Ecolab Inspexx Manual

Inspexx - Mixing System

Directions for use

Gebrauchsanweisung

Declaration of Conformity

Inspexx

Declaration of Conformity Konformitätserklärung

Déclaration de Conformité Dichiarazione di Conformità

Declaración de Conformidad Declaração de Conformidade

Δήλωση Συμμόρφωσης Overeenkomstigheidsverklaring

Försäkran om överensstämmelse Vaatimustenmukaisuusvakuutus

Overensstemmelseserklæring Deklaracja zgodności

Декларация осоответствии Megfelelőségi nyilatkozat

Izjava o skladnosti Izjava o usklađenosti

Deklaracija o konformitetu Declaraţie de Conformitate

Декларация за съответствие Prohlášení o shodě

Prehlásenie o konformite Uygunluk Bildirgesi

Vastavusdeklaratsioon Atitikties deklaracija

Paziņojums par atbilstību prasībām Свідчення про відповідність вимогам

Nilfisk FOOD

Blytækkervej 2

9000 Aalborg

Danmark

Declaration of Conformity

We Nilfisk FOOD, declare under our sole responsibility that the

products Inspexx 119000354. To which this declaration relates, are

in conformity with these Council directives on the approximation of

the laws of the EC menber states:

Machinery Directive (2006/42/EC).

- EN 60335-2-79 : 2012

EMC Directive (2014/30/EU)

- EN 55014-1 : 2007

- EN 55014-1 : 2015

- EN 61000-3-2 : 2014

- EN 61000-3-2 : 2013.

Konformitätserklärung

We Nilfisk FOOD, declare under our sole responsibility that the

products Inspexx 119000354. To which this declaration relates, are

in conformity with these Council directives on the approximation of

the laws of the EC menber states:

Machinery Directive (2006/42/EC).

- EN 60335-2-79 : 2012

EMC Directive (2014/30/EU)

- EN 55014-1 : 2007

- EN 55014-1 : 2015

- EN 61000-3-2 : 2014

- EN 61000-3-2 : 2013.

Déclaration de conformité

Nous, Nilfisk FOOD, déclarons sous notre seule responsabilité, que

les produits Inspexx 119000354, auxquels se réfère cette décla-

ration, sont conformes aux Directives du Conseil concernant le

rapprochement des législations des Etats membres CE relatives aux

normes énoncées ci¬dessous :

Directive Machines (2006/42/EC).

- EN 60335-2-79 : 2012

Directive Compatibilité Electromagnétique CEM (2014/30/EU)

- EN 55014-1 : 2007

- EN 55014-1 : 2015

- EN 61000-3-2 : 2014

EN 61000-3-2 : 2013.

Dichiarazione di conformità

Nilfisk FOOD dichiara sotto la sua esclusiva responsabilità che i

prodotti Inspexx 119000354, ai quali si riferisce questa dichiarazi-

one, sono conformi alle seguenti direttive del Consiglio riguardanti il

riavvicinamento delle legislazioni degli Stati membri CE:

Direttiva Macchine (2006/42/EC).

- EN 60335-2-79 : 2012

Direttiva EMC (2014/30/EU)

- EN 55014-1 : 2007

- EN 55014-1 : 2015

- EN 61000-3-2 : 2014

- EN 61000-3-2 : 2013.

Declaración de conformidad

Nosotros, Nilfisk FOOD, declaramos bajo nuestra entera responsa-

bilidad que los productos Inspexx 119000354, a los cuales se refiere

esta declaración, están conformes con las Directivas del Consejo

en la aproximación de las leyes de las Estados Miembros del EM:

Directiva de Maquinaria (2006/42/EC).

- EN 60335-2-79 : 2012

Directiva EMC (2014/30/EU)

- EN 55014-1 : 2007

- EN 55014-1 : 2015

- EN 61000-3-2 : 2014

- EN 61000-3-2 : 2013.

Declaração de Conformidade

A Nilfisk FOOD declara sob sua única responsabilidade que os pro-

dutos Inspexx 119000354, aos quais diz respeito esta declaração,

estão em conformidade com as seguintes Directivas do Conselho

sobre a aproximação das legislações dos Estados Membros da CE:

Directiva Máquinas (2006/42/EC).

- EN 60335-2-79 : 2012

Directiva EMC (2014/30/EU)

- EN 55014-1 : 2007

- EN 55014-1 : 2015

- EN 61000-3-2 : 2014

- EN 61000-3-2 : 2013

Δήλωση συμμόρφωσης

-

- EN 60335-2-79 : 2012

- EN 55014-1 : 2007

- EN 55014-1 : 2015

- EN 61000-3-2 : 2014

- EN 61000-3-2 : 2013.

Verklaring van overeenstemming

Wij, Nilfisk FOOD, verklaren geheel onder eigen verantwoordelijk-

heid dat de producten Inspexx 119000354 waarop deze verklaring

betrekking heeft, in overeenstemming zijn met de Richtlijnen van de

Raad in zake de onderlinge aanpassing van de wetgeving van de

EG Lidstaten betreffende:

Machine Richtlijn (2006/42/E).

- EN 60335-2-79 : 2012

EMC Richtlijn (2014/30/EU).

- EN 55014-1 : 2007

- EN 55014-1 : 2015

- EN 61000-3-2 : 2014

- EN 61000-3-2 : 2013.

Försäkran om överensstämmelse

Vi, Nilfisk FOOD, försäkrar under ansvar att produkterna Inspexx

119000354, som omfattas av denna försäkran, är i överensstämmel-

se med rådets direktiv om inbördes närmande till EU-medlemssta-

ternas lagstiftning, avseende:

Maskindirektivet (2006/42/EG).

- EN 60335-2-79 : 2012

EMC-direktivet (2014/30/EU).

- EN 55014-1 : 2007

- EN 55014-1 : 2015

- EN 61000-3-2 : 2014

- EN 61000-3-2 : 2013.

Vaatimustenmukaisuusvakuutus

Me, Nilfisk FOOD, vakuutamme omalla vastuullamme, että tuotteet

Inspexx 119000354, joita tämä vakuutus koskee, ovat EY:n jäsenval-

tioiden lainsäädännön yhdenmukaistamiseen tähtäävien Euroopan

neuvoston direktiivien vaatimusten mukaisia seuraavasti:

Konedirektiivi (2006/42/EY).

- EN 60335-2-79 : 2012

EMC-direktiivi (2014/30/EU).

- EN 55014-1 : 2007

- EN 55014-1 : 2015

- EN 61000-3-2 : 2014

- EN 61000-3-2 : 2013.

Overensstemmelseserklæring

Vi, Nilfisk FOOD, erklærer under ansvar at produkterne Inspexx

119000354som denne erklæring omhandler, er i overensstemmelse

med disse af Rådets direktiver om indbyrdes tilnærmelse til EF-

medlemsstaternes lovgivning:

Maskindirektivet (2006/42/EF).

- EN 60335-2-79 : 2012

EMC-direktivet (2014/30/EU).

- EN 55014-1 : 2007

- EN 55014-1 : 2015

- EN 61000-3-2 : 2014

- EN 61000-3-2 : 2013.

Deklaracja zgodności

nasze wyroby Inspexx 119000354, których deklaracja niniejsza

-

Dyrektywa Maszynowa (2006/42/WE).

- EN 60335-2-79 : 2012

Dyrektywa EMC (2014/30/EU).

- EN 55014-1 : 2007

- EN 55014-1 : 2015

- EN 61000-3-2 : 2014

- EN 61000-3-2 : 2013.

Декларация соответствия

-

-

-

- EN 60335-2-79 : 2012

- EN 55014-1 : 2007

- EN 55014-1 : 2015

- EN 61000-3-2 : 2014

- EN 61000-3-2 : 2013.

Megfelelőségi nyilatkozat

proizvod Inspexx 119000354, na koji se ova izjava odnosi, u skladu

Direktiva za strojeve (2006/42/EZ).

- EN 60335-2-79 : 2012

Direktiva za elektromagnetsku kompatibilnost (2014/30/EU).

- EN 55014-1 : 2007

- EN 55014-1 : 2015

- EN 61000-3-2 : 2014

- EN 61000-3-2 : 2013.

Izjava o skladnosti

V Nilfisk FOODu s polno odgovornostjo izjavljamo, da so naši izdelki

Inspexx 119000354na katere se ta izjava nanaša, v skladu z nasled-

Direktiva o strojih (2006/42/ES).

- EN 60335-2-79 : 2012

- EN 55014-1 : 2007

- EN 55014-1 : 2015

- EN 61000-3-2 : 2014

- EN 61000-3-2 : 2013.

Izjava o usklađenosti

proizvod Inspexx 119000354, na koji se ova izjava odnosi, u skladu

Direktiva za strojeve (2006/42/EZ).

- EN 60335-2-79 : 2012

Direktiva za elektromagnetsku kompatibilnost (2014/30/EU).

- EN 55014-1 : 2007

- EN 55014-1 : 2015

- EN 61000-3-2 : 2014

- EN 61000-3-2 : 2013.

Deklaracija o konformitetu

proizvod Inspexx 119000354 na koji se ova izjava odnosi, u skladu

Direktiva za mašine (2006/42/EC).

- EN 60335-2-79 : 2012

EMC direktiva (2014/30/EU).

- EN 55014-1 : 2007

- EN 55014-1 : 2015

- EN 61000-3-2 : 2014

- EN 61000-3-2 : 2013.

Declaraţie de conformitate

-

Statelor Membre CE:

Directiva Utilaje (2006/42/CE).

- EN 60335-2-79 : 2012

Directiva EMC (2014/30/EU)

- EN 55014-1 : 2007

- EN 55014-1 : 2015

- EN 61000-3-2 : 2014

- EN 61000-3-2 : 2013.

Декларация за съответствие

- EN 60335-2-79 : 2012

EU).

- EN 55014-1 : 2007

- EN 55014-1 : 2015

- EN 61000-3-2 : 2014

- EN 61000-3-2 : 2013.

Prohlášení o shodě

- EN 60335-2-79 : 2012

EU)

- EN 55014-1 : 2007

- EN 55014-1 : 2015

- EN 61000-3-2 : 2014

- EN 61000-3-2 : 2013.

Prehlásenie o zhode

My firma Nilfisk FOOD prehlasujeme na svoju plnú zodpoved-

oblastiach:

Smernica pre strojové zariadenie (2006/42/EC).

- EN 60335-2-79 : 2012

Smernica pre elektromagnetickú kompatibilitu (2014/30/EU).

- EN 55014-1 : 2007

- EN 55014-1 : 2015

- EN 61000-3-2 : 2014

- EN 61000-3-2 : 2013.

Uygunluk Beyanı

-

- EN 60335-2-79 : 2012

EU).

- EN 55014-1 : 2007

- EN 55014-1 : 2015

- EN 61000-3-2 : 2014

- EN 61000-3-2 : 2013.

Vastavusdeklaratsioon

Meie, Nilfisk FOOD, deklareerime enda ainuvastutusel, et tooted Inspexx

Masinate ohutus (2006/42/EC).

- EN 60335-2-79 : 2012

Elektromagnetiline ühilduvus (EMC direktiiv) (2014/30/ EU).

- EN 55014-1 : 2007

- EN 55014-1 : 2015

- EN 61000-3-2 : 2014

- EN 61000-3-2 : 2013.

Atitikties deklaracija

- EN 60335-2-79 : 2012

EU).

- EN 55014-1 : 2007

- EN 55014-1 : 2015

- EN 61000-3-2 : 2014

- EN 61000-3-2 : 2013.

Atbilstības deklarācija

- EN 60335-2-79 : 2012

EU).

- EN 55014-1 : 2007

- EN 55014-1 : 2015

- EN 61000-3-2 : 2014

- EN 61000-3-2 : 2013.

Свідчення про відповідність

вимогам

-

- EN 60335-2-79 : 2012

EU).

- EN 55014-1 : 2007

- EN 55014-1 : 2015

- EN 61000-3-2 : 2014

- EN 61000-3-2 : 2013.

Technical file responsible:

Flemming Asp

Nilfisk FOOD

9000 Aalborg, Denmark

Signature:

Flemming Asp

R & D Manager

Aalborg d. 01-06-2017

1. Contents

1. Contents ................................................................................................... 9

2. Symbols used in this document ........................................................................ 10

3. General information...................................................................................... 11

3.1. Identification plate.................................................................................. 11

3.2. Specifications...................................................................................... 12

4. Overview and use ........................................................................................ 13

5. Installation................................................................................................ 13

5.1. Directions for mounting of the Inspexx unit ........................................................... 13

5.2. Water connection .................................................................................. 13

................................................................................. 13

6. Setting before use - Operation .......................................................................... 13

6.1. Setting before use ................................................................................. 13

6.2. Daily operation..................................................................................... 13

7. 7. Guides ................................................................................................. 14

8. Maintenance.............................................................................................. 16

8.1. Instructions ........................................................................................ 16

8.2. Maintenance kits................................................................................... 16

9. Warranty .................................................................................................. 17

10

English (EN)

2. Symbols used in this document

Read before use

Wear glasses when using the unit.

Wear gloves and suitable clothing when using the unit.

Caution:

injuries. Can also be used to warn against damage to prop-

erty or other goods prevention.

Warning:

11

English (EN)

3. General information

The Inspexx unit is used for mixing and distribution of

pre-diluted detergent for cleaning stations or other types

of outlets. Water and detergent are mixed by a dosing

pump and stored in a tank.

It is very important that the operational staff reads this

user guide thoroughly prior to installation and start of op-

eration. Operation as laid down in the directions for use

will ensure an optimum level of hygiene in your factory

and a minimum level of repair work.

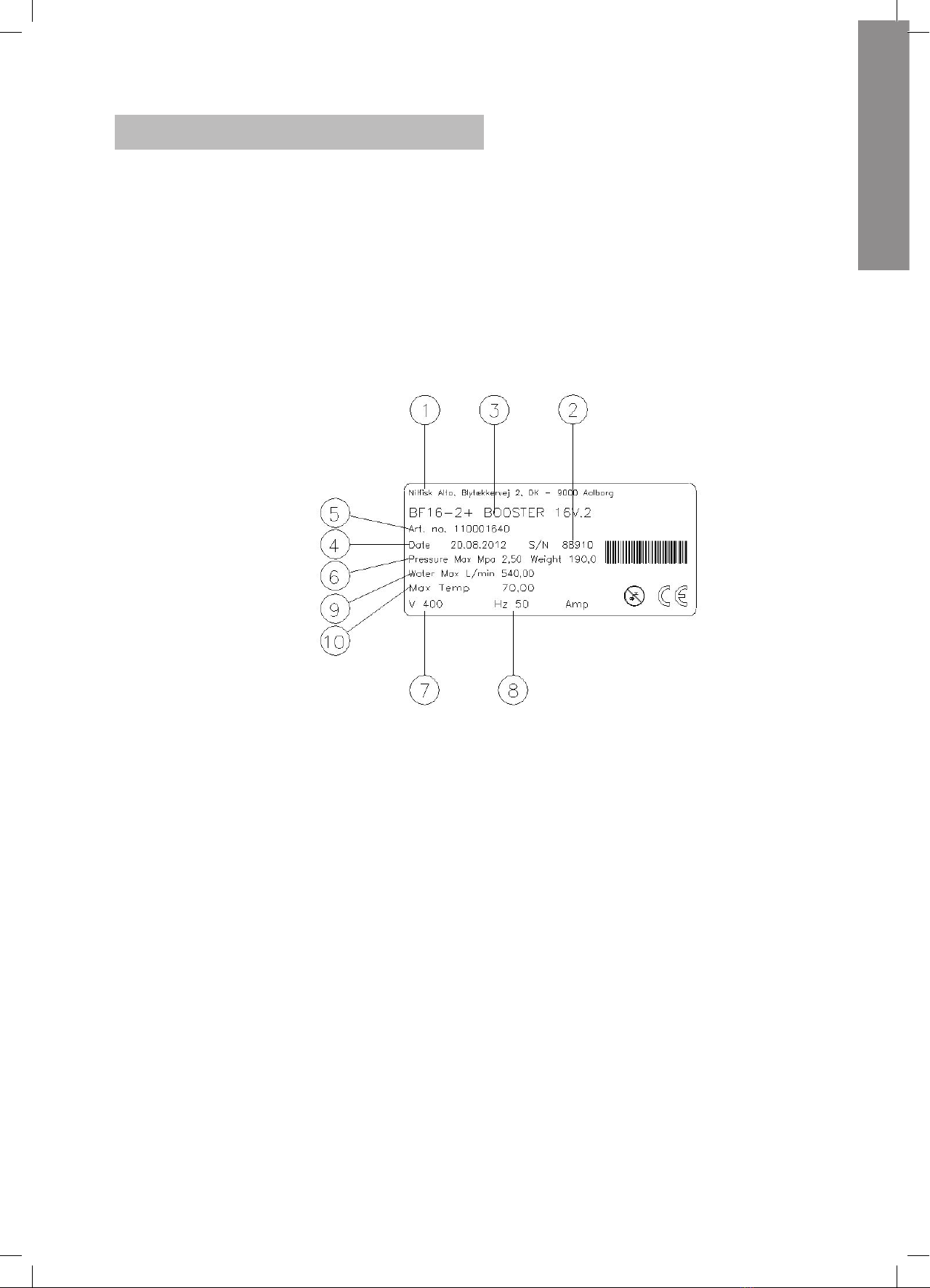

3.1. Identication plate

2. Serial number

3. Type

4. Date

5. Article number

6. Max. pressure

8 Frequency

9 Max. flow

10 Max temperature

Supplier

Nilfisk FOOD

DK-9000 Aalborg, Denmark

Tel.: +45 7218 2000

CVR no. 6257 2213

www.nilfiskfood.com

12

English (EN)

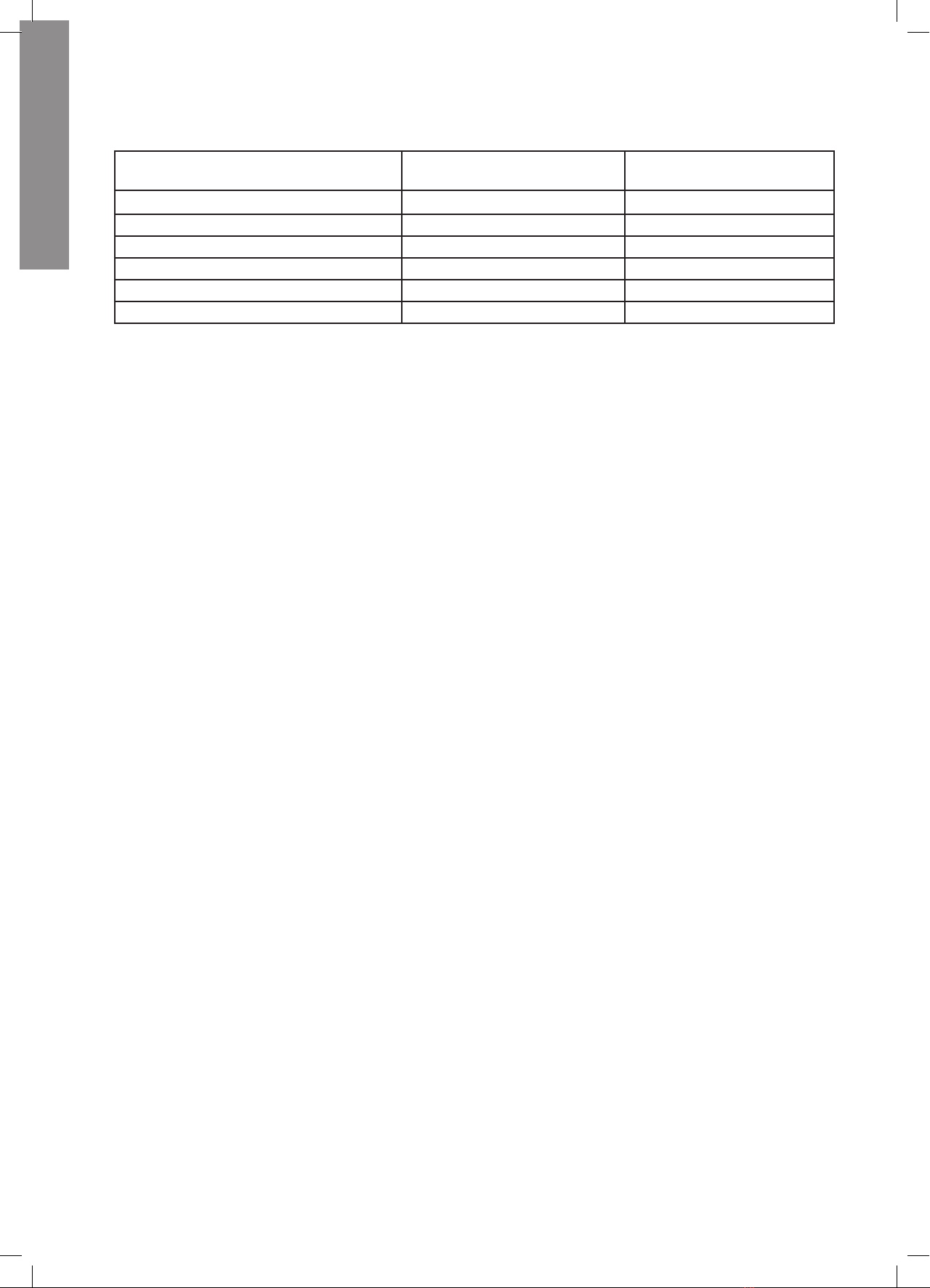

Water Unit INSPEXX

Max.operational pressure. (bar) 5

L/min 50

L/min 50

Max. temperature of water °C 40

Weight kg 100

Dimension WxHxD 1330x1525x725

3.2. Specications

13

English (EN)

3. When installing the piping, take care to avoid air traps.

4. Max. supply water temperature: 40°C

Max. water supply Inspexx: 50 l/min

Max. allowed inlet water pressure: 5 bar

5.3. Bleeding the pump

WARNING

Never start up the supply pump before

the pump has been bled.

When the unit has been mounted and water has been

connected to the inlet side, the pump must be bled. This is

done by opening the bleeding screw in the top of the pump.

Operate the valve for the dosing pump and fill the tank with

water and bled the supply pump. The pump must be bled

until only water comes out of the pump.

6. Setting before use - Operation

6.1. Setting before use

When delivered the unit is pre-set for use. For the Inspexx

this means that the tank will be automatically refilled and

that the pump will start up when flow appears in one or

more outlets. Further, the pump will stop when the flow

ends.

Via a signal from a pressure sensitive switch the pumps

starts up and stops running via a signal from a flow switch.

The pressure sensitive switch is pre-set by the supplier.

The flow switch might have to be fine tuned.

The adjustment of the flow switch is carried out as follows:

open up one outlet, adjust the flow switch screw until one

yellow diode and one green diode lights up. This must cor-

respond the min. achievable consumption.

Concentration of detergent is to be adjusted directly on the

inlet of the dosing pump. For further data and service on

the dosing pump please see data sheet and manual for the

dosing pump.

6.2. Daily operation

When adjusted according to the above descriptions the unit

runs automatically. This means that the tank automatically

is refilled and that the pump, during flow in one or more

outlets, is in operation.

-

zle or foam nozzle to the pistol/closing valve.

Only seconds after opening of the pistol/low pressure valve

the pump starts up and a working pressure automatically

appears.

4. Overview and use

The Inspexx unit consists of a dosing system – mixing

water and chemicals. The mixed solution is led into

a tank (the pre-diluted solution). From this tank the

solution is pumped out to outlets where the solution is

used for cleaning.

For the Inspexx the liquid level in the tank is adjusted

via level sensors placed inside the tank. These sen-

sors send a signal to the controller operating the

valve and the dosing pump leading the water into the

tank.

The unit is made of corrosion resistant material –

mainly stainless steel and plastic – and is therefore

especially suitable for application within the food

industry.

5. Installation

5.1. Directions for mounting of the Inspexx unit

ATTENTION

1. The unit should be mounted in frost free rooms

only.

2. The unit is leveled by adjusting the feet. When

the unit is leveled the lock nuts on the feet are to

be tightened thoroughly.

3. The unit is fastened to the floor using a bolt

through the hole on each foot. It is sufficient to

fasten the feet in the corners.

5.2. Water connection

CAUTION

1. -

ply pipe, the supply line should be rinsed care-

fully in order to remove coarse impurities and

metal shavings.

2. The pressure loss in the supply line should be

held as low as possible by:

- avoid long supply pipes

- mounting of low pressure resistance ball valves and

- avoiding fittings with high pressure loss

14

English (EN)

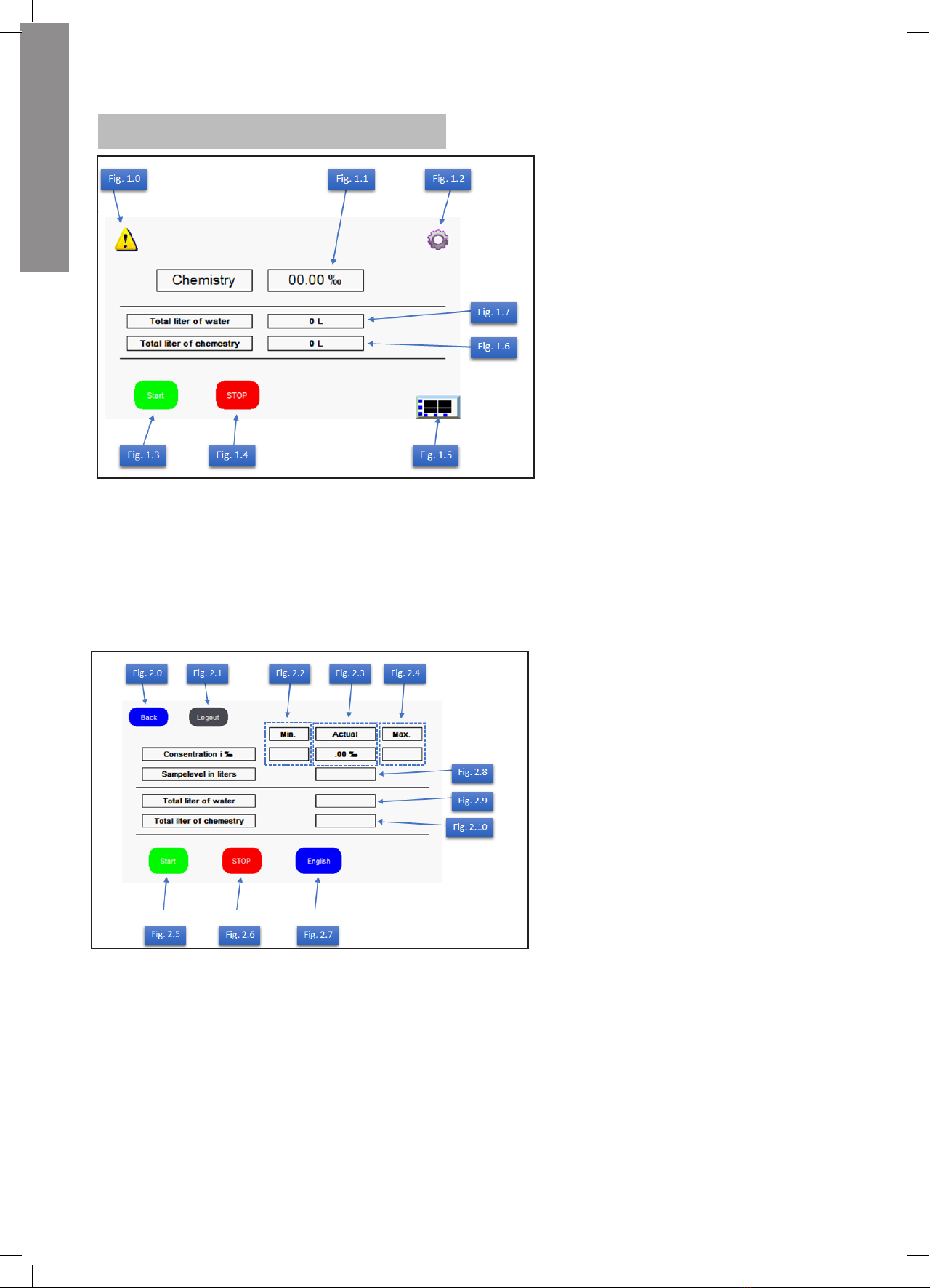

Fig. 1.0 Go to alarm list.

Fig. 1.1 Shows the amount of chemical in per mille right now.

Fig. 1.2 Go to settings, requires login.

Fig. 1.3 Start the unit. Shows when not in operation.

Fig. 1.4 Stop the unit. Shows when in operation.

Fig. 1.5 Not shown. (hidden icon necessary for data logging)

Fig. 1.6 Total amount of water in liter.

Fig. 1.7 Total amount of chemical in liter.

Fig. 2.0 Return to front page.

Fig. 2.1 Log out and go back.

Fig. 2.2 My alarm limit for low chemical level.

Fig. 2.3 Shows the amount of chemical in per mille right now.

Fig. 2.4 Max alarm limit for high level of chemical.

Fig. 2.5 Start the unit. Shows when the unit is not in operation.

Fig. 2.6 Stop the unit. Shows when the unit is on operation.

Fig. 2.7 Changes the display language.

Fig. 2.8 If set to e.g. 100 liter, the mix is calculated for every 100 liter. After 100 liter a new calculation is made.

Fig. 2.9 The total amount of water in liter. Can be adjusted.

Fig. 2.10 The total amount of chemical in liter. Can be adjusted.

7. Guides

15

English (EN)

ID Messages

5 Warning, almost empty chemical tank.

6 Stop, chemical tank is empty.

7 Stop, mixing tank is too full.

31 Max. Limit for chemical content is reached. (stated in per mille)

32 Min. Limit for chemical content has been reached. (stated in per mille)

Fig. 3.1 Delete all alarms.

Fig. 3.2 Sets all to ACK. (ACK= Alarm receipt)

Fig. 3.3 Go to top of alarm list.

Fig. 3.4 Go up on the alarm list.

Fig. 3.5 Go down on the alarm list.

Fig. 3.6 Go to end of alarm list.

16

English (EN)

8. Maintenance

8.1. Instructions

a) After one month of use the Inspexx station must be

maintained by a service engineer. The functionality

and any possible errors should be maintained. Fur-

thermore, the unit must be checked for leaks.

The above maintenance should be carried out mini-

mum every third month.

If required the interval might be shorter.

b) Depending on usage, at least once a year mainte-

nance should be undertaken by an authorised service

engineer in order to prevent defects and failure of op-

eration. Authorised engineers are persons who due to

their skills and experience have sufficient knowledge

of the unit in question and are confident with the state

work safety regulations, accident preventing regula-

tions, lines and generally acknowledged technical

regulations such as DIN-norms and VDE provisions.

For your safety this cleaning unit has been manu-

factured according to all relevant regulations valid in

the EU and it has therefore been fitted with the CE

marking.

Item no Description Amount

110005502 Service kit for D3R3000VF 1

Repairs must only be carried out when the water sup-

ply has been disconnected.

ATTENTION!

Maintenance is only to be carried out by authorised

personnel.

8.2. Maintenance kits

The dosing pumps have som moving parts and in

the combination with different detergents these parts

have to be changed during time and use. It is recom-

mended to make service on these pumps according

to working conditions to keep these in function. O-ring

in motor part and or in dosing part should be changed

during service.

Dosatron spare parts

17

English (EN)

9. Warranty

ATTENTION!

Our guarantee is given for a period of 12 months from

delivery on all parts which have provable become

unfit for use due to material, construction or manu-

facturing defects as well as inadequate work. The

guarantee compensation will occur in the shape of

reimbursement, replacement or repair of the defective

or damaged part at our works. Installation and freight

costs are always on the purchaser’s account. Any de-

fective parts are to be placed at our disposal. Claims

that may otherwise be raised for any legal reason will

not be acknowledged. No liability will be accepted for

damage occurred indirectly. The purchaser has no

right to let any third party repair possible defects on

our account.

All hoses, rubber parts or synthetic materials natural

wear and tear as well as damage caused by care-

less and inappropriate handling, including transport

damage are not covered by the guarantee. Further,

the guarantee does not apply if the system has been

subjected to frost. The obligation of guarantee com-

pensation also ceases if changes or repairs are made

by non-authorized persons. Claims under the guaran-

tee will only be acknowledged when they are placed

immediately after the defect has been noticed. The

guarantee ceases in case of change of ownership.

The dealer cannot be held responsible for personal

injury, damage to equipment, working deficits, includ-

ing production loss, loss of profits, loss of stock or

the like which may occur by imperfect and delayed

delivery of the sold product, regardless of the reason,

see our standard terms of sale and delivery.

1. Inhalt

1. Inhalt ...................................................................................................... 19

2. Verwendete Symbole .................................................................................... 20

3. Allgemeine Informationen ............................................................................... 21

3.1. Spezifikationen .................................................................................... 22

4. Überblick und Verwendung.............................................................................. 23

5. Installation................................................................................................ 23

5.1. Anweisungen zur Montage der Inspexx-Anlage ...................................................... 23

5.2. Wasseranschluss .................................................................................. 23

............................................................................... 23

6. Einstellungen – Betrieb.................................................................................. 23

6.1. Einstellungen ...................................................................................... 23

7. Guides .................................................................................................... 24

8. Wartung................................................................................................... 26

8.1. Instruktione........................................................................................ 26

8.2. Wartungskits....................................................................................... 26

9. Garantie................................................................................................... 27

20

English (EN)

2. Verwendete Symbole

Vor inbetriebnahme lesen.

passende Kleidung.

Vorsicht:

Eine gefährliche Situation. 'Mögliche Konsequenzen: Leichte

oder geringfügige Verletzungen. Kann auch genutzt werden, um

zu warnen.

Warnung:

Eine potenziell gefährliche Situation. Mögliche Konsequenzen:

Tod oder schwere Verletzungen.

Table of contents

Languages: