earth loop water temperatures. Typical electric hot water

heaters supply 16,720 Btu/hr (4.9 kwhr) of capacity.

The heat pump heats the DHW by circulating the water

from the storage tank through a double-walled,

refrigerant-to-water condenser coil. When the

temperature of the water in the storage tank drops below a

reset point of 113"F, a pump, built into the heat pump,

circulates the water and the number two compressor

starts. The compressor continues to run, heating the

DHW, until the water reaches 1l9oF. The DHW pump is

controlled to run continuously only when the compressor

is activated in DHW mode. This pump will also run for a

one minute sampling period every seven minutes to

continuously sample the tank's water temperature and

bring the compressor on at the correct times. The tank

temperature is controlled with a simple temperature

sensor mounted on a copper pipe inside the heat pump.

The minimum entering water temperature on the DHW

side (water in the storage tank) is 50oF. Startup on the

system with colder water will require restricting flow to

the unit until tank temperatures rise. A maximum DHW

tank temperature of 126oF is also specified to keep the

system from locking out on high head pressure. Figure 4

shows the required plumbing to connect the system.

Figure 5 shows an example of a plumbing circuit for a

-DWR unit that has enough capacity for both domestic

hot water and radiant floor heating. Figure 6 shows a

plumbing circuit for a -DWR unit that is sized to full

capacity for radiant floor heating. With this setup, the

-DWR unit can provide supplemental domestic hot water

to an additional water heater when the radiant floor is not

utilizing the full load. Reduced flow rates and increased

leaving water temperatures can lock the DHW circuit out

on rhe high pressure switch, so follow the plumbing

dia-eram closely.

of 30 gallons is required; normally a 50 to 80 gallon tank

would be used.

When installing a GeoSource Invision3 with the -DWR

option, use an indirectly fired water heater as a storage

tank (shown in Figures 5 and 6).

The electric elements can be left in and wired to provide

backup water heating ability, but be sure to leave the

circuit breaker off during normal operation, so that it does

not interfere with tank temperatures.

€Note: While all hot water tanks are insulated on the top

and sides, many do not have insulation on the bottom" An

insulated pad beneath uninsulated tanks will reduce

ener-qy loss to the floor.

Always check local codes to be sure hot water tanks can

be used for this purpose.

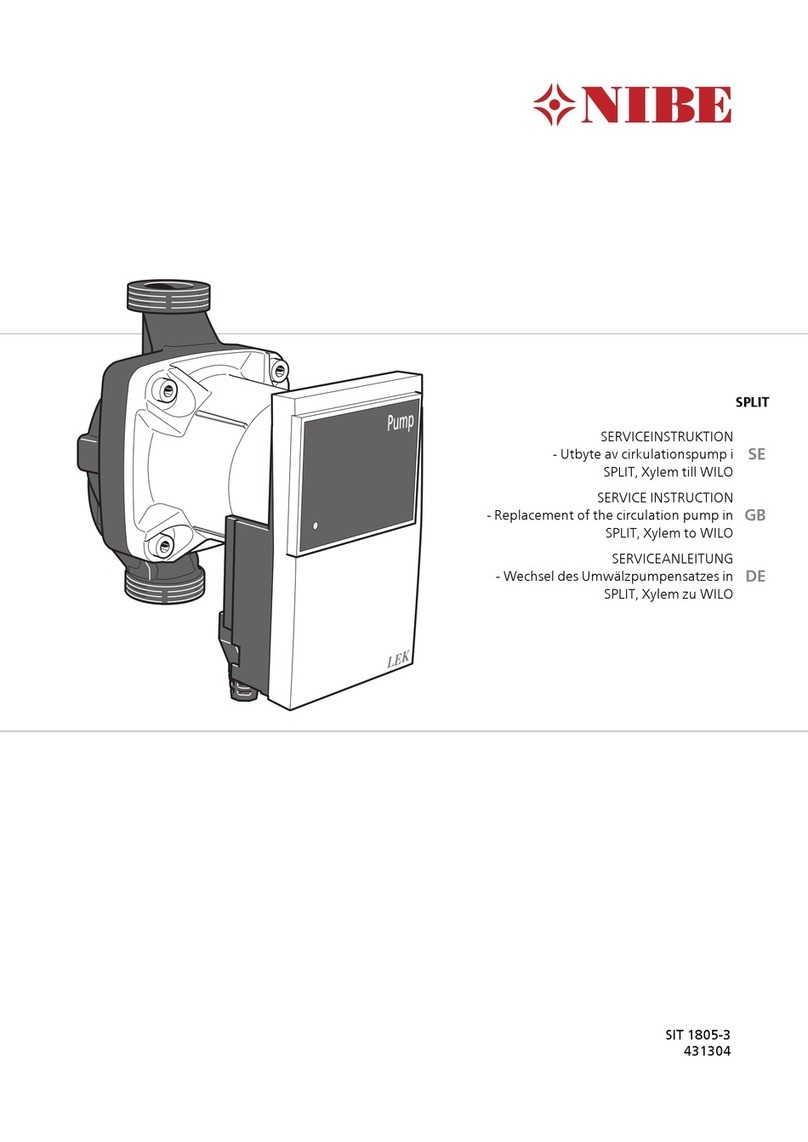

2. DHW Pump

The DHW pump transfers the energy supplied by the

GeoSource Invision'heat pump to the storage tank. This

pump is impedance protected and does not require

additional fusing. A two-amp inline fuse is supplied on

the pump for additional safety and for use as a shut off

switch.

This pump has been sized to provide the required flow to

the heat exchanger with a total system pressure drop of 2 1

feet ofhead. This pressure drop can be calculated from

the total pressure drop through *re piping, added to the

pressure drop of the heat pump of 15 feet of head. Figure

3 shows the pump curve of the DHW pump. The pump

can provide 8 GPM at 2l feetof head. Using one inch

copper pipe is critical to maintain the proper flow. The

remaining six feet of head is equivalent to 100 feet of one

inch type L copper tubing or a combination of straight

pipe and fittings. If extremely long distances separate the

heat pump and storage tank, or ifadditional pressure drop

cannot be avoided, a booster pump must be added to the

plumbing system. For the most efficient operation, locate

the heat pump and storage tank as close together as

possible and insulate all water piping.

A common problem with circulator pumps is trapped air

in the system. This air accumulates in the suction port of

the circulator pump, causing cavitation in the pump. The

cavitation can stop the flow of water and leadio

premature pump failure and noisy operation. The air can

be eliminated by completely purging the system or by

placing an air separator in the plumbing lines.

The entire system must be purged of air during initial

installation. Normal systems will operate on iater supply

pressure, which keeps air from reentering the system. If a

system is not working on water supply pressure, maintain

110 to 30 psi static pressure to keep air out of the loop.

Otherwise, corrosion, bacteria growth, or pump cavitation

may occur.

An operating temperature range for the earth loop side of

the heat pump is also specified as follows:

- 20"F (minimum for heating)

- 100"F (maximum for cooling)

- 80"F (maximum for -DHW and -DWR option)

These limits have been established based on efficiency

limitations and safety pressure switch limits (50_psi low_

pressure curout and 580 psi high-pressure cutout). DHW

operation is limited to 80nF because at this warm of a

source temperature, the heating capacity increases to the

point of overloading the water-cooled condenser, tripping

the system offon high head pressure.

eNote: After all plumbing and purging of the circuit

is complete; MOVE DIp SWITCH #4, Iocated on the

controller, to the ON position to initiate DHW

operation. Allowing the pump to run dry will damage

the circulating pump and overheat the motor.

1. Storage Tanks

Insulated electric hot water heaters are used for storage

tanks for the DHW circuit of the heat pump. A minimum

3