Ecom CN User manual

w w w . e c o m u s a . c o m

A supplement to the CN manual

Important Things to Remember

In order to receive accurate measurements,

please allow reading to stabilize

for at least 2 minutes.

The CN is not suitable for continuous emission

testing. Please allow at least 10 minutes of

fresh air purge for each hour of testing.

The following substances may cause damage

to the electrochemical sensors:

Cleaning agents

Degreasers

Wax polishes

Adhesives

Formaldehyde

1. Charge the battery after each use

2. Always store unit with fully charged battery

3. Charge the battery at least once a month if

not in frequent use

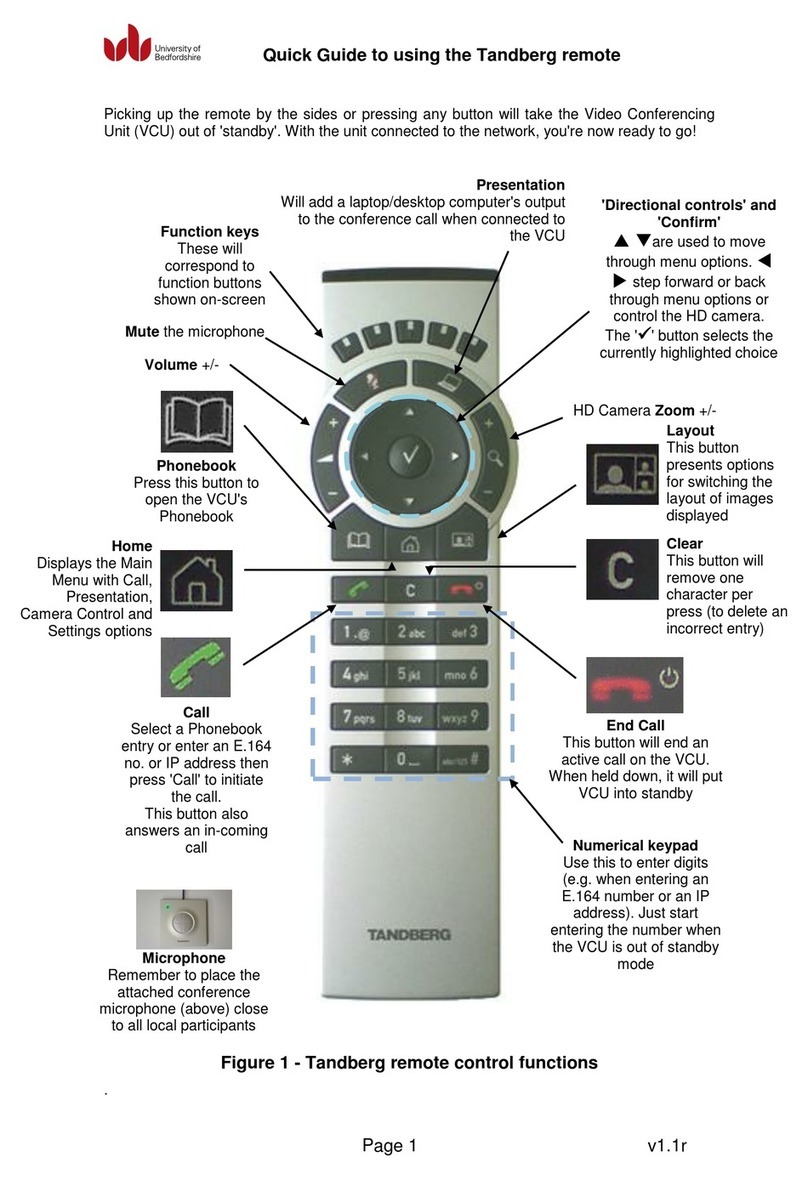

Connections

Top

Bottom

Gas Connection

Draft/Pressure

Connection

Thermocouple

Connection

Condensate

Monitoring

Connection

Auxiliary

temperature

connection

(optional)

Ambient

temperature

sensor

Charging

socket

Pressure

connection

(optional)

Infrared sensor

(for IR printer)

Water Trap Assembly

Keypad

Function keys

Display backlight

ON/OFF

Dispersive cooler

with spiraling

gas path

Particulate filter

(located below

water trap cap)

Electrical

connection

to analyzer

Condensate

monitoring

electrodes

Note: The CN constantly monitors the level of water in the water trap.

When the condensate filter has fully expanded, the electrodes touch

the electrode plate. This signals the pump to stop, protecting the

sensors from harmful exposure. When this happens, it is time to

change the expandable filter.

Expandable

condensate

filter

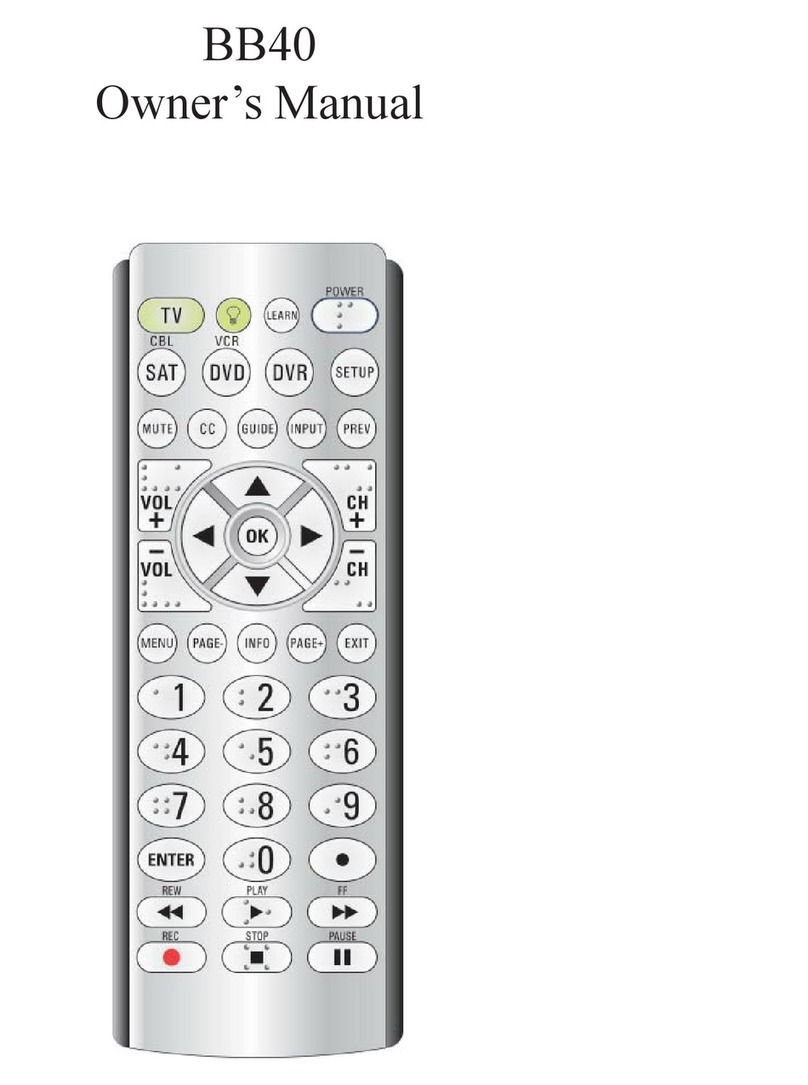

Contrast

Scroll Down

Print to IR Printer

Power ON/OFF

OK / Press to

Confirm

Escape / Return

to Previous Screen

Save Snapshot to

Internal Memory

Scroll Up

Gas

Draft/

Pressure

Gas

Temp.

Condensate

Monitoring

Electrode plate

(located on top of

expandable filter)

Calibration Procedure

For best results, the gas concentration should be as close to the

expected levels of emissions as possible. Because each sensor is

linear through a nominal range, one calibration gas concentration can

be used for a reasonably wide range of emission levels. For

applications with extremely low or extremely high levels of emissions,

the sensors should be calibrated as close as possible to expected

concentration levels. It is also recommended that—for gas mixtures

that support oxygen content—a small percentage of oxygen (i.e. 2% -

5%) be present in the calibration gas to aid in the system leak check.

Fully charge analyzer:

Place unit on charge the night before you plan to use analyzer to

ensure full charge of battery.

Initiate analyzer:

1. Attach thermocouple, water trap, sample line, and power cord.

2. Switch on analyzer.

3. Select Combustion Measurement on main menu.

4. Select Fuel Type, press OK.

5. Select No for Data Processing.

6. Allow instrument to complete auto-zero sequence.

Perform air leak test:

1. Apply nitrogen gas to analyzer through probe/sample line (you

can use NO calibration gas that is balanced in nitrogen).

2. Allow gas to flow for 3 minutes.

3. After 3 minutes, check that O2 reading is 0.0% (spec is +/- 0.2%).

If reading other than 0.0 %, troubleshoot to source of leak and

correct.

4. Do not proceed to calibrate analyzer until air leak is corrected.

Put analyzer in calibration mode:

1. Select Control on main menu (press Escape/8 to return to main

menu if necessary).

Calibration Procedure (continued)

2. Swipe calibration magnet over the silver Cal Magnet sticker,

located left of the display screen (look under protective cover).

The calibration screen should appear with title Adjustment.

3. The analyzer is now in calibration mode.

Calibrate your analyzer:

1. Connect calibration gas to analyzer using one of the following 4

set-ups:

(1st option) Measure flow of pump at point of cal gas input with

flow meter. Connect calibration gas to analyzer through flow

meter and adjust flow to match pump draw.

(2nd option) Vented flow meter configuration. Ensure sensors are

not over or under pressurized by allowing small amount of gas

out of flow meter. This prevents air from entering system and

allows pump to control internal pressure within analyzer.

(3rd option) Use a 15-liter gas bag or higher to ensure enough gas

is present for analyzer to stabilize. A gas bag allows analyzer to

draw gas at the correct flow rate.

(4th option) Use on-demand regulator which uses pump draw to

establish flow. No need to measure and match flow from the

regulator, as pump is controlling the flow.

2. Flow calibration gas for 5 minutes.

3. After reading has stabilized for target sensor, press OK to display

input mode. Input concentration of calibration gas using

numbers on keypad. Press OK.

4. Disconnect calibration gas.

5. After calibrating target sensor, allow analyzer to flush with fresh

air for 5 minutes or until readings are below 10 ppm.

6. Press Escape/8 to return to main menu.

7. Press On/Off to turn off analyzer.

Data Logging

CN Data Logging allows you to save data snapshots into an on-

board flash memory. The purpose is to allow you to record multiple

data snapshots during a day of testing, and then retrieve the data at a

later time. This allows you to view the data only. If you want to upload

the data to a computer, you will need to send your CN to ECOM for

Bluetooth installation. You may also use an IR printer to print

snapshots on-the-spot. Call 1-877-ECOM-411 if you have any

questions.

How to Save a Data Snapshot

1. Initiate analyzer: Power on -> Go to Combustion Measu. -> Select

Type of Fuel -> Press F4/No for Data Processing -> Wait for the

analyzer to complete self-check -> Press to return to Main

Menu

2. Go to Data Processing -> Select ->Memory Number

3. Input Memory Number using the numbered keypad and press OK

Note: This assigns a number to your test for retrieval later (valid

numbers 0-4088). Write down or remember this number!

4. Press OK again to confirm Memory Number selection

Note: Display may read “Data Record is Empty!” Press OK

5. Press to return to Main Menu and go to Combustion Measu.

6. Insert probe into sample port -> Wait 2 min for readings to

stabilize -> Press 5/Save to capture snapshot -> An M icon will

appear -> Snapshot has been saved temporarily

7. Press (printer button) and select Store to Memory (you can

also Look At or Print) -> Another Micon will appear -> Snapshot

has been saved permanently to on-board memory

Data Logging (continued)

Note: If error message “Flash-memory?” is displayed -> Press

OK -> Press twice to return to Main Menu -> Go to Data

Processing -> Format Memory -> Press F1/Yes (may take up to 5

minutes) -> This erases all permanent memory!

8. Press to escape and press 5/Save to clear temporary memory

9. To save another data snapshot, press to return to Main Menu

and repeat steps 2-8

How to Retrieve a Data Snapshot

1. In the Main Menu, go to Data Processing -> Select -> Memory

Number

2. Input Memory Number for the data snapshot you are retrieving

and press OK

3. Press OK again to confirm Memory Number selection

4. Scroll down to select Look At –> Scroll down again to see data

5. Repeat steps 1-5 to retrieve other data snapshots

For simpler data logging, you can use Bluetooth to view real-time

data on a computer. If you are interested in this feature, please call

ECOM at 1-877-ECOM-411.

Frequently Asked Questions

Where do I find important in-

strument information?

How long is the life span of the

sensors?

Which sensors can I exchange?

The instrument shows the error

message “O2sensor 0 mV“

The instrument shows the error

message “T-Gas“ or “T-Air“

The instrument shows wrong or

inaccurately CO2values

In the Control screen, all important instru-

ment information is shown (e.g. battery volt-

age, sensor values, serial number, next ser-

vice date, operation hours, etc.).

The life span depends on the operating hours

and the instrument equipment. The life span

of the toxic sensors (CO, NO, SO2, NO2) is

affected by high gas concentrations or insuf-

ficient purging. The life span for these sensors

is on average 3 years. The life span of the O2

sensor is independent of the operating hours

and amounts to approximately 2 years.

The following sensors are exchangeable:

- O2sensor

- CO sensor (pre-calibrated available)

- NO sensor (pre-calibrated available)

- NO2 sensor (pre-calibrated available)

The O2 sensor must be changed.

Possible reasons could be:

- Cable is broken (at the plug)

- T-Air sensor –check connection

- T-Gas sensor –check all connections

- Thermocouple is defective

Possible reasons could be:

- Fuel selection is incorrect

- O2is defective

(CO2values are calculated from O2value and

carbon content of the fuel)

- Pump is not working correctly

- Air leakage in the gas path

- Ambient gas cooler is clogged

Frequently Asked Questions (continued)

If you have any further questions, do not hesitate to contact

the ECOM America Service Department at 770-532-3280

CN cannot be switched on

Can I change the printout?

Pump flow seems too low

No flow is getting to the

sensors

CN display is blank when I

turn it on but the analyzer is

clearly powered on

- Check the battery charger for defects

- Recharge the batteries for a minimum of 8 hours

(Battery could be completely discharged)

Please contact ECOM if you want to change the

printout.

Check all hose connections for tearing/cracking

and check ambient gas cooler for blockage

Check all connections and bypass the water trap to

pinpoint if the lead is in the water trap

Display contrast may be set incorrectly –press the

Contrast button #9 many times after you turn on

the remote unit to see if screen comes back

Hint: If you have several CN analyzers, you can

find the source of an error by exchanging the ac-

cessories (probe, hose, temperature sensor, etc.)

Calculations

Note: A2, B, and CO2max are coefficients based on fuel type.

Carbon Dioxide (CO2) Range=0-CO2max

CO2= CO2 max X(21 –O2measured)

21

Combustion Efficiency (Eta) Range=0-99.9%

Efficiency = 100 –(A2 + B) X(TGas –TAir)

21 –O2measured

Excess Air (Lambda) Range=1-infinity

Excess air =1 + O2 measured

21 –O2measured

Losses Range=0-99.9%

Losses = (A2 + B) X(TGas –TAir)

21 –O2measured

Technical Data

Parameter Range Principle

O20-21% vol. Electrochemistry

CO 0-4000 ppm Electrochemistry

NO 0-4000 ppm Electrochemistry

NO20-50 ppm Electrochemistry

CO% 4001-63000 ppm Electrochemistry

Air pressure 300-1100 hPa DMS bridge

CO20-25% Calculation

T-Gas 0-1000°C/1832°F NiCr/Ni

T-Air 0-100°C/212°F Semi-conductor

Differential pressure +/- 100 hPa DMS bridge

Efficiency 0-120% Calculation

Losses 0-99.9% Calculation

Excess air 0-50% Calculation

CO sensor purges thru separate fresh air pump

Electronic water trap monitoring with ambient gas cooler

Power Supply Main Power 230V...50 Hz

Base Unit Battery 6V/2.0 AH NiMH

Display Screen LCD Display with Backlight

Dimensions (LxHxD) 115mm x 250mm x 77mm

Weight 1500g

ECOM America Ltd.

1628 Oakbrook Drive

Gainesville, GA 30507

Toll Free (877) 326-6411

Phone (770) 532-3280

Fax (770) 532-3620

www.ecomusa.com

Other manuals for CN

1

Table of contents