ECOJOHN SR Series User manual

3

About Us

Global Inventive Industries (GII) is the exclusive manufacturer of ECOJOHN –

the most efficient, reliable, and unique toilets for any mobile or remote

application. The ECOJOHN product line consists of waterless incinerating toilets,

separating composting toilets, and incinerating waste control systems for use

with low-flush toilets. These products have been carefully tested and are

designed to solve the problems with toilets in remote applications.

ECOJOHN is superior where there is no power or water available, or where

septic tanks are restricted, or simply in situations where a regular toilet is too

costly or difficult to install. In addition to our self contained toilets, we also

build upscale portable restrooms that include our own ECOJOHN toilet

solutions that don’t need unsanitary and costly pump outs – the ECOJOHN

restrooms provide hygienic, logistical, and economical benefits.

GII continues to enhance and develop its products through a combination of

company values and customer-focused design. Our products are built to last

and provide superior efficiency; every ECOJOHN that leaves our factory is

a clear indication of an absolute commitment to quality and design for which

we are very proud. From the beautiful design and sparkling look, to quality

built stainless steel parts; all reflects the meticulous attention to details. You will

rapidly notice why ECOJOHN has received a reputation as the premiere brand

for toilet solutions.

Click anywhere in the top portion of this page for updated/expanded articles on septic system design, inspection,

testing, maintenance, and repair online at InspectAPedia.com

4

SR Series waterless incinerating toilet

2 x 12V DC Batteries

or 120V AC

Propane, Natural Gas,

or Diesel

Catalytic Converter

(Optional)

Introduction

The SR models are self-contained waterless toilets that use

an incineration process to reduce waste into sterile ash.

These models are extremely efficient and leave a very

minimal amount of ash that only needs to be emptied

periodically (depending on usage). They require minimal

effort to install, very little maintenance, and feature an

aesthetically pleasing design. Due to its unique features, it

can be used virtually anywhere. The SR toilets are perfect

for areas where plumbing connections or sewage systems

are unavailable (i.e. cabins, work shops, construction sites,

camp grounds, fishing and hunting camps etc.) or as a

replacement for the traditional porta potties.

The SR toilets are available in various sizes, and colors; they

also differ in burning capacity and what type of fuel they

use. The SR5 models use Propane and are our smallest

models (capacity wise) that are ideal where the usage is

small. SR12 models are built to handle a higher capacity

environment and are available in Propane, Natural Gas,

and Diesel.

How the toilet works

The only requirements for the SR to operate are a power

source and Propane, Natural Gas, or Diesel. They conveniently attach to 120V AC power, or

12V DC as its power source, which can be recharged by solar energy. To operate the toilet after

use, one simply has to close the lid and press the “flush buttons". The toilet has two flush buttons:

one for urine, and one for waste. By pressing the button, a feeder screw will start to move any

waste present into the burn chamber, which is located at the back of the toilet. At this point the

incineration process starts up automatically and begins the burning

cycles. Since these models burn all the waste after each usage,

there will never be any waste left inside the toilet that can cause

unpleasant odor. Depending on the SR model used, the process can

take a few minutes for a quick urine cycle, or up to 30 minutes for

a waste cycle. One of the great features of these units is that even

though a burn cycle is in progress, one can still use the toilet.

It will simply shut off the burning process when the toilet lid is

lifted up. Once the lid has been

closed again, it will resume the

burn process and finish the burn

cycle. A display panel signals

when the process is complete

or if something has gone wrong

with the unit or malfunction has

occured, i.e. Propane or Diesel is out.

Click anywhere in the top portion of this page for updated/expanded articles on septic system design, inspection,

testing, maintenance, and repair online at InspectAPedia.com

5

CLOSE TOILET

AND PRESS

URINE OR WASTE

AUGER MOVES

WASTE INTO

BURN CHAMBER

BURNER IGNITES

AND STARTS

INCINERATION

PROCESS

WC5

DISPLAY PANEL

SHOWS TWO

GREEN LIGHTS

WHEN CYCLE

IS COMPLETE

CHIMNEY FAN

RUNS FOR

60 SECONDS

(Optional)

The SR is controlled by a display

panel, which signals when the

burn cycles are completed, if

fuel is out, or if there has been

too many users in a too short

time period, etc.

Display Panel

UL and CE approved.

SR Models

The SR is a safe and convenient appliance when

assembled and used properly. In order to provide a high

quality toilet, we have chosen high quality materials that

are made to withstand high usage and a severe

environment. Throughout the production, it goes through

several meticulous testing procedures, which has been

approved by Underwriters Laboratory (UL) and CE. Also, the

toilet is equipped with multiple safety devices that recognize

if any minor problems occur and shut off the unit.

Cost of Usage

The cost of running this unit is

considerably low. Electricity usage

is minimal since it only uses

electricity to start the incineration

process and run the auger.

Fuel cost is also low: On average

the cost per flush is 8 to 10 cents

per flush.

Maintenance / Cleaning

For regular usage, the SR only has to be emptied periodically

(depending on usage). The chamber is easily accessable

through a lid from the outside of the toilet, and it makes the

ash removal process extremely easy. To ensure a clean bowl

and auger, the toilet is equipped with a small reservoir of

water, which can be used to clean the bowl. One only

needs to press a rinse button to rinse the bowl. As an option,

it is also possible to add a liner in the bowl before usage; the

liner gets moved into the burn chamber along with other

waste material. Once inside the chamber, the incineration

process quickly eliminates the paper liner along with the waste.

Applications

Cabins / Guest and Pool houses

Military

Disaster situations

Construction

Work sites

Trains / Barges / RVs

Remote Camp sites

Mobile offices

Barns

Waste

Button

Urine

Button

Models Power Fuel Capacity

SR5-P12 12V DC Propane 4-6 people

SR5-P120 120V AC Propane 4-6 people

SR12-P120 120V AC Propane 10 people

SR12-N120 120V AC Natural Gas 10 people

SR12-D120 120V AC Diesel 10 people

Safety

Operation

Click anywhere in the top portion of this page for updated/expanded articles on septic system design, inspection,

testing, maintenance, and repair online at InspectAPedia.com

6

WC Series waste combustion system

Introduction

The WC Series consist of a wide range of incinerators in

different sizes and fuel sources. All products in the WC

Series incinerate waste and operate with low-flush toilets.

The WC5, WC12, WC32, and WC48 are all included in

the WC Series and use Propane, Natural Gas, or Diesel as

fuel source depending on model and size. The WC Series

are ideal in any remote application where a

conventional toilet is too expensive or difficult to install.

These incinerators along with a low flush toilet provide

ecological, economical, and logistical benefits as well as

eliminate costly and potential harmful environment

which is often associated with a standard pump out

process.

How the system works

After flushing the toilet, the low-flush toilet dissolves the

waste with the built in macerator pump before

Water Tank

Low-Flush

Toilet

Waste

Tank

Lid for

cleaning ashes

WC

transporting it into the waste holding tank. Only 0.3-0.5 gallons of water is being consumed. Inside

the holding tank, a sensor reads the level of the tank. Once a certain level has been reached, a

portioned amount of waste gets transferred by another waste pump into the WC incinerator (as

long as the system is set in automatic mode). The incineration process takes approximately 7

minutes until completed. If there is still waste in the waste tank, the pump will automatically

portion another batch of black water into the incinerator. This process is continuous for as long as

the sensor signals that waste is in the tank. Once the tank is empty, the WC models set itself in a

standby mode until the sensor signals that more black water in the holding tank and the

incineration process start over. WC Series may also be set in a manual mode; by doing so, one

can control the burn process manually and start and stop the incineration process if needed.

As shown in figure below, the WC incinerator is just one part of a complete WC system. In addition

to the incinerator, a water tank, a low-flush toilet with a macerator pump, a waste tank, fuel

(Propane, Natural Gas, or Diesel), and 12V DC or 120V AC are required.

A great advantage of installing this system is that

one can install multiple toilets to one system, which

makes the system more cost effective. It is also

possible to upgrade the size of the tanks if needed.

This is typically done when usage is higher.

By having larger water and fuel tanks,

refilling the tanks doesn’t need to be done

as frequently. By having a larger waste

holding tank, the max capacity of the

system increases. Larger or additional

WC incinerators can also be added to

the system to increase the amount of waste

burned per hour.

Click anywhere in the top portion of this page for updated/expanded articles on septic system design, inspection,

testing, maintenance, and repair online at InspectAPedia.com

7

Control Board

WC Models

Safety

The WC series are very safe when assembled and

used properly. In order to provide a high quality

system, we have chosen to only use top quality

materials that can withstand high usage and

operate in a severe environment. All WC models

go through several meticulous testing procedures

to monitor operations and quality.

Maintenance / Cleaning

Under normal usage, the WC models only need to

be emptied a few times per year. The remaining

ashes is sterile and it can easily be vacuumed out

by a ShopVac. To access the burn chamber, the

WC units are equipped with a rear access door

that may be opened from the outside of the unit.

In addition to emptying the ashes, the water and

fuel levels must also be monitored and maintained.

Models Power Fuel Burning Capacity

WC5-P12 12V DC Propane 1 gal/hour

WC5-P120 120V AC Propane 1 gal/hour

WC12-P120 120V AC Propane 2.5 gal/hour

WC12-N120 120V AC Natural gas 2.5 gal/hour

WC12-D120 120V AC Diesel 2.5 gal/hour

WC32-P120 120V AC Propane 4 gal/hour

WC32-N120 120V AC Natural gas 4 gal/hour

WC32-D120 120V AC Diesel 4 gal/hour

WC48-P120 120V AC Propane 8 gal/hour

WC48-N120 120V AC Natural gas 8 gal/hour

All WC models have a control board that

indicates the fluid level in the tanks and

the status of the unit. This can be set to an

automatic or manual mode. It also displays

the current temperature, hours left before

service needed, or if there are any error

messages.

FLUSH TOILET TOILET MACERATOR

OPERATES

WATER TANK

SUPPLIES TOILET

WITH FLUSH WATER

MACERATED WASTE

IS TRANSFERRED

TO WASTE TANK

WHEN WASTE

LEVEL RISES IT

ACTIVATES THE

WASTE LEVEL

SENSOR

WC RECEIVES

SIGNAL FROM LOW

LEVEL SWITCH AND

INCINERATION

CYCLE INITIATES

MORE WASTE IN THE

WASTE TANK NO

YES

FINAL COOLING

CYCLE

COMMENCES

WC PUTS ITSELF IN A

STANDBY MODE

Operation

Cost of Usage

The cost of running this system is

considerably low. Electricity usage is

minimal since it only uses electricity to

start the incineration process, run the

water, macerator and waste pumps

for a very short time. The cost of the

fuel is also low due to the efficiency

of the burn units.

Applications

Cabins / Guest and Pool houses

Military

Disaster situations

Construction

Work sites

Trains / Barges / RVs

Remote Camp sites

Mobile offices

Barns

The low-flush toilets only use 0.3-0.5

gallons per flush. A built-in macerator

pump dissolves the waste before

pumping it into the waste holding tank.

Click anywhere in the top portion of this page for updated/expanded articles on septic system design, inspection,

testing, maintenance, and repair online at InspectAPedia.com

8

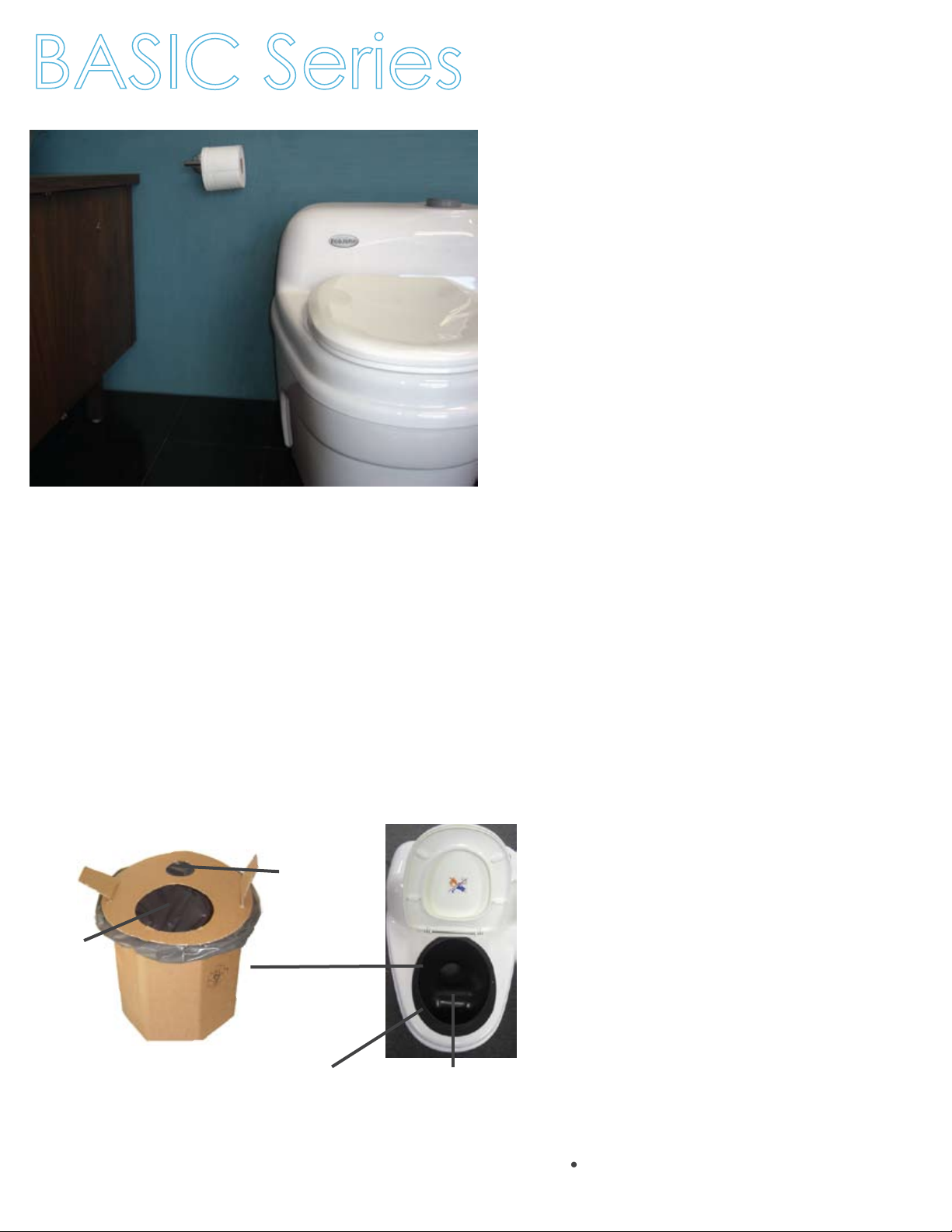

BASIC Series waterless composting toilet

Introduction

The BASIC Series consists of two models; one

that operates on 12V DC and one that

operates on 120V AC. Both are waterless

composting toilets that are ideal for

applications where a conventional toilet is too

expensive or logistically difficult to install. The

BASIC Series uses a simple design, yet it is

equipped with several smart features that makes

it a very attractive and popular toilet.

How the the toilet works

The BASIC Series toilets are equipped with a

separating, and drying feature, which is the

Advantages:

• Waterless toilet, no need for sewage

or septic systems

• Runs on 12V DC or 120V AC

• Can operate in extreme cold and hot

climates

• Ecological, economical, and

logistical benefits

• Easy to install, maintain, and use

• Can be installed in fixed or mobile

applications

• Liquid waste can be reused as a

garden fertilizer

• Lightweight, only 45 pounds and

can be easily transported

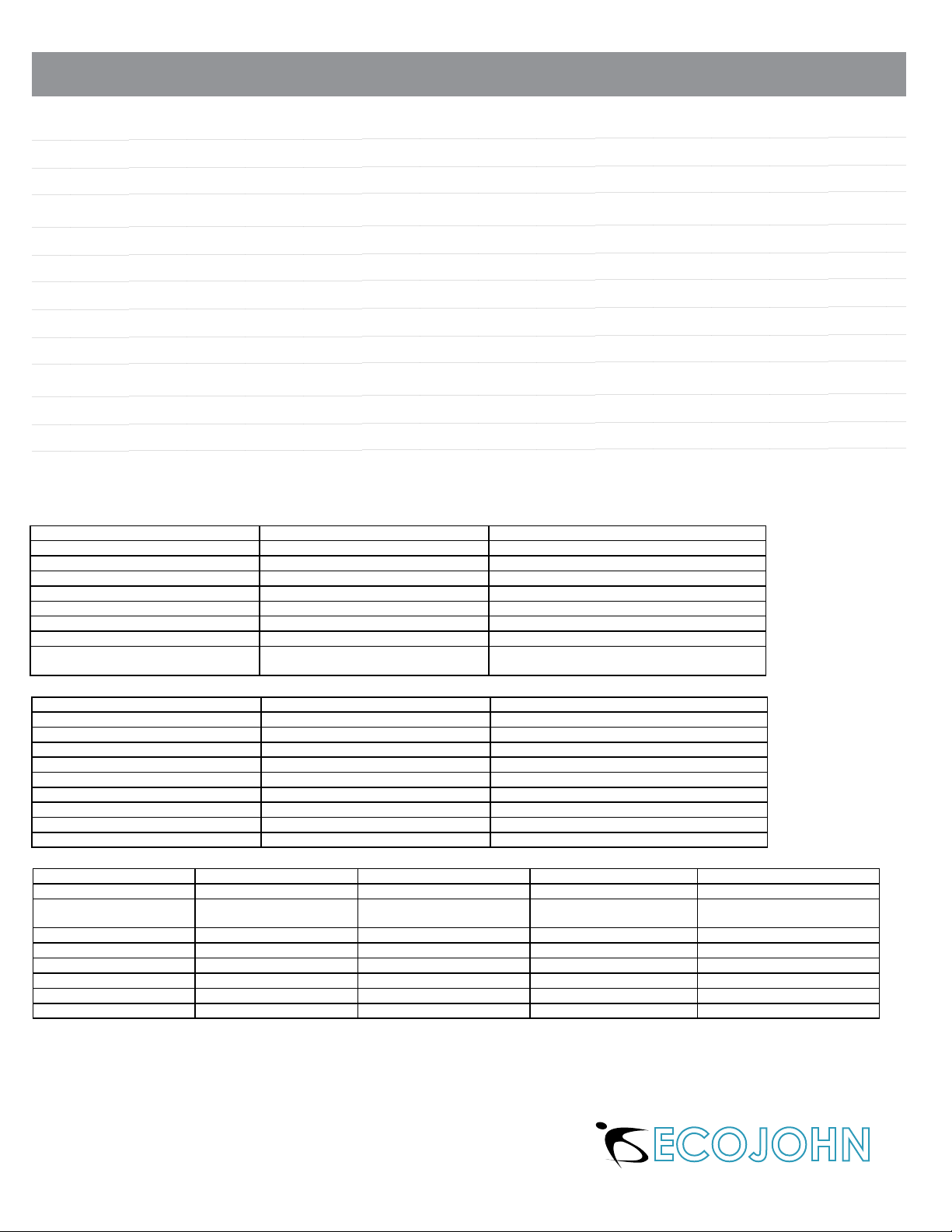

first step in its composting process. The solid waste is collected in a special environmental box inside

the toilet. The liquid waste is separated from the toilet through a special liquid waste hose.

Underneath the waste box, there is a heating plate that dries out the waste material in the box;

the heating plate is thermostatically controlled and it reaches a temperature where most bacteria

die. When the box is full, one can easily open the toilet and remove the entire waste box with its

waste bag, or only take out the waste bag itself and then add the entire box/bag to a composting

pile; after a few months, the waste and bag will decompose.

The liquid waste is separated away in the front of the toilet bowl. By using gravity the liquid waste

gets drained outside the rear of the unit. The liquid waste is collected with a domestic wastewater

system, or guided to a drain pit or to a container. By mixing 1 part of liquid waste with 8 parts of

water, it can be used as a fertilizer.

Hole that

connects

to vent

system

Waste

gets

collected

in box

The liquid waste hose

connects to the front

of the bowl

Biodegradable

Waste Box/Waste Bag

A removable hard

plastic toilet bowl

that can be easily

cleaned

Click anywhere in the top portion of this page for updated/expanded

articles on septic system design, inspection, testing, maintenance,

and repair online at InspectAPedia.com

9

Maintenance / Cleaning

For regular usage, the BASIC only has to be

emptied about once every 2-3 weeks. The

waste box and bags are easily accessible,

which makes the waste removal process very

easy. The removable bowl can easily be

removed for cleaning. The liquid waste can

be collected in a container for reuse as a

garden fertilizer, or guided into a drain pit or

an existing sewage system.

Applications

Cabins

Guest houses

Outhouses

Remote camps

RVs

Barns

Capacity

There is no maximum limit of usage, simply

change the box when it gets full. Below is a

guide as to how often the box needs to be

changed.

Daily usage

3 people (empty the waste bag every 2-3 weeks)

Weekend usage:

3 people (empty the waste bag every 4-6 weeks)

The cost of running this unit is considerably

low. There is no fuel cost associated with the

BASIC. The only operating cost is the

electricity usage which is low, and the cost

for replacing the waste boxes and waste

bags. If a 12V DC battery is being used, solar

panels can be installed to back up and

recharge the battery.

BASIC Models

Models Power Usage

BASIC-12 12V DC Residential

BASIC-120 120V AC Residential

The vent system can be installed vertically

(straight up), or horizontally (out through

a wall). A fan is located inside the vent and

runs continously. The fan ensures that the

air inside the toilet gets to the outside air.

USE TOILET

(ONE MUST SIT

WHEN USING IT)

FAN IN VENT RUNS

WASTE AND URINE

GET SEPARATED

FROM TOILET BOWL

HEATER RUNS AND

DRIES THE WASTE.

URINE SEPARATED

AND TRANSPORTED

OUTSIDE OF THE

UNIT

WC5

WHEN BOX IS

FULL, REMOVE BOX

AND ADD TO A

COMPOSTING

PILE

Operation

Safety

The BASIC models are very safe and reliable

to operate. They have no moving parts that

can fail; its basic design keeps it a very easy

to operate and maintain unit. The BASIC

toilets don’t operate on any fuel and the

heating element keeps the temperature

below 130 degrees F.

Cost of Usage

Vent System

Click anywhere in the top portion of this page for updated/expanded articles on septic system design, inspection,

testing, maintenance, and repair online at InspectAPedia.com

10

Specification

Technical Data

DIMENSIONS SR5 SR12 WC5 WC12 WC32 WC48 BASIC Series

Height 25 in 32 in 30 in 37 in 37 in 37 in 25 in

Width 23 in 25 in 16 in 19 in 19 in 19 in 23 in

Depth 34 in 39 in 25 in 29 in 29 in 29 in 34 in

Sitting Depth 19 in 20 in 19 in

Weight 132 lbs 160 lbs 120 lbs 185 lbs 185 lbs 185 lbs 45 lbs

WC Series TANK DIMENSIONS (Standard size: 16 gallons) Waste Tank Water Tank Fuel Tank

Height 11.5 in 11.5 in 11.5 in

Width 14 in 14 in 14 in

Length 26 in 26 in 26 in

*Note: Larger water and waste tanks are also available

ECOJOHN

®

S R 5 S R 12

Hea t F low 5kW 12kW

F uel P ropane P ropane, Natural G as , Dies el

Operating V oltage 12V DC or 120V AC 120V AC

Hourly B tu 18,000 50,000

Temperature Operation: -30 to 120 F Operation: -30 to 120 F

Ma terial P olypropylene P las tic C olor C oded S teel

C olor White White, Black, G ray Metallic

E lectrical C ons umption Urine C ycle: 0.215 AmpH

Waste C ycle: 0.312 AmpH

Urine C ycle: 0.215 AmpH

Waste C ycle: 0.312 AmpH

B A S IC -12 B A S IC -120

Operating V oltage 12V DC 120V AC

Temperature Operation: -30 to 120 F Operation: -30 to 120 F

Ma terial P olypropylene P las tic C olor C oded S teel

C olor White White

E lectrical C onsumption 2.3 Amp 2.3 Amp

Watts C onsumption 0.26kW/day 0.26kW/day

V ent S ize 2.5” P V C P ipe 2.5” P V C P ipe

Waste Hose 6’ Long 6’ Long

Was te B ox 7.5 G allons 7.5 G allons

WC 5 WC 12 WC 32 WC 48

Hea t F low 5kW 12kW 32kW 48kW

F uel P ropane P ropane, Natural G as ,

Diesel

P ropane, Natural G a s,

Diesel

P ropane, Natural G a s,

Diesel

Operating V oltage 12V DC or 120V AC 120V AC 120V AC 120V AC

Hourly B tu 18,000 50,000 100, 000 160, 000

Temperature Operation: 32 to 120 F Operation: 32 to 120 F Operation: 32 to 120 F Operation: 32 to 120 F

Material C olor C oded S teel C olor C oded S teel C olor C oded S teel C olor C oded S teel

C olor G ray Metallic G ray Metallic G ray Metallic G ray Metallic

E lectrical C onsumption 2.5 Amp 2.5 Amp 2.5 Amp 2.5 Amp

Click anywhere in the top portion of this page for updated/expanded articles on septic system design, inspection,

testing, maintenance, and repair online at InspectAPedia.com

11

SR Series

The SR is easy to install. The standard SR models include an 8 ft long chimney system. It can go

vertically straight up or horizontally out through the wall and then vertically up along the

wall to the outside air.

- must be located inside a weatherproof building.

- must be installed on a non-combustible level and even base.

- must not be operated in areas where there is a risk of accumulation of flammable vapors or dusts.

- At no times should the flue be obstructed i.e. overhanging branches.

When the chimney system has been installed, one only has to connect the

power supply and fuel (Propane, Natural Gas, or Diesel). The toilets need to be placed inside a

weather proof building/structure, and they need a minimum of 12 inches clearance from any wall.

Furthermore, the SR should not be operated in any area where there is a risk of an accumulation

of flammable vapors or dust

• Catalytic converter - a catalytic converter may be installed in the chimney pipe; the catalytic

converter cleans the outgoing air and ensures that there are no harmful agents going out. (optional)

• Chimney fan - an extra fan may be installed in areas where extra draft is needed. (optional)

WC Series

The installation of the system can be done in a few easy steps. The WC models can be installed up

to 10 feet from the toilet and 3 feet above the ground. The incinerator and waste tank must be

placed within 10 feet from each other. When the chimney system has been installed, connect the

power supply (120V AC or 12VDC as an option for WC5) and the fuel source. The WC must be

installed inside a weather proof building/structure. A minimum of 12 inches clearance from any

outside wall is required. Furthermore, it should not be operated in an area where there is a risk of an

accumulation of flammable vapors or dust. The chimney has to be a minimum of 4 ft long. It can go

vertically up or horizontally out through the wall to the outside air.

• Catalytic converter - a catalytic converter may be installed in the chimney pipe; the catalytic

converter cleans the outgoing air and ensures that there are no harmful agents going out. (optional)

BASIC Series

The BASIC is extremely easy to install. The first step in the installation process is to install the vent pipe

through the roof or out through the wall. Next, one only has to connect the power supply and

decide what to do with the liquid waste hose. There are three options of how the liquid waste hose

can be installed (see BASIC Series Section)

When installing the liquid waste hose, it is imperative that it has an adequate

drop through its entire length to prevent it from getting clogged up. This is

especially important when the toilet is being installed where the temperature

gets below freezing. Note: Check with your local authorities for any restrictions

regarding installing a drain pit.

Installation

Click anywhere in the top portion of this page for updated/expanded articles on septic system design, inspection,

testing, maintenance, and repair online at InspectAPedia.com

12

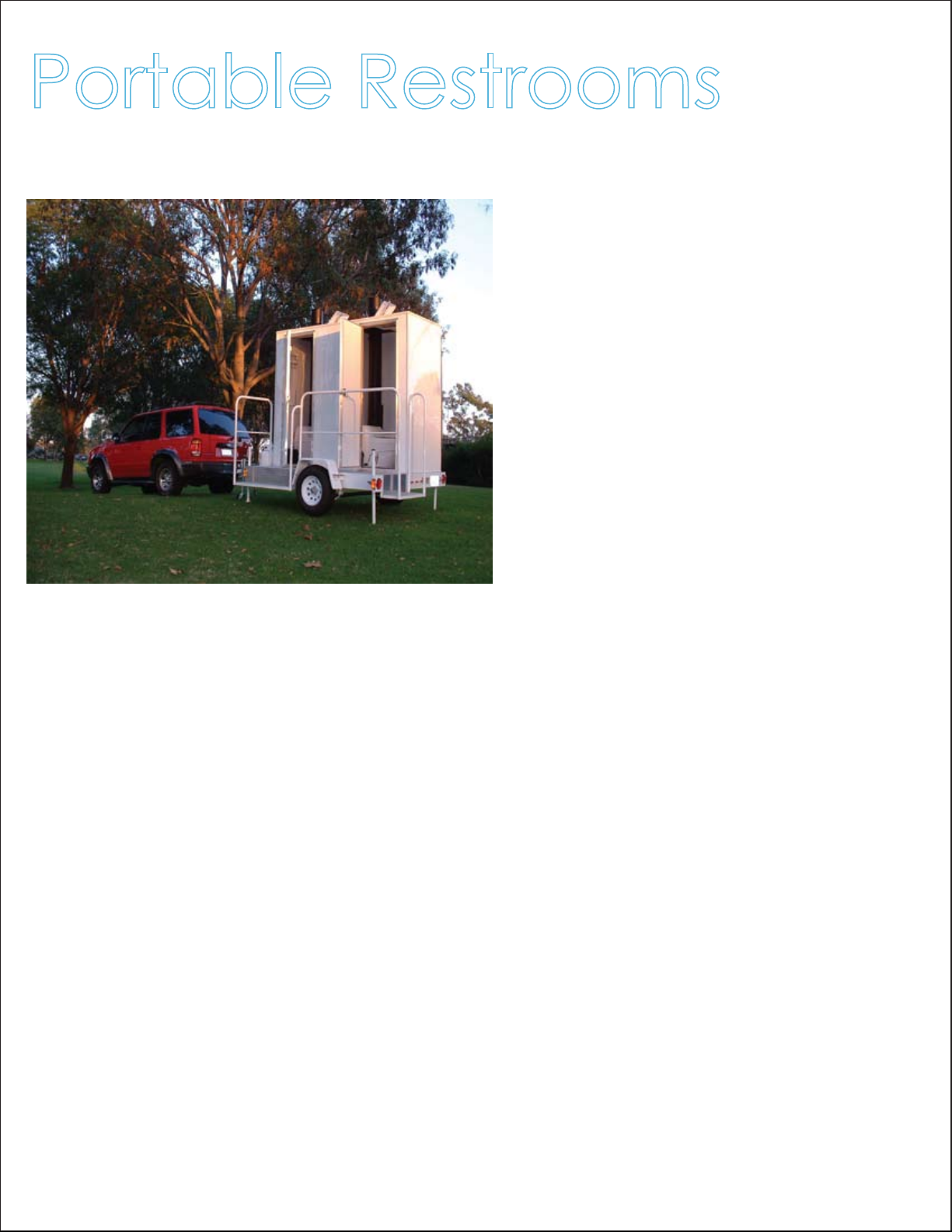

Portable Restrooms

Restrooms with incinerating technology

How the ECOJOHN restrooms differ

The ECOJOHN restrooms are different from other portable restroom. Instead of pumping out the

waste, our restrooms are equipped with incinerating toilet systems that eliminate the need for

pumping out the waste. The restrooms can be installed with either waterless incinerating toilets

or with low flush toilets in combination with a waste incinerator.

The restrooms are available in various sizes and configurations; the incinerators can be fuelled by

Propane or Diesel. For restrooms that need to be used in cold or hot climates, a combined

heater and A/C can be installed.

Advantages:

• Very clean and upscale toilets compared to today's unpleasant

porta-potties

• Doesn't require any pump outs of waste holding tanks

• Can be operated with water toilets or waterless toilets

• Mobile units that can be moved from site to site

• Very little maintenance - Refill water, add Diesel Fuel, or Propane

• Can be powered by 12V DC with solar panels or 120V AC

GII offers new upscale mobile restrooms

equipped with one of our unique incinerator

models which make these mobile restrooms

ideal for work sites, sporting events, military,

disaster areas, etc. Portable restrooms with

incinerating technology can be used

anywhere a mobile restroom is used or

needed.

Our mobile restrooms may either be skid

mounted or permanently secured on a

trailer. By using the ECOJOHN restroom, it is

now possible to provide your crews with a

pleasant and fresh portable restroom that

require a minimal of maintenance. All our

restrooms come installed with waterless

incinerating toilets or low-flush toilets with

Propane or Diesel fuelled incinerators.

All of our standard moveable restrooms have a sparkling interior, stainless steel urinal and low

flush toilets and a waste combustion system. Portable restrooms may also be configured using

the free standing SR model incineraing toilet. In addition to our standard mobile restrooms,

GII can also design custom restrooms designed to fit your specific needs. These restrooms can be

configured to include upgrades such as air conditioning, hardwood floors, upscale counter tops,

stereo systems, mirrors, or special insulation for use in colder climates.

Click anywhere in the top portion of this page for updated/expanded articles on septic system design, inspection,

testing, maintenance, and repair online at InspectAPedia.com

Applications

Construction/Work sites Military

Barges Golf courses

Remote camps Temporary Restrooms

Parks Sport Events

Models Waterless With Water # of Toilets

Elite 1S

Elite 1T

Elite 2S

Elite 2T

Elite 4S

Elite 4T

Deluxe 1S

Deluxe 1T

Deluxe 2S

Deluxe 2T

Deluxe 4S

Deluxe 4T

x

x

x

x

x

x

x

x

x

x

x

x

1

1

1

1

2

2

2

2

4

4

4

4

S = skid mounted T = trailer

Portable Restroom Models

13

High Efficiency A/C and Heater

Waste Tank Heaters

Outside Lighting

Motion Sensors

Storage Units

Generators

Air Vent Covers

Vinyl Trailer Skirts

Baby Changing Station

Hand Sinks

Solid Surface Sink Tops

AM/FM/CD Player

Sanitary Napkin Disposal

Toilet Paper Dispensers (Double Roll)

H/D Option To Move Trailer Loaded

Solar Option To Power D/C Items

Woodgrain Flooring

Custom Exterior Colors

Caster Wheel For Front Jack

Options

DELUXE 2T

Maintenance

Room

Tanks

WC

Maintenance

Room

DELUXE 4T

Tanks

WC

DELUXE 1S

Maintenance

Room

Tanks

WC

ELITE 1S

Maintenance

Room

SR

Click anywhere in the top portion of this page for updated/expanded articles on septic system design, inspection,

testing, maintenance, and repair online at InspectAPedia.com

14

Today’s fresh water is decreasing. 1/3 of the world’s

population lives in areas that have a moderate or

severe water shortage. It is estimated that the amount

of water available to each individual will be cut in half

over the next 25 years. It is also known that only three

percent of the world's water is fresh; water that we

today use in our regular toilets! In the 21st century ,

water is becoming a scarce resource. China, where

some 82 million people are struggling with severe

water shortages, is no longer an isolated example.

ECOJOHN is at the forefront of a worldwide push to

save our planet’s most precious resource - water.

Click anywhere in the top portion of this page for updated/expanded articles on septic system design, inspection,

testing, maintenance, and repair online at InspectAPedia.com

ECOJOHN

®

Global Inventive Industries

17150 Newhope St. Ste 707

Fountain Valley, CA 92708

P: 1.866.ECOJOHN

F: 714.568.1068

www.ECOJOHN.com

Click anywhere in the top portion of this page for updated/expanded articles on septic system design, inspection,

testing, maintenance, and repair online at InspectAPedia.com

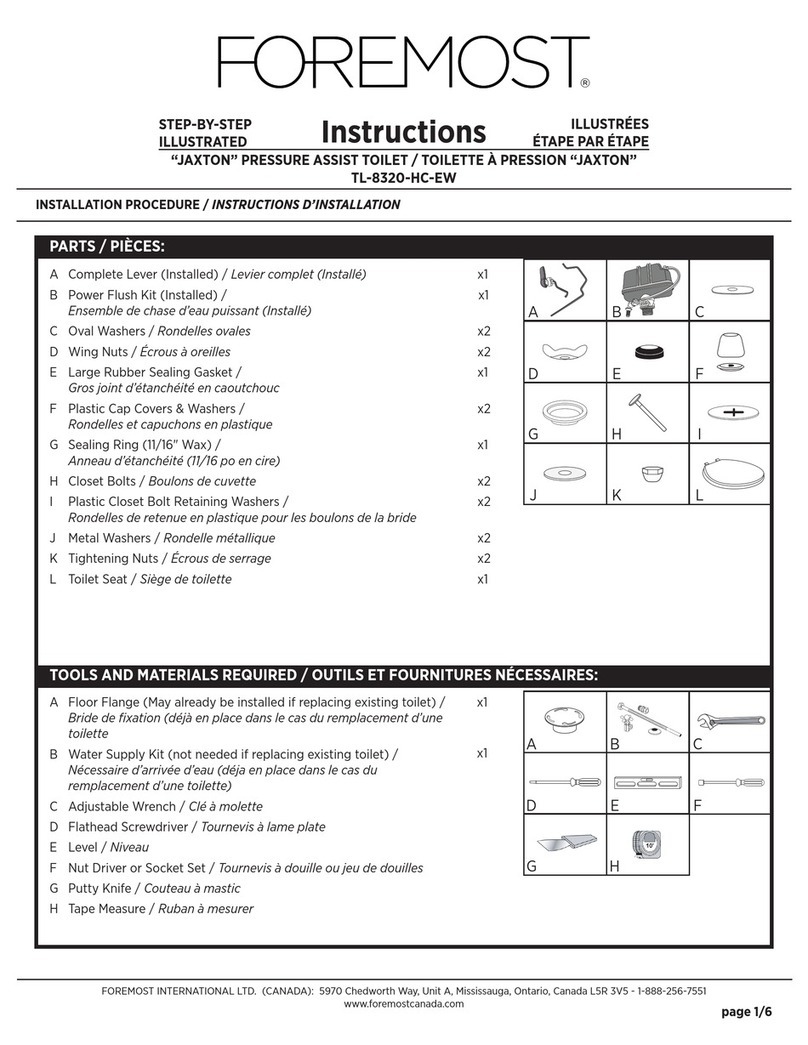

This manual suits for next models

31

Table of contents

Popular Toilet manuals by other brands

Thetford

Thetford C2 Repair guide

Swiss Madison

Swiss Madison SM-1T113 installation instructions

Foremost

Foremost JAXTON TL-8320-HC-EW instructions

Grohe

Grohe Eurocube 39736000 installation instructions

SeaLand

SeaLand Traveler Lite 500 Plus Series owner's manual

Separett

Separett Tiny 1271-01 installation manual

Kohler

Kohler SAN SOUCI CLASS FIVE K-21865T-S installation instructions

Dometic

Dometic SANIPOTTIE 960 Series instruction manual

Ideal-Standard

Ideal-Standard Waverley Assembly and installation instructions

Toto

Toto NEOREST AS instruction manual

Toto

Toto CST484CEMF Installation and owner's manual

rba

rba The Big John Econo installation instructions