2

GENERAL

The 50PEC water source heat pump (WSHP) console unit is a de-

centralized room terminal designed for field connection to a

closed-circuit piping loop.

Units are typically installed in perimeter zones, usually under win-

dows. Supply air is discharged directly into the conditioned space

through discharge grilles located in the top of the unit.

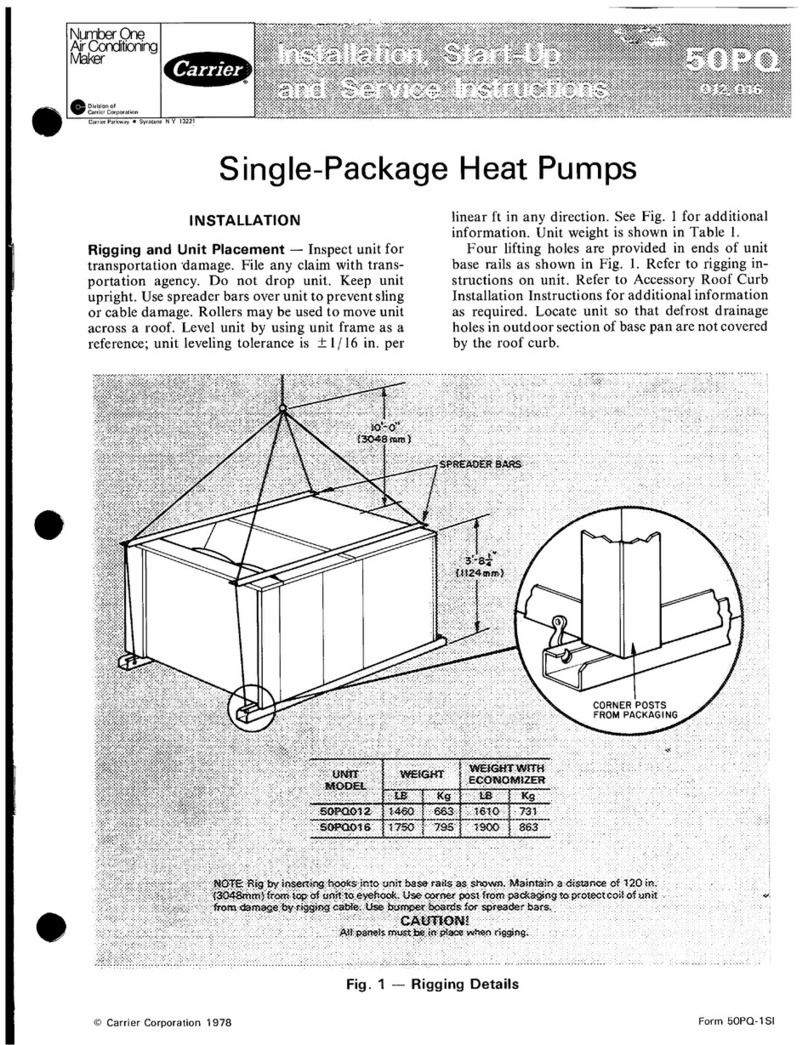

INSTALLATION

Step 1 — Check Jobsite

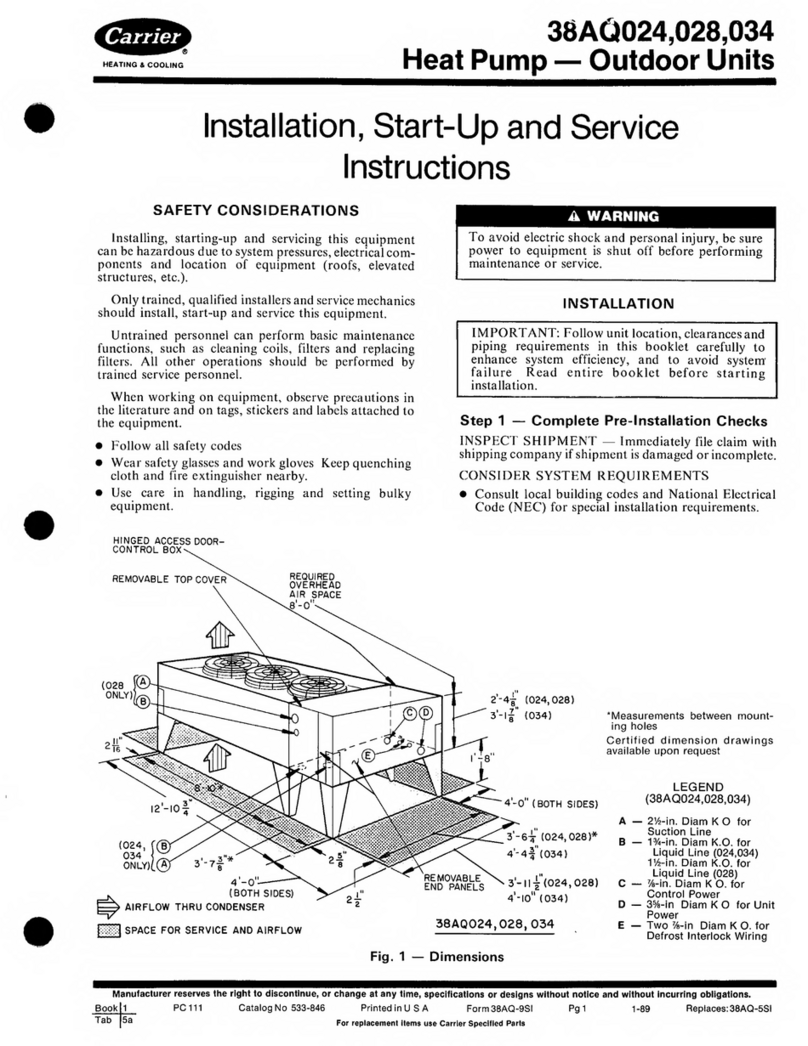

Units are typically installed along an outside wall of the room. Re-

fer to Fig. 1 for an illustration showing piping locations. Install

units with adequate clearance to allow maintenance and servicing.

Refer to Table 1. Locate the console unit so that it provides ade-

quate air circulation throughout the room.

Installation, operation and maintenance instructions are provided

with each unit. Before unit start-up, read all manuals and become

familiar with the unit and its operation. Thoroughly check out the

system before operation. Complete the inspections and instruc-

tions listed below to prepare a unit for installation.

1. Compare the electrical data on the unit nameplate with order-

ing and shipping information to verify that the correct unit

has been shipped.

2. Keep both the chassis and cabinet covered with the shipping

carton until all plastering, painting, and finish work is com-

plete and it is time to install the chassis and cabinet.

3. Verify that the refrigerant tubing is free of kinks or dents, and

that it does not touch other unit components.

4. Inspect all electrical connections. Connections must be clean

and tight at the terminals.

Step 2 — Check Unit

Upon receipt of shipment at the jobsite, carefully check the

shipment against the bill of lading. Make sure all units have been

received. Inspect the carton or crating of each unit, and inspect

each unit for damage. Ensure the shipping company makes proper

notation of any shortages or damage on all copies of the freight

bill. Concealed damage not discovered during unloading must be

reported to the shipping company within 5 days of receipt of

shipment.

NOTE: It is the responsibility of the purchaser to file all necessary

claims with the shipping company.

STORAGE

Upon the arrival of equipment at the jobsite, immediately store

units in their shipping cartons in a clean, dry area.

UNIT PROTECTION

Cover console units on the jobsite with either shipping cartons,

vinyl film, or an equivalent protective covering. Cap the open ends

of pipes stored on the jobsite. In areas where painting, plastering,

or the spraying of fireproof material has not been completed, all

due precautions must be taken to avoid physical damage to the

units and contamination by foreign material. Physical damage and

contamination may prevent proper start-up and may result in

costly equipment clean-up.

Examine all pipes, fittings, and valves before installing any of the

system components. Remove any dirt found on these components.

CAUTION

DO NOT re-use compressor oil or any oil that has been ex-

posed to the atmosphere. Dispose of oil per local codes and

regulations. DO NOT leave refrigerant system open to air any

longer than the actual time required to service the equipment.

Seal circuits being serviced and charge with dry nitrogen to

prevent oil contamination when timely repairs cannot be com-

pleted. Failure to follow these procedures may result in dam-

age to equipment.

IMPORTANT: The installation of console water source heat

pump units and all associated components, parts, and accesso-

ries which make up the installation shall be in accordance with

the regulations of ALL authorities having jurisdiction and

MUST conform to all applicable codes. It is the responsibility

of the installing contractor to determine and comply with ALL

applicable codes and regulations.

CAUTION

To avoid equipment damage, do not use these units as a source

of heating or cooling during the construction process. The me-

chanical components and filters used in these units quickly be-

come clogged with construction dirt and debris which may

cause system damage.

CAUTION

To avoid the release of refrigerant into the atmosphere, the

refrigerant circuit of this unit must only be serviced by

technicians who meet local, regional, and national proficiency

requirements.

CAUTION

All refrigerant discharged from this unit must be recovered

without exception. Technicians must follow industry accepted

guidelines and all local, regional, and national statutes for the

recovery and disposal of refrigerants.

CAUTION

When a compressor is removed from this unit, system refriger-

ant circuit oil will remain in the compressor. To avoid leakage

of compressor oil, the refrigerant lines of the compressor must

be sealed after it is removed.

CAUTION

DO NOT store or install console units in corrosive environ-

ments or in locations subject to temperature or humidity ex-

tremes (e.g., attics, garages, rooftops, etc.). Corrosive condi-

tions and high temperature or humidity can significantly re-

duce performance, reliability, and service life. Always move

units in an upright position. Tilting units on their sides may

cause equipment damage.

CAUTION

DO NOT stack units. Take care when moving the unit. The

unit’s weight is located on the left (compressor) end. Always

store and move unit in an upright position. Take care to protect

the unit cabinet and sub-base when moving or storing. Never

move or lift unit by its water connections. Units must be

moved and stored in an upright position, never lay the unit on

it’s side.

CAUTION

When installing unit in cold air climates, an outside air damper

must be provided to prevent possible condenser freeze-up.