SKY Engines SKY 110 User manual

SKY 110

U

SER

’

S

M

ANUAL

2

TABLE OF CONTENT

1.0 INTRODUCTION

1.1 GENERAL WARNINGS

1.2 HOW TO PREVENT ACCIDENTS

2.0 USING DIRECTIONS

2.1 FUEL

2.2 ENGINE BREAK-IN

2.3 STARTING THE ENGINE

3.0 TECHNICAL SPECIFICATIONS

3.1 ENGINE ILLUSTRATION

3.2 TECHNICAL SPECIFICATIONS

3.3 ASSEMBLY OF SECONDARY COMPONENTS

3.3.1 SPECIAL ASSEMBLY INSTRUCTIONS

3.3.2 RADIATOR

3.3.3 MUFFLER

3.3.4 CLUTCH

3.3.5 STARTER

3.3.6 RODS AND SILENT BLOCK

3.3.7 SILENCER

3.3.8 LAMINAR BUNDLE

3.3.9 CARBURETOR

4.0 MAINTENANCE

4.1 CLEANING

4.2 TOPPING UP LIQUIDS

4.3 ADJUSTMENTS

4.4 SCHEDULE AND GENERAL RECOMMENDATIONS

3

5.0 SPARE PARTS

6.0 WARRANTY

6.1 REQUIREMENTS

6.2 THE WARRANTY APPLIES TO

6.3 THE WARRANTY SHALL NOT APPLY TO

6.4 SPECIFIC INFORMATION

6.5 WARRANTY CERTIFICATE

4

1.0 INTRODUCTION

Thank you for purchasing a SKY110 engine developed and

manufactured by SkyEngines.

If you require more information, have any questions or need to purchase

spare parts, please contact us by phone or e-mail using the contact

details printed on the cover.

Thank you for selecting SkyEngines and SkyEngines USA. Have fun and

sincerely hope you are and will be satisfied with your purchase.

SkyEngines S.R.L.

SkyEngines USA

5

1.1 GENERAL WARNINGS

SkyEngines / SkyEngines USA shall not be directly or

indirectly liable for the use of this engine, especially if it is

altered or tampered with by third parties.

To avoid severely damaging the engine, MAINTENANCE

must be follow as specified in this manual. Carefully read

chapter 4.0 of this manual and follow the instructions

thoroughly.

As you use the engine some of the secondary components

tend to deteriorate with time. Chapter 3.0 (paragraph 3.3)

illustrates the assembly procedures for these components.

SkyEngines / SkyEngines USA shall not be liable for

damages caused by improper maintenance or incorrect

assembly, except for replacement of components covered by

the warranty. (If you are not sure how to perform maintenance

or how to assemble the unit, please contact us and we will

gladly help you.)

The engine has a maximum load capacity of 264-297 lb.

(120-135 Kg), meaning that it can transport a person within

these parameters. If you attempt to carry more weight it may

cause the unit to be out of balance resulting in an accident.

Before each flight the pilot shall perform all inspections

required in order to verify that the engine is safe and in good

working order. (Inspection shall also be performed to the

frame, trike, quad or other means were the engine is to be

6

used.)

Any alterations made to the engine by the user or third

parties, are full responsibility of the user. Spare parts used for

such alterations are not covered by warranty. (Be advised

that any alterations or the removal of original parts may

jeopardize the safety of the engine.)

SkyEngines reserves the right to change the engine models

and or the catalogue without warning and without any

obligation whatsoever. Further information is provided at

www.skyengines.com.

Aircraft driven by this engine must be used in open spaces

only and in areas reserved for these activities. The pilot must

be aware of all the hazards connected with the use of this

engine and be aware that the engine can shut down at any

time.

For detailed information on the warranty terms, see Chapter

6.0 in this manual.

7

1.2 HOW TO PREVENT ACCIDENTS

As the use of this engine can be very dangerous, it is

important to adopt all the necessary precautions during,

before and after each flight in order to avoid severe accidents.

We advise you to follow the general precautions below in

order to avoid damages and or accidents.

The engine does not solve all flying problems; hence, it is

imperative to avoid risky moves. One of the most common

mistakes is flying at low altitude in areas without a safe

landing zone. It is important never to underestimate the

possibility of an engine failure.

Always take into consideration that you may not have enough

thrust to clear an obstacle; better prevent and be at a safe

altitude before maneuvering close to an obstacle.

Pay particular attention to swinging movements caused by

the change of trimming of your wing which can cause you to

fall 13-16 feet in altitude (4-5 meters).

Always have a landing zone available in the event the engine

quits and an emergency landing is required.

For your own safety, ALWAYS avoid flying over water in order

to prevent damage to yourself or the engine.

8

2.0 USING DIRECTIONS

The using directions provided in this manual refer to models

available at the time of print. Although the manufacturer is not

obligated to provide updates on changes, users may request

specific information on any upgrades of single products. For

more information visit www.skyengines.com or

www.skyenginesusa.com.

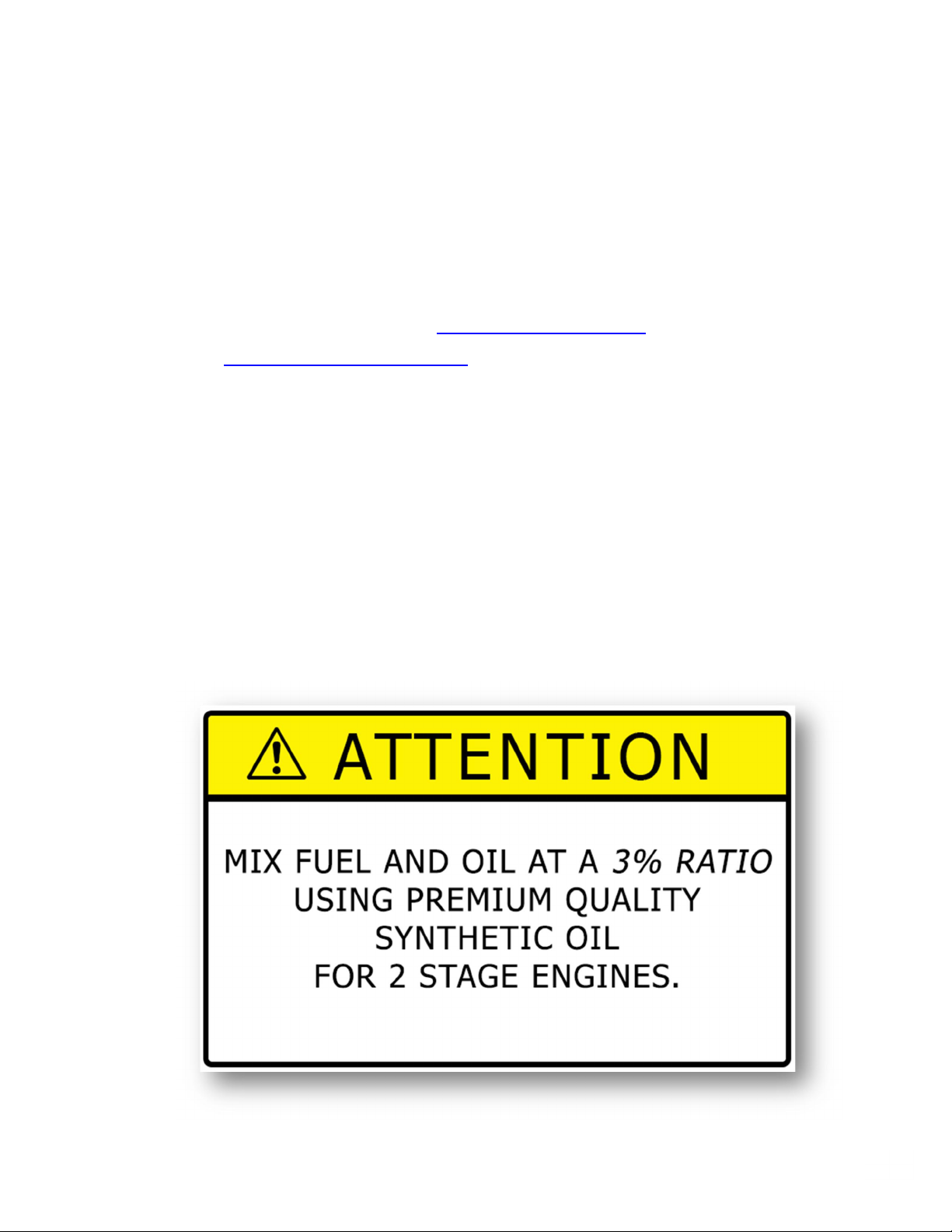

2.1 FUEL

SKY110 is a 2 stage engine that employs a mixture of fuel

and oil.

Always remember that a correct carburetion and fuel mixing

are essential to prevent the seizure of pistons fitted on any 2

stage engines, which are not covered by warranty.

9

10

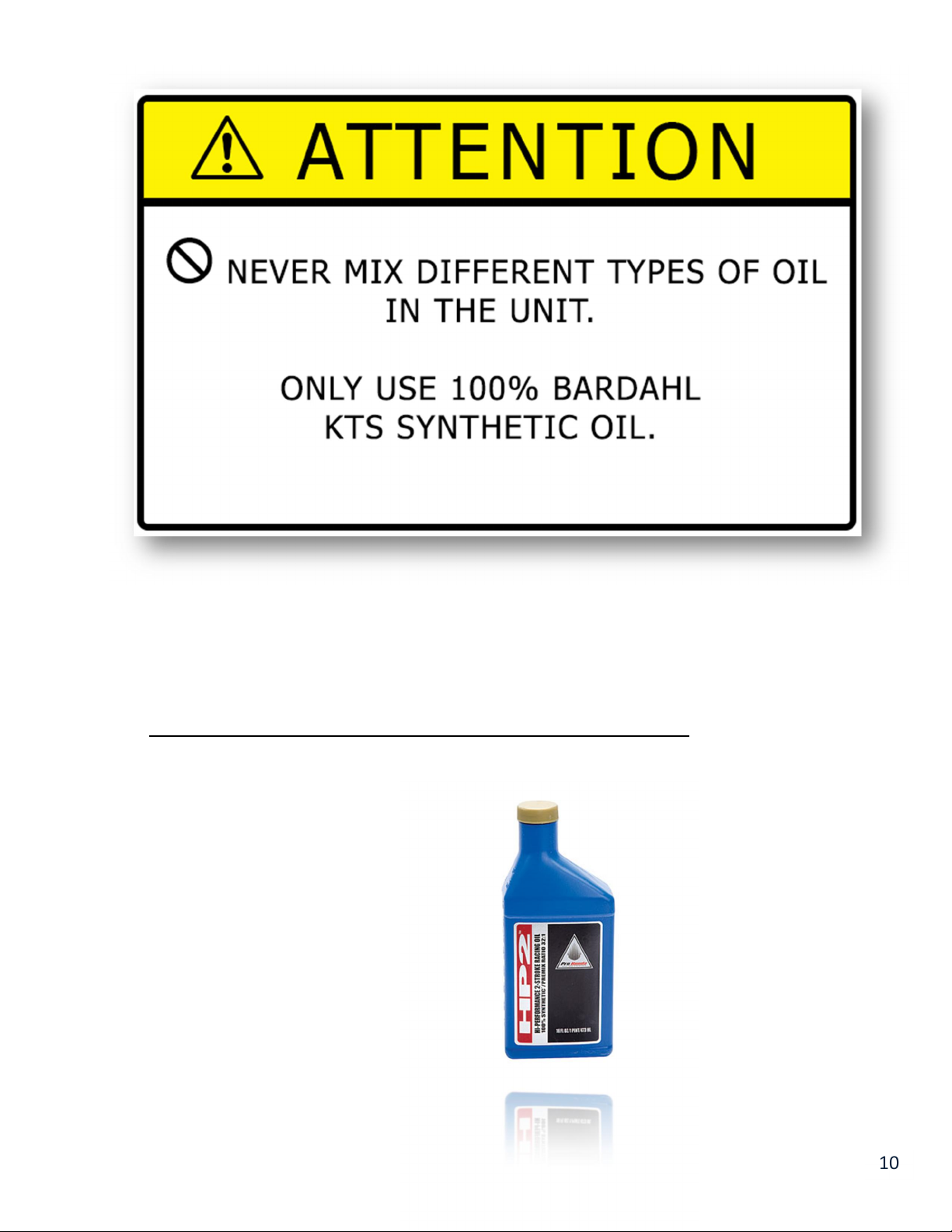

Note: Although Bardahl is a company based in the United States (HQ’s in Seattle,

Washington), as of July 28, 2016, they do not produce the 100% KTS Synthetic Oil

in the U.S.A., it is produced in Italy and Europe and hard to find locally. Make sure

you use a premium quality 100% Synthetic Oil for 2 Cycle Engines. SkyEngines USA

recommends that you use the Honda “Pro Honda HP2 Hi-Performance 2-Stroke

100% Synthetic Racing Oil”.

11

DURING BREAK-IN

PERIOD 3% (1:32

*

)

AFTER BREAK-IN

PERIOD 2.4% (1:40

*

)

* Based on U.S. Gallons

12

2.2 ENGINE BREAK-IN

A good break-in ensures a long life of the engine and

enhances the performance of its components. Although you

may use your engine for flight during the break-in, it is

suggested that you perform the break-in for the first 3 hours

on the ground. However, if you do perform any flights during

the first three hours, use the engine very careful as the

internal parts are not well lubricated during that period. Also

make sure you follow the following procedures if you select to

do the break-in in the air.

Do not use the engine at maximum power for extended

periods of time.

Do not keep the accelerator in the same position of

several seconds; in this case it is preferable to open

and close the accelerator without increasing the altitude

in order not to force the engine.

Use the engine for 10 minutes at a time, and then

allow cooling before the next flight.

Repeat the same operation during the break-in for the

first 3 hours.

As stated previously, although not a requirement, doing the

break-in of the engine on the ground it is the preferred

method. If you opt for this option, the following instructions

apply to you.

Start the engine and make sure you do not exceed

5,000 RPM for the first 1.5 hours of engine running.

Also during this time, make sure you open and close the

13

accelerator changing the RPM from low to high, again,

without exceeding 5,000 RPM for the first 1.5 hours.

From 1.5 hours to 3 hours, follow the same procedure

but this time do not exceed 8,000 RPM. Again, do not

keep the accelerator in the same position for several

seconds, keep opening and closing it. This will ensure

all the internal parts benefit from the break-in.

THE BEAK-IN PERIOD CAN BE CONSIDERED COMPLETED AFTER

THE FIRST 3 HOURS OF FLIGHT OR GROUND BREAK-IN

PROCEDURES, OR AFTER THE USE OF 10 LITERS (2.2 GALLONS)

OF FUEL!

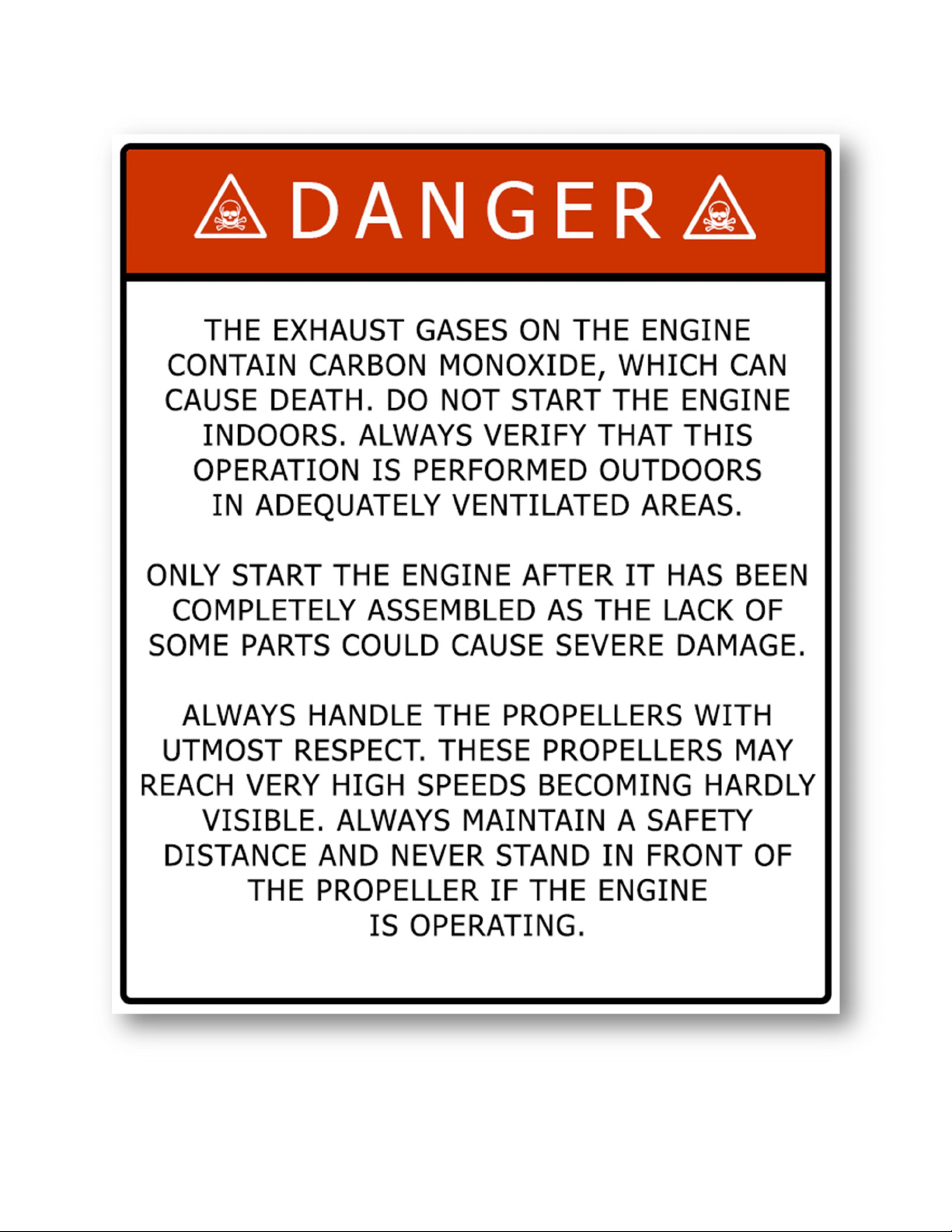

2.3 STARTING THE ENGINE

The SKY110 engine is started by a manual starter. You must

strongly pull the starter rope. Be careful not to flood the

engine while doing so.

On your first flight of the day, or if the engine is cold,

always run the engine a few minutes after startup to heat

the engine. Accelerate at regular intervals to avoid

damaging it.

14

15

3.1 ENGINE ILLUSTRATION AND PART NUMBERS

PART NAME PART NUMBER PART NAME PART NUMBER

1: CYLINDER SK006 11: IGNITION COIL SK033

2: RADIATOR CAP SK013 12: MUFFLER SK040

3: RADIATOR SK010 13: RADIATOR HOSES SK011/012

4: LAMINAR BUNDLE SK021/024/026 14: DRAIN RESERVOIR SK014

5: MUFFLER SEAL SK043 15: RADIATOR RODS SK017

6: HEAD + COVER SK007/008 16: GUARD SK001

7: WALBRO CARBURETOR SK019 17: SPIDER SK032

8: MUFFLER MANIFOLD SK045 18: MANUAL STARTER SK036

9: REDUCTION GEAR SK031 19: SILENT BLOCK SK015/016

10: SILENCER SK041

16

3.2 TECHNICAL SPECIFICATIONS

TYPE SINGLE-CYLINDER 2 STAGE ENGINE WITH LIQUID

COOLING

SWEPT VOLUME 112cc

MAXIMUM POWER 26 HP @ 10900 RPM

MAXIMUM RATED SPEED 26 HP @ 11300 RPM

BORE 55 mm

STROKE 43 mm

REDUCTION MECHANICAL 1:4 OIL LUBRICATED

THRUST 72 Kg WITH TWO 125cm PROPELLERS @ 10900 RPM*

CARBURETOR WALBRO WG8

TOTAL ENGINE WEIGHT 13 Kg WITH LIQUIDS (28.66 Lbs.)

EGT 700° C (1292° F)

CHT 170° C (338° F)

MAXIMUM COOLANT

TEMPERATURE 95° C (206° F)

MAXIMUM CAPACITY MAXIMUM WEIGHT OF USER: 120-135 Kg (264-297

Lbs.)

CLUTCH DRY CENTRIFUGAL

* Test was made in optimal conditions at sea level and after running break-in.

17

18

3.3 ASSEMBLY OF SECONDARY COMPONENTS

3.3.1 SPECIAL ASSEMBLY INSTRUCTIONS

The engine SKY110 is more complex than other models

and a higher level of experience is required to assemble

its components, specifically its internal ones. As the

engine is liquid cooled, the assembly of the components

that use the radiator’s coolant requires the

implementation of specific tasks that only a skilled

mechanic is able to carry out. Therefore all users who

are not specifically skilled or trained to perform these

operations SHOULD NOT WORK WITH THE ENGINE EXCEPT

FOR ORDINARY MAINTENANCE OPERATIONS, WHICH SHOULD

BE PERFORMED FOLLOWING THE DETAILED INSTRUCTIONS

SPECIFIED BELOW. DO NOT IMPROVISE OR ATTEMPT TO MAKE

UNAUTHORIZED CHANGES THAT COULD DAMAGE THE ENGINE

AND VOID THE WARRANTY.

Unauthorized changes could make the engine very

unstable.

Replace the components of the engine with original

SKYENGINES spare parts to guarantee reliable and

smooth operation.

19

3.3.2 RADIATOR

20

3.3.3 MUFFLER

Table of contents

Other SKY Engines Engine manuals

Popular Engine manuals by other brands

bar

bar 670 owner's manual

AGG

AGG AS4300 Operation and maintenance manual

O.S. engine

O.S. engine MAX-32SX Owner's instruction manual

Farymann Diesel

Farymann Diesel 15W Series Repair manual

Alutech

Alutech AM3-PP/140-07 Operation manual

Briggs & Stratton

Briggs & Stratton Intek 110600 Operation and owner's manual