most energy efficient units currently available. It is even more efficient

when connected to demand response power and the noise level is so low it will operate

unobtrusively throughout the night.

How it works

The Sanden Sanco2 Heat Pump Water Heater System heats water by transferring the heat

from the surrounding air to the water using a refrigerant. The refrigerant is heated by a

heat exchanger that absorbs heat from the surrounding air (Figure 1).

Figure 1: Heat Pump Water Heater System

Note:

The unit must have a minimum of 5 hours continuous power available at all time to allow

the unit to operate without affecting reliability.

SANCO2

How It Works

Air bleeding valves

145°F

(63°C)-

Cold Water & Hot Water Connections on Tank shown are only 3/4" NPT size on SAN-

43SSAQA & SAN-83SSAQA Tanks

SANCO2Heat Pump – Owner’s Manual

Page 4 of 28

■The extent of the possible harm or damage caused by misuse of the product falls into the following classications.

Danger Indicates an imminently hazardous situation that will result in death

or serious injury in case it is not avoided.

Warning The column with this classication indicates “the extent of harm that

includes the possibility of death or serious injury”.

Caution The column with this classication indicates “the extent of harm/damage

that includes the possibility of injury or damage to property”.

■The type of content to be observed can be explained with the following pictorial classications.

Indicates content requiring “attention”.

Indicates content that is prohibited.

Indicates content with “instructions” that need to be fully followed.

Sanden Heat Pump – Owner’s Manual

Page 4 of 20

Do not touch the tap while hot water is being

supplied

Hot water heater temperature over 125°F can cause severe burns instantly or death from scalding.

Children, disabled and elderly are at the highest risk of scalding.

Feel water temperature before bathing or showering.

Temperature Time to Produce a Serious Burn

120°F(49°C) More than 5minutes

125°F(52°C) 1-1/2 to 2minutes

130°F(54°C) About 30 seconds

135°F(57°C) About 10 seconds

140°F(60°C) Less than 5 seconds

145°F(63°C) Less than 3 seconds

150°F(66°C) About 1-1/2 seconds

155°F(68°C) About 1 second

Teble courtesy of Shriners Burn Institute

Danger

HOT!!

BURN

SANCO2Heat Pump – Owner’s Manual

Page 5 of 28

If the water heater has been subjected to re, ood, natural disasters or physical damage, DO NOT operate the

water heater again until it has been checked by a qualied service technician.

Failure to do so will cause injury.

Hydrogen gas can be produced in a hot water tank served by this water heater that has not been used for two

weeks or more. Hydrogen gas is extremely dangerous since it is ammable.

It is recommended to open the water faucet for few minutes before using any electrical appliance connected to

the hot water system.

If hydrogen gas is stored inside of a tank, there is a noise of air bleeding, in case that sound is heard, please do

not use re around the unit.

Sanden Heat Pump – Owner’s Manual

Page 4 of 20

Do not touch the tap while hot water is being

supplied

Do not touch the faucet while hot water is being

supplied.

Warning

Please wear gloves when you touch unit.

SANCO2Heat Pump – Owner’s Manual

Page 6 of 28

Sanden Heat Pump – Owner’s Manual

Page 5 of 20

LPG

・Please contact the Dealer about insulating the pipes.

・Contact the Dealer for repair.

Warning

SANCO2Heat Pump – Owner’s Manual

Page 7 of 28

Sanden Heat Pump – Owner’s Manual

Page 6 of 20

Check the installation conditions of the unit.

Installation of the unit in the following places could result

in accidents or failure and the performance of the unit

not being guaranteed.

· Anywhere the lowest temperature reached is below

minus 10 degrees centigrade

· Indoors (Applies only to the heat pump unit)

· Anywhere not completely flat, unstable or where

drainage is difficult

· Ensure not to put anything around the heat pump unit.

Could result in poor performance and unexpected

problems.

In the winter in particular please pay attention to any

snow coverage.

Could significantly i

nfluence performance and lead to failure.

Please select a place where noise an

d vibration while operating will

not bother your neighbours.

Could harmfully inuence performance and lead to failure.

Caution

· Wipe the unit with a soft dry cloth and do not use

chemical items when cleaning.

· Do not use gasoline, benzene, thinners, or any polishing

compounds.

Check the installation conditions of the unit.

Installation of the unit in the following places could result

in accidents or failure and the performance of the unit

not being guaranteed.

· Anywhere the lowest temperature reached is under

14 degrees Fahrenheit

· Indoors (Applies only to the heat pump unit)

· Anywhere not completely at, unstable or where

drainage is difcult

· Ensure not to put anything around the heat pump unit.

Could result in poor performance and unexpected problems.

In the winter in particular please pay attention to any

snow coverage.

SANCO2Heat Pump – Owner’s Manual

Page 8 of 28

Sanden Heat Pump –Installation Manual

Page 4 of 40

Installation details

This Sanden SANCO₂ Heat Pump Water Heater System must be installed by licensed

personnel in accordance with local building codes:

Installing contractor should be licensed by applicable state/province and municipal

authorities to install an Electrical & Plumbing product.

The unit has been designed for heating potable domestic hot water. Any other

usage, such as use for DHW in combination with space heating requires both a

heat exchanger suitable for local codes to be installed on the system to separate

potable and non-potable water and consultation with Sanden.

The unit is designed to operate when connected to the water supply with a

maximum operating pressure of 95PSI (655 kPa). To ensure the mains pressure

does not exceed this, first check incoming cold water mains pressure, and then a

pressure regulating device must be connected to the water supply line.

This system delivers hot water exceeding 120 oF (50 oC).

Installation of a temperature tempering device is MANDATORY to avoid potential

scalds and burns.

The unit must be stored and transported in an upright position. Failure to do so may

render the unit faulty. Such failure is not covered under any warranty agreements.

Failure to comply with the above conditions will void the warranty.

ECO2 Systems.

Sanden Heat Pump –Owner’s Manual

Page 7 of 24

Installation details

This Sanden Eco Hot water Heat Pump System must be installed by licensed personnel in

accordance with local building codes:

Installing contractor should be licensed by applicable state/province and municipal

authorities to install an Electrical & Plumbing product.

The unit has been designed for heating potable domestic hot water and any other

usage, such as space heating requires a heat exchanger suitable for local codes to

be installed on the system to separate potable and non-potable water.

The unit is designed to operate when connected to the water supply with a

maximum operating pressure of 95PSI (655 kPa). To ensure the mains pressure

does not exceed this, first check incoming cold water mains pressure, and then a

pressure regulating device must be connected to the water supply line.

This system delivers hot water exceeding 120 oF (50 oC).

Installation of a temperature tempering device is MANDATORY to avoid potential

scalds and burns.

The unit must be stored and transported in an upright position. Failure to do so may

render the unit faulty. Such failure is not covered under any warranty agreements.

Failure to comply with the above conditions will void the warranty.

California Proposition 65 WARNING

This product contains chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

Sanden Heat Pump –Installation Manual

Page 4 of 40

Installation details

This Sanden SANCO₂ Heat Pump Water Heater System must be installed by licensed

personnel in accordance with local building codes:

Installing contractor should be licensed by applicable state/province and municipal

authorities to install an Electrical & Plumbing product.

The unit has been designed for heating potable domestic hot water. Any other

usage, such as use for DHW in combination with space heating requires both a

heat exchanger suitable for local codes to be installed on the system to separate

potable and non-potable water and consultation with Sanden.

The unit is designed to operate when connected to the water supply with a

maximum operating pressure of 95PSI (655 kPa). To ensure the mains pressure

does not exceed this, first check incoming cold water mains pressure, and then a

pressure regulating device must be connected to the water supply line.

This system delivers hot water exceeding 120 oF (50 oC).

Installation of a temperature tempering device is MANDATORY to avoid potential

scalds and burns.

The unit must be stored and transported in an upright position. Failure to do so may

render the unit faulty. Such failure is not covered under any warranty agreements.

Failure to comply with the above conditions will void the warranty.

Installation Details

if the Cold

Water mains pressure is above 75 PSI.

Sanden Heat Pump –Installation Manual

Page 4 of 40

Installation details

This Sanden SANCO₂ Heat Pump Water Heater System must be installed by licensed

personnel in accordance with local building codes:

Installing contractor should be licensed by applicable state/province and municipal

authorities to install an Electrical & Plumbing product.

The unit has been designed for heating potable domestic hot water. Any other

usage, such as use for DHW in combination with space heating requires both a

heat exchanger suitable for local codes to be installed on the system to separate

potable and non-potable water and consultation with Sanden.

The unit is designed to operate when connected to the water supply with a

maximum operating pressure of 95PSI (655 kPa). To ensure the mains pressure

does not exceed this, first check incoming cold water mains pressure, and then a

pressure regulating device must be connected to the water supply line.

This system delivers hot water exceeding 120 oF (50 oC).

Installation of a temperature tempering device is MANDATORY to avoid potential

scalds and burns.

The unit must be stored and transported in an upright position. Failure to do so may

render the unit faulty. Such failure is not covered under any warranty agreements.

Failure to comply with the above conditions will void the warranty.

75PSI (520 kPa).

SANCO2Heat Pump – Owner’s Manual

Page 9 of 28

Sanden Heat Pump – Owner’s Manual

Page 9 of 20

Trouble Shooting Guide

If you are faced with a problem in using our Hot Water Heat Pump system, please check

the following items, before seeking professional help.

For those problems not listed in the list above, an inspection provided by a skilled engineer

is required. Please contact your local Dealer.

Caution:

Do not turn off the electricity supplied to the heat pump system even if you go away from

home and do not use hot water for a long while.

If the system is equipped with freeze protect heaters, also do not turn off the power supply

to the heaters.

Failure to do so may cause the pipes to crack, due to freezing.

Status Considerable Causes Action to Take

No hot water

comes out of

water tap

Temperature

of hot water is

too low

Small or no hot water is left in

the storage tank.

- Stop using hot water and wait for about 1

hour

- Consider a change of the electricity

supply off-peak mode (Length of power-

supply hours may be too short for the

water heating cycle to cover the hot water

consumption)

Air removing procedure from the

heat pump system may be

insufficient.

- Open the water drain plugs on the Heat

Pump Unit to remove air from water circuit.

(Be careful for burning)

Filter on cold inlet connector may

be blocked.

- Check the filter and remove if there is any

blockage

Water flow speed may be

dropped due to the heat pump

piping bend, blockage or crush.

- Check for any piping bend or crush and

remove if any

Pipes may be frozen. - If frozen area is found on the piping, melt

the ice on the pipe and provide a heat

insulation

Stop valve is closed. - Open the valve

Air absorption is not sufficient

due to a blockage on the

evaporator.

-Remove the object blocking the air flow

through the evaporator

(e.g. fallen leaves, grass, snow, etc.)

For those problems not listed in the list above, an inspection provided by a skilled engineer is

required. Please contact your local distributor.

Caution:

Do not shut the electricity supplied to the Heat Pump system off even if you go away from home

and do not use hot water for a long while.

If the system is equipped with freeze protection heaters, also do not shut the power supply to the

heaters.

Failure to do so may cause a crack on the pipes due to the pipes getting frozen.

Sanden Heat Pump –Owner’s Manual

Page 8 of 24

Trouble shooting guide

If you face a problem while using our Heat Pump water heater system, please check the

following table prior to calling for support.

For those problems not listed above, an inspection provided by a skilled engineer is

required. Please contact the distributor.

Caution:

Do not shut the electricity supplied to the Heat Pump system off even if you go away from

home and do not use hot water for a long while.

If the system is equipped with freeze protect heaters, also do not shut the power supply to

the heaters.

Failure to do so may cause a crack on the pipes due to the pipes getting frozen.

Status

Considerable Causes

Action to Take

No hot water

comes out of

water tap

Temperature

of hot water is

too low

Small or no hot water is left in

the storage tank.

- Stop using hot water and wait for about 1

hour

- Consider a change of the electricity

supply off-peak mode (Length of power-

supply hours may be too short for the

water heating cycle to cover the hot water

consumption)

Air removing procedure from the

heat pump system may be

insufficient.

- Open the water drain plugs on the Heat

Pump Unit to remove air from water circuit.

(Be careful for burning)

Filter on cold inlet connector may

be blocked.

- Check the filter and remove if there is any

blockage

Water flow speed may be

dropped due to the heat pump

piping bend, blockage or crush.

- Check for any piping bend or crush and

remove if any

Pipes may be frozen.

- If frozen area is found on the piping, melt

the ice on the pipe and provide a heat

insulation

Stop valve is closed.

- Open the valve

Air absorption is not sufficient

due to a blockage on the

evaporator.

-Remove the object blocking the air flow

through the evaporator

(e.g. fallen leaves, grass, snow, etc.)

bleeding

bleed air from water circuit.

Sanden Heat Pump –Installation Manual

Page 4 of 40

Installation details

This Sanden SANCO₂ Heat Pump Water Heater System must be installed by licensed

personnel in accordance with local building codes:

Installing contractor should be licensed by applicable state/province and municipal

authorities to install an Electrical & Plumbing product.

The unit has been designed for heating potable domestic hot water. Any other

usage, such as use for DHW in combination with space heating requires both a

heat exchanger suitable for local codes to be installed on the system to separate

potable and non-potable water and consultation with Sanden.

The unit is designed to operate when connected to the water supply with a

maximum operating pressure of 95PSI (655 kPa). To ensure the mains pressure

does not exceed this, first check incoming cold water mains pressure, and then a

pressure regulating device must be connected to the water supply line.

This system delivers hot water exceeding 120 oF (50 oC).

Installation of a temperature tempering device is MANDATORY to avoid potential

scalds and burns.

The unit must be stored and transported in an upright position. Failure to do so may

render the unit faulty. Such failure is not covered under any warranty agreements.

Failure to comply with the above conditions will void the warranty.

Sanden Heat Pump –Installation Manual

Page 4 of 40

Installation details

This Sanden SANCO₂ Heat Pump Water Heater System must be installed by licensed

personnel in accordance with local building codes:

Installing contractor should be licensed by applicable state/province and municipal

authorities to install an Electrical & Plumbing product.

The unit has been designed for heating potable domestic hot water. Any other

usage, such as use for DHW in combination with space heating requires both a

heat exchanger suitable for local codes to be installed on the system to separate

potable and non-potable water and consultation with Sanden.

The unit is designed to operate when connected to the water supply with a

maximum operating pressure of 95PSI (655 kPa). To ensure the mains pressure

does not exceed this, first check incoming cold water mains pressure, and then a

pressure regulating device must be connected to the water supply line.

This system delivers hot water exceeding 120 oF (50 oC).

Installation of a temperature tempering device is MANDATORY to avoid potential

scalds and burns.

The unit must be stored and transported in an upright position. Failure to do so may

render the unit faulty. Such failure is not covered under any warranty agreements.

Failure to comply with the above conditions will void the warranty.

SANCO2Heat Pump – Owner’s Manual

Page 10 of 28

Error

code Error contents

E1 Main PCB error

E2 Control PCB error

E6 Compressor booting error

E7 Fan motor locked

E8 High inlet current error

E9 Water circulation pump error

EC High water outlet error

F3 Discharged temperature error

F5 Communication error between main PCB

to control PCB

FA High pressure side error

H0 High water outlet error

H3 Pressure switch error

H6 Compressor revolution error

H7 Tank temperature thermistor error

H8 Current error

Sanden Heat Pump – Owner’s Manual

Page 10 of 20

Error Codes

When an error has occurred, a red LED on the operation panel turns on and an error code

is displayed on the LED display. The panel does not turn to the display sleep mode while

the error code is shown.

Figure 3 Error Code example

Below is the list of the error codes. If the corrective action does not solve the error problem,

a malfunction of the PCB is highly likely.

Error

code

Error contents

Error

code

Error contents

H9 HP ambient(outdoor)

temperature thermistor error F5 Communication error between main

PCB to control PCB

HC HP water outlet(outgoing)

temperature thermistor error E8 High inlet current error

J3 HP discharge temperature

thermistor error H8 Current error

J5 HP suction temperature thermistor

error L4 High temperature of module error

J6 HP defrost temperature thermistor

error L5 High outlet current error

J8 HP water inlet(return)

temperature thermistor error P4 Module temperature thermistor

error

H7 Tank temperature thermistor error U2 High voltage error

E6 Compressor booting error HJ Water circuit error

H6 Compressor revolution error EC High water outlet error

U0 Refrigerant leakage error E9 Water circulation pump error

E1 Main PCB error E7 Fan motor locked

E2

L7 Control PCB error F3 Discharged temperature error

Error

code Error contents

H9 HP ambient(outdoor) temperature

thermistor error

HC HP water outlet(outgoing) temperature

thermistor error

HJ Water circuit error

J3 HP discharge temperature thermistor

error

J5 HP suction temperature thermistor error

J6 HP defrost temperature thermistor error

J8 HP water inlet(return) temperature

thermistor error

L4 High temperature of module error

L5 High outlet current error

L7 Control PCB error

P4 Module temperature thermistor error

U0 Refrigerant leakage error

U2 High voltage error

SANCO2Heat Pump – Owner’s Manual

Page 11 of 28

The following steps must be taken to ensure all air is bled from the system.

Incorrect bleeding of air may cause the water temperature to vary during operation.

Ensure that all piping to tank unit and heat pump unit are installed and

connections are tight, then open the Cold Water Supply Valve to the system.

Push up the lever on the PR valve to open, and ll the tank unit with water.

Conrm that water comes out of the relief valve, and then close the lever.

Open the hot water faucets to bleed air from the house piping system.

Close the faucets after no air is seen in the water.

Open the 3 x water bleed screws on the heat pump unit.

Close the plugs after no air is seen in the water.

Leave the hot water faucets open for 3 minutes.

Close the faucet after no air can be seen in the water.

Supply power to the heat pump unit.

Display shows "1200" then "Clock setting mode" is started with operating "Air bleeding

process" at the same time.

In case nish time setting or nothing is operated for 1 minute, "Clock setting mode" is

terminated and "APon" will be displayed on the monitor.

"Air bleeding process" will be done in 5 minutes.

Once it's nished, current time will be shown on monitor.

Sanden Heat Pump – Owner’s Manual

Page 11 of 20

Removing air from the system

Please note:

Plumbing work should only be completed by a licensed plumber

• The following steps must be taken to ensure all air is removed from the system.

Incorrect removal of air may cause the water temperature to vary.

• Plumb pipes to the tank unit and the heat pump unit.

• Push up the lever on the PTR valve to open, and fill the tank unit with water.

• Confirm that the water comes out of the relief valve and then close the lever.

• Open the hot water taps in the home to remove air.

• Close the hot water taps in the home after no air is confirmed in the water.

• Open the water drain plug on the heat pump unit.

• Close the plug after no air is confirmed in the water.

• Connect the power to the heat pump unit.

• Air removing process (Refer to figure 4)

1. Switching to Air Removing Mode

Long press the “Up” and “Down” keys to switch to the “Heat Setting Mode”.

2. Press the “Up” or “Down” keys to switch to the “Air Removing Mode” and press

the “Enter” key. Press the “Up” keys again to display “APon”, then press the

“Enter” key.

After 5 minutes, the air removing mode will automatically finish and the display will

show [Air ] again.

• Open the hot water taps in the home to remove air.

• Close the hot water taps in the home after no air is confirmed in the water.

*Caution

If air removing mode is not completed, the system will not start the heating cycle.

Figure 4: Air removing process

PR valve lever

PR valve to open,

Figure 4: Air bleeding process

Open

The air bleeding valve

CAUTION : Be sure to follow the procedure below.

If the procedure is not followed, the pump may run idle and be damaged.

Filling the System & Bleeding Air

Open the faucet to bleed air. Close the faucet

after no air bubbles can be seen in the water.

Open the 3 x air bleeding screws on the Heat

Pump Unit.

Close the valve after no air is conrmed in the

water supply.

Then connect power to the Heat Pump Unit.

Open faucet.

CAUTION : One Air bleeding screw is located underneath the heat pump unit!

SANCO2Heat Pump – Owner’s Manual

Page 12 of 28

Sanden Heat Pump –Owner’s Manual

Page 11 of 24

Mains Power/Electrical Installation

All Electrical Wiring should be done in accordance with the latest edition of the

National Electrical Code (NEC) and all local State/Province and Municipality codes.

The power requirement for the system is a dedicated 15 amp circuit fitted with a

circuit breaker. This circuit may be connected to constant power or off-peak power.

A local disconnect should be installed adjacent to the Heat Pump unit in

accordance to NEC and local codes.

Installation of this system must be carried out only by a qualified installation

technician (electrical or plumbing).

Electrical connections

Breaker size and wiring must be sized per NEC rules for the rating plate amperage,

MCA and MOP or Max Circuit Breaker.

Power Supply is 208/230V-1Ph-60Hz

Verify that the tank unit is full of water and the

water shut off valves are open before turning on the

power.

How to connect Main Power

Remove the terminal block cover (Philips head screwdriver required)

Connect the power wiring to the terminal block per the wiring diagram/manual.

Ensure ground wire is connected.

Secure the power supply wiring below the terminal block with the screw clamp

fitting.

Attach the terminal block cover and piping cover back on the heat pump unit.

Electrical Connections

SANCO2Heat Pump – Owner’s Manual

Page 13 of 28

Sanden Heat Pump –Owner’s Manual

Page 11 of 24

Mains Power/Electrical Installation

All Electrical Wiring should be done in accordance with the latest edition of the

National Electrical Code (NEC) and all local State/Province and Municipality codes.

The power requirement for the system is a dedicated 15 amp circuit fitted with a

circuit breaker. This circuit may be connected to constant power or off-peak power.

A local disconnect should be installed adjacent to the Heat Pump unit in

accordance to NEC and local codes.

Installation of this system must be carried out only by a qualified installation

technician (electrical or plumbing).

Electrical connections

Breaker size and wiring must be sized per NEC rules for the rating plate amperage,

MCA and MOP or Max Circuit Breaker.

Power Supply is 208/230V-1Ph-60Hz

Verify that the tank unit is full of water and the

water shut off valves are open before turning on the

power.

How to connect Main Power

Remove the terminal block cover (Philips head screwdriver required)

Connect the power wiring to the terminal block per the wiring diagram/manual.

Ensure ground wire is connected.

Secure the power supply wiring below the terminal block with the screw clamp

fitting.

Attach the terminal block cover and piping cover back on the heat pump unit.

How to Connect Main Power

Remove the power box cover (Philips head screwdriver required)

Connect the power wiring to the terminal block per the wiring diagram/manual.

Ensure ground wire is connected.

Secure the power supply wiring below the terminal block with the screw clamp tting.

Re attach the power box cover to the heat pump unit.

Figure 5: Connect power

0.5mm~1mm

Power wire

Core

·Heat Pump 208/230V Power Wiring must use solid copper wire.

·Appropriately sized ring or fork terminals are recommended for easier connection.

Power supply

208/230V

Black

White

Green/Yellow

Power line

Ground

5×M4 Screws

Wire holder band

SANCO2Heat Pump – Owner’s Manual

Page 14 of 28

Sanden Heat Pump –Owner’s Manual

Page 12 of 24

Figure 5: Power connection

System operation using continuous power

The system runs its water heating cycle once a day to fill up the storage tank unit

with heated water.

If the block out time function is selected the unit will not operate during the block out

times – this function is typically used on installations that have time of use electricity

tariffs.

The water heating cycle operation starts automatically when the residual hot water

in the tank unit is less than 40 gallons (150 litres).

The system will not run if the electrical power supply is cut off (i.e. if it is connected

to demand response power). However, the system will automatically start operation,

once the electric power is restored.

Power supply

208/230V

Wire holder band

Power line

Ground

How to Connect Thermistor Cable

Remove the piping cover.

Connect the thermistor cable line to the terminal block.

Fix the thermister cable with the code clip and conduit clip.

Attach the piping cover back on the heat pump unit.

Conduit clip

Code clip

Thermistor cable

White

Green

Green

Blue

Black

25mm

or

less

Standard System Operation

The system will not run if the power supply is cut off.

SANCO2Heat Pump – Owner’s Manual

Page 15 of 28

Sanden Heat Pump –Owner’s Manual

Page 13 of 24

System operation if connected to Demand Response power

There are no special settings for the Demand Response. The system will run once

power becomes available and the temperature in the tank drops below the set point

of the tank thermistor.

If connecting the unit to Demand Response power, ensure that the off peak tariff

provides a minimum of 5 hours continuous power, as it can take at least four hours

to fill the tank unit with hot water.

If the ambient temperature is lower than 50oF (10oC) this can be longer.

If the unit is connected to Demand Response power and hot water consumption has

been higher than normal, hot water might not be available until the next power

supply cycle.

Daily frequency and amount of hot water consumption may also affect the duration

of the heating cycle operation.

Select the electrical supply mode that best suits the customer’s hot water

consumption. The type of off-peak connection may need to be changed

if hot water supply is not maintained as required.

The basic system installation is now complete; the unit is now ready for initial filling,

air purge and then start up.

Check the Installation against the Installation Check list provided

at the end of this manual

Ensure that the work site is tidy; Sanden International recommends the use of Slim Duct or

Fortress product to cover water piping on the outside of the house

Caution

Use copper wiring

208/230V Power

Ground Wire

Breaker Box

Figure 6: Outline of electrical system connections

208/230V Power

Ground Wire

System Operation If Connected to Dry Contact

There are no special settings for the Dry contact input. The system will run once dry

contact input becomes available and the temperature in the tank drops below the set

point of the tank thermistor.

If the Unit is connected to Dry Contact and Hot Water consumption has been higher

than normal, hot water may not be available until the closure of the Dry Contact.

Daily frequency and amount of hot water consumption may also affect the duration of

the heating cycle operation.

Sanden Heat Pump –Owner’s Manual

Page 12 of 24

Figure 5: Power connection

System operation using continuous power

The system runs its water heating cycle once a day to fill up the storage tank unit

with heated water.

If the block out time function is selected the unit will not operate during the block out

times – this function is typically used on installations that have time of use electricity

tariffs.

The water heating cycle operation starts automatically when the residual hot water

in the tank unit is less than 40 gallons (150 litres).

The system will not run if the electrical power supply is cut off (i.e. if it is connected

to demand response power). However, the system will automatically start operation,

once the electric power is restored.

Power supply

208/230V

Wire holder band

Power line

Ground

bleeding and then start up.

ECO2 Systems LLC recommends the use of Slim Duct or

SANCO2Heat Pump – Owner’s Manual

Page 16 of 28

Sanden Heat Pump –Owner’s Manual

Page 14 of 24

Water Supply Quality (Supplemental)

Chloride and PH

In areas with a high concentration of chloride in the water, that water can cause

corrosion and subsequent failures. Where the chloride level exceeds 0.1 ounces per

gallons (200 mg/litre), the warranty is no longer valid on to the heat pump unit and tank

unit.

PH is a measure of whether the water is alkaline or acid. In an acidic water supply, the

water can attack the parts and cause them to fail.

No warranty coverage is given on the heat pump unit and tank unit where the PH is

less than 6.0.

Supply Water with a PH less than 6.0 may be treated to raise the PH.

It is recommended that an analysis of the Supply Water be conducted before

connecting the Heat pump unit to the system.

Figure 7 Chlorides and PH

Change of water supply

Changing, or alternating, from one water supply to another can have a detrimental

effect on the operation and/or life expectation of the water tank unit cylinder, PR valve,

water heating circulation and the heat exchanger in the system.

Where there is a changeover from one water supply to another, for example, a

rainwater tank supply, desalinated water supply, public recirculated water supply or

water brought in from another supply, then water chemistry information should be

sought from the supplier or the water should be tested to ensure it meets the warranty

requirements in this installation manual.

Water Supply Quality

Chloride, Water Hardness and pH

In high chloride water supply areas, the water can corrode some parts and cause them

to fail. Where the chloride level exceeds 0.1 ounces per gallons (200 mg/litre) or Water

Hardness level exceeds 0.1 ounces per gallons (200 mg/litre) warranty does not apply

to the heat pump unit and tank unit. pH is a measure of whether the water is alkaline or

acid. In an acidic water supply, the water can attack the parts and cause them to fail.

No warranty applies to the heat pump unit and tank unit where the pH is less than 6.5

or more than 8.0. The water supply from a rainwater tank unit in a metropolitan area is

likely to be corrosive due to the dissolution of atmospheric contaminants. Water with

a pH less than 6.5 may be treated to raise the pH. It is recommended that an analysis

of the water from a rainwater tank be conducted before connecting this type of water

supply to the system.

SANCO2Heat Pump – Owner’s Manual

Page 17 of 28

*SAN-119GLBK tank is a glass-lined steel tank with a 10 year warranty.

Note: Materials and specifications are subject to change without notice.

All dimensions displayed in inches. Heat Pump Stainless Steel

Storage Tank*

Eco2 Systems LLC

P.O. Box 1358, Walled Lake, MI 48390

Phone: 1-844-726-3262 or 1-844-SANDCO2

Email: info@sandenwaterheater.com

Website: www.sandenwaterheater.com

For more information, please call 1-844-SANDCO2 or email info@sandenwaterheater.com.

Specifications

35-1/4"11"

32-1/2"

3/4"

2-3/4"5"

4-3/4" 23" 4-3/4"

27-1/2

1/2"3-3/4"1/2"

14-1/4"

Sanden Dealer

YEAR

LABOR

0

C

Outdoor Unit (Heat Pump) Model No. GS3-45HPA-US

REV 011620

3

Specifi cations

Water Temperature Setting 130 ºF to 175 ºF

Ambient Air Operating Temperature -20ºF to +110ºF

Heat Pump Capacity 15,400 Btu/h

Heat Pump Capacity 4.5 kW

Heat Pump COP 5.2

Refrigerant Type R744 (CO2)

Compressor Type Inverter

Power Voltage 208/230v –1Ph – 60Hz

Breaker Size 15 Amps

MCA 13 Amps

Outdoor Operating Noise Level 37 dB

Weight 106 lbs

Pipe Size (Tank to Heat Pump) 1/2" (Hot & Cold)

Max Length Inc Vertical 50 ft

Max Vertical Separation 16 ft

Max Water Pressure 95 Psig

Performance 43-gal. sys. 83-gal. sys. 119-gal. sys.

Uniform Energy Factor 2.85 3.34 3.23

First Hour Rating 65 gallons 109 gallons 130 gallons

Tank Model No: SAN-43SSAQA SAN-83SSAQA SAN-119GLBK*

AHeight 38-

1

/

8

"68-

7

/

8

”63-

3

/

5”

BHot Water Outlet & PR Valve 29-

1

/

2

"60-

1

/

4

”56”

CHeat Pump Return 29-

1

/

2

"60-

1

/

4

”60-

1

/

4

"

DSensor Port 9-

3

/

4

" 40

3

/

8

”56”

E

Cold Water Inlet / Cold Water to HP

8-

3

/

4

"8-

3

/

4

”4”

FDiameter 24-

1

/

2

"24-

1

/

2

”28”

Weight (lbs) 88 lbs 115 lbs 345 lbs

Tank Capacity (gallons) 43 gallons 83 gallons 119 gallons

Warranty 15 years 15 years 10 years*

Connection Sizes

Cold Water Inlet

3

/

4

" NPT

Hot Water Outlet

3

/

4

" NPT

Cold Water to Heat Pump

3

/

4

" NPT

Hot Water Return from Heat Pump

3

/

4

” NPT

Pressure Relief Valve Setting (Psig)

125 Psig

*

Storage Tank Dimensions

Technical Data

(11/2" SAN-119GLBK)

(11/2" SAN-119GLBK)

125/150 Psig

SANCO2Heat Pump – Owner’s Manual

Page 18 of 28

Sanden Heat Pump –Owner’s Manual

Page 17 of 24

GS3-45HPA-US Dimensions

Specification

Refrigerant type

R744(CO2)

Mass volume

22 oz. (650g)

Setting Outlet water temp

130~175°F

Product weight

106lb (48 kg)

Thermal capacity

4.5 kw

Fan motor FLA

0.3A , 70W

Water pump FLA

0.2A , 30W

Compressor RLA / LRA

7.5 / 9.8A

MCA

13A

Circuit Breaker Size

15A

Design Pressure(High / Low)

1885 /1059 PSI

Max inlet water temperature

110°F

Protection Raining Class

IPX4

Max, Operating water Pressure

700kPa

GS4-45HPC/GS4-45HPC-D Dimensions

Refrigerant type R744(CO2)

Mass volume 25.4oz (720g)

Setting Outlet water temp 145/150°F

Product weight GS4-45HPC 108lb (49kg)

GS4-45HPC-D 110lb (50kg)

Thermal capacity 4.5 kw

Power consumption of drain pan heater ※132W

Fan motor FLA 0.3A / 30W

Water pump FLA 0.6A / 60W

Compressor RLA / LRA 5.0A / 9.0A

MCA 7.2A

Circuit Breaker Size 15A

Design Pressure(High/Low) 1740/1160 PSI

Max inlet water temperature 100°F

Protection Raining Class IPX4

Max, Operating water Pressure 125 Psig

2.7”32.48”0.91”

1.02”

14.02”

1.18”

12.88”

2.95”

4.82”

16.24”

3.86”

DRAIN CONNECTOR

HP INLET (COLD WATER) PT1/2 HP OUTLET (HOT WATER) PT1/2

4.82” 22.83”

2.39”0.88” 11.81”

25.94”0.63”

26.57”

5.85” 1.08”

Unit:inch

2.76”

9.89”14.2”

5.91”

1.41”

※GS4-45HPC-D only

SANCO2Heat Pump – Owner’s Manual

Page 19 of 28

Sanden Heat Pump –Owner’s Manual

Page 17 of 24

GS3-45HPA-US Dimensions

Specification

Refrigerant type

R744(CO2)

Mass volume

22 oz. (650g)

Setting Outlet water temp

130~175°F

Product weight

106lb (48 kg)

Thermal capacity

4.5 kw

Fan motor FLA

0.3A , 70W

Water pump FLA

0.2A , 30W

Compressor RLA / LRA

7.5 / 9.8A

MCA

13A

Circuit Breaker Size

15A

Design Pressure(High / Low)

1885 /1059 PSI

Max inlet water temperature

110°F

Protection Raining Class

IPX4

Max, Operating water Pressure

700kPa

1 | Page

SANCO2 Warranty Policy 12-01-2020

Residential Warranty Policy covering the following Model #’s :

Heat Pump : GS4-45HPC

Storage Tanks : SAN-43SSAQA, SAN-83SSAQA, SAN-119GLBK

Warranty Conditions as of December 1st 2020 to the Original Owner Only

1. Warranty period

Subject to the Warranty Conditions and Exclusions stated below, the Eco2 Systems LLC Heat

Pump Water Heater System with the corresponding model numbers warranted in Residential /

Combi DHW & Heating applications ONLY (For Commercial applications as defined the

warranty is covered in a separate document) as follows:

1-1. Residential DHW application ; Heat Pump unit

Eco2 Systems LLC warrants all parts & labor on the SANCO₂system for a period of 3 years

from date of installation and a further 7 years on Parts only excluding shipping costs.

Labor costs are paid per the payment cost schedule published by Eco2 Systems LLC and

revised from time to time at Eco2 Systems LLC’s requirement (Exhibit A).

Should at any time during the 10 year Parts warranty any component directly part of the CO₂

refrigerant circuit fail, where replacement of that component would require opening of the

refrigerant circuit, Eco2 Systems LLC will replace the Heat Pump unit in it’s entirety. If this failure

occurs in the first 3 years of operation, then Labor costs will be paid per Exhibit A.

1-2. Residential DHW application ; Tank

Eco2 Systems LLC warrants that the SAN-43SSAQA, SAN-83SSAQA tanks will be free from

defects for 10 years at 100% replacement, and for a further 5 years under a pro-rated scale,

culminating in warranty ending after 15 years from date of installation.

Failure in Year 11: 80% of replacement value

Failure in Year 12: 60% of replacement value

Failure in Year 13: 40% of replacement value

Failure in Year 14: 20% of replacement value

SAN-119GLBK tanks have a warranty of 10 years only at 100% replacement value.

2 | Page

SANCO2 Warranty Policy 12-01-2020

1-3. Combined DHW/Heating application

When used in a Combined DHW/Heating System application providing that the winter design

(99%) temperature must be above 22˚F and with a single heat pump unit serving a heating load

of less than 10,000 Btu/h in addition to a minimum DHW demand of 20 Gallons per day then the

warranty period will be amended to that stated below.

1-3.1. Combined DHW/Heating application ; Heat Pump unit

Eco2 Systems LLC warrants all parts & labor on the SANCO₂combi system for a period of 2

years from date of installation and a further 5 years on Parts only excluding shipping costs.

Labor costs are paid per the payment cost schedule published by Eco2 Systems LLC and

revised from time to time at Eco2 Systems LLC’s requirement.

1-3.2. Combined DHW/Heating application ; Tank

The Storage tank warranty period is unaffected by the usage in a Combined DHW/Heating

system and remains unchanged from the warranty period stated previously.

2. Warranty Conditions – All Residential Applications

2-1. The Eco2 Systems LLC Heat Pump Water Heater System must be installed in accordance with

the installation instructions supplied with the Heat Pump Water Heater System, all relevant

industry practices and in accordance with all applicable relevant plumbing codes plus

statutory/local requirements of the state/province/municipality of the location where the water

heater is installed.

2-2. Where a failed component or Heat Pump Water Heater System is replaced under warranty, the

balance of the original warranty period will remain effective. The replaced part or complete new

Heat Pump Water Heater System does not carry a new warranty.

2-3. Warranty period only applies from the verified date of system installation, if such a date cannot

be verified then the warranty will be deemed to have started using a date calculated after 2 (two)

months have elapsed from the date of unit manufacture.

Heat Pumps : GS4-45HPC/GS4-45HPC-D

SANCO2Heat Pump – Owner’s Manual

Page 20 of 28

2 | Page

SANCO2 Warranty Policy 12-01-2020

1-3. Combined DHW/Heating application

When used in a Combined DHW/Heating System application providing that the winter design

(99%) temperature must be above 22˚F and with a single heat pump unit serving a heating load

of less than 10,000 Btu/h in addition to a minimum DHW demand of 20 Gallons per day then the

warranty period will be amended to that stated below.

1-3.1. Combined DHW/Heating application ; Heat Pump unit

Eco2 Systems LLC warrants all parts & labor on the SANCO₂combi system for a period of 2

years from date of installation and a further 5 years on Parts only excluding shipping costs.

Labor costs are paid per the payment cost schedule published by Eco2 Systems LLC and

revised from time to time at Eco2 Systems LLC’s requirement.

1-3.2. Combined DHW/Heating application ; Tank

The Storage tank warranty period is unaffected by the usage in a Combined DHW/Heating

system and remains unchanged from the warranty period stated previously.

2. Warranty Conditions – All Residential Applications

2-1. The Eco2 Systems LLC Heat Pump Water Heater System must be installed in accordance with

the installation instructions supplied with the Heat Pump Water Heater System, all relevant

industry practices and in accordance with all applicable relevant plumbing codes plus

statutory/local requirements of the state/province/municipality of the location where the water

heater is installed.

2-2. Where a failed component or Heat Pump Water Heater System is replaced under warranty, the

balance of the original warranty period will remain effective. The replaced part or complete new

Heat Pump Water Heater System does not carry a new warranty.

2-3. Warranty period only applies from the verified date of system installation, if such a date cannot

be verified then the warranty will be deemed to have started using a date calculated after 2 (two)

months have elapsed from the date of unit manufacture.

3 | Page

SANCO2 Warranty Policy 12-01-2020

2-4. Where the Heat Pump Water Heater System is installed in a position that does not allow safe

operating practices, such as not installing a properly size metal drain pan if installed in an area

where leakage from the tank or it’s connections would result in damage to the area adjacent to

the heat pump or the storage tank.

2-5. The cost of accessing the site safely, including the cost of additional materials handling and/or

safety equipment, shall be the owner's responsibility.

2-6. The warranty only applies to the Heat Pump Water Heater System (heat pump & storage tank)

and original or genuine (company) component replacement parts and therefore does not cover

any plumbing or electrical parts supplied by the installer and not an integral part of the Heat

Pump Water Heater System. Such parts would include but not limited to; pressure regulating

valves, isolation valves, solenoid valves, electrical switches, pumps, trace heating, fuses or any

other field supplied parts used in the installation of the Eco2 Systems LLC Heat Pump Water

Heater System.

2-7. The Heat Pump Water Heater System must be sized to the hot water demand in accordance

with the guidelines in the current Eco2 Systems LLC Heat Pump Water Heater System literature

and application guides and training information.

2-8. This warranty is for parts only, any and all labor costs associated with diagnosis, removal of the

faulty part and installation of replacement parts will solely be the owner’s responsibility except

where covered by the labor warranty section of this warranty.

3. Warranty Exclusions

Repair and replacement work will be carried out as set out in the Eco2 Systems LLC Heat Pump

Water Heater System warranty. However the following exclusions may void the warranty and

may incur additional service charges and/or cost of parts:

3-1. Accidental damage to the Heat Pump Water Heater System or any component, including: Acts

of God, failure due to misuse, incorrect installation, attempts to repair the water heater other

than by an Eco2 Systems LLC accredited service agent or the Eco2 Systems LLC service dept.

This manual suits for next models

4

Table of contents

Other ECO2 Systems Water Heater manuals

Popular Water Heater manuals by other brands

Viessmann

Viessmann VITOCELL 300B Installation and service instructions

A.O. Smith

A.O. Smith HSE-SBS 6 user guide

Unical

Unical SERBHA 300 Installation and maintenance instructions

Magontec

Magontec CORREX MP 1.9-900 operating instructions

andrews

andrews 32/143 Installation guide, operation and service manual

A.O. Smith

A.O. Smith 710 ASME Service manual

OSO HOTWATER

OSO HOTWATER Delta Coil DC120 installation manual

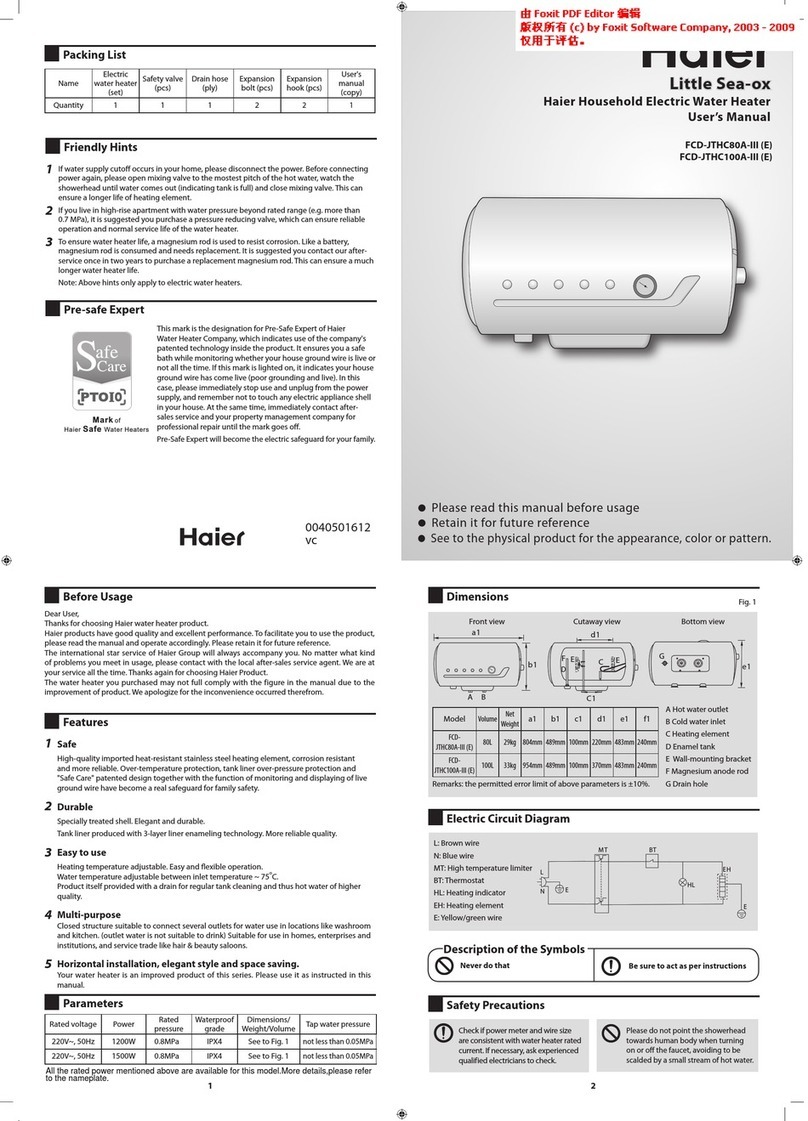

Haier

Haier FCD-JTHC100A-III (E) user manual

Heatworks

Heatworks MODEL 3 User manual & installation guide

aldes

aldes T.Flow Hygro+ installation instructions

Noritz

Noritz GQ-2457WS US owner's guide

Wijas

Wijas POW-LCD 12 Installation and operation manual