ECO2 Systems SANCO2 GS4-45HPC User manual

SANCO2Heat Pump – Installation Manual

Page 1 of 44

Sanden Heat Pump –Installation Manual

Page 1 of 40

.

Page title

Covering model numbers for residence

Heat Pump Unit GS3-45HPA-US

This appliance is not to be installed by unqualified and unlicensed persons,

please read and understand this manual prior to installing and operating the unit.

※This manual is for TO BE USED

by the installing Contractor

only.

Sanden Heat Pump –Installation Manual

Page 1 of 40

.

Page title

Covering model numbers for residence

Heat Pump Unit GS3-45HPA-US

This appliance is not to be installed by unqualified and unlicensed persons,

please read and understand this manual prior to installing and operating the unit.

※This manual is for TO BE USED

by the installing Contractor

only.

20916710 (K)

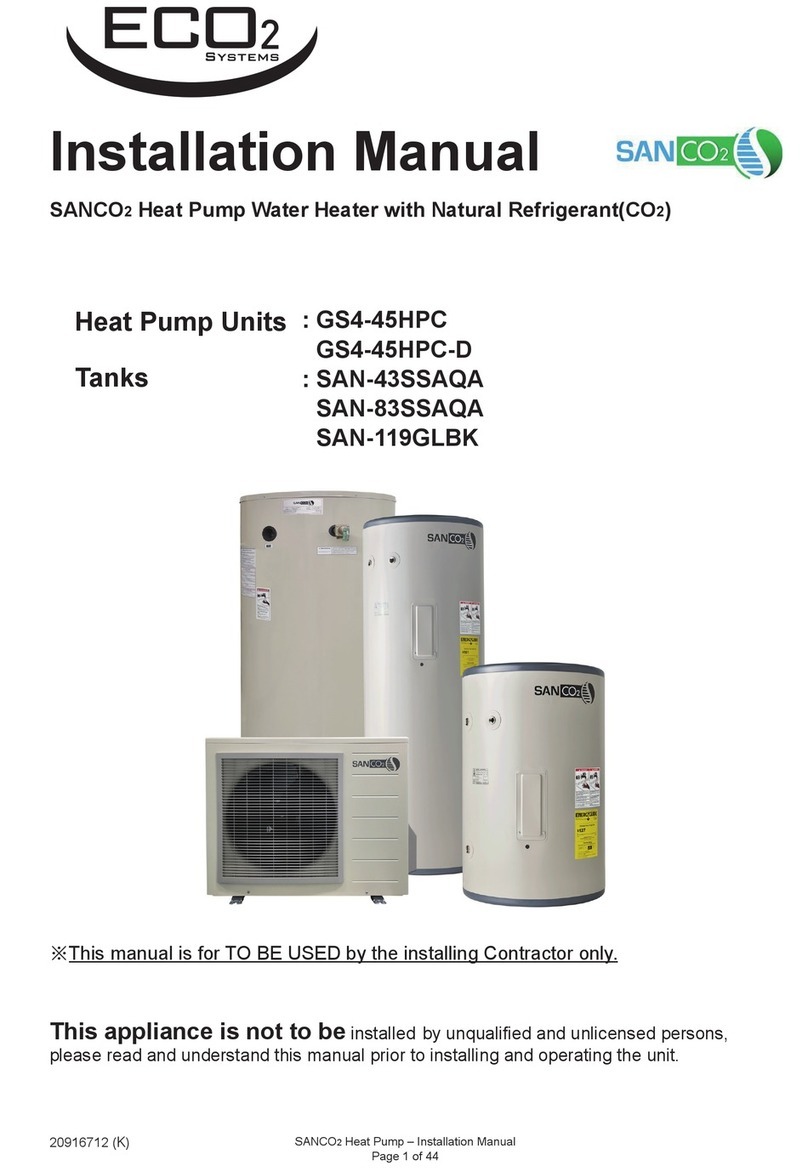

Installation Manual

SANCO2Heat Pump Water Heater with Natural Refrigerant(CO2)

Heat Pump Unit

Tanks

: GS4-45HPC

: SAN-43SSAQA

SAN-83SSAQA

SAN-119GLBK

※This manual is for TO BE USED by the installing Contractor only.

SANCO2Heat Pump – Installation Manual

Page 2 of 44

PATENTS

This water heater may be protected by one or more patents or registered designs in the name of ECO2 Systems LLC

TRADE MARKS

® Registered trademark of ECO2 Systems LLC

Note: Every care has been taken to ensure accuracy in preparation of this publication.

No liability can be accepted for any consequences that may arise as a result of its application.

Contents

Page title …………………………………………………………………………………………………… 1

Contents …………………………………………………………………………………………………… 2

Introduction………………………………………………………………………………………………… 3

How It Works……………………………………………………………………………………………… 3

Installation Details ……………………………………………………………………………………… 4

Installation Location …………………………………………………………………………………… 5

Heat Pump Unit Installation ……………………………………………………………………… 6

Water Piping Installation

-

Heat Pump Unit & Tank …………………………………… 7

Heat Pump Unit Water Piping …………………………………………………………………… 9

Mains Power/Electrical Installation …………………………………………………………… 10

Electrical Connections ……………………………………………………………………………… 10

How to Connect Main Power……………………………………………………………………… 10

How to Connect Tank Thermistor Cable to Heat Pump Unit ……………………… 12

Standard System Operation ……………………………………………………………………… 15

System Operation If Connected to Dry Contact ………………………………………… 15

How to Connect Dry Contact……………………………………………………………………… 16

Filling the System & Bleeding Air ……………………………………………………………… 17

Freeze Protection ……………………………………………………………………………………… 18

Commissioning Mode ………………………………………………………………………………… 21

How to Switch to Commissioning Mode …………………………………………………… 21

Error Codes ……………………………………………………………………………………………… 26

Water Supply Quality ………………………………………………………………………………… 29

Technical Data …………………………………………………………………………………………… 30

Wiring Diagram ………………………………………………………………………………………… 33

Warranty Policy ………………………………………………………………………………………… 34

Check Sheet ……………………………………………………………………………………………… 40

Replace Controller Assembly …………………………………………………………………… 41

Memo ………………………………………………………………………………………………………… 42

SANCO2Heat Pump – Installation Manual

Page 3 of 44

Sanden Heat Pump –Installation Manual

Page 3 of 40

Introduction

The Sanden SANCO₂ Heat Pump Water Heater System has been designed using the

latest refrigeration technology to remove the heat from the air to heat water. The

refrigerant we use is CO2 which does not contribute to global warming so it allows us to

help keep a clean healthy earth for future generations.

By using CO2 as the refrigerant, we have produced one of the most energy efficient units

currently available. It is even more efficient when connected to demand response power

and the noise level is so low it will operate unobtrusively at any time.

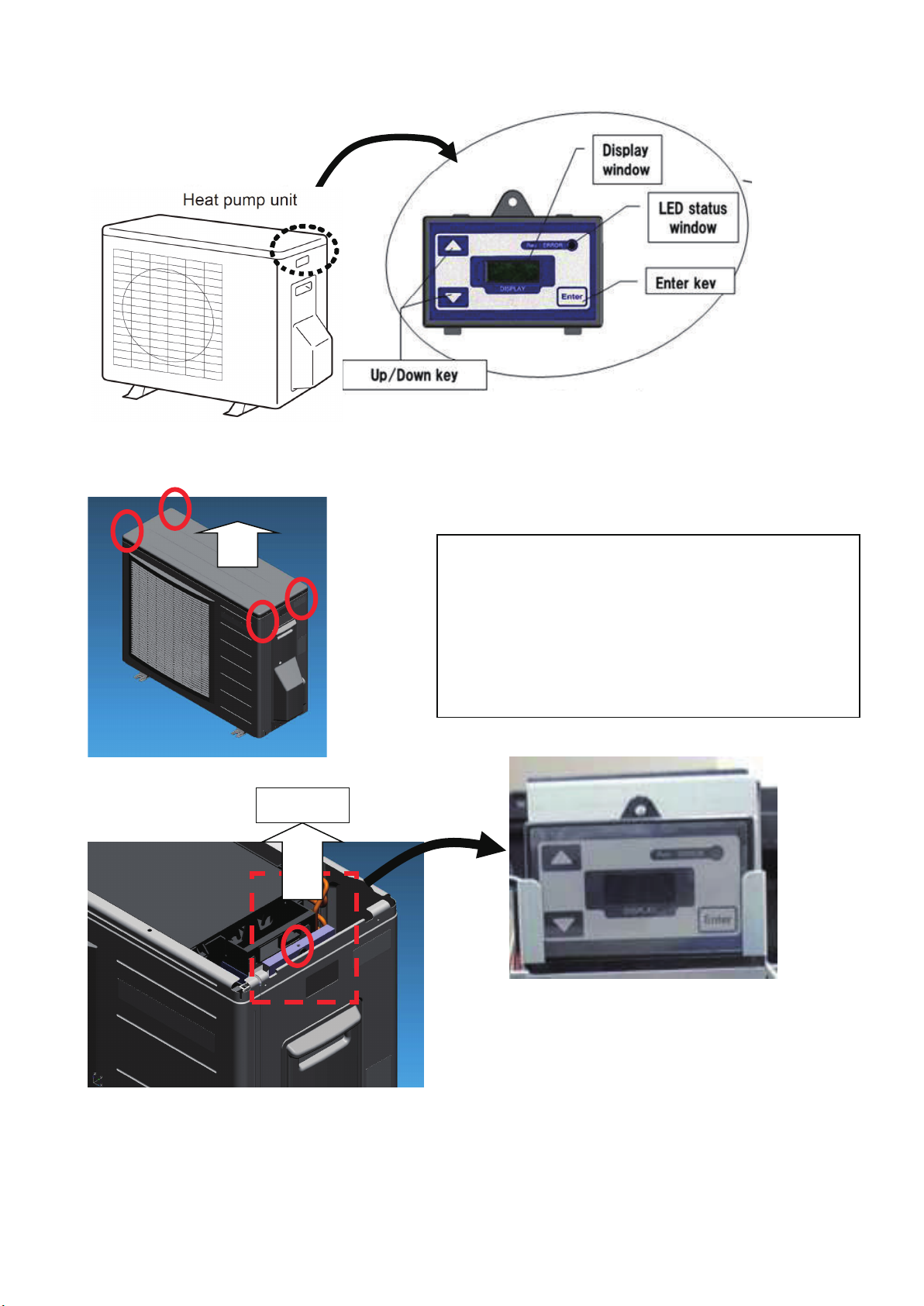

How it works

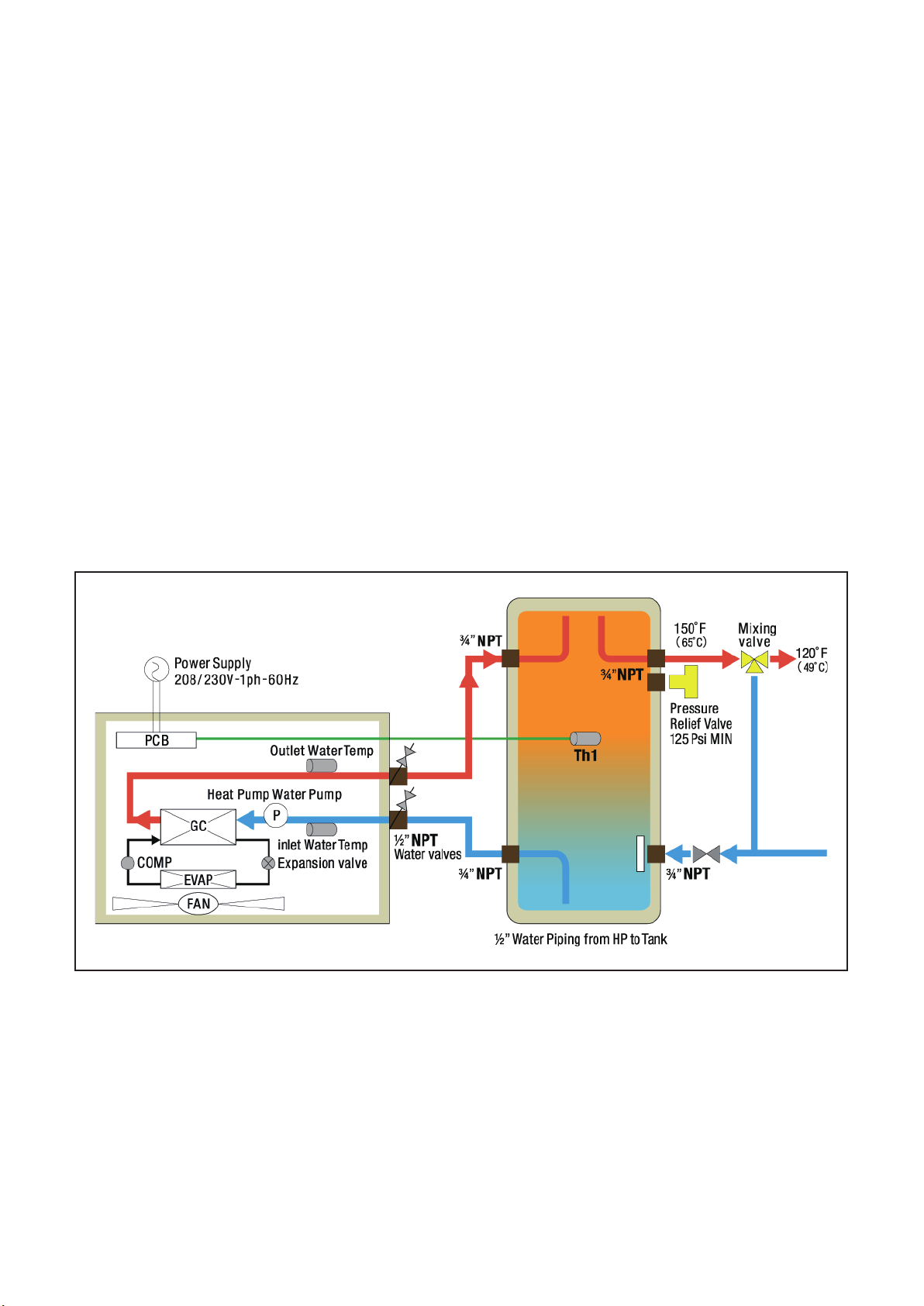

The Sanden SANCO₂ Heat Pump Water Heater System heats water by transferring the

heat from the surrounding air to the water using a refrigerant. The refrigerant is heated by

a heat exchanger that absorbs heat from the surrounding air (Figure 1).

Figure 1: Heat Pump Water Heater System

Note:

The unit must have a minimum of 5 hours continuous power available at all time to allow

the unit to operate without affecting reliability.

Sanden Heat Pump –Installation Manual

Page 3 of 40

Introduction

The Sanden SANCO₂ Heat Pump Water Heater System has been designed using the

latest refrigeration technology to remove the heat from the air to heat water. The

refrigerant we use is CO2 which does not contribute to global warming so it allows us to

help keep a clean healthy earth for future generations.

By using CO2 as the refrigerant, we have produced one of the most energy efficient units

currently available. It is even more efficient when connected to demand response power

and the noise level is so low it will operate unobtrusively at any time.

How it works

The Sanden SANCO₂ Heat Pump Water Heater System heats water by transferring the

heat from the surrounding air to the water using a refrigerant. The refrigerant is heated by

a heat exchanger that absorbs heat from the surrounding air (Figure 1).

Figure 1: Heat Pump Water Heater System

Note:

The unit must have a minimum of 5 hours continuous power available at all time to allow

the unit to operate without affecting reliability.

Sanden Heat Pump –Installation Manual

Page 3 of 40

Introduction

The Sanden SANCO₂ Heat Pump Water Heater System has been designed using the

latest refrigeration technology to remove the heat from the air to heat water. The

refrigerant we use is CO2 which does not contribute to global warming so it allows us to

help keep a clean healthy earth for future generations.

By using CO2 as the refrigerant, we have produced one of the most energy efficient units

currently available. It is even more efficient when connected to demand response power

and the noise level is so low it will operate unobtrusively at any time.

How it works

The Sanden SANCO₂ Heat Pump Water Heater System heats water by transferring the

heat from the surrounding air to the water using a refrigerant. The refrigerant is heated by

a heat exchanger that absorbs heat from the surrounding air (Figure 1).

Figure 1: Heat Pump Water Heater System

Note:

The unit must have a minimum of 5 hours continuous power available at all time to allow

the unit to operate without affecting reliability.

How It Works

Air bleeding

valves

SANCO2Heat Pump – Installation Manual

Page 4 of 44

Sanden Heat Pump –Installation Manual

Page 4 of 40

Installation details

This Sanden SANCO₂ Heat Pump Water Heater System must be installed by licensed

personnel in accordance with local building codes:

Installing contractor should be licensed by applicable state/province and municipal

authorities to install an Electrical & Plumbing product.

The unit has been designed for heating potable domestic hot water. Any other

usage, such as use for DHW in combination with space heating requires both a

heat exchanger suitable for local codes to be installed on the system to separate

potable and non-potable water and consultation with Sanden.

The unit is designed to operate when connected to the water supply with a

maximum operating pressure of 95PSI (655 kPa). To ensure the mains pressure

does not exceed this, first check incoming cold water mains pressure, and then a

pressure regulating device must be connected to the water supply line.

This system delivers hot water exceeding 120 oF (50 oC).

Installation of a temperature tempering device is MANDATORY to avoid potential

scalds and burns.

The unit must be stored and transported in an upright position. Failure to do so may

render the unit faulty. Such failure is not covered under any warranty agreements.

Failure to comply with the above conditions will void the warranty.

SANCO2.

Sanden Heat Pump –Owner’s Manual

Page 7 of 24

Installation details

This Sanden Eco Hot water Heat Pump System must be installed by licensed personnel in

accordance with local building codes:

Installing contractor should be licensed by applicable state/province and municipal

authorities to install an Electrical & Plumbing product.

The unit has been designed for heating potable domestic hot water and any other

usage, such as space heating requires a heat exchanger suitable for local codes to

be installed on the system to separate potable and non-potable water.

The unit is designed to operate when connected to the water supply with a

maximum operating pressure of 95PSI (655 kPa). To ensure the mains pressure

does not exceed this, first check incoming cold water mains pressure, and then a

pressure regulating device must be connected to the water supply line.

This system delivers hot water exceeding 120 oF (50 oC).

Installation of a temperature tempering device is MANDATORY to avoid potential

scalds and burns.

The unit must be stored and transported in an upright position. Failure to do so may

render the unit faulty. Such failure is not covered under any warranty agreements.

Failure to comply with the above conditions will void the warranty.

California Proposition 65 WARNING

This product contains chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

Sanden Heat Pump –Installation Manual

Page 4 of 40

Installation details

This Sanden SANCO₂ Heat Pump Water Heater System must be installed by licensed

personnel in accordance with local building codes:

Installing contractor should be licensed by applicable state/province and municipal

authorities to install an Electrical & Plumbing product.

The unit has been designed for heating potable domestic hot water. Any other

usage, such as use for DHW in combination with space heating requires both a

heat exchanger suitable for local codes to be installed on the system to separate

potable and non-potable water and consultation with Sanden.

The unit is designed to operate when connected to the water supply with a

maximum operating pressure of 95PSI (655 kPa). To ensure the mains pressure

does not exceed this, first check incoming cold water mains pressure, and then a

pressure regulating device must be connected to the water supply line.

This system delivers hot water exceeding 120 oF (50 oC).

Installation of a temperature tempering device is MANDATORY to avoid potential

scalds and burns.

The unit must be stored and transported in an upright position. Failure to do so may

render the unit faulty. Such failure is not covered under any warranty agreements.

Failure to comply with the above conditions will void the warranty.

Installation Details

Sanden Heat Pump –Installation Manual

Page 5 of 40

Installation location

For the most efficient operation of the heat pump unit, the optimum location is the

warmest side of the property and there should be sufficient space for the air to

circulate through the unit.

The tank unit should be located as close as possible to the most frequently used

hot water outlet such as a bathroom. It may be located either outside or inside. The

heat pump unit must be located outside and as close as practicable to the tank unit

but not further than 50ft (15m) away from the tank.

Ensure sufficient clearance around the heat pump unit to allow air to circulate and

provide adequate space for service maintenance of the unit (Figure 3).

Although the heat pump unit is very quiet, it is preferable to avoid installing it

directly below a bedroom window.

Install the heat pump unit in an area which allows sufficient ventilation. Poor

ventilation may cause the unit to short cycle and this could increase power

consumption by more than 10%.

Do not install the heat pump unit in a confined space without making provision for

intake or exhaust airflow for the unit.

If the heat pump unit is installed facing a wall, exhaust air may stain the wall.

Figure 3: Restrictions on where the heat pump unit can be installed (overhead view)

※1Unit should have a minimum of 18” or 500mm space above the unit to ensure correct operation

2Discharge Air blowing against a wall/obstacle in front of the unit may stain the wall/obstacle

3If the unit is not able to operate with adequate airflow due to obstacles and reduced clearances,

Then heating output will be reduced by approx. 10% and power consumption increased by approx.10%

4For optimum operation install the unit per the above or in a location with no obstacles

Flat wall installation

Corner installation

>6” 㼛㼞㻌㻝 㻡 㻜 㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

>6” 㼛㼞㻌㻝 㻡 㻜 㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

>6” 㼛㼞㻌㻝 㻡 㻜 㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

>6” 㼛㼞㻌

㻝㻡㻜㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

>8” or

㻞㻜㻜㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

>12” or

㻟㻜㻜㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

Caution: Water fitting side must have 12” clearance.

24”is desirable

㻲㼞㼛㼚㼠

㻲㼞㼛㼚㼠

㻲㼞㼛㼚㼠

㻲㼞㼛㼚㼠

Sanden Heat Pump –Installation Manual

Page 5 of 40

Installation location

For the most efficient operation of the heat pump unit, the optimum location is the

warmest side of the property and there should be sufficient space for the air to

circulate through the unit.

The tank unit should be located as close as possible to the most frequently used

hot water outlet such as a bathroom. It may be located either outside or inside. The

heat pump unit must be located outside and as close as practicable to the tank unit

but not further than 50ft (15m) away from the tank.

Ensure sufficient clearance around the heat pump unit to allow air to circulate and

provide adequate space for service maintenance of the unit (Figure 3).

Although the heat pump unit is very quiet, it is preferable to avoid installing it

directly below a bedroom window.

Install the heat pump unit in an area which allows sufficient ventilation. Poor

ventilation may cause the unit to short cycle and this could increase power

consumption by more than 10%.

Do not install the heat pump unit in a confined space without making provision for

intake or exhaust airflow for the unit.

If the heat pump unit is installed facing a wall, exhaust air may stain the wall.

Figure 3: Restrictions on where the heat pump unit can be installed (overhead view)

※1Unit should have a minimum of 18” or 500mm space above the unit to ensure correct operation

2Discharge Air blowing against a wall/obstacle in front of the unit may stain the wall/obstacle

3If the unit is not able to operate with adequate airflow due to obstacles and reduced clearances,

Then heating output will be reduced by approx. 10% and power consumption increased by approx.10%

4For optimum operation install the unit per the above or in a location with no obstacles

Flat wall installation

Corner installation

>6” 㼛㼞㻌㻝 㻡 㻜 㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

>6” 㼛㼞㻌㻝 㻡 㻜 㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

>6” 㼛㼞㻌㻝 㻡 㻜 㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

>6” 㼛㼞㻌

㻝㻡㻜㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

>8” or

㻞㻜㻜㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

>12” or

㻟㻜㻜㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

Caution: Water fitting side must have 12” clearance.

24”is desirable

㻲㼞㼛㼚㼠

㻲㼞㼛㼚㼠

㻲㼞㼛㼚㼠

㻲㼞㼛㼚㼠

SANCO2Heat Pump – Installation Manual

Page 5 of 44

Sanden Heat Pump –Installation Manual

Page 4 of 40

Installation details

This Sanden SANCO₂ Heat Pump Water Heater System must be installed by licensed

personnel in accordance with local building codes:

Installing contractor should be licensed by applicable state/province and municipal

authorities to install an Electrical & Plumbing product.

The unit has been designed for heating potable domestic hot water. Any other

usage, such as use for DHW in combination with space heating requires both a

heat exchanger suitable for local codes to be installed on the system to separate

potable and non-potable water and consultation with Sanden.

The unit is designed to operate when connected to the water supply with a

maximum operating pressure of 95PSI (655 kPa). To ensure the mains pressure

does not exceed this, first check incoming cold water mains pressure, and then a

pressure regulating device must be connected to the water supply line.

This system delivers hot water exceeding 120 oF (50 oC).

Installation of a temperature tempering device is MANDATORY to avoid potential

scalds and burns.

The unit must be stored and transported in an upright position. Failure to do so may

render the unit faulty. Such failure is not covered under any warranty agreements.

Failure to comply with the above conditions will void the warranty.

Sanden Heat Pump –Installation Manual

Page 5 of 40

Installation location

For the most efficient operation of the heat pump unit, the optimum location is the

warmest side of the property and there should be sufficient space for the air to

circulate through the unit.

The tank unit should be located as close as possible to the most frequently used

hot water outlet such as a bathroom. It may be located either outside or inside. The

heat pump unit must be located outside and as close as practicable to the tank unit

but not further than 50ft (15m) away from the tank.

Ensure sufficient clearance around the heat pump unit to allow air to circulate and

provide adequate space for service maintenance of the unit (Figure 3).

Although the heat pump unit is very quiet, it is preferable to avoid installing it

directly below a bedroom window.

Install the heat pump unit in an area which allows sufficient ventilation. Poor

ventilation may cause the unit to short cycle and this could increase power

consumption by more than 10%.

Do not install the heat pump unit in a confined space without making provision for

intake or exhaust airflow for the unit.

If the heat pump unit is installed facing a wall, exhaust air may stain the wall.

Figure 3: Restrictions on where the heat pump unit can be installed (overhead view)

※1Unit should have a minimum of 18” or 500mm space above the unit to ensure correct operation

2Discharge Air blowing against a wall/obstacle in front of the unit may stain the wall/obstacle

3If the unit is not able to operate with adequate airflow due to obstacles and reduced clearances,

Then heating output will be reduced by approx. 10% and power consumption increased by approx.10%

4For optimum operation install the unit per the above or in a location with no obstacles

Flat wall installation

Corner installation

>6” 㼛㼞㻌㻝 㻡 㻜 㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

>6” 㼛㼞㻌㻝 㻡 㻜 㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

>6” 㼛㼞㻌㻝 㻡 㻜 㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

>6” 㼛㼞㻌

㻝㻡㻜㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

>8” or

㻞㻜㻜㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

>12” or

㻟㻜㻜㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

Caution: Water fitting side must have 12” clearance.

24”is desirable

㻲㼞㼛㼚㼠

㻲㼞㼛㼚㼠

㻲㼞㼛㼚㼠

㻲㼞㼛㼚㼠

2

Sanden Heat Pump –Installation Manual

Page 5 of 40

Installation location

For the most efficient operation of the heat pump unit, the optimum location is the

warmest side of the property and there should be sufficient space for the air to

circulate through the unit.

The tank unit should be located as close as possible to the most frequently used

hot water outlet such as a bathroom. It may be located either outside or inside. The

heat pump unit must be located outside and as close as practicable to the tank unit

but not further than 50ft (15m) away from the tank.

Ensure sufficient clearance around the heat pump unit to allow air to circulate and

provide adequate space for service maintenance of the unit (Figure 3).

Although the heat pump unit is very quiet, it is preferable to avoid installing it

directly below a bedroom window.

Install the heat pump unit in an area which allows sufficient ventilation. Poor

ventilation may cause the unit to short cycle and this could increase power

consumption by more than 10%.

Do not install the heat pump unit in a confined space without making provision for

intake or exhaust airflow for the unit.

If the heat pump unit is installed facing a wall, exhaust air may stain the wall.

Figure 3: Restrictions on where the heat pump unit can be installed (overhead view)

※1Unit should have a minimum of 18” or 500mm space above the unit to ensure correct operation

2Discharge Air blowing against a wall/obstacle in front of the unit may stain the wall/obstacle

3If the unit is not able to operate with adequate airflow due to obstacles and reduced clearances,

Then heating output will be reduced by approx. 10% and power consumption increased by approx.10%

4For optimum operation install the unit per the above or in a location with no obstacles

Flat wall installation

Corner installation

>6” 㼛㼞㻌㻝 㻡 㻜 㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

>6” 㼛㼞㻌㻝 㻡 㻜 㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

>6” 㼛㼞㻌㻝 㻡 㻜 㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

>6” 㼛㼞㻌

㻝㻡㻜㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

>8” or

㻞㻜㻜㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

>12” or

㻟㻜㻜㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

Caution: Water fitting side must have 12” clearance.

24”is desirable

㻲㼞㼛㼚㼠

㻲㼞㼛㼚㼠

㻲㼞㼛㼚㼠

㻲㼞㼛㼚㼠

2

Do not place the unit to an area where leakage of the unit will result in damage.

Sanden Heat Pump –Installation Manual

Page 5 of 40

Installation location

For the most efficient operation of the heat pump unit, the optimum location is the

warmest side of the property and there should be sufficient space for the air to

circulate through the unit.

The tank unit should be located as close as possible to the most frequently used

hot water outlet such as a bathroom. It may be located either outside or inside. The

heat pump unit must be located outside and as close as practicable to the tank unit

but not further than 50ft (15m) away from the tank.

Ensure sufficient clearance around the heat pump unit to allow air to circulate and

provide adequate space for service maintenance of the unit (Figure 3).

Although the heat pump unit is very quiet, it is preferable to avoid installing it

directly below a bedroom window.

Install the heat pump unit in an area which allows sufficient ventilation. Poor

ventilation may cause the unit to short cycle and this could increase power

consumption by more than 10%.

Do not install the heat pump unit in a confined space without making provision for

intake or exhaust airflow for the unit.

If the heat pump unit is installed facing a wall, exhaust air may stain the wall.

Figure 3: Restrictions on where the heat pump unit can be installed (overhead view)

※1Unit should have a minimum of 18” or 500mm space above the unit to ensure correct operation

2Discharge Air blowing against a wall/obstacle in front of the unit may stain the wall/obstacle

3If the unit is not able to operate with adequate airflow due to obstacles and reduced clearances,

Then heating output will be reduced by approx. 10% and power consumption increased by approx.10%

4For optimum operation install the unit per the above or in a location with no obstacles

Flat wall installation

Corner installation

>6” 㼛㼞㻌㻝 㻡 㻜 㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

>6” 㼛㼞㻌㻝 㻡 㻜 㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

>6” 㼛㼞㻌㻝 㻡 㻜 㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

>6” 㼛㼞㻌

㻝㻡㻜㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

>8” or

㻞㻜㻜㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

>12” or

㻟㻜㻜㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

Caution: Water fitting side must have 12” clearance.

24”is desirable

㻲㼞㼛㼚㼠

㻲㼞㼛㼚㼠

㻲㼞㼛㼚㼠

㻲㼞㼛㼚㼠

6″(150mm) or more

※A

※A

6″(150mm) or more

※A 14″(350mm) or more in case of the height of wall is less than 47″(1200mm)

24″(600mm) or more in case of the height of wall is more than 47″(1200mm)

Sanden Heat Pump –Installation Manual

Page 5 of 40

Installation location

For the most efficient operation of the heat pump unit, the optimum location is the

warmest side of the property and there should be sufficient space for the air to

circulate through the unit.

The tank unit should be located as close as possible to the most frequently used

hot water outlet such as a bathroom. It may be located either outside or inside. The

heat pump unit must be located outside and as close as practicable to the tank unit

but not further than 50ft (15m) away from the tank.

Ensure sufficient clearance around the heat pump unit to allow air to circulate and

provide adequate space for service maintenance of the unit (Figure 3).

Although the heat pump unit is very quiet, it is preferable to avoid installing it

directly below a bedroom window.

Install the heat pump unit in an area which allows sufficient ventilation. Poor

ventilation may cause the unit to short cycle and this could increase power

consumption by more than 10%.

Do not install the heat pump unit in a confined space without making provision for

intake or exhaust airflow for the unit.

If the heat pump unit is installed facing a wall, exhaust air may stain the wall.

Figure 3: Restrictions on where the heat pump unit can be installed (overhead view)

※1Unit should have a minimum of 18” or 500mm space above the unit to ensure correct operation

2Discharge Air blowing against a wall/obstacle in front of the unit may stain the wall/obstacle

3If the unit is not able to operate with adequate airflow due to obstacles and reduced clearances,

Then heating output will be reduced by approx. 10% and power consumption increased by approx.10%

4For optimum operation install the unit per the above or in a location with no obstacles

Flat wall installation

Corner installation

>6” 㼛㼞㻌㻝 㻡 㻜 㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

>6” 㼛㼞㻌㻝 㻡 㻜 㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

>6” 㼛㼞㻌㻝 㻡 㻜 㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

>6” 㼛㼞㻌

㻝㻡㻜㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

>8” or

㻞㻜㻜㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

>12” or

㻟㻜㻜㼙㼙 㼏㼘㼑㼍㼞㼍㼚㼏㼑

Caution: Water fitting side must have 12” clearance.

24”is desirable

㻲㼞㼛㼚㼠

㻲㼞㼛㼚㼠

㻲㼞㼛㼚㼠

㻲㼞㼛㼚㼠

12

″

300

6″(150mm) or more

6″(150mm) or more

Installation Location

66ft(20m)

SANCO2Heat Pump – Installation Manual

Page 6 of 44

Sanden Heat Pump –Installation Manual

Page 6 of 40

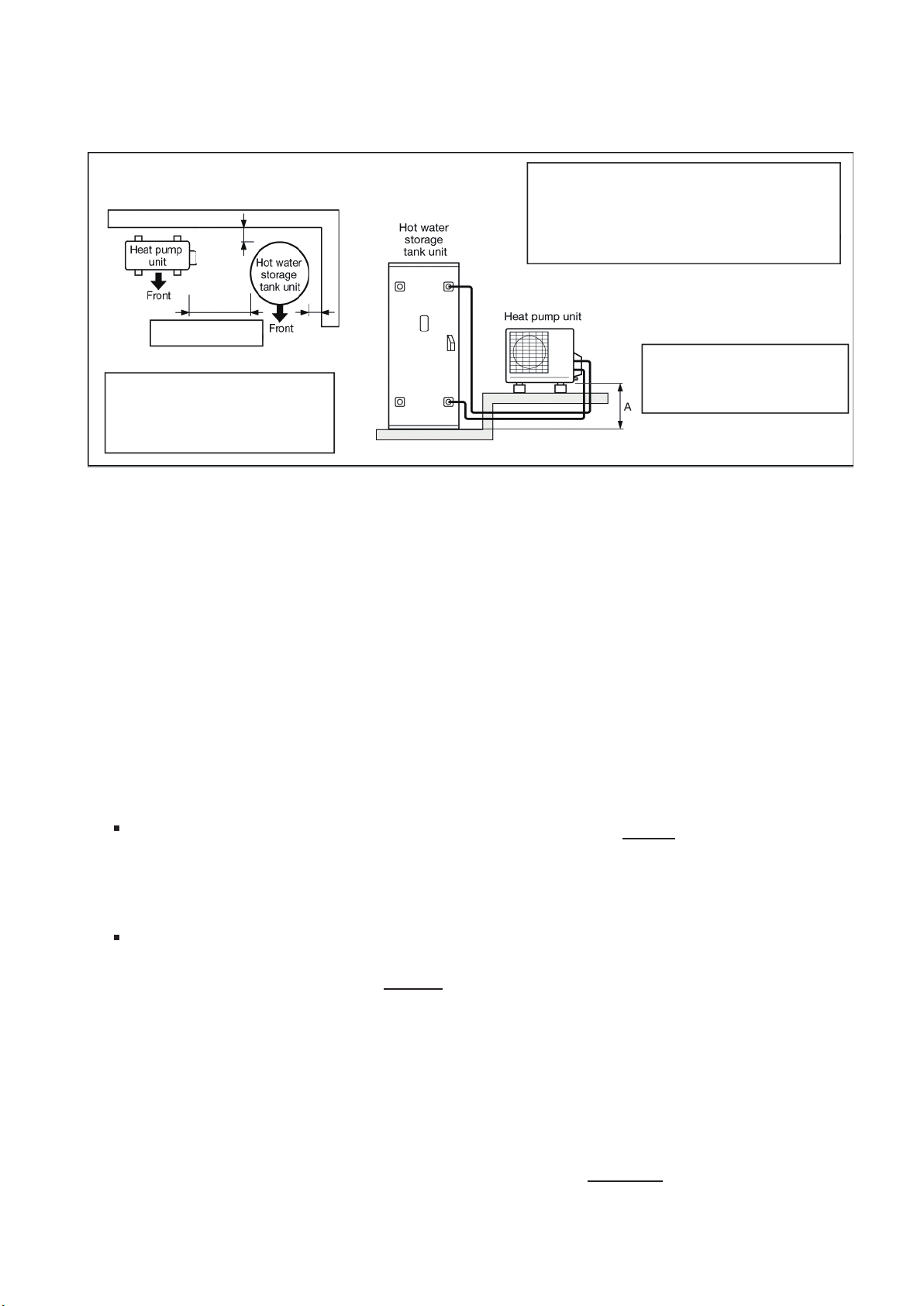

Figure 4: Restrictions on installation with the space between the tank unit and the

heat pump unit

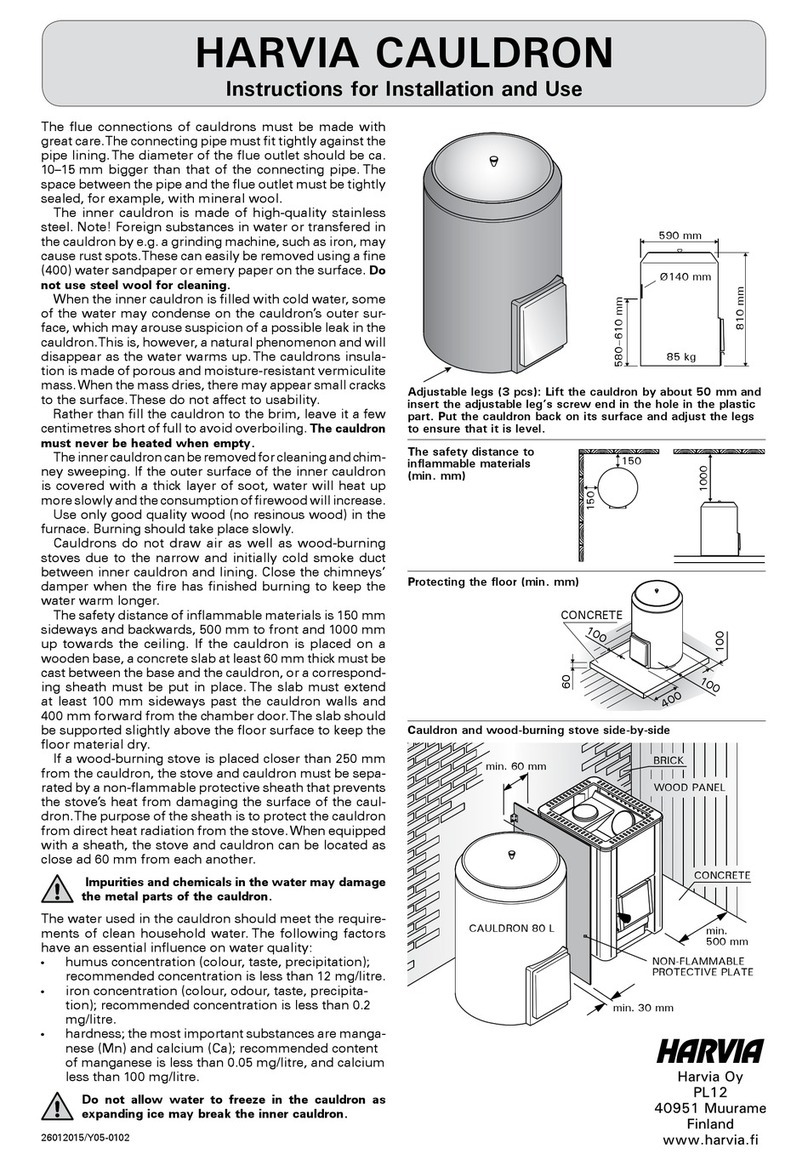

Heat pump Unit Installation

The surface to which the heat pump unit is installed must be firm, preferably a

concrete pad or block. If the surface is firm there is no need to fix the unit to a base

surface, unless there is a likelihood of high wind or local vibration.

If the heat pump unit and tank unit are to fixed, appropriate fixing devices for the

weight/expected duty should be used. It is permissible to install the Heat Pump on

the side of a wall provide an adequate support is used.

Note: For California installation the Tank section water heater must be braced,

anchored, or strapped to avoid falling or moving during an earthquake. For Tank

size over 52 Gallons (236l) consult your local building jurisdiction for appropriate

bracing designs.

Note: For Florida installation the Heat Pump unit should be installed in accordance

with all local codes regarding Hurricane winds.

Use appropriately treated lumber or pre-fabricated “pump ups” to raise the Heat

Pump unit 4”-6” from the ground – this will allow defrost condensate to drain. In

areas with significant snowfall ensure unit is mounted above the anticipated

snowfall depth.

A Pressure Relief (PR) valve MUST be installed during the installation of the tank

unit. This is installed in a defined point near the top of the tank unit. The PR Valve

must have clear drainage where escaping steam or water can flow freely. PR Valve

setting should be 100 Psig.

The installation site must be well drained so that any water accumulating (such as

rain or pipe leakage) will drain away and not enter the heat pump unit and the tank

unit.

Supply water pressure must be a minimum of 29 PSI (200 kPa) to ensure Heat

Pump unit operation – If pressure is below 29 PSI install a booster pump to water

supply.

Caution

Keep the piping run to a minimum

as the longer the pipe run, the

greater the potential for heat loss

.

Side view

Overhead view

Standard layout

(A) Difference in height between

the base of tank and base of

Heat pump should be no more

than: 16ft(

5

m) Max.

>24” or 600mm

(Minimum Separation

Maximum pipe length

50

ft

(

15

m)

per

line between Tank & Heat Pump

Unit.

Maximum number of bends

–

6, use

long radius bends not street “L’s”

2”or

more

2”or

more

Sanden Heat Pump –Installation Manual

Page 6 of 40

Figure 4: Restrictions on installation with the space between the tank unit and the

heat pump unit

Heat pump Unit Installation

The surface to which the heat pump unit is installed must be firm, preferably a

concrete pad or block. If the surface is firm there is no need to fix the unit to a base

surface, unless there is a likelihood of high wind or local vibration.

If the heat pump unit and tank unit are to fixed, appropriate fixing devices for the

weight/expected duty should be used. It is permissible to install the Heat Pump on

the side of a wall provide an adequate support is used.

Note: For California installation the Tank section water heater must be braced,

anchored, or strapped to avoid falling or moving during an earthquake. For Tank

size over 52 Gallons (236l) consult your local building jurisdiction for appropriate

bracing designs.

Note: For Florida installation the Heat Pump unit should be installed in accordance

with all local codes regarding Hurricane winds.

Use appropriately treated lumber or pre-fabricated “pump ups” to raise the Heat

Pump unit 4”-6” from the ground – this will allow defrost condensate to drain. In

areas with significant snowfall ensure unit is mounted above the anticipated

snowfall depth.

A Pressure Relief (PR) valve MUST be installed during the installation of the tank

unit. This is installed in a defined point near the top of the tank unit. The PR Valve

must have clear drainage where escaping steam or water can flow freely. PR Valve

setting should be 100 Psig.

The installation site must be well drained so that any water accumulating (such as

rain or pipe leakage) will drain away and not enter the heat pump unit and the tank

unit.

Supply water pressure must be a minimum of 29 PSI (200 kPa) to ensure Heat

Pump unit operation – If pressure is below 29 PSI install a booster pump to water

supply.

Caution

Keep the piping run to a minimum

as the longer the pipe run, the

greater the potential for heat loss

.

Side view

Overhead view

Standard layout

(A) Difference in height between

the base of tank and base of

Heat pump should be no more

than: 16ft(

5

m) Max.

>24” or 600mm

(Minimum Separation

Maximum pipe length

50

ft

(

15

m)

per

line between Tank & Heat Pump

Unit.

Maximum number of bends

–

6, use

long radius bends not street “L’s”

2”or

more

2”or

more

3

6″(150mm)

or more

2″(50mm)

or more

24″(600mm) or more

Appropriately treated lumber or pre-fabricated “pump ups” MUST be used to raise

the Heat Pump unit 4”-6” from the ground – this will allow defrost condensate to

drain. In areas with signicant snowfall ensure unit is mounted above the anticipated

snowfall depth.

Wall Brackets and other mounting solutions are also available from ECO2 Systems LLC

.

Sanden Heat Pump –Installation Manual

Page 6 of 40

Figure 4: Restrictions on installation with the space between the tank unit and the

heat pump unit

Heat pump Unit Installation

The surface to which the heat pump unit is installed must be firm, preferably a

concrete pad or block. If the surface is firm there is no need to fix the unit to a base

surface, unless there is a likelihood of high wind or local vibration.

If the heat pump unit and tank unit are to fixed, appropriate fixing devices for the

weight/expected duty should be used. It is permissible to install the Heat Pump on

the side of a wall provide an adequate support is used.

Note: For California installation the Tank section water heater must be braced,

anchored, or strapped to avoid falling or moving during an earthquake. For Tank

size over 52 Gallons (236l) consult your local building jurisdiction for appropriate

bracing designs.

Note: For Florida installation the Heat Pump unit should be installed in accordance

with all local codes regarding Hurricane winds.

Use appropriately treated lumber or pre-fabricated “pump ups” to raise the Heat

Pump unit 4”-6” from the ground – this will allow defrost condensate to drain. In

areas with significant snowfall ensure unit is mounted above the anticipated

snowfall depth.

A Pressure Relief (PR) valve MUST be installed during the installation of the tank

unit. This is installed in a defined point near the top of the tank unit. The PR Valve

must have clear drainage where escaping steam or water can flow freely. PR Valve

setting should be 100 Psig.

The installation site must be well drained so that any water accumulating (such as

rain or pipe leakage) will drain away and not enter the heat pump unit and the tank

unit.

Supply water pressure must be a minimum of 29 PSI (200 kPa) to ensure Heat

Pump unit operation – If pressure is below 29 PSI install a booster pump to water

supply.

Caution

Keep the piping run to a minimum

as the longer the pipe run, the

greater the potential for heat loss

.

Side view

Overhead view

Standard layout

(A) Difference in height between

the base of tank and base of

Heat pump should be no more

than: 16ft(

5

m) Max.

>24” or 600mm

(Minimum Separation

Maximum pipe length

50

ft

(

15

m)

per

line between Tank & Heat Pump

Unit.

Maximum number of bends

–

6, use

long radius bends not street “L’s”

2”or

more

2”or

more

125

Heat Pump Unit Installation

66ft(20m)

23ft(7m)

bottom of

SANCO2Heat Pump – Installation Manual

Page 7 of 44

Sanden Heat Pump –Installation Manual

Page 7 of 40

Note:

The entire system is set up and fully functional when supplied. Once all the water and

electric connections have been made, the system will operate automatically provided that

mains power is available.

The only adjustments to the unit are to set the desired hot water supply temperature & set

the current time on the operation panel under the top housing cover, especially if the block

out time setting is desired. See Set point adjustment, current time setting, and block out

time section on page 19.

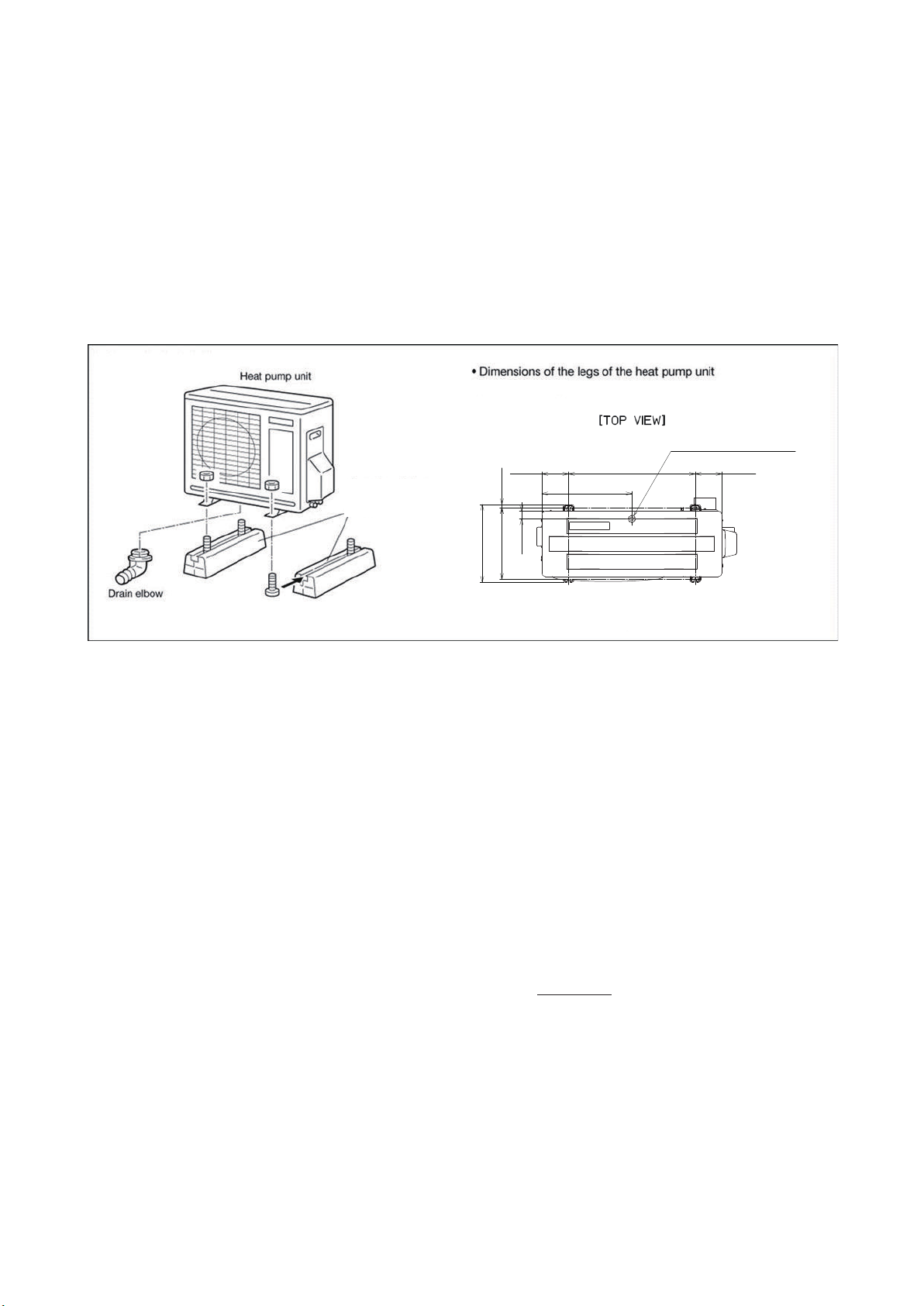

Figure 5: Heat pump installation example and dimensions

Attach the drain elbow to the drain opening located on the bottom of the heat pump

unit. The drain elbow is included in the installation kit for the heat pump unit.

Attach a drain hose with 5/8 inch (16mm) of inner diameter to the drain elbow to guide

the drained water to an appropriate drain.

Water Piping Installation – Heat Pump Unit & Tank

All piping that connects to the water supply must be installed by a licensed contractor.

The water supplied to the system must comply with the potable water quality standard.

Use of water that does not comply with this standard could result in a malfunction of

the system.

Description

PH

TDS

(Total

Dissolved

Solids)

Total

Hardness

(calcium Ion

concentration)

Aluminium

Chlorides

Copper

Iron

Manganese

Zinc

Maximum

Levels

6.0

to

9.0

Up to

500 ppm

Up to

200ppm or

12 grains

hardness

Up to

0.2 ppm

Up to

200

ppm

Up to

1.0

ppm

Up

to

0.3

ppm

Up to

0.05 ppm

Up

to 5

ppm

The water supply must have a pressure of 29 PSI (200 kPa) or higher.

A drain trap must be installed on the drain pipe if water is to be drained to a drain pan.

Unit Weight

106lbs

(㼀㻻㻼㻌㼂㻵㻱㼃)

4

108lbs

Sanden Heat Pump –Installation Manual

Page 7 of 40

Note:

The entire system is set up and fully functional when supplied. Once all the water and

electric connections have been made, the system will operate automatically provided that

mains power is available.

The only adjustments to the unit are to set the desired hot water supply temperature & set

the current time on the operation panel under the top housing cover, especially if the block

out time setting is desired. See Set point adjustment, current time setting, and block out

time section on page 19.

Figure 5: Heat pump installation example and dimensions

Attach the drain elbow to the drain opening located on the bottom of the heat pump

unit. The drain elbow is included in the installation kit for the heat pump unit.

Attach a drain hose with 5/8 inch (16mm) of inner diameter to the drain elbow to guide

the drained water to an appropriate drain.

Water Piping Installation – Heat Pump Unit & Tank

All piping that connects to the water supply must be installed by a licensed contractor.

The water supplied to the system must comply with the potable water quality standard.

Use of water that does not comply with this standard could result in a malfunction of

the system.

Description

PH

TDS

(Total

Dissolved

Solids)

Total

Hardness

(calcium Ion

concentration)

Aluminium

Chlorides

Copper

Iron

Manganese

Zinc

Maximum

Levels

6.0

to

9.0

Up to

500 ppm

Up to

200ppm or

12 grains

hardness

Up to

0.2 ppm

Up to

200

ppm

Up to

1.0

ppm

Up

to

0.3

ppm

Up to

0.05 ppm

Up

to 5

ppm

The water supply must have a pressure of 29 PSI (200 kPa) or higher.

A drain trap must be installed on the drain pipe if water is to be drained to a drain pan.

Unit Weight

106lbs

(㼀㻻㻼㻌㼂㻵㻱㼃)

4.82"22.83"

4.82"

16.24"

14.02"

0.59"12.88"

1.41"

DRAIN CONNECTOR

Unit:inch

top housing cover & especially if the block out time setting is desired.

set the current time on the operation panel under the

Sanden Heat Pump –Installation Manual

Page 6 of 40

Figure 4: Restrictions on installation with the space between the tank unit and the

heat pump unit

Heat pump Unit Installation

The surface to which the heat pump unit is installed must be firm, preferably a

concrete pad or block. If the surface is firm there is no need to fix the unit to a base

surface, unless there is a likelihood of high wind or local vibration.

If the heat pump unit and tank unit are to fixed, appropriate fixing devices for the

weight/expected duty should be used. It is permissible to install the Heat Pump on

the side of a wall provide an adequate support is used.

Note: For California installation the Tank section water heater must be braced,

anchored, or strapped to avoid falling or moving during an earthquake. For Tank

size over 52 Gallons (236l) consult your local building jurisdiction for appropriate

bracing designs.

Note: For Florida installation the Heat Pump unit should be installed in accordance

with all local codes regarding Hurricane winds.

Use appropriately treated lumber or pre-fabricated “pump ups” to raise the Heat

Pump unit 4”-6” from the ground – this will allow defrost condensate to drain. In

areas with significant snowfall ensure unit is mounted above the anticipated

snowfall depth.

A Pressure Relief (PR) valve MUST be installed during the installation of the tank

unit. This is installed in a defined point near the top of the tank unit. The PR Valve

must have clear drainage where escaping steam or water can flow freely. PR Valve

setting should be 100 Psig.

The installation site must be well drained so that any water accumulating (such as

rain or pipe leakage) will drain away and not enter the heat pump unit and the tank

unit.

Supply water pressure must be a minimum of 29 PSI (200 kPa) to ensure Heat

Pump unit operation – If pressure is below 29 PSI install a booster pump to water

supply.

Caution

Keep the piping run to a minimum

as the longer the pipe run, the

greater the potential for heat loss

.

Side view

Overhead view

Standard layout

(A) Difference in height between

the base of tank and base of

Heat pump should be no more

than: 16ft(

5

m) Max.

>24” or 600mm

(Minimum Separation

Maximum pipe length

50

ft

(

15

m)

per

line between Tank & Heat Pump

Unit.

Maximum number of bends

–

6, use

long radius bends not street “L’s”

2”or

more

2”or

more

SANCO2Heat Pump – Installation Manual

Page 8 of 44

Sanden Heat Pump –Installation Manual

Page 8 of 40

This product cannot be connected to a solar water heater.

The piping must be insulated with MINIMUM ¾” to 1” closed cell insulation.

Self Regulating Heat tape (3-5W per foot) must be installed on both Water Lines to the

Heat Pump to protect the water piping in areas with design temperatures below 27°F.

If the piping needs brazing, make sure that all flux and flux splatter is wiped away with

a wet cloth. When brazing, ensure connections are protected using a wet cloth.

As the hot-water supply pipe will expand and contract, use sleeves when penetrating

through concrete walls or slabs.

With buried piping, an outer cover will need to be used that has had both ends sealed

to avoid any ingress of rain.

Use only heat-resistant and corrosive-resistant material to seal the pipe joints.

Cutting and wrenching the piping material may result in oil and dust adhering to it. After

processing, clean the material with a mild detergent before doing any piping work and

smooth the edges to remove any scratches and burrs. (After flowing water through it

verify whether any debris has accumulated on the filter of the faucet and heat pump

unit pipe.)

When using PTFE sealing tape, ensure that no tape is sticking out of the threads.

Any heat-resistant PVC piping use is NOT recommended due to high outlet water

temperature for between the heat pump and the tank as well as the tank and the

mixing valve.

Follow the manufacturer’s instruction manual for the type of bond, amount to be

applied, curing time, and other specifications.

If any bond or flux has entered the tank unit and the hot water has a chemical/acrid

smell, take the following countermeasures.

a) After heating the water in the tank unit, drain it and clean inside the tank unit. Fill

the tank unit with 26 gallons (100 litres) of water and exchange twice.

b) Clean or change the filter.

c) Fill up the tank unit.

d) Drain water from the relief valve for one to two minutes.

e) Run water from all the hot water supply faucets in the house for about ten minutes

to clean inside the pipes.

5-8W

SANCO2Heat Pump – Installation Manual

Page 9 of 44

Bleed the air from the system according to the instructions below on Page 17.

Make sure all the necessary devices are mounted to the pipes as shown in diagram.

If the heat pump unit piping is kinked or clogged or the air inside was not bled during

the test operation, temperature of the supplied hot water may become inconsistent.

Sanden Heat Pump –Installation Manual

Page 8 of 40

This product cannot be connected to a solar water heater.

The piping must be insulated with MINIMUM ¾” to 1” closed cell insulation.

Self Regulating Heat tape (3-5W per foot) must be installed on both Water Lines to the

Heat Pump to protect the water piping in areas with design temperatures below 27°F.

If the piping needs brazing, make sure that all flux and flux splatter is wiped away with

a wet cloth. When brazing, ensure connections are protected using a wet cloth.

As the hot-water supply pipe will expand and contract, use sleeves when penetrating

through concrete walls or slabs.

With buried piping, an outer cover will need to be used that has had both ends sealed

to avoid any ingress of rain.

Use only heat-resistant and corrosive-resistant material to seal the pipe joints.

Cutting and wrenching the piping material may result in oil and dust adhering to it. After

processing, clean the material with a mild detergent before doing any piping work and

smooth the edges to remove any scratches and burrs. (After flowing water through it

verify whether any debris has accumulated on the filter of the faucet and heat pump

unit pipe.)

When using PTFE sealing tape, ensure that no tape is sticking out of the threads.

Any heat-resistant PVC piping use is NOT recommended due to high outlet water

temperature for between the heat pump and the tank as well as the tank and the

mixing valve.

Follow the manufacturer’s instruction manual for the type of bond, amount to be

applied, curing time, and other specifications.

If any bond or flux has entered the tank unit and the hot water has a chemical/acrid

smell, take the following countermeasures.

a) After heating the water in the tank unit, drain it and clean inside the tank unit. Fill

the tank unit with 26 gallons (100 litres) of water and exchange twice.

b) Clean or change the filter.

c) Fill up the tank unit.

d) Drain water from the relief valve for one to two minutes.

e) Run water from all the hot water supply faucets in the house for about ten minutes

to clean inside the pipes.

Figure 5: Reguired System piping (Typical System piping)

Sanden Heat Pump –Installation Manual

Page 9 of 40

Heat Pump Unit Water piping

ALL PIPING BETWEEN HEAT PUMP & TANK SHOULD BE ½” NO EXCEPTIONS

Connect the heat pump unit COLD supply to the tank unit fitting marked Cold Supply. –

½” NPT Connection (Certain early units may use ½” BSP connections).

Connect the heat pump unit HOT return to the tank unit fitting marked Hot Return – ½”

NPT Connection (Certain early units may use ½” BSP connections).

Connect the mains water supply to the lower fitting on the tank unit marked Cold Water

Inlet.

Connect the hot water supply pipe to the top of the tank unit marked Hot Water Outlet.

Install the PR valve to the fitting on the tank unit marked PR valve, pipe from PR valve

directly to a Building drain; do not install any shut off valve between PR valve and

Building drain.

Run water through the pipe(s) to remove any debris inside before connecting the

pipe(s).

After all the piping connections are completed, run water through the system.

Remove the air from the system according to the instructions below on Page 15.

Make sure all the necessary devices are mounted to the pipes as shown in diagram.

If the heat pump unit piping is kinked or clogged or the air inside was not removed

during the test operation, temperature of the supplied hot water may become

inconsistent.

Figure 6: System piping (Typical System piping)

Piping

WATER

. (Use 1/2” BSP

to 1/2” NPT connection adapter.)

. (Use 1/2” BSP

to 1/2” NPT connection adapter.)

HOT WATER

1/2"

1/2"

Notes :

Isolation Valves shown in typical positions

Union type connections and Isolation valves

recommended for ease of installation and service

Condensate drain line from base of Heat Pump

not shown, pipe to drain or other location in

1/2"

accordance with local codes

Tank Temperature sensor connecting Tank

to Heat Pump not shown

Piping between Tank and Heat Pump

66ft Maximum length, 23ft Maximum vertical separation

To/from bottom of Tank to bottom of Heat Pump

No more than 6 x Elbows/Bends

Insulate ALL piping external to the building

with minimum 3/4" Closed Cell insulation

Check coldest expected ambient temperature

to determine if Trace Heat Kit FG2-6L is required 1/2"

ECO-FPVKT3540 Power Outage kit also available

Cold Water Inlet should be regulated to below 95 Psi

Cold Water Inlet from Building

Title : SANCO2 Heat Pump unit & Storage Tank Standard Installation

Drg # :ECO2-GSHP-001 Drawn : JLM Rev : 01 Reissue 10/2020

©2020 Eco2 Systems LLC

11/19/2019

HEAT

PUMP

Hot Out

HEAT

PUMP

Cold In

GS4-45HPC HEAT PUMP

DHW STORAGE

TANK

COLD

TANK

to HP

HOT

HP to

TANK

DHW

COLD

IN

DHW

HOT

OUT

PRV

PIPE to

DRAIN

Mixed Outlet to

Building/Home

Cold Water

to Anti Scald

Valve

Hot Water

to Anti Scald

Valve

Anti Scald

Valve -

Supplied with

System

SANCO2Heat Pump – Installation Manual

Page 10 of 44

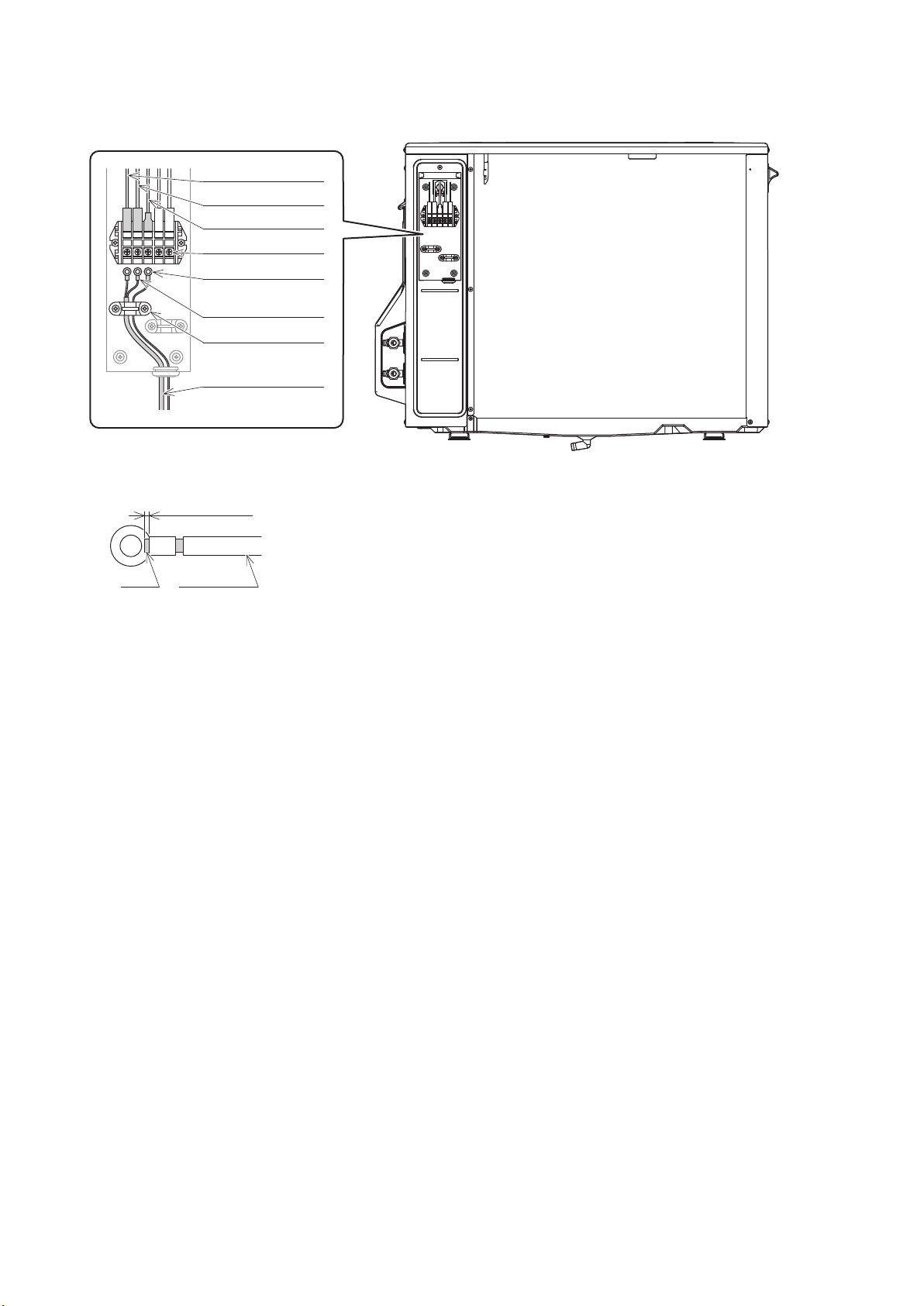

How to Connect Main Power

Remove the power box cover (Philips head screwdriver required).

Connect the power wiring to the terminal block per the wiring diagram/manual.

Ensure ground wire is connected.

Secure the eld power supply wiring below the terminal block with the screw

clamp tting.

Re attach the power box cover to the heat pump unit.

Sanden Heat Pump –Installation Manual

Page 10 of 40

Mains Power/Electrical Installation

All Electrical Wiring should be done in accordance with the latest edition of the

National Electrical Code (NEC) and all local State/Province and Municipality codes.

The power requirement for the system is a dedicated 15 amp circuit fitted with a

circuit breaker. This circuit may be connected to constant power or off-peak power.

A local disconnect should be installed adjacent to the Heat Pump unit in

accordance to NEC and local codes.

Installation of this system must be carried out only by a qualified installation

technician (electrical, HVAC or plumbing).

Electrical connections

Breaker size and wiring must be sized per NEC rules for the rating plate amperage,

MCA and MOP or Max Circuit Breaker.

Power Supply is 208/230V-1Ph-60Hz

Verify that the tank unit is full of water and the

water shut off valves are open before turning on the

power.

How to connect Main Power

Remove the terminal block cover (Philips head screwdriver required)

Connect the power wiring to the terminal block per the wiring diagram/manual.

Ensure ground wire is connected.

Secure the field power supply wiring below the terminal block with the screw clamp

fitting.

Re attach the terminal block cover to the heat pump unit.

Electrical Connections

SANCO2Heat Pump – Installation Manual

Page 11 of 44

Figure 6:Main Power Connection

0.5mm〜1mm

Power wire

Core

Heat Pump 208/230V Power Wiring must use solid copper wire.

Appropriately sized ring or fork terminals are recommended for easier connection.

Power supply

208/230V

Black

Wihte

Green/Yellow

Power line

Ground

5×M4 Screws

Wire holder band

Sanden Heat Pump –Installation Manual

Page 10 of 40

Mains Power/Electrical Installation

All Electrical Wiring should be done in accordance with the latest edition of the

National Electrical Code (NEC) and all local State/Province and Municipality codes.

The power requirement for the system is a dedicated 15 amp circuit fitted with a

circuit breaker. This circuit may be connected to constant power or off-peak power.

A local disconnect should be installed adjacent to the Heat Pump unit in

accordance to NEC and local codes.

Installation of this system must be carried out only by a qualified installation

technician (electrical, HVAC or plumbing).

Electrical connections

Breaker size and wiring must be sized per NEC rules for the rating plate amperage,

MCA and MOP or Max Circuit Breaker.

Power Supply is 208/230V-1Ph-60Hz

Verify that the tank unit is full of water and the

water shut off valves are open before turning on the

power.

How to connect Main Power

Remove the terminal block cover (Philips head screwdriver required)

Connect the power wiring to the terminal block per the wiring diagram/manual.

Ensure ground wire is connected.

Secure the field power supply wiring below the terminal block with the screw clamp

fitting.

Re attach the terminal block cover to the heat pump unit.

SANCO2Heat Pump – Installation Manual

Page 12 of 44

Sanden Heat Pump –Installation Manual

Page 12 of 40

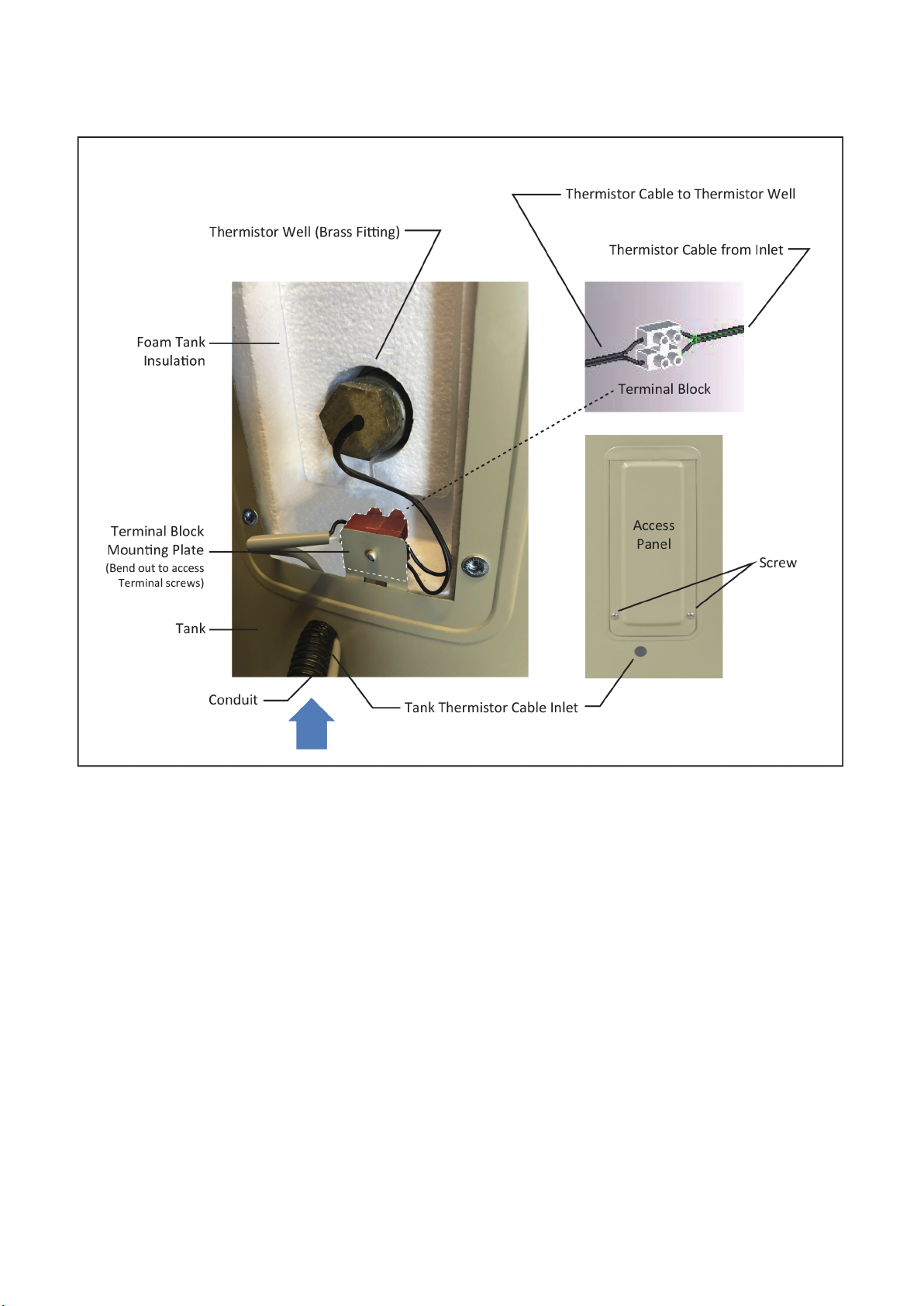

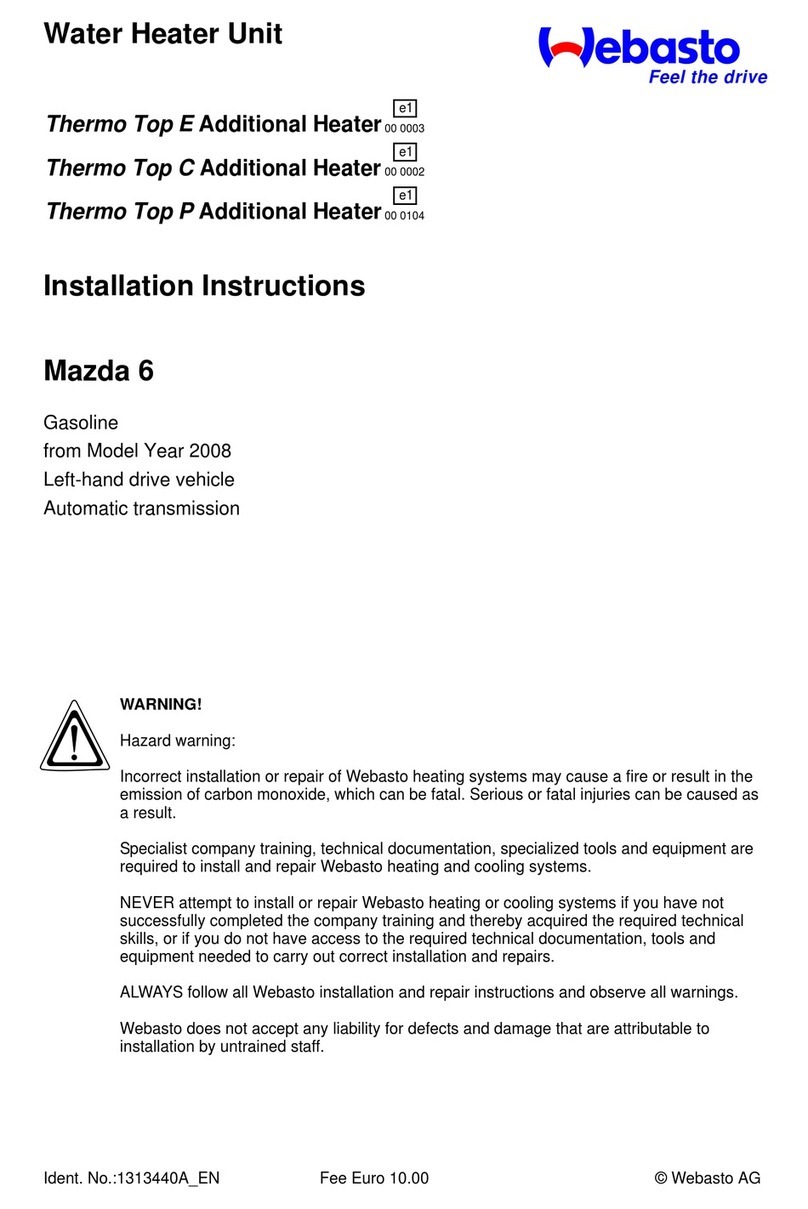

How to connect Tank thermistor cable to Heat Pump unit

The thermistor cable and conduit length are provided to cover 16.5 feet between the

tank and the Heat Pump.

If the units are located closer, the thermistor cable and conduit may be cut to the

desired length (Figure 8).

If the units are further apart, the thermistor cable may be extended by connecting an

18-2 AWG Shielded wire to the existing thermistor cable – connections are not

polarity sensitive.

Attach the conduit connector to the conduit end. Push the conduit into the opening on

the connector until the conduit does not go any further. Pull the conduit several times

to ensure the connector is fixed properly to the conduit.

Unscrew and carefully remove the terminal block cover on the tank. Do not use

unnecessary force to remove the cover as this could pull and break the cable coming

out of the tank unit.

Attach the connector on the end of the thermistor conduit coming from the heat pump

unit side to the opening on the bottom of the cover on the tank unit.

Confirm the gasket is adhered to the thread of the conduit connector before attaching

the connector to the cover. If the gasket is not present, there is a risk of water getting

inside the cover and this may result in a malfunction of the terminal block.

Connect the thermistor cables to the bottom of the terminal block.

Replace the terminal block cover back onto the tank unit and tighten the screws.

Note :

SAN-119GLBK tank does not include an access panel / terminal block.

7

How to Connect Tank Thermistor Cable to Heat Pump Unit

SANCO2Heat Pump – Installation Manual

Page 13 of 44

Sanden Heat Pump –Installation Manual

Page 12 of 40

How to connect Tank thermistor cable to Heat Pump unit

The thermistor cable and conduit length are provided to cover 16.5 feet between the

tank and the Heat Pump.

If the units are located closer, the thermistor cable and conduit may be cut to the

desired length (Figure 8).

If the units are further apart, the thermistor cable may be extended by connecting an

18-2 AWG Shielded wire to the existing thermistor cable – connections are not

polarity sensitive.

Attach the conduit connector to the conduit end. Push the conduit into the opening on

the connector until the conduit does not go any further. Pull the conduit several times

to ensure the connector is fixed properly to the conduit.

Unscrew and carefully remove the terminal block cover on the tank. Do not use

unnecessary force to remove the cover as this could pull and break the cable coming

out of the tank unit.

Attach the connector on the end of the thermistor conduit coming from the heat pump

unit side to the opening on the bottom of the cover on the tank unit.

Confirm the gasket is adhered to the thread of the conduit connector before attaching

the connector to the cover. If the gasket is not present, there is a risk of water getting

inside the cover and this may result in a malfunction of the terminal block.

Connect the thermistor cables to the bottom of the terminal block.

Replace the terminal block cover back onto the tank unit and tighten the screws.

Note :

SAN-119GLBK tank does not include an access panel / terminal block.

Figure 7: Connecting tank unit thermistor cable - SAN Tanks shown as example

SANCO2Heat Pump – Installation Manual

Page 14 of 44

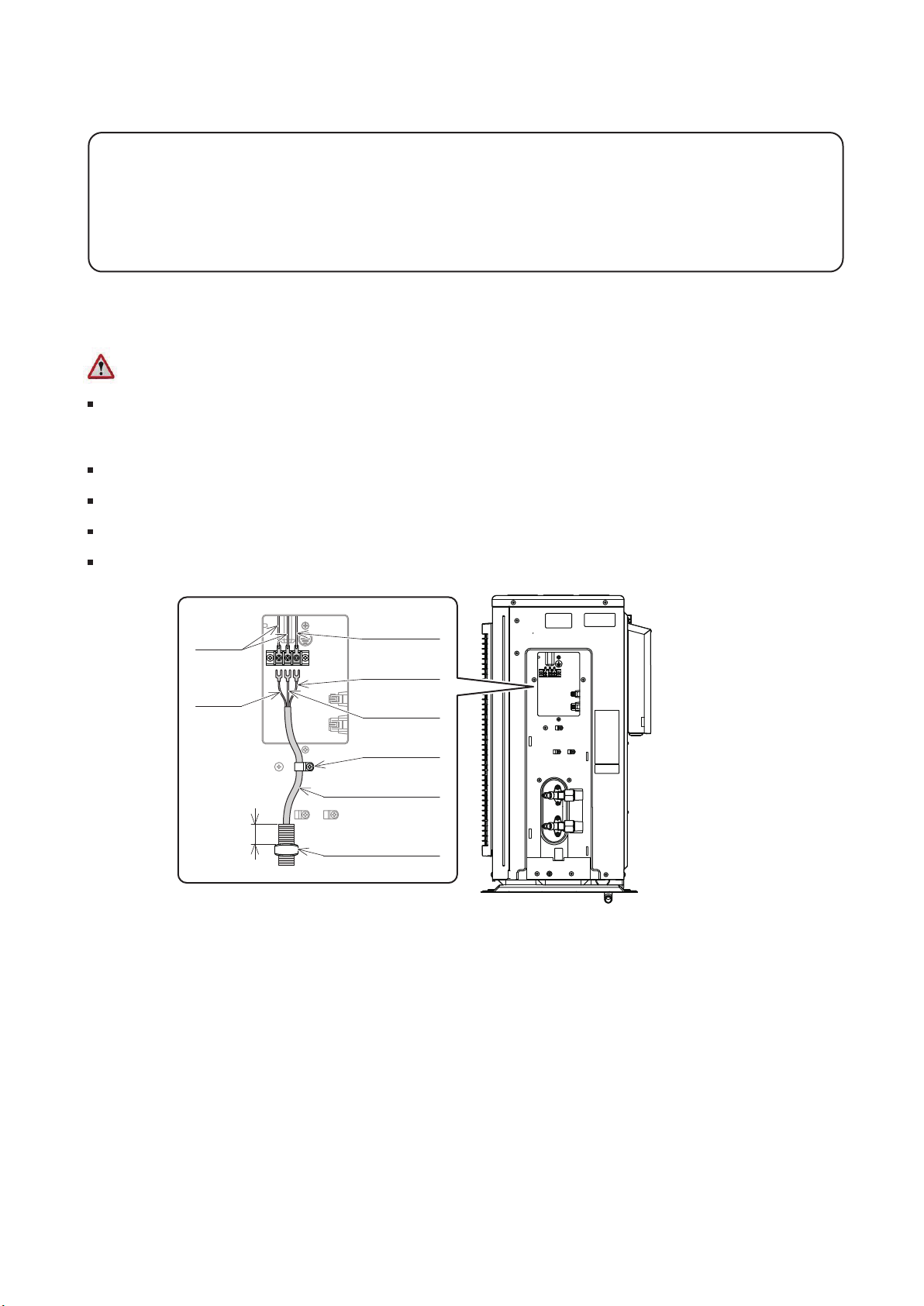

Electrical Installation

Please note:

All Electrical Wiring should be done in accordance with the latest

edition of the National Electrical Code (NEC) and all local State/

Province and Municipality codes.

Remove the piping cover.

Connect the thermistor cable line to the terminal block.

Installation of this system must be carried out only by a qualied installation

technican (electrical, HVAC or plumbing).

Fix the thermistor cable with the code clip and conduit clip.

Attach the piping cover back on the heat pump unit.

Conduit clip

Code clip

Thermistor cable

Wihte

Green

Green

Blue

Black

25mm

or

less

Figure 8:Connecting Heat Pump unit thermistor cable

Sanden Heat Pump –Owner’s Manual

Page 7 of 24

Installation details

This Sanden Eco Hot water Heat Pump System must be installed by licensed personnel in

accordance with local building codes:

Installing contractor should be licensed by applicable state/province and municipal

authorities to install an Electrical & Plumbing product.

The unit has been designed for heating potable domestic hot water and any other

usage, such as space heating requires a heat exchanger suitable for local codes to

be installed on the system to separate potable and non-potable water.

The unit is designed to operate when connected to the water supply with a

maximum operating pressure of 95PSI (655 kPa). To ensure the mains pressure

does not exceed this, first check incoming cold water mains pressure, and then a

pressure regulating device must be connected to the water supply line.

This system delivers hot water exceeding 120 oF (50 oC).

Installation of a temperature tempering device is MANDATORY to avoid potential

scalds and burns.

The unit must be stored and transported in an upright position. Failure to do so may

render the unit faulty. Such failure is not covered under any warranty agreements.

Failure to comply with the above conditions will void the warranty.

DANGER

SANCO2Heat Pump – Installation Manual

Page 15 of 44

Sanden Heat Pump –Installation Manual

Page 14 of 40

If the unit is connected to Demand Response power and hot water consumption has

been higher than normal, hot water might not be available until the next power

supply cycle.

Daily frequency and amount of hot water consumption may also affect the duration

of the heating cycle operation.

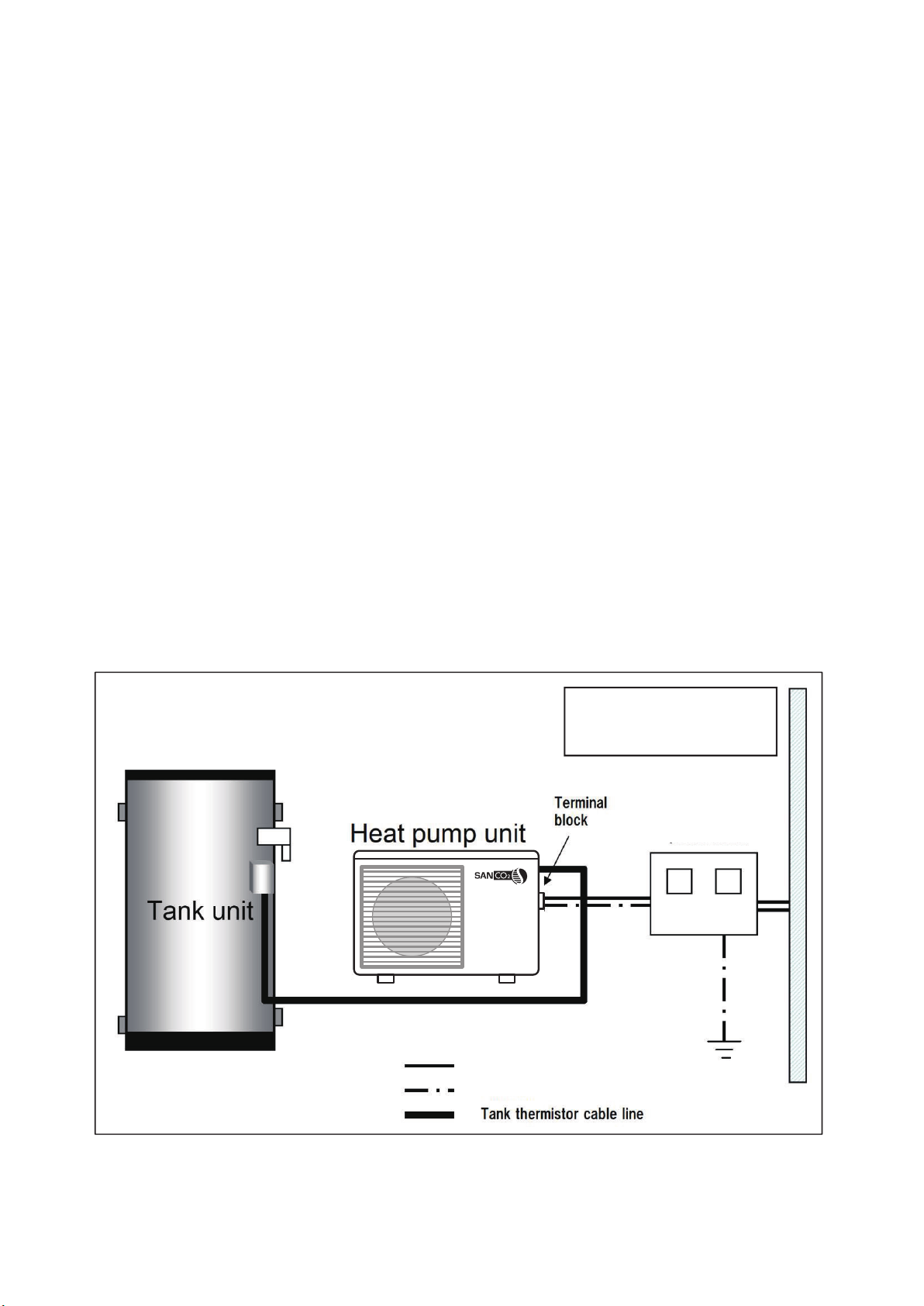

Figure 9: Outline of electrical system connections

The basic system installation is now complete; the unit is

now ready for initial water filling, air purge and then start up

Check the Installation against the Installation Check list

provided at the end of this manual

Ensure that the work site is tidy; Sanden International recommends the use of Slim Duct or

Fortress product to cover water piping on the outside of the house.

Caution

Use copper wiring

208/230V Power

Ground Wire

Breaker Box

Sanden Heat Pump –Installation Manual

Page 14 of 40

If the unit is connected to Demand Response power and hot water consumption has

been higher than normal, hot water might not be available until the next power

supply cycle.

Daily frequency and amount of hot water consumption may also affect the duration

of the heating cycle operation.

Figure 9: Outline of electrical system connections

The basic system installation is now complete; the unit is

now ready for initial water filling, air purge and then start up

Check the Installation against the Installation Check list

provided at the end of this manual

Ensure that the work site is tidy; Sanden International recommends the use of Slim Duct or

Fortress product to cover water piping on the outside of the house.

Caution

Use copper wiring

208/230V Power

Ground Wire

Breaker Box

Sanden Heat Pump –Installation Manual

Page 13 of 40

Figure 8: Connecting tank unit thermistor cable – GAUS Tanks shown as example

System operation using continuous Power Supply

If the block out time function is selected (setting is covered on Page 18) the unit will

not operate during the block out times – this function is typically used on

installations that have time of use electricity tariffs.

The water heating cycle operation starts automatically when the residual hot water

in the tank unit is less than 40 gallons (150 litres).

The system will not run if the electrical power supply is cut off. However, the system

will automatically start operation, once the electric power supply is restored.

System operation if connected to Demand Response Power

There are no special settings for the Demand Response. The system will run once

power becomes available and the temperature in the tank drops below the set point

of the tank thermistor.

If connecting the unit to Demand Response power ensure that the power supply

provides a minimum of 5 hours continuous power, as it can take at least four hours

to fill the tank unit with hot water.

If the ambient temperature is lower than 50oF (10oC) this can be longer.

Thermistor

cable

Gasket

Conduit

connector

Conduit

Terminal

block

Tank unit

Screw

Sanden Heat Pump –Installation Manual

Page 13 of 40

Figure 8: Connecting tank unit thermistor cable – GAUS Tanks shown as example

System operation using continuous Power Supply

If the block out time function is selected (setting is covered on Page 18) the unit will

not operate during the block out times – this function is typically used on

installations that have time of use electricity tariffs.

The water heating cycle operation starts automatically when the residual hot water

in the tank unit is less than 40 gallons (150 litres).

The system will not run if the electrical power supply is cut off. However, the system

will automatically start operation, once the electric power supply is restored.

System operation if connected to Demand Response Power

There are no special settings for the Demand Response. The system will run once

power becomes available and the temperature in the tank drops below the set point

of the tank thermistor.

If connecting the unit to Demand Response power ensure that the power supply

provides a minimum of 5 hours continuous power, as it can take at least four hours

to fill the tank unit with hot water.

If the ambient temperature is lower than 50oF (10oC) this can be longer.

Thermistor

cable

Gasket

Conduit

connector

Conduit

Terminal

block

Tank unit

Screw

Sanden Heat Pump –Installation Manual

Page 13 of 40

Figure 8: Connecting tank unit thermistor cable – GAUS Tanks shown as example

System operation using continuous Power Supply

If the block out time function is selected (setting is covered on Page 18) the unit will

not operate during the block out times – this function is typically used on

installations that have time of use electricity tariffs.

The water heating cycle operation starts automatically when the residual hot water

in the tank unit is less than 40 gallons (150 litres).

The system will not run if the electrical power supply is cut off. However, the system

will automatically start operation, once the electric power supply is restored.

System operation if connected to Demand Response Power

There are no special settings for the Demand Response. The system will run once

power becomes available and the temperature in the tank drops below the set point

of the tank thermistor.

If connecting the unit to Demand Response power ensure that the power supply

provides a minimum of 5 hours continuous power, as it can take at least four hours

to fill the tank unit with hot water.

If the ambient temperature is lower than 50oF (10oC) this can be longer.

Thermistor

cable

Gasket

Conduit

connector

Conduit

Terminal

block

Tank unit

Screw

22

System Operation If Connected to Dry Contact

Dry Contact input. The system will run once dry

power supply is cut off. However, the system will

automatically start operation, once the electric power supply is restored.

contact input is closed and the temperature in the tank drops below the set point of

the tank thermistor.

Dry Contact and hot water consumption has been higher

than normal, hot water might not be available until the next power supply cycle.

Standard System Operation

23

SANCO2Heat Pump – Installation Manual

Page 16 of 44

How to Connect Dry Contact

Dry Contact Purpose

・

UNIT START INPUT

Allow External ON/OFF switching of the Heat Pump –

Commonly used in Utility programs or other installations where having control of the Heat

Pump other than Tank temperature is required.

Note: Even should the unit be in the OFF mode via the Dry Contact the Freeze Protection

program may still start the unit depending on Ambient and Water temperatures.

・

ERROR SIGNAL OUTPUT

Send an error to Utility programs.

Installation of Dry Contact switching

Remove the pipe cover.

Locate the Dry Contact loop.

Cut the loop and strip wire from the two ends.

Wire to external utility, note the maximum

voltage and current requirements.

CAUTION : If voltage is applied to the Dry contact terminal from the outside switch, the

equipment will be damaged.

Unit Operation

・

UNIT START INPUT

When the switch is in the OPEN position the unit is OFF

(Exception – Unit will run if Freeze protection mode is activated)

When the switch is in the CLOSED position the unit is ON

The unit will now be controlled by the Tank Temperature Thermistor

Unit will run if the Tank temperature is below 113°F as sensed by the thermistor

・

ERROR SIGNAL OUTPUT

When an error has occurred, the switch is open.

UNIT START INPUT

Cut

ERROR SIGNAL

OUTPUT

To Utility

Contact specication

Voltage 5V

Current 2mA

Sanden Heat Pump –Installation Manual

Page 14 of 40

If the unit is connected to Demand Response power and hot water consumption has

been higher than normal, hot water might not be available until the next power

supply cycle.

Daily frequency and amount of hot water consumption may also affect the duration

of the heating cycle operation.

Figure 9: Outline of electrical system connections

The basic system installation is now complete; the unit is

now ready for initial water filling, air purge and then start up

Check the Installation against the Installation Check list

provided at the end of this manual

Ensure that the work site is tidy; Sanden International recommends the use of Slim Duct or

Fortress product to cover water piping on the outside of the house.

Caution

Use copper wiring

208/230V Power

Ground Wire

Breaker Box

SANCO2

The basic system installation is now complete; the unit is

now ready for initial water lling, bleeding and then start up

Check the Installation against the Installation Check list

provided at the end of this manual

SANCO2Heat Pump – Installation Manual

Page 17 of 44

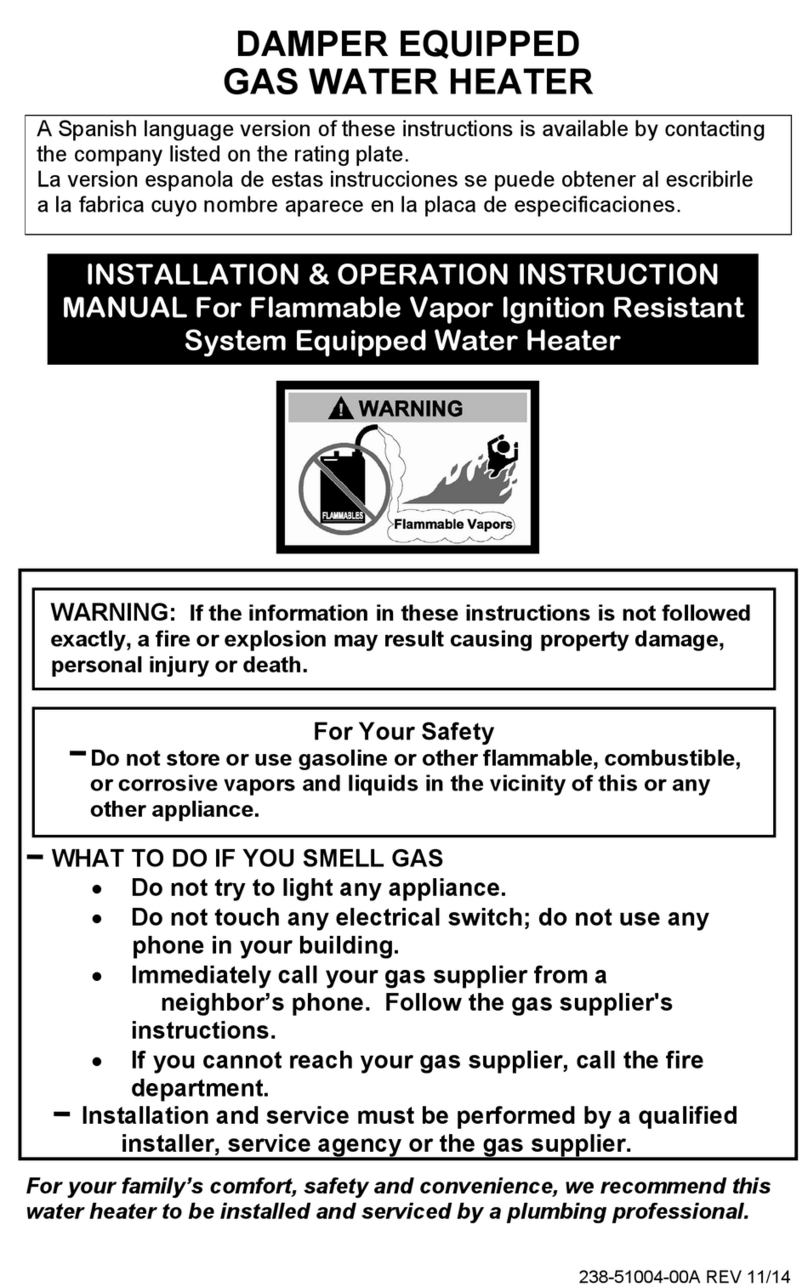

Filling the System & Bleeding Air

The following steps must be taken to ensure all air is bled from the system.

Incorrect bleeding of air may cause the water temperature to vary during operation, and

lead to possible error codes.

・

Ensure that all piping to tank unit and heat pump unit are installed and connections are

tight, then open the Cold Water Supply Valve to the system.

・

Push up the lever on the PR valve to open, and ll the tank unit with water.

Conrm that water comes out of the relief valve, and then close the lever.

・

Open the hot water faucets to bleed air from the house piping system.

・

Close the faucets after no air is seen in the water.

・

Open the water drain plug on the heat pump unit.

Close the plugs after no air is seen in the water or a steady stream of water is present.

・

Supply power to the heat pump unit.

・

Display shows "1200" then "Clock setting mode" is started with operating "Air bleeding

process" at the same time.

・

In case nish time setting or nothing is operated for 1 minute, "Clock setting mode" is

terminated and "APon" will be displayed on the monitor.

・

"Air bleeding process" will be done in 5 minutes.

Once it's nished, current time will be shown on monitor.

・

Leave the hot water faucets open for 3 minutes.

Close the faucets after no air can be seen in the water.

Sanden Heat Pump – Owner’s Manual

Page 11 of 20

Removing air from the system

Please note:

Plumbing work should only be completed by a licensed plumber

• The following steps must be taken to ensure all air is removed from the system.

Incorrect removal of air may cause the water temperature to vary.

• Plumb pipes to the tank unit and the heat pump unit.

• Push up the lever on the PTR valve to open, and fill the tank unit with water.

• Confirm that the water comes out of the relief valve and then close the lever.

• Open the hot water taps in the home to remove air.

• Close the hot water taps in the home after no air is confirmed in the water.

• Open the water drain plug on the heat pump unit.

• Close the plug after no air is confirmed in the water.

• Connect the power to the heat pump unit.

• Air removing process (Refer to figure 4)

1. Switching to Air Removing Mode

Long press the “Up” and “Down” keys to switch to the “Heat Setting Mode”.

2. Press the “Up” or “Down” keys to switch to the “Air Removing Mode” and press

the “Enter” key. Press the “Up” keys again to display “APon”, then press the

“Enter” key.

After 5 minutes, the air removing mode will automatically finish and the display will

show [Air ] again.

• Open the hot water taps in the home to remove air.

• Close the hot water taps in the home after no air is confirmed in the water.

*Caution

If air removing mode is not completed, the system will not start the heating cycle.

Figure 4: Air removing process

PR valve lever

PR valve to open,

Figure 10: Air bleeding process

Sanden Heat Pump –Installation Manual

Page 14 of 40

If the unit is connected to Demand Response power and hot water consumption has

been higher than normal, hot water might not be available until the next power

supply cycle.

Daily frequency and amount of hot water consumption may also affect the duration

of the heating cycle operation.

Figure 9: Outline of electrical system connections

The basic system installation is now complete; the unit is

now ready for initial water filling, air purge and then start up

Check the Installation against the Installation Check list

provided at the end of this manual

Ensure that the work site is tidy; Sanden International recommends the use of Slim Duct or

Fortress product to cover water piping on the outside of the house.

Caution

Use copper wiring

208/230V Power

Ground Wire

Breaker Box

CAUTION : Air bleeding valve is located at the bottom of the heat pump unit!

Open

The air bleeding valve

Open the faucet to bleed air. Close the faucet

after no air bubbles can be seen in the water.

Open the air bleeding valve on the Heat Pump

Unit.

Close the valve after no air is conrmed in the

water supply.

Then connect power to the Heat Pump Unit.

Open faucet.

SANCO2Heat Pump – Installation Manual

Page 18 of 44

Sanden Heat Pump –Installation Manual

Page 16 of 40

Freeze protection

Even if the water pipes have been insulated, the piping can freeze if the

surrounding temperature falls below freezing (32oF). This could cause damage to

the equipment and piping so make sure the appropriate freeze protection measures

are taken.

Follow the instructions in the installation manual provided with the freeze protection

heat tape.

After completion of the piping, inspect the plumbing for any water leaks from the

joints before installing freeze protection.

Wrap the freeze protection heater around the pipes, up to the water connectors of

the Heat Pump unit.

Ensure the freeze protection heaters are connected to a 24 hours continuous

power supply.

It is important to fully explain the use and operation of the freeze protection heater

to the customer.

When turning off the power, because the unit will not be in use, ALL water

must be drained from the unit and piping.

Note: Heat tape that uses the outside temperature to energize, may not maintain

the temperature of the pipes correctly. It is important to use a heat tape that

directly senses the pipe’s temperature.

Figure 11: Details on wrapping thermal insulation around the piping connector

Heater

Insulation

Tapes

Thermal

Insulation

Band

Pipe wrapping Connection wrapping

Sanden Heat Pump –Installation Manual

Page 16 of 40

Freeze protection

Even if the water pipes have been insulated, the piping can freeze if the

surrounding temperature falls below freezing (32oF). This could cause damage to

the equipment and piping so make sure the appropriate freeze protection measures

are taken.

Follow the instructions in the installation manual provided with the freeze protection

heat tape.

After completion of the piping, inspect the plumbing for any water leaks from the

joints before installing freeze protection.

Wrap the freeze protection heater around the pipes, up to the water connectors of

the Heat Pump unit.

Ensure the freeze protection heaters are connected to a 24 hours continuous

power supply.

It is important to fully explain the use and operation of the freeze protection heater

to the customer.

When turning off the power, because the unit will not be in use, ALL water

must be drained from the unit and piping.

Note: Heat tape that uses the outside temperature to energize, may not maintain

the temperature of the pipes correctly. It is important to use a heat tape that

directly senses the pipe’s temperature.

Figure 11: Details on wrapping thermal insulation around the piping connector

Heater

Insulation

Tapes