Ecofly Smart M 160/1 User manual

Manual

Smart M 160/1

Engine

Manufacturer: Ecofly GmbH, Germany

Manual Smart M160 / 1–UL-Engine

July 05

Ecofly GmbH Page 1

Table of Contents

1. Technical Concept .................................................................... 1

1.1. Description....................................................................... 2

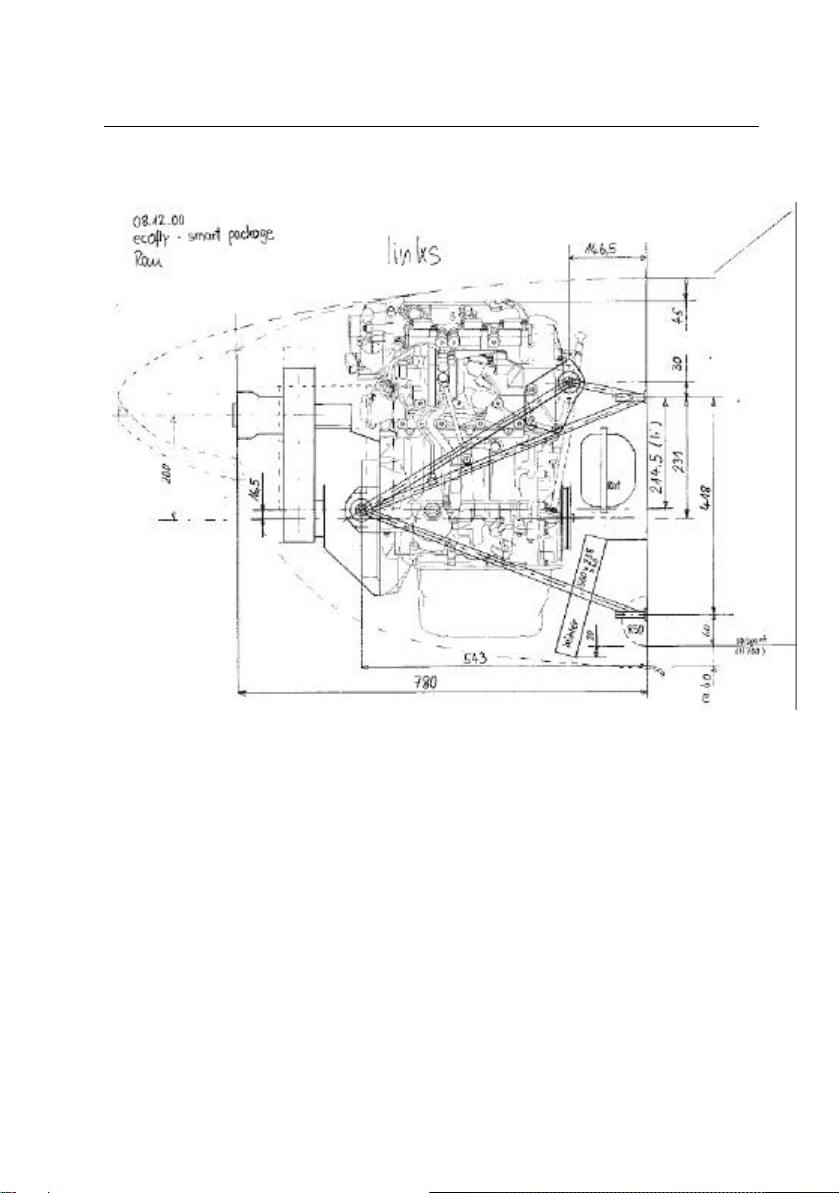

1.2. Engine Layout / Dimensions .............................................. 3

2. Technical Data ......................................................................... 5

2.1. Principal Dimensions / Data............................................... 5

2.2. Performance and Torque Curve for 60KW Engine............... 6

2.3. Performance and Torque Curve for 74KW Engine............... 7

2.4. Fuels / Fuel System.......................................................... 8

2.5. Lubricants ........................................................................ 9

2.6. Cooling system and Coolant .............................................10

2.7. Manifold Intake................................................................10

2.8. Propeller Gear.................................................................10

3. Operating Limits ......................................................................11

3.1. Water / Oil.......................................................................11

3.2. Height .............................................................................13

3.3. Manifold Temperature ......................................................13

3.4. Manifold Pressure............................................................13

3.5. ECU / Relay Box..............................................................14

4. Engine Operation.....................................................................14

4.1. Ignition / Warming-up.......................................................14

4.2. Takeoff............................................................................15

4.3. Landing...........................................................................15

4.4. Switching off....................................................................15

5. Checks....................................................................................15

5.1. Daily Checks...................................................................15

5.2. Checks after first 25hrs (in addition to 5.1.)........................16

5.3. Checks after 100hrs / 1 year (in addition to 5.1.)................16

5.4. Checks after 300hrs / 3 years (in addition to 5.1. & 5.3.).....16

5.5. Checks after 1500hrs or 15 years .....................................17

6. Maintenance............................................................................17

6.1. Oil Circuit ........................................................................17

6.2. Air intake / Air filter (Oil in intake system?).........................17

6.3. Compression...................................................................17

6.4. Spark Plugs.....................................................................17

6.5. Belt Tension ....................................................................17

6.6. Extending Engine Life......................................................17

6.7. Torque Table...................................................................18

7. Document Version History ........................................................18

Manual Smart M160 / 1–UL-Engine

July 05

Ecofly GmbH page 1

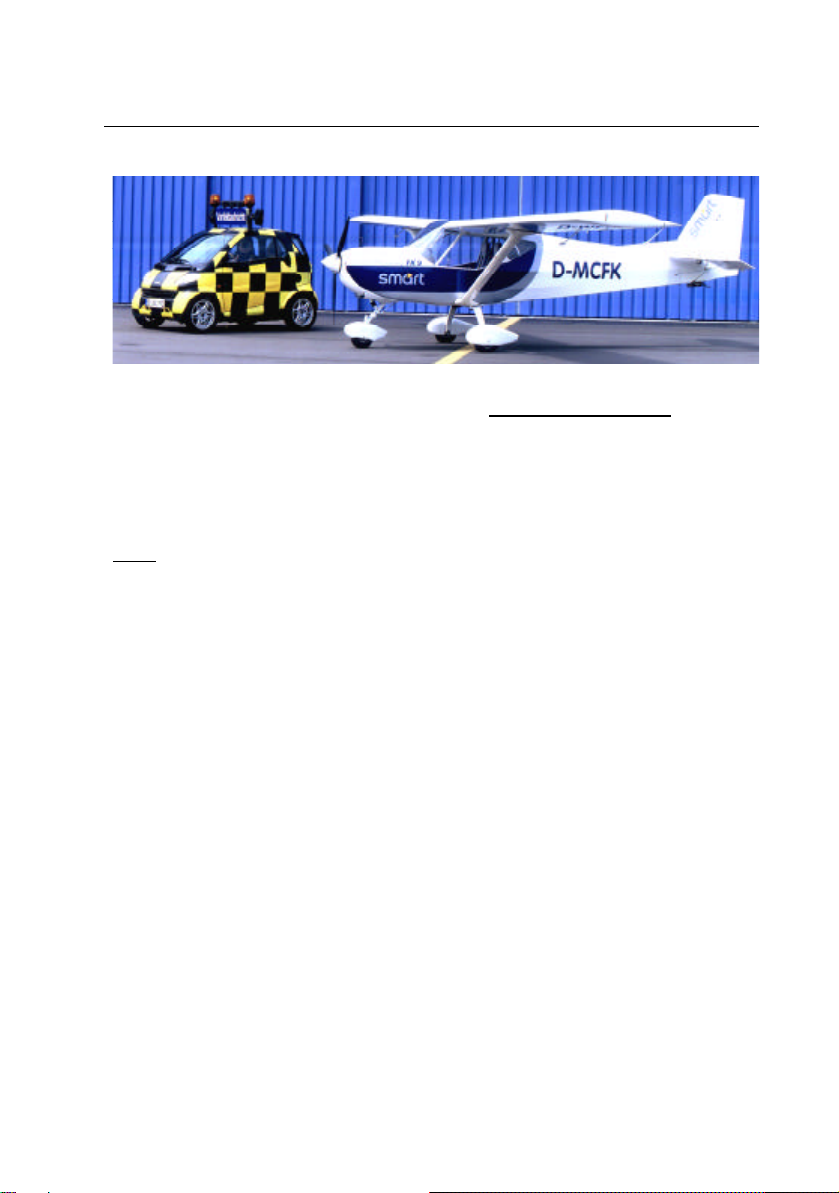

1. Technical Concept

Our engine is a series-produced automobile enginefrom the smart car withbelt

drive for use as a stationary engine or as an uncertified power train for sports

aircraft.

Engine RPM is reduced with the help of atoothed belt drive.

Car-like vibration damping is achieved by using a centrifugal clutch with soft

torsion coupling.

Note:

Since this engine is a variant of a serially produced stationary engine, itdoesnot

meet the safety requirements of certified aircraft engines. The engine may

therefore only be used in aircraft types where sudden engine failure does not

endanger safety.

This meansthat the glide and landing characteristicsof the aircraft must notbe

affected by engine failure, proof of which must be produced during aircraft

certification.

Therefore, aircraft equipped with this engine must only be flown over such

terrain and at altitudes and speeds sothat in the event of sudden engine failure,

safe landing is always possible, responsibility for whichrests with the pilot.

Local regulations may apply. For Germany, see Civil Aviation Act (Luft VO) §6.

The user acknowledgesby signing below that engine failure is possible at any

time because the engine is used for a purpose other than designed.

Place......................................... Date:....................................

Signature:..................................................................................................

Furthermore, any modifications to the engine and/or drive pose potential safety

risks. As such, distributors are advised to not undertake any changes prior to

qualified engineeringanalysis and exhaustive testing!

Any irregularities, anomalies and damage must be immediately reported to the

distributor!Signature:....................................................

Manual Smart M160 / 1–UL-Engine

July 05

Ecofly GmbH page 2

1.1. Description

o3-cylinder series

engine with

turbocharger;

60KW /74KW

oFully electronic

sequential

injection

oLambda sensor

controlled 3-way

catalytic

converter

integrated into

muffler (optional)

oElectronic knock

control using

knock sensor

oPower control

using redundant

potentiometer

and e-gas

oDual ignition for maximum smoothness (single-circuit)

oManifold pressure controlled by variable valve timing, intercooler

oWater-cooled turbocharger housing with pressurised lubrication

oThermostat-controlled water cooling

oOil circuit with wet sump

oOverhead camshaft with maintenance-free chain drive

oMaintenance-free valve control with hydraulic valve-play compensators

oAll-aluminium crankcase

oBelt-driven water pump andalternator

oElectrical starter

oElectrical fuel pump

oElectronic engine control unit (ECU) with relays and 2 sets of cables

Manual Smart M160 / 1–UL-Engine

July 05

Ecofly GmbH page 3

oFlanged gearboxwith bearing-

mounted drive shaft

oToothed belt drive with

adjustable belt tension

oCNC machined propeller

bearing and shaft

oCentrifugal clutch withmetal

bushings to reduce torsional

vibration

oElastically suspended

mounting plate for sensors,

relay boxand ECU

o4-point engine mount

1.2. Engine Layout / Dimensions

Manual Smart M160 / 1–UL-Engine

July 05

Ecofly GmbH page 4

Manual Smart M160 / 1–UL-Engine

July 05

Ecofly GmbH page 5

2. Technical Data

2.1. TechnicalData/ Key Features

60 KW 74 KW

Capacity(cm³) 698

Stroke / Bore (mm) 68 / 66

Compression ratio 9.5 (-0.4) : 1

Cylinders/ Valves 3 cylinders;2valves per cylinder

Spark plugs (per cylinder)2

Engine weightper DIN (kg) 57

Max. torque (Nm) 110 at

2000 –4750RPM 130 at

2500 –5300RPM

Max. power output(kW) 60 at5250RPM

(continuous running)

74 at5600RPM

(continuous running)

Max. continuous RPM 5800 RPM

Max. short-timeRPM 6000 RPM

Max. manifold pressure(bar)

0.9 (+ 0.1 / -0.2) 1.3 (+ 0.1 / -0.1)

Charge air control Map-guided

Oil pump Chain-driven, external gear pump; wet sump

Ventilation Integrated full and partial load ventilation

Fuel injection/ injection

pressure Bosch EV6 / 3.8 bar via intake manifold

(max. 4.8bar)

Fuel Min.RON95 (super unleaded)

Lambda sensor Bosch LSF4

Anti-knock control Electronic, adaptive; 1knock sensor

Max. permissible

turbocharger RPM 240 000

Max. exhaust temperature 950°C (at turbocharger inlet),

short-time980°C

Engine DiagnosticsDiagnostics module to read stored errors

Manual Smart M160 / 1–UL-Engine

July 05

Ecofly GmbH page 6

2.2. Performance and Torque Curve for60KW Engine

Manual Smart M160 / 1–UL-Engine

July 05

Ecofly GmbH page 7

2.3. Performance and Torque Curve for74KW Engine

Manual Smart M160 / 1–UL-Engine

July 05

Ecofly GmbH page 8

2.4. Fuels / Fuel System

Use only unleaded, min. 95 octane fuel (unleaded Super = standard automotive

fuel). Do not use any fuel additives!

Remarks:

oLeaded fuels damage not only the catalytic converter but also thelambda

sensor! The general rule also for engines not fitted with a catalytic converter

is therefore: do not use leaded fuel!

oIn case only Normal unleaded fuel is available, it can be used in exceptional

cases provided maximum power is reduced to80% (the knock control

system automatically adjusts the ignition angle, minimising the risk of

engine damage).

oRecommended optionally:

oUnleaded Super –Plus (RON98); at very high ambient

temperatures and limited cooling of charge air, this fuel grade might

even result in slightly higher performance.

oWe also recommend sulphur-free fuels such asShell Optimax

(RON99)(very environment-friendly and extremely knock-resistant)

oAll other fuels, even aviation-grade fuels willcause irreparabledamage to

the engine sooner or later!

oInjection valves aresusceptible to clogging due tofuel impurities, souse

only filtered fuel and check/replace fuel filter at regular intervals.

oA noisy fuel pump may be indicative of a clogged fuel filter: replace fuel

filter!

oTake special care when working with or checking the fuel system.

oGuide all fuel lines away from heat sources so as to protect them from

thermal fatigue. Insulate fuel lines against heat where necessary.

Manual Smart M160 / 1–UL-Engine

July 05

Ecofly GmbH page 9

2.5. Lubricants

The oil tank has a capacity of about 3.2l.

Replace the oil filter when changing the oil. Use suction to withdraw spent oil

completely.

Ecofly will install an oil bleed screw upon request.

The difference between the maximum and minimum oil level amounts toabout

0.5l.

Note: While topping up oil, ensure that the oil level NEVER exceeds the

max. level indicated on the dip stick.

Withdraw excess oil by suction if necessary.

The air-exhaust system of this engine is sensitive to excess oil; excessive oil

levels may even result in irreparable damage to the engine!

Minimum requirements:

Use only branded oils of API grade “SG”and higher.

Recommended:

Semi-synthetic or synthetic oils are recommended.

The best oils currently on the market are classified “SJ” (API).

The best oil you can use for this engine will meet the current Mercedes-Benz

Specification 229.3 (includes 229.1).

We cite an excerpt fromMB Specification 229.3:

The viscosity class must be

selected according to the

temperature range:

15W –40 should usually be

adequate for most

applications.

Manual Smart M160 / 1–UL-Engine

July 05

Ecofly GmbH page 10

2.6. Cooling System /Coolant

The coolant is a 50:50 mixture of water and antifreeze/anticorrosive fluid.

A 50:50 mixture provides frost protectiondown to -37°C.

At temperatures as low as -45°C,increase the ratio of the antifreeze

/anticorrosive fluid to 55% but not higher,since otherwise heat drain will be

impeded.

Use only antifreeze/anticorrosive fluids recommended by Mercedes-Benz. For

further information, contact the nearest Mercedes-Benz or smart service station.

In the event of coolant loss, determine cause, correct and refill as necessary. At

the time of refilling, top up with the recommended ratio of water and anti-

freeze/anticorrosive fluid.

Completely replace the coolant every 2 years.

Since coolant temperature is thermostatically controlled, do not cover the cooler

in winter!

2.7. Manifold Intake

Ensure that the air taken in is as cool as possible.

If necessary, take special measures to ensure that air taken in is not

inadvertently preheated by the cooler or the exhaust.

Since carburettor icing cannot occur in this engine by design (being an injection

system) preheated air is not merely superfluous, it actually reduces engine

performance!

If the intake temperature is too high, the ECU will automatically reduce engine

power output, WHICH MAY GIVE RISE TO DANGEROUS SITUATIONS.

Use only suitable air filters. Check, clean or replace the air filter at regular

intervals.

Ensure that all water entering the air intake is drained completely ahead of the

air filter.

Ensure that no rubber particles from the belt drive are sucked in.

Optimum charge air cooling must be ensured whenever the engine is

operational. NEVER cover theintercooler fully or even partially in winter.

2.8. Propeller Gear

The transmission ratio is2.1 : 1.

Toothed belt: HTD-(Powergrip GT2) 8M; 60mmwidth.

Check belt tension at regular intervals. When the engine is cold, the belt should

yield 5-10mm when pressed down at the centre of the exposed length.

If necessary, insert washers to adjust the distance of the propeller axle fromthe

drive shaft.

Manual Smart M160 / 1–UL-Engine

July 05

Ecofly GmbH page 11

Note:

oEnsure that the drive axes are perfectly parallel.

oMisalignments will provoke damage

oNEVER assemble the propeller axle without locating pins.

oDo not insert any spacers to extend the engine-propeller distance: this will

increase the bending load on the gears beyond permissible limits!

Note that a new belt will initially lose some rubber; this is not indicative of

unusual wear.

Check for play on the bottom bearing by pressing the belt down with a finger (in

case of damage, the play can be felt).

The same applies to the front and rear propeller bearings. Push against the

propeller to check that there is no radial play.

To increase comfort, the engine is fitted with a centrifugal clutch (which engages

at 1600 –2000RPM) and a soft, metal torsion coupling.

Never get out of an aircraft when the engine is idling, not even when the

propeller has stopped turning!Always switch off the engine before getting

out of the cockpit!

3. Operating Limits

While the engine is rated for maximum power output of 60/74KW, we

recommend that the engine power is suitably adjusted for cruise flight to

conserve fuel.

Note that the engine is completely unsuited for aerobatic manoeuvres! Do not

conduct stall exercises!

Aerobatic manoeuvres will damage the engine!

Avoid any critical RPM at which the natural frequency of the propeller and

cockpit cell resonate.

Maximum permissible engine rating amounts to5800 RPM.

3.1. Water / Oil

Maximum permissible water temperature is105°C.

Water temperature of 110°C is permissible for short times.

If the water temperature increases, the ECU will automatically reduce engine

power output.

Minimum water temperature for takeoff amounts to60°C.

Maximum permissible oil temperature is 140°C.

Oil temperature of 150°C is permissible for short times.

Minimum oil temperature for takeoff amounts to60°C.

Manual Smart M160 / 1–UL-Engine

July 05

Ecofly GmbH page 12

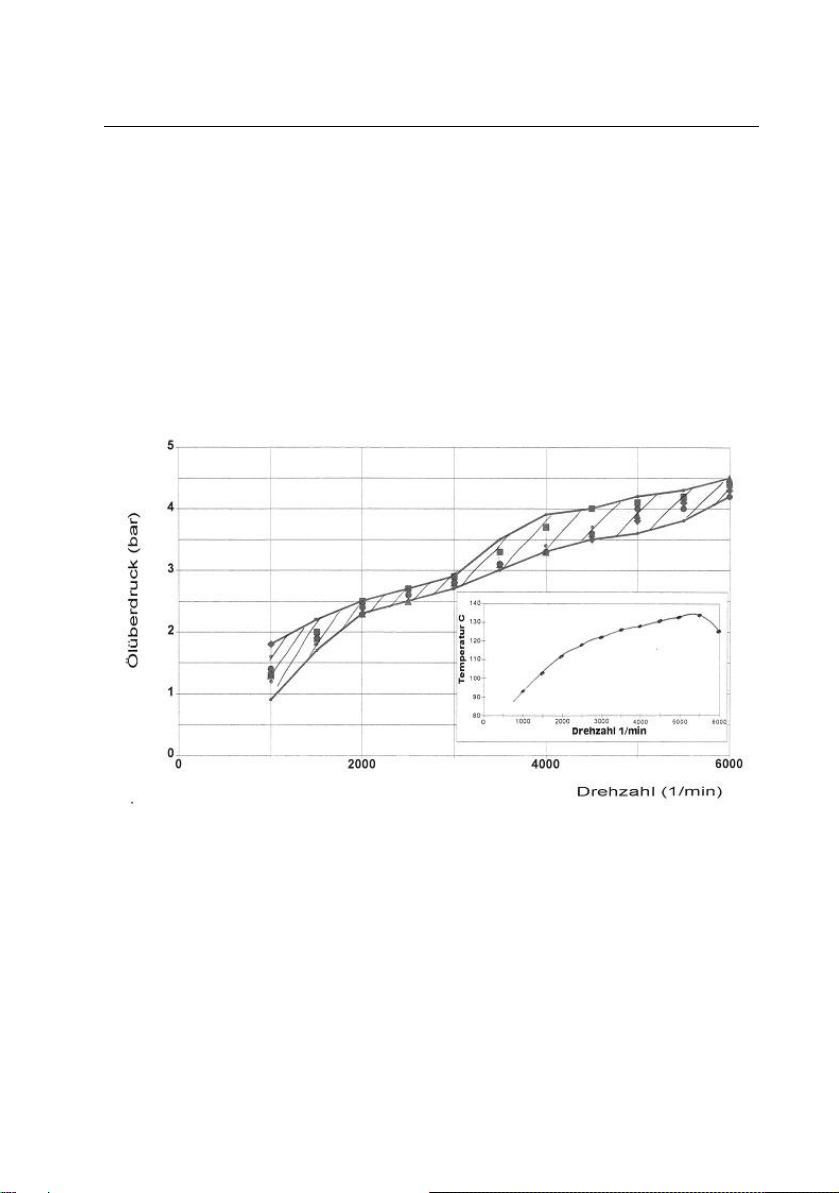

The diagram below indicates normal temperatures against RPM.

The minimum permissible oil pressure is a function of the oil temperature and

RPM.

See diagram below (applies to engines when new)

In the engines that have been in operation for longer periods, the indicated

values can be lower by about 10%. For instance:

At 2000RPM:Min. oil pressure2.0 bar (oil temperature 110°C); if oil

temperature is higher, oil pressure will be lower

At 4000RPM:Min. oil pressure 2.9 bar (oil temperature 125°C); if oil

temperature is higher, oil pressure will be lower

At 5500RPM:Min. oil pressure 3.3 bar (oil temperature 135°C); if oil

temperature is higher, oil pressure will be lower

Manual Smart M160 / 1–UL-Engine

July 05

Ecofly GmbH page 13

3.2. Height

The turbocharger is configured such that the engine will deliver 60/74KW of

power up to 2500m height.

Reduce power setting above 2400m so that the turbocharger does not

exceed its maximum rotational speed.

As a thumb rule:

Reduce power by 50 RPM (i.e. by about 1%) for every100m increase in height

above 2400m. For example, at 3000m, reduce power by 300 RPM(6*50=300).

We recommend that you reduce the RPM even further above a certain height.

3.3. Manifold Temperature

Maximum permissible manifold temperature is 45°C at 20°C ambient

temperature.

The lower the manifold temperature, the better will be engine performance due

to the more favourable ignition angle and higher air density.

Engine power output is lower at 45–55°C while at 60°C, the ECU will sharply

lower manifold pressure!

Use Super Plus (98 RON) fuel at very highambient temperatures to prevent the

anti-knocking system from scaling back ignition.

If necessary, use an electric fan to support cooling (in cases where air flow is

poor, e.g. in trike applications).

In general, allow uniform air flow on the surface of the intercooler!

3.4. Manifold Pressure

Manifold pressure at full power setting must show between 0.7 and 1.0 bar (60

KW) or 1.2 and 1.4 bar (74 KW).

The SMART-MIP (engine monitoring unit) which shows total pressure, will

indicate at full load 1.7 to 2 bar (60KW) and 2.2 to 2.4 bar (74 KW).

If pressure is not high enough, check system for leaks. If no obvious faults are

found, contact the service centreand have the turbocharger recalibrated.

If the manifold pressure exceeds 1.0 bar (60 KW) or 1.4 bar (74 KW),contact

the service centreand have the turbocharger recalibrated.

Manual Smart M160 / 1–UL-Engine

July 05

Ecofly GmbH page 14

3.5. ECU / Relay Box

Install the ECU so that the rear of the ECU is ventilated by cool ambient air.This

arrangement is necessary todrain the heat from active components.

Max. temperatureon ECU housing: 90°C.

Install the relay box and contacts such that they are protected from spray.

Moisture will cause contact problems!

4. Engine Operation

Read the manualbefore operating the engine!

Note:

Always adjust engine RPM so that the engine runssmoothly.

Make sure that the centrifugal clutch does not “drag”. Avoid the4100-4200 RPM

range as engine operation is not as smooth as at other speeds.

4.1. Ignition / Warming-up

Complete the daily check (see 5.1) before switching on the engine.

To start engine:

Fuel valve:Open

Throttle:Idle position (fuel/air mixture is controlled electronically)

Main switch:On

Ignition:On

Starter:Operate

As soon as the engine starts, throttle up sufficiently so that the engine runs

smoothly in conjunction with the resonance frequency of the cell/propeller.

Never operate the engine for long periods at low RPM (with stationary

propeller) so as to provoke overheating situations.

If water temperature touches 100°C on ground, increase engine RPM to

2000 for better cooling!

Allow engine to warm up at about 2000 RPM.

After 2 minutes, engine RPM can be raised to2500 RPM until all temperatures

have reached minimum operating temperatures(water: min. 60°C, oilmin60°C).

After taxying to the holding point, apply brakes and set the engine briefly to full

power. Check that manifold pressure increases to between 0.7-1 bar (60KW)or

1.2 to 1.4 bar (74 KW). The SMART-MIP will indicate total pressure, so at the

time of this check, it should indicate 1.7 to 2 bar (60 KW) or 2.2 to2.4 bar (74

KW).

If manifold pressure does not increase, abort takeoff immediately,

determine the cause of the fault and correct.

Monitor oil pressure at all times.

Manual Smart M160 / 1–UL-Engine

July 05

Ecofly GmbH page 15

4.2. Takeoff

Always set full power for takeoff.

In addition to observing temperatures, monitorespecially the indicated oil and

manifold pressure.

Leave engine at full power until youreach safe flying altitude; since the engine

regulates itself, it is not necessary to power down!

4.3. Landing

Set engine speed to 2000 RPM during landing approach. The centrifugal clutch

is fully engaged at this speed and the propeller will show better retarding

characteristics.

4.4. Switching off

After landing and taxi in, all engine components would have cooled down

sufficiently so that the engine can be switched off without taking any special

measures.

The turbocharger has a self-regulating thermosyphon to cool the exhaust

manifold in order to prevent oil coking.

After stationary full-load operation, it is sensible to allow the engine to run for

two minutes (with propeller engaged at about 2000 RPM) to allow it to cool

down.

5. Checks

5.1. Daily Checks

oRemove cowling completely (top and bottom halves)

oCheck engine frame and bearing seats(gearbox) for cracks

oCheck bearing washers for cracks, replace if necessary

oTurn the drive belt around once and check for damage (outside and inside)

oCheck drive and coolant lines as well as connections for coolant loss;

correct as necessary

oCheck drive for oil leaks; correct all leaks immediately

oEnsure that oil level is betweenMin. and Max. markingson the dip stick;top

up oil if necessary. DO NOT OVERFILL!

oCheck fuel system for leaks

oCheck all cables for abrasion damage; check proper seating of plugs

oCheck proper functioning of the centrifugal clutch

(Clutch should engage at 1800 ±200 RPM)

Manual Smart M160 / 1–UL-Engine

July 05

Ecofly GmbH page 16

5.2. Checks after first 25hrs (in addition to 5.1.)

oCheck the entire power train for loose or missing nuts and screws. Replace

or tighten as necessary.

oCheck belt, belt tension, propeller drive and propeller bearings

oCheck air filter

oChange oil, renewoil filter

oClean and renew fuel filter if necessary

5.3. Checks after 100hrs /1 year (in addition to 5.1.)

oCheck the entire power train for loose or missing nuts and screws. Replace

or tighten as necessary

oCoat engine bearing and other rubber components witha rubber-care fluid

oCheck belt, belt tension, propeller drive and propeller bearings

oCheck belt tension:must yield 5-10mm in a cold enginewhen pressed

down with a finger;adjust if necessary

oChange oil, renew oil filter

oRenew fuel filter

oCarefully check fuel system and lines for signs of brittleness; check all

guides, joints and connectors, renew ageing components where necessary

oClean air filter; renew if necessary

oCheck for dirt in the interstices between cooling fins oftheintercooler,clean

carefully

5.4. Checks after 300hrs/3 years (in addition to 5.1. &5.3.)

oRenew spark plugs

oCheck compression

oRenew coolant

oUntil and such time long-term tests are concluded, we strongly recommend

renewing the belt to be on the safe side.

Contact Ecofly GmbH.

oaftercompletion oflong-term testswe expect a renewal of the belt every

600h (check in advance withEcofly GmbH)

Manual Smart M160 / 1–UL-Engine

July 05

Ecofly GmbH page 17

5.5. Checks after 1500hrs or 15years

We recommend full engine overhaul after 1500hrs. Contact your engine service

station.

Since these engines are produced in large numbers, it may be cheaper tobuya

new engine(crankcase with power plant and cylinder head) and install it along

with a new e-gas unit and turbocharger.

If the belt pulleys are not severely damaged, you will only need to replace three

bearings in the gearbox.

6. Maintenance

Contact Ecofly GmbHuntil long-term tests are concluded. If necessary, detailed

maintenance instructions can be obtained from any smart-center website.

6.1. Oil Circuit

In process

6.2. Air intake / Air filter (Oil in intake system?)

In process

6.3. Compression

In process

6.4. Spark Plugs

In process

6.5. Belt Tension

In process

6.6. Extending Engine Life

In process

Manual Smart M160 / 1–UL-Engine

July 05

Ecofly GmbH page 18

6.7. Torque Table

All M6 in aluminium: 12 ±1 Nm

All M8 in aluminium: 20 ±1,6 Nm

Engine frame strut to cylinder head:23 ±2 Nm

Alternator to aggregate frame:28 ±2 Nm

Starter to crankcase / gearbox:20 ±1,6 Nm

Mitnehmerscheibe to crankshaft (M10*1): 47Nm ±2Nm, angle of twist90°

LU Turbocharger to cylinder head (stud): 6 Nm±0,5 Nm

LU Turbocharger to cylinder head (M6 nut): 16 Nm±1 Nm

Lambda sensor in turbocharger housing:50 Nm±5 Nm

Knock-sensor to crankcase:20 Nm±1,6 Nm

Fuel distributor on manifold (M6): 8,5 Nm±0,5 Nm

Pressure sensor on manifold:5,5 Nm±0,5 Nm

E-Gas Drosselklappensteller an Saugrohr:8,5 Nm ±0,5 Nm

Oil line to Turbo (screw M8 * 1): 10 Nm±1 Nm

Water line to turbocharger (M12.5 * 1.5): 19 Nm±1 Nm

Spark plugs:20 Nm±2 Nm

Drive wheel to crankshaft extension:180 Nm + 20 Nm

Slotted nut: drive wheel to propeller shaft:200 Nm + 20 Nm

7. Document Version History

The current version of this document can be downloaded fromwww.ecofly.de.

First edition English version July 2005

Table of contents

Popular Engine manuals by other brands

SKY Engines

SKY Engines SKY 110 user manual

SunStar

SunStar Fortuna series user manual

Jacobsen

Jacobsen J-501 Operator's manual

Nidec

Nidec Leroy-Somer IMfinity LC Series manual

MaxPower

MaxPower CT35 Installation operation & maintenance

Vemco

Vemco W41 Series Installation, operating and maintenance instructions