EcoPower CIPR-250W Guide

Installation and User Instructions

CIPR-250W Natural Gas

Generator

Mobile Gaseous Generator

May 2023

Version 4.1

DISCLAIMER

Eco Power Equipment Ltd. makes no representations or warranties with respect to this manual and, to

the maximum extent permitted by law, expressly limits its liability for breach of any warranty that may be

implied to the replacement of this manual with another. Furthermore, Eco Power Equipment Ltd.

reserves the right to revise this publication at any time without incurring an obligation to notify any

person of the revision.

The information provided in this documentation contains general descriptions and/or technical

characteristics of the performance of the products contained herein. This documentation is not intended

as a substitute for and is not to be used for determining suitability or reliability of these products for

specific user applications. It is the duty of any such user or integrator to perform the appropriate and

complete risk analysis, evaluation and testing of the products with respect to the relevant specific

application or use thereof. Neither Eco Power Equipment Ltd. nor any of its affiliates or subsidiaries shall

be responsible or liable for misuse of the information that is contained herein. If you have any

suggestions for improvements or amendments or have found errors in this publication, please notify us.

All pertinent state, regional, and local safety regulations must be observed when installing and using this

product.

When devices are used for applications with technical safety requirements, the relevant instructions

must be followed.

Failure to observe this information can result in injury or equipment damage.

Copyright © 2018 by Eco Power Equipment Ltd.

All rights reserved. No part of this publication may be reproduced, distributed, or transmitted in any

form or by any means, including photocopying, recording, or other electronic or mechanical methods,

without the prior written permission of the publisher. For permission requests, write to the publisher,

addressed “Attention: Permissions Coordinator,” at the address below.

Eco Power Equipment Ltd.

8, 26004 TWP 544, Sturgeon County, AB, T8T 0B6, Phone: 1-888-483-4843

2

TRADEMARKS

Eco Power Equipment Ltd. has made every effort to supply trademark information about company

names, products, and services mentioned in this manual. Trademarks shown below were derived from

various sources. All trademarks are the property of their respective owners.

General Notice: Some product names used in this manual are used for identification purposes only and

may be the trademarks of their respective companies.

Product Modifications

Year

Type

Modifications

2019

1

CIPR-250W V1

2021

2

CIPR V2 Gas Power

2022

3

CIPR V3 Gas Power

2023

4.1

CIPR V4 Gas Power

Document Revisions

Date

Version Number

Document Changes

3

Table of Contents

1 Preface 5

1.1 Description of the User 5

1.2 Conventions Used in This Manual 5

1.3 Explanation of Safety Warnings 6

1.4 Retaining Instructions 6

1.4.1 Internet 7

1.4.2 Ordering Documentation 7

1.4.3 Other Languages 7

1.4.4 Documentation Feedback 7

1.4.5 Support and Service 7

2 Description of the product 8

2.1 Intended Use and Reasonably Foreseeable Misuse 8

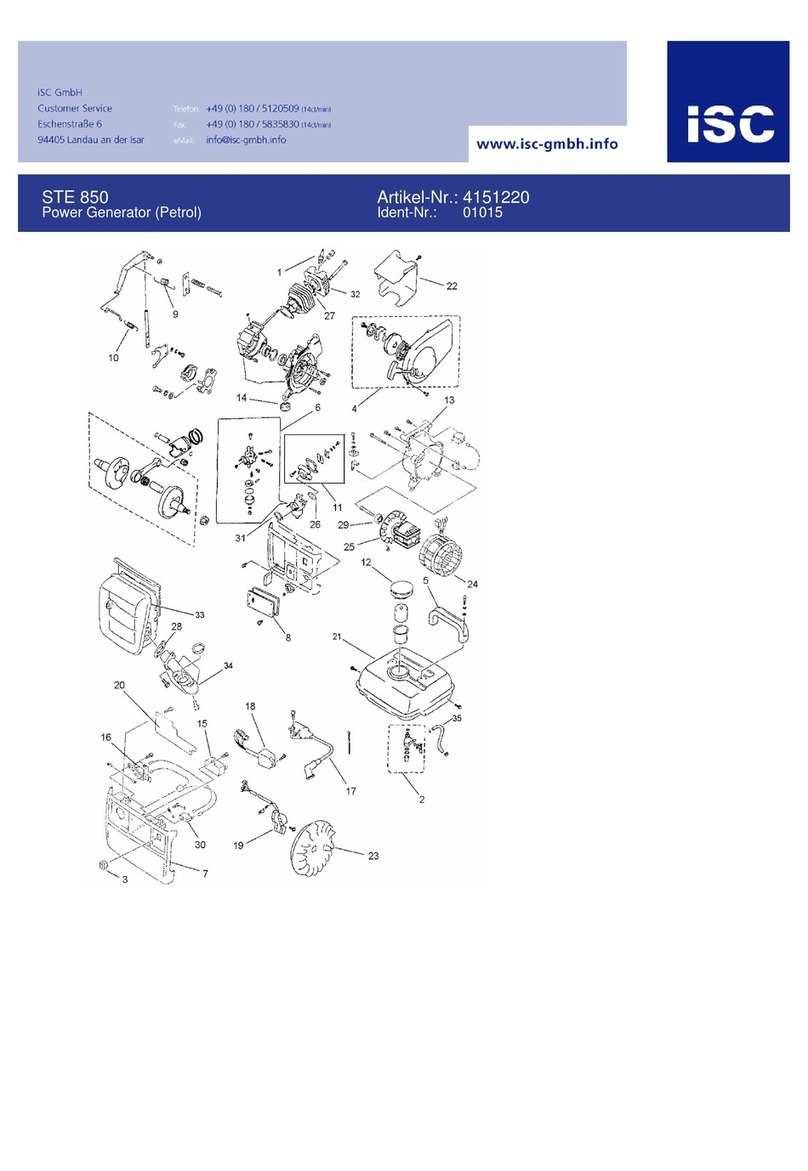

2.2 Product Elements 11

2.3 Understanding the User Interface and Control Panel 12

2.4 Setup Process 17

2.4.1 Quick Setup Guide 17

2.4.2 Operation 18

2.4.3 Shutdown and Storage 18

2.5 How to Use the Product Safely 19

2.5.1 Safety Information 19

2.5.2 Technical Lifespan 20

2.5.3 Personal Protective Equipment 20

2.5.4 Inspection Requirements 20

3 Maintenance 22

3.1 Check Engine Oil 23

3.2 Check Coolant Level 24

3.3 Check Oil Pressure 24

3.4 Change Oil and Oil Filter 25

3.5 Engine Valve Lash Adjustment 27

3.6 Inspect Spark Plugs 29

3.7 Fuel System 30

3.8 Exhaust System 34

4

1 Preface

1.1 Description of the User

Welcome to the Eco Power Equipment CIPR mobile power generator operator's manual. This manual is

designed to assist end-users in utilizing our product for temporary and prime rated power solutions in a

variety of applications. The CIPR generator is an ideal solution for generating power, and is commonly

used on construction job sites, oil and gas job sites, pipelines, events, security, and government or

military operations.

To ensure safe and efficient use, it is crucial that the user is qualified and follows all instructions

contained in this operating manual. This manual will guide the user through deploying and setting up the

CIPR, providing comprehensive instructions for use.

1.2 Conventions Used in This Manual

The following style conventions are used in this document:

Bold

Names of product elements, commands, options, programs, processes, services, and utilities names of

interface elements (such windows, dialog boxes, buttons, fields, and menus)

Interface elements the user selects, clicks, presses, or types

Italic

Publication titles referenced in text

Emphasis (for example a new term)

Variables

Courier

System output, such as an error message or script

5

URLs, complete paths, filenames, prompts, and syntax

1.3 Explanation of Safety Warnings

Danger indicates a hazard with a high level of risk which, if not avoided, will result in death or serious

injury

Warning indicates a hazard with a medium level of risk which, if not avoided, could result in death or

serious injury.

Caution indicates a hazard with a low level of risk which, if not avoided, could result in minor or

moderate injury.

Indicates information considered important, but not hazard-related.

1.4 Retaining Instructions

Read and understand this manual and its safety instructions before using this product. Failure to do so

can result in serious injury or death.

Follow all the instructions. This will avoid fire, explosions, electric shocks or other hazards that may result

in damage to property and/or severe or fatal injuries.

The product shall only be used by persons who have fully read and understand the contents of this user

manual and understand the safe operation of the machine.

Ensure that each person who uses the product has read these warnings and instructions and follows

them.

Keep all safety information and instructions for future reference and pass them on to subsequent users

of the product.

6

The manufacturer is not liable for cases of material damage or personal injury caused by incorrect

handling or non-compliance with the safety instructions. In such cases, the warranty will be voided.

1.4.1 Internet

The latest version of the documentation is available at the following address:

http://www.ecopowerequip.com

1.4.2 Ordering Documentation

Documentation, user instructions and technical information can be ordered by calling Eco Power

Equipment Ltd. at 1-888-483-4843

1.4.3 Other Languages

This is the English user manual. Manuals in other languages are available upon request. Not all

languages are covered.

1.4.4 Documentation Feedback

If you are reading Eco Power Equipment Ltd. product documentation on the internet, any comments can

be submitted on the support website. Comments can also be sent to support@ecopowerequip.com

We appreciate your comments.

1.4.5 Support and Service

For other questions, information, technical assistance, ordering user instructions, and service related

information please contact the manufacturer:

Eco Power Equipment Ltd.

Address: #8, 26004 TWP 544, Sturgeon County, AB, T8T 0B6

Phone: 1-888-483-4843

Web: www.ecopowerequip.com

7

2 Description of the product

2.1 Intended Use and Reasonably Foreseeable Misuse

The Eco Power Equipment CIPR Mobile Generator is a versatile power solution, featuring a gaseous

generator, control panel, and protective sheet metal enclosure mounted on either a trailer or skid for

easy transportation. It is designed to meet prime rated power demands and can operate continuously

24/7, providing reliable electrical power to connected loads.

As the engine operates, the generator transforms mechanical energy into electricity. Multiple receptacles

are available for connecting auxiliary loads. The user-friendly control panel allows the operator to

efficiently manage and monitor the generator, while the digital display presents essential operating

parameters.

Please consult the product specifications for detailed information on the unit's output voltage,

frequency, and maximum power output. This generator is specifically designed for the intended use

described; using it for other purposes may result in irreversible damage to the machine, severe injury to

the operator or others nearby, and will void the warranty.

The following are some examples of misuse:

Connecting a load that has voltage and frequency requirements that are incompatible with the machine

output

Overloading the machine with a device that draws excessive power during either continuous running or

start-up

Operating the machine in a manner that is inconsistent with all federal, provincial and local codes and

regulations

Operating the machine outside of factory specifications

Operating the machine in a manner inconsistent with all warnings found on the machine and in the

Operator’s Manual

8

This machine has been designed and constructed in compliance with the most recent Canadian safety

standards. It features protective guards and clear labeling to minimize hazards and enhance operator

safety. However, despite these precautions, residual risks may persist. Potential hazards associated with

this machine include:

●Heat, noise, exhaust, and carbon monoxide emissions from the engine

●Multiple heat sources, such as the engine and alternator end

●Fire hazards resulting from improper refueling techniques

●Risks of electric shock and arc flash

●Exposure to gaseous fuel and its fumes

To ensure your safety and the safety of others, carefully read and understand the safety information

provided in this manual before operating the machine.

Remember that gasoline, natural gas, and LPG are flammable and can be explosive if leaked and

confined. Keep cigarettes and other open flames away from these areas. If you detect a fuel leak, shut

off the fuel supply immediately and address the issue or have it serviced. Inspect the entire fuel supply

line from the cylinder/tank to the engine for leaks using a soapy water bubble mixture whenever a

cylinder/tank is changed or the fuel supply line is maintained. Regularly check for fuel leaks as part of

routine engine maintenance.

Depending on your engine and fuel system configuration, your machine is designed to run on natural gas

and/or vapor LPG. Refer to the "SPECIFICATIONS" section for information on required fuel supply

pressures for each fuel type.

Natural Gas

Your engine is certified to run on "pipeline-quality natural gas". EPA defines pipeline-quality natural gas

as being supplied by a pipeline and being composed of at least 70% methane by volume or having a

heating value of 950-1100 BTUs per cubic foot. If your natural gas supply does not meet these

specifications, your engine is considered to be being operated as a non-certified engine. See "U.S. EPA

Legal Requirements" at the front of this manual.

LPG

In order to maintain emissions compliance and the engine warranty, use commercial-grade HD-5 or

better LPG, the unit is designed to run on vapor, do not connect liquid source.

9

Enclosure / Skid Unit

Unit

Gross Weight

3806 KG / 8368 LBS

Lifting Bail

Yes, Engineered and Rated, See Decal

Enclosure

Powder Coated Carbon Steel

Control

AGC 150

Control Panel

Nema 3R

Generator End

Unit

Make / Model

Mecc Alte, ECO38-2L

Voltage

480V Three Phase, High Wye, Dedicated

Main Circuit Breaker

400 Amp

Efficiencies @ 60HZ

93.4% @ 480V, Full Load

AVR

DER1

Pole

4

Overspeed (RPM)

2250

Protection Class

IP23

Altitude Rating

0-1000m

Bearings

6314.2RS

Standby 163/27

330 kVa, 264 kW

Continuous 125/40 (50HZ)

300 kVa, 240 kW

Engine

Unit

Engine Make/Model

PSI 12.5L Rich Burn

Configuration

Inline, 6 Cylinder

Aspiration

Turbocharged / air cooled aftercooler

Fuel

Natural Gas / Vapour Propane

Radiator

Shroud, Pusher Fan, Guard

Governor

Electric

Temperature

50C Ambient Rating

10

Oil Capacity

30 Litres

Oil Type

API/CD/CF 15W-40 Low Ash

Gross NG Standby Power Rating

250 kW

Gross LP Standby Power Rating

150.9 kW

Gross NG Prime Power Rating

234.1 kW

Gross LP Prime Power Rating

150.9 kW

Power Rating 1,2,3 Per ISO 3046 at the Flywheel

2.2 Product Elements

11

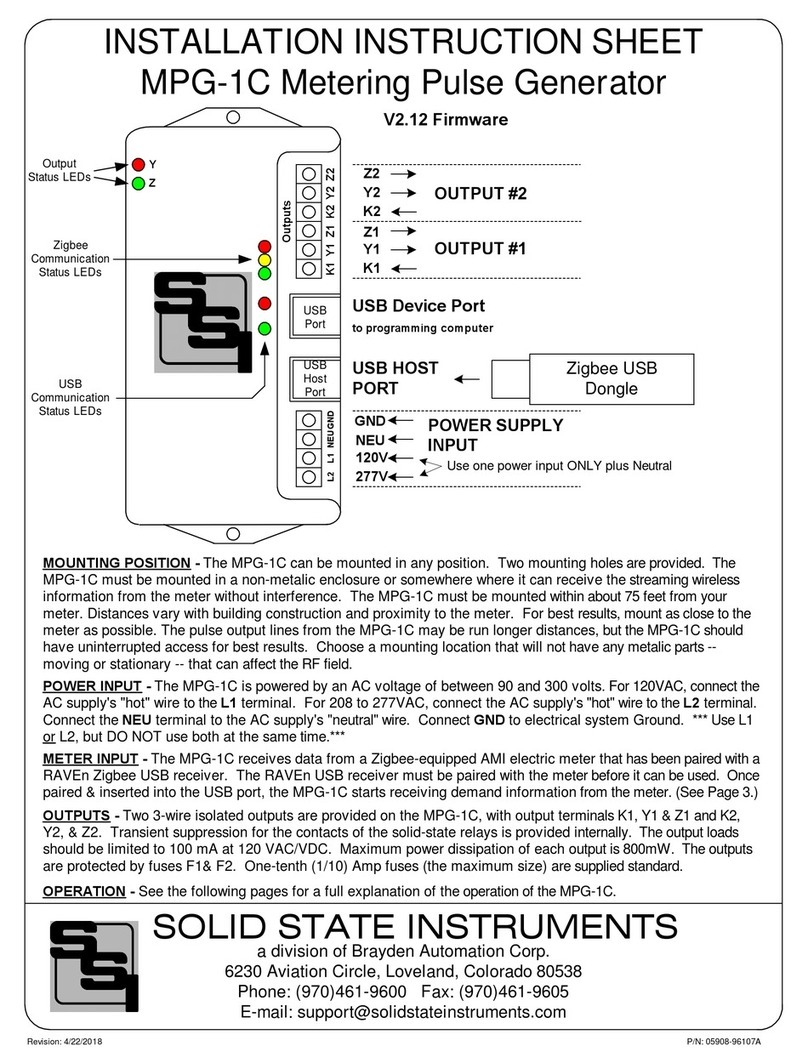

2.3 Understanding the User Interface and Control Panel

The main user interface is within the main control panel door. The control panel consists of a series of

toggle switches and a graphical user interface to provide control of all operating systems - and provide

the user with operating parameters.

12

13

14

15

16

2.4 Setup Process

The setup and deployment process involved for the CIPR generator involves locating the machine on a

level, suitable terrain, connecting earth ground and fuel source, and connecting electrical distribution.

Before using the unit, be sure to read and understand all of the instructions. This equipment was

designed for specific applications; DO NOT modify or use this equipment for any application other than

which it was designed for. Equipment operated improperly or by untrained personnel can be dangerous.

Before starting, visually inspect the unit for leaks or damage. A complete visual inspection of all engine,

generator, and power distribution connections.

Note: Be sure to fill out and complete the Eco Power Equipment new application form, and ensure to

check and verify all aspects of the equipment and application. It is the responsibility of the user to

ensure that the equipment is ready for operation.

2.4.1 Quick Setup Guide

1. Inspect the engine, intake, exhaust, and cooling system to confirm the engine is fully assembled

and not being serviced.

2. Ensure the engine can turn freely without obstruction.

3. Verify that all safety guards are correctly positioned and secure.

4. Check the coolant level in the radiator overflow bottle, ensuring it's between "Add" and "Full."

5. Confirm the oil level on the dipstick is between "Add" and "Full."

6. Ensure the fuel supply is connected, shut-off valves are open, and there are no leaks.

7. For LPG fuel systems, confirm there's fuel in the cylinder/tank; for natural gas systems, verify the

correct fuel supply pressure. It is imperative to check the inlet pressure and the engine pressure

at no load and full load to ensure the machine is operating properly

8. Read and understand all safety sections in this manual.

9. Confirm that all maintenance procedures are up-to-date per this manual and the engine and

generator manuals

10. Set up the unit on firm, level ground, and keep the surrounding area clean.

11. Ground the unit following local grounding requirements using the ground lug connection on the

distribution panel; the unit ground is marked with the IEC 60417, No 5019 ground symbol.

12. Inform on-site personnel of the pending startup.

13. Connect the fuel source according to local guidelines and safety requirements; check fuel

pressure during initial startup and new site commissioning, ensuring primary, secondary, or

vaporizer regulators are set for this equipment (10-14" WC inlet pressure, even under load).

14. Turn main breakers to the OFF or Green position.

17

15. Visually inspect the engine for leaks, and examine belts, electrical connections, and wiring

outside the generator enclosure.

16. Inspect all electrical connections; repair or replace any damaged or worn connections, including

external cords connected to the load. Follow local guidelines and best practices for safe electrical

practices.

17. Ensure battery connections are secure.

18. Check the engine fan belt tension and condition, referring to the engine manual for tension

requirements.

19. Inspect the engine fan belt guard.

20. Check the engine exhaust system for loose or rusted components.

21. Turn ON the DEIF control power switch.

22. Press the start button to initiate the cranking/run sequence.

23. Verify the voltage and frequency are correct before turning on the main circuit breaker; the

machine is designed to operate at 480V Three Phase, 60 Hertz.

24. Activate the generator breaker by pressing the generator breaker button.

2.4.2 Operation

1. Observe the control panel to monitor the generator's operating parameters, including voltage,

frequency, and load levels. Make adjustments as needed to maintain optimal performance.

2. Inspect the generator for any signs of overheating, unusual noises, or vibrations. Address any

issues immediately to prevent further complications.

3. Monitor the fuel and oil consumption rates regularly to ensure they remain within the

acceptable range. Refill or replace as necessary, following safety precautions and manufacturer

recommendations.

4. Periodically check the generator's safety guards, ensuring they remain securely in place and are

in good condition. Replace any damaged or worn guards as needed.

5. Regularly inspect the generator's electrical connections and wiring for wear or damage. Repair or

replace any compromised components to maintain safe and efficient operation.

6. Routinely perform preventive maintenance tasks, including checking and cleaning air filters,

replacing spark plugs, and changing the oil and filter according to the manufacturer's

recommendations.

7. Maintain a log of all maintenance activities, inspections, and adjustments to track the

generator's performance and help identify potential issues.

2.4.3 Shutdown and Storage

1. Turn off the connected loads and disconnect them from the generator by opening the main

circuit breaker

18

2. Press the stop button on the control panel to initiate the shutdown sequence, allow the engine

to cool down for 120 second cool down period

3. After the engine has stopped, turn off the DEIF control power switch.

4. If storing the generator for an extended period, perform proper storage procedures, such as

removing the battery. Consult the manufacturer's guidelines for specific storage instructions.

5. Store the generator in a cool, dry, and well-ventilated area, away from direct sunlight and

sources of moisture.

6. Periodically inspect the generator during storage to ensure it remains in good condition, ready

for future use.

7. Following these procedures will ensure the safe and efficient operation of your generator,

prolonging its lifespan and maintaining optimal performance. Always refer to the manufacturer's

guidelines for specific instructions and recommendations.

WARNING

It is crucial for the operator to ensure the generator is safely and appropriately positioned at the

designated location. The design and setup of applications involving mobile power systems should be

carried out exclusively by qualified personnel to ensure proper functionality and safety.

DANGER

Entering the electrical compartment while equipment is in operation can result in death or serious injury.

Read and understand this manual and its safety instructions before using this product. Failure to do so

can result in serious injury or death.

2.5 How to Use the Product Safely

2.5.1 Safety Information

To ensure the safe and efficient use of the product, adhere to the following safety guidelines:

●Treat the engine as rotating machinery and exercise caution at all times.

●High voltage is present in the system when powered on; never attempt to service the

electrical system while the engine or system is active. Only qualified technicians should set

up and maintain this equipment.

●Avoid operating the generator if there are visible signs of wear or damage.

●Ensure proper training for anyone operating the machine.

●Do not modify the equipment without written consent from Eco Power Equipment.

19

●Never transport or move the generator while it's running.

●Be aware of explosion hazards: flammable gaseous fuel and combustible gases can be

present in the generator.

●Do not attempt to charge a frozen 12V battery.

2.5.2 Technical Lifespan

●Gaseous Engine: 20,000+ hours

●Eco Power recommends implementing a regular inspection process to ensure the

generator's longevity and successful operation. This product is designed to run on

pipeline-quality natural gas or propane gas (HD5 or better).

2.5.3 Personal Protective Equipment

●Always wear personal protective equipment, including appropriate head protection,

clothing, gloves, steel-toed boots, eye and hearing protection as required by the task at hand

when operating the generator

2.5.4 Inspection Requirements

To ensure safe and efficient operation of a natural gas engine power generator, follow these inspection

points, with special attention to mobile operation and electrical connections during each new

deployment, we recommend creating a detailed inspection protocol on a daily basis from this point.

1. Fuel System Inspection:

●Check for gas leaks, proper connections, and valve positions.

●Verify that the gas supply pressure is within the specified range.

2. Engine Components:

●Inspect belts for wear and proper tension.

●Examine the air filter for cleanliness and replace if necessary.

●Check the engine oil level and quality, changing it according to the manufacturer's

recommendations.

●Inspect the cooling system, ensuring that the coolant level is between "Add" and "Full."

●Inspect engine for loose components or signs of wear

●Ensure that the service log shows detail of routine maintenance items, such as spark plugs, valve

set, oil changes, etc (see PSI engine manual for complete details)

3. Mobile Operation:

●Check the trailer or skid's structural integrity and security.

●Examine the wheels, tires, and suspension components for wear and proper torque.

20

Table of contents

Other EcoPower Portable Generator manuals