DELTA DORE TYMOOV IOFB User manual

EN Mechanical wired asynchronous tubular motors

TYMOOV

10FB - 20FB - 30FB

EN

2 3

Recommendations

WARNING: Important safety instructions

Incorrect installation can result in serious injuries.

Follow all instructions and retain these installation instructions for

future reference.

-TYMOOV xFB motors are designed solely for the operation of rollers

shutters for home use. For any other use, please contact our technical

department.

- The minimum internal diameter of the rolling tube is 47 mm,

however, the tube must be chosen according to the weight and

length of the apron. Consult the tube manufacturers’ charts.

- Do not operate the roller shutter if people or objects are within the

movement area.

- Moving parts of the motor installed at a height of less than 2.5m

must be protected.

- Before installing the motor, remove all superuous cords and take

any equipment not required for the motor to operate out of service.

- NOTE: Do not operate the shutters or cut off their power supply

when maintenance or cleaning work is being carried out on the

equipment or in close proximity (e.g. window cleaning).

- Monitor the shutter when it is moving and stand clear until it is

completely closed.

-

Do not allow children to play with the xed control devices. Keep

remote control devices out of the reach of children.

- This device can be used by children of at least 8 years of age, and by

persons with reduced physical, sensory, or mental capacities, and also

by persons lacking in experience or knowledge, provided that they are

correctly supervised or that instructions relating to the use of the safe

use of the device have been provided to them, and provided that they

understand the risks involved.

Children must not play with the device. Cleaning and maintenance by

the user must not be performed by children if unsupervised.

- The operating device for a switch without a lock must be in direct

view of the driven part, but away from the moving parts. It must be

installed at a height of at least 1.5m.

- Fixed control devices must be installed so as visible.

- During the use of a switch without a lock, make sure that all other

persons present keep their distance;

- Frequently check the equipment to detect any imbalances or signs of

wear or damage to cables and springs.

- Do not use the device when repairs or adjustments are required.

Preliminary elements

- Sufciently rigid roller shutter slats should be used.

- When the roller shutter is closed, the apron must not overlap the

runners by any more than one 1/2 slat.

- The apron clips or automatic locks used on the shutter must be used

in accordance with their manufacturer’s instructions for use.

It is essential that you adjust the number of locks based on the

model and the number of links.

- If used with upper stops, you should preferably use systems that are

built into the runners.

- Pay attention to the frame rigidity with stop systems on the shutter

slats.

Translation of the

Original Manual

EN

4 5

Recommendations

- Correct operation of the motor is ensured if it is installed and used

according to the following recommendations.

It is essential that peripheral components such as the rolling tube,

the supports, the screws etc. are appropriate and are assembled

in accordance with the latest standards. The specications of the

driven part must be compatible with the assigned load and operating

time.

- Weighted noise pressure level A: LpA ≤ 70 dB(A).

- Cables passing through a metallic wall must be protected and

isolated by a sleeve.

- If the power cable is damaged, the motor must be replaced by the

manufacturer, by the aftersales service, or by similar qualied

personnel, so as to avoid any danger.

- The motor must be chosen according to the requirements of the load

bearing support. See our charts regarding the selection of the motor

according to shutter type. A plate on the motor indicates the nominal

torque and operating time.

- TYMOOV xFB tubular motors are designed to operate

intermittently (4 minutes of continuous operation). They are

electronically protected to prevent overheating. If there is a thermal

shutdown, the motor will operate again after a timeout period of

around 20 minutes. To operate again for a period of 4 minutes, the

motor must have returned to room temperature.

DELTA DORE hereby declares that the motorised drive unit covered by these

instructions is compliant with the essential requirements of the Machinery

Directive 2006/42/EC, and the European directive 2014/30/EC

The EU declaration regarding this device is available on request,

with requests to be submitted to the following address:

«Technical info» department

DELTA DORE – 35270 Bonnemain (France)

Email: [email protected]

DELTA DORE

35270 - BONNEMAIN - France

Because of changes in standards and equipment, the characteristics specied in the text and illustrations

in this document are not binding unless conrmed by our respective departments.

EN

67

Contents

• Power supply: 230V - 50 Hz +/- 10%

• Class I insulation

• Operating time: 4 minutes

• Electrical power ratings:

TYMOOV 10FB : 112 W

TYMOOV 20FB : 145 W

TYMOOV 30FB : 191 W

• Weighted noise pressure level A: LpA ≤ 70 dB(A).

• Protection rating: IP44

• Operating temperature: -10°C -> +50°C

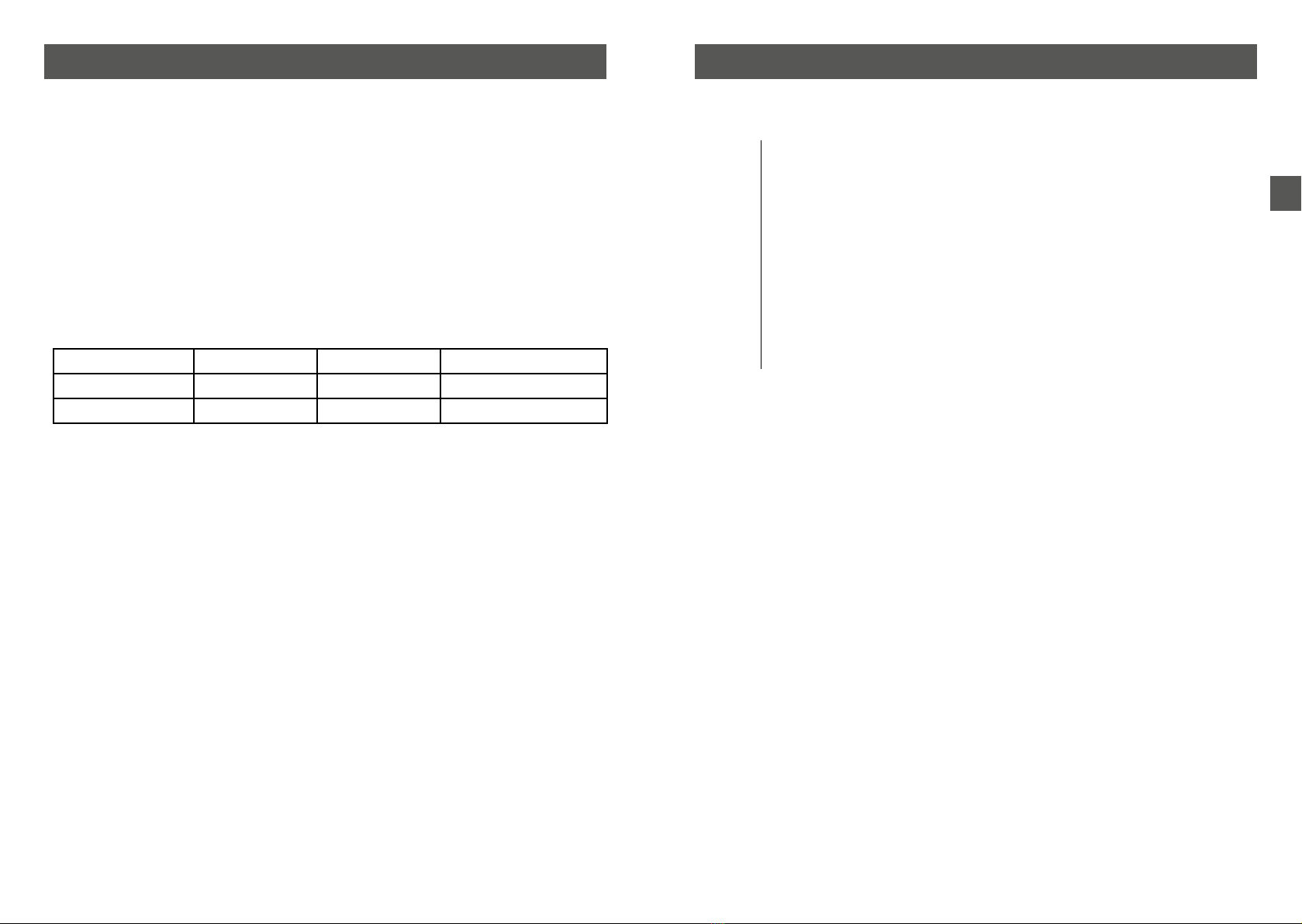

• Dimensions:

Model Diameter Total length Length excluding head

10 FB and 20 FB 45 mm 486 mm 467,4 mm

30 FB 45 mm 556 mm 537,4 mm

Technical specifications

1/ Motor tting.................................................................................................8

1.1 Crown and wheel assembly ................................................................................. 8

1.2 Mounting in the tube............................................................................................... 8

1.3 Motor head position................................................................................................ 9

1.4 Mounting of the motor onto its support........................................................ 9

2/ Connection ................................................................................................10

3/ Setting stops..............................................................................................11

3.1 Adjusting screw selection table ...................................................................... 12

3.2 Setting the bottom stop...................................................................................... 12

3.3 Setting the top stop............................................................................................... 12

4/ Troubleshooting.......................................................................................13

EN

89

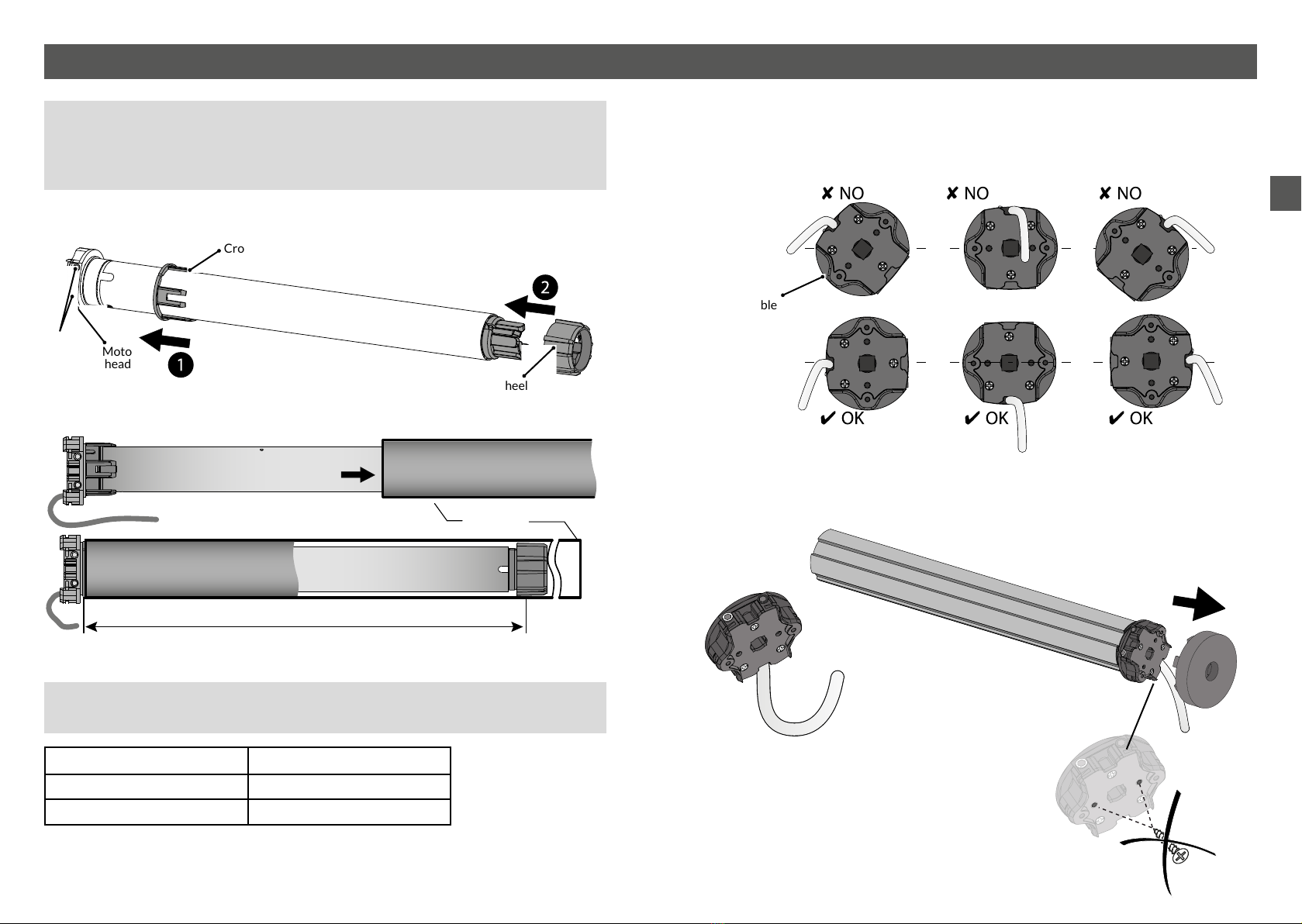

1/ Motor fiing

• Never strike the motor head or output shaft to t the motor into the tube.

Never pierce the tube when the motor is installed.

• To attach the apron, use screws that do not protrude into the tube by more

than 1 mm.

1.1 Crown and wheel assembly

1.2 Mounting in the tube

For mechanical parts and drive and mounting accessories,

consult our catalogue.

Model Length for drilling (L)

TYMOOV 10Nm et 20 Nm 455 mm

TYMOOV 30 Nm 525 mm

Tube

L: length for drilling wheel

attachment using screws or rivets

1.3 Motor head position

The motor head must be positioned on the support as such that the cable outlet is in

the lower part relative to the horizontal.

1.4 Mounting of the motor onto its support

Push the tube/motor assembly (A) onto the support (B) until it engages (click).

Câble

(A)

(B)

“Click”

Always make a kink in the power cable

to avoid the penetration of water into

the motor.

Screwing into the motor

head is strictly prohibited.

Crown

Motor

head

Wheel

“Click”

Adjusting

screw

EN

10 11

The electrical wiring must comply with EN, IEC and national institute standards (e.g.

NF C15-100 for France).

In all instances, it must still be possible to switch off the power supply using an

omnipolar device in accordance with the applicable installation requirement. If

the motor is supplied with a H05VVF power cable, this cable cannot be installed

outdoors, unless it is inside a UV-resistant duct.

For outdoor use, the motor must be equipped with a RNF or RRF rubber cable with

at least 2% carbon. Contact the sales department.

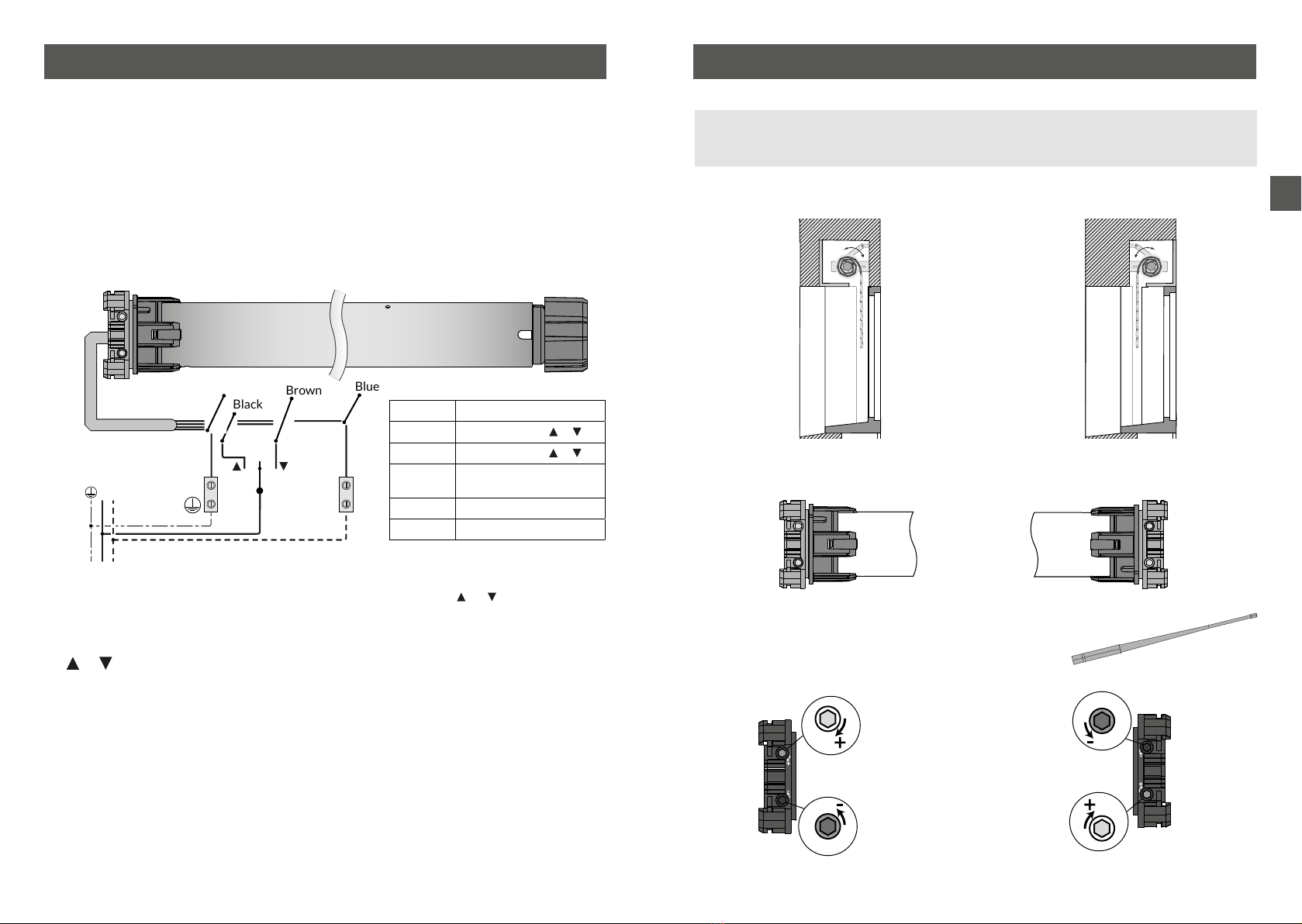

Connection with a toggle or biased change-over switch

- A change-over switch prohibiting the simultaneous pressing of

the or buttons must be used.

- In the case where a biased change-over switch is used, the user must press and

hold the button throughout the shutter operating time.

You can wire several motors to the same change-over switch, within the maximum

permissible current capacity, however, the adjustment of the stops must be

performed separately.

2/ Connection 3/ Seing stops

You can connect Tyxia 5630 micromodules to the Tymoov xFB motors.

They must be connected after the setting of the stops.

4 x 0.75 mm²

L

L

N

N

Blue Neutral

Brown Phase for rotation or .

Black Phase for rotation or .

Yellow /

Green

Earth

L Phase

N Neutral

Black

Brown Blue

Note: If the raise and lower directions

are reversed, swap the brown and

black wires ( and on the change-

over switch).

Power supply

230 V, 50 Hz

Single-phase

Yellow / Green

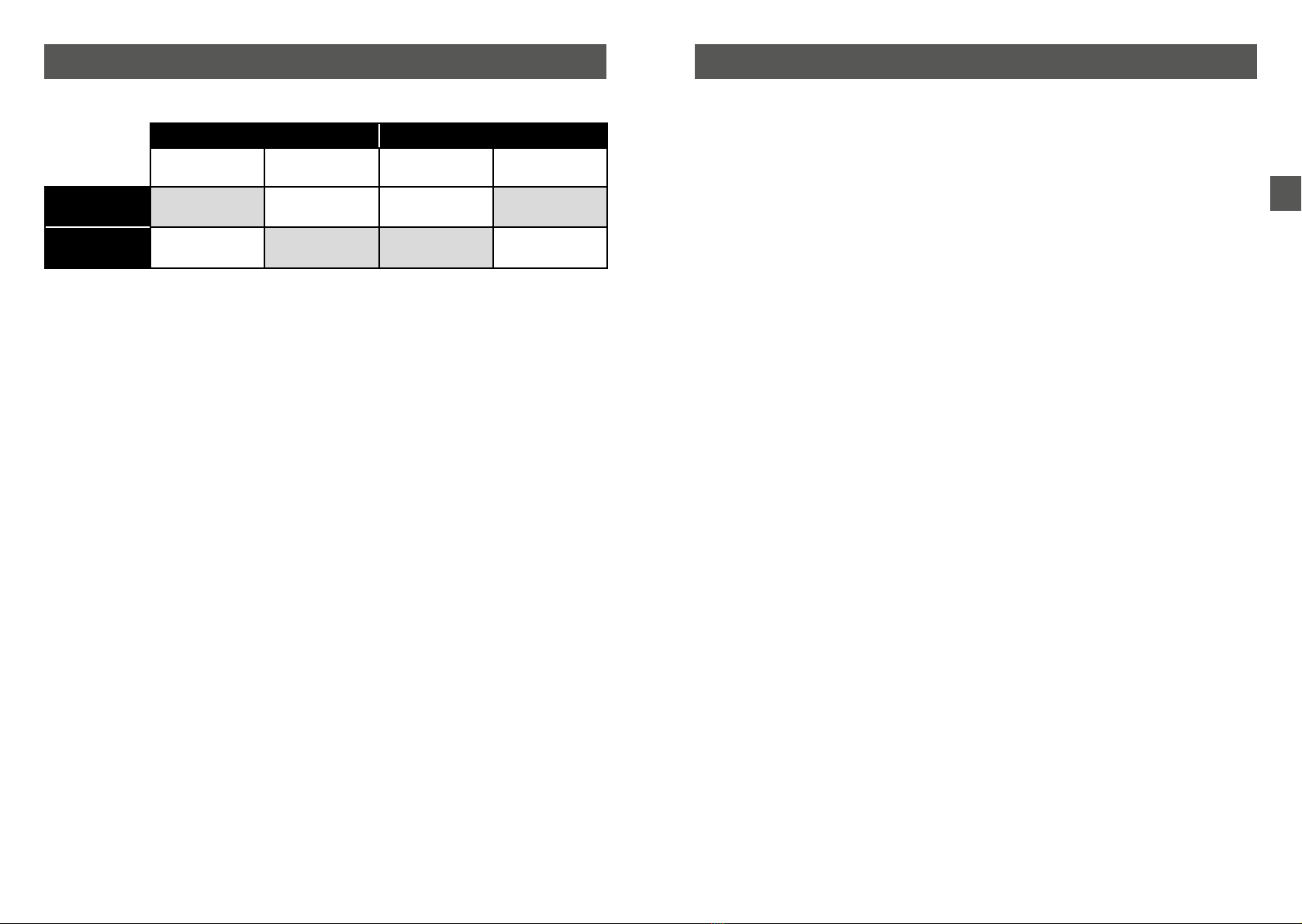

❶Identify the type of roller shutter winding

❷Determine the position of the motor viewed from the outside of the dwelling

❸Setting the stops

To set the stops, use the adjusting tool or a 4 mm hex

screwdriver.

Exterior

housing

Interior

winding

Exterior

winding

Exterior

housing

Interior

housing

Interior

housing

Left

mounted

motor

Right

mounted

motor

White adjusting

screw

Red adjusting

screw

Red adjusting

screw

White adjusting

screw

Left

mounted

motor

Right

mounted

motor

EN

12 13

3/ Seing stops

3.1 Adjusting screw selection table

Interior winding Exterior winding

Left mounted

motor

Right mounted

motor

Left mounted

motor

Right mounted

motor

Setting the top

stop

Red adjusting

screw

White adjusting

screw

White adjusting

screw

Red adjusting

screw

Setting hte

bottom stop

White adjusting

screw

Red adjusting

screw

Red adjusting

screw

White adjusting

screw

3.2 Seing the boom stop

The skirt of the roller shutter must be detached from the winding spindle.

❶Activate the motor to lower the shutter until its reaches its stop.

❷While still holding the control to lower the shutter, turn the bottom stop (see

table) adjusting screw towards (+) until it reaches the correct position for the

securing of the lock.

❸ Attach the roller shutter to the tube using the locks.

3.3 Seing the top stop

❶Activate the motor to raise the shutter.

❷NOTE: if the shutter reaches the stop before the motor stops, switch it off

immediately. In the opposite case (if the motor stops before reaching the top stop),

move on to step ❻.

❸Turn the adjusting screw for the top stop (see table) in the (-) direction.

❹By applying the control to lower the shutter, bring the roller shutter to beneath

the desired position, and stop it there.

❺Repeat operations ❶to ❹until the shutter reaches the top stop (in this case,

move on to step ❻).

❻The motor stops beneath the top stop.

Holding down the control to raise the shutter, turn the top stop adjusting screw

towards (+) until the roller shutter reaches the desired position.

❼The stops have been set.

If the motor is not working:

- Check that the wiring corresponds to the diagrams in the «Connection» chapter.

- Check the power supply within the network.

- Check that the motor is not in thermal protection mode; just wait 20 minutes for it

to cool down.

- Reset the end of travel positions if necessary.

The end of travel points are not adhered to:

- Check the mechanical components of the system

(stabilisation, play, distortion, etc.)

- Reset the end of travel positions if necessary.

Inversion of the direction of rotation.

- Switch the black and brown wires connecting the motor to the change-over switch.

4/ Troubleshooting

www.deltadore.com

04/23

This manual suits for next models

2

Table of contents

Other DELTA DORE Engine manuals

DELTA DORE

DELTA DORE TYMOOV 30FB User manual

DELTA DORE

DELTA DORE TYMOOV 30FB User manual

DELTA DORE

DELTA DORE TYMOOV RP Series User manual

DELTA DORE

DELTA DORE TYMOOV radio RP2 Series User manual

DELTA DORE

DELTA DORE TYMOOV 6F2 User manual

DELTA DORE

DELTA DORE TYMOOV F Series User manual

DELTA DORE

DELTA DORE TYMOOV 2 Silence+ 10 User manual