Introduction............................................................................................................................................................................3

....................................................................................................................................................................3

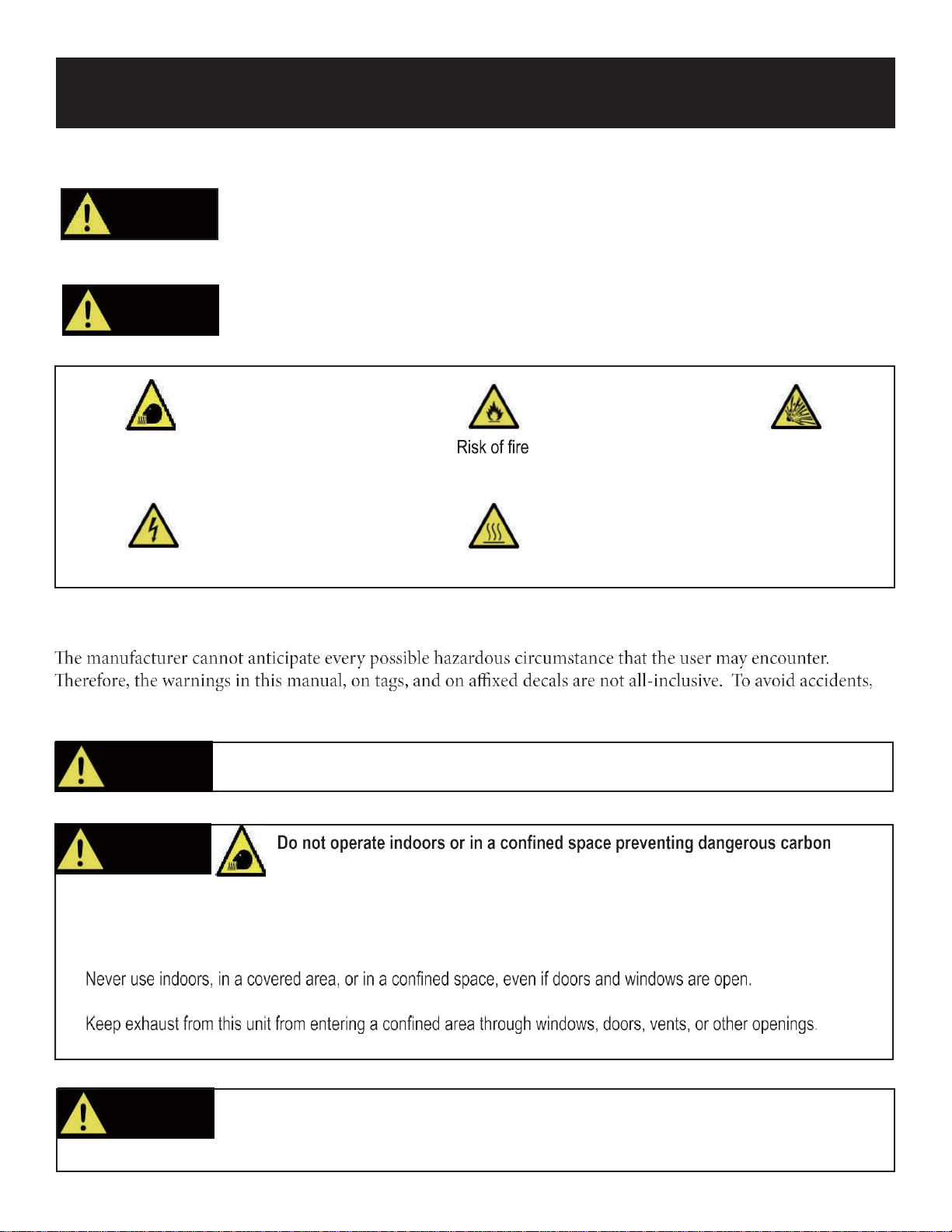

Safety Rules...........................................................................................................................................................................4

Safety Symbols...........................................................................................................................................................4

Safety Instructions......................................................................................................................................................4

Features..................................................................................................................................................................................7

Control Panel Functions .......................................................................................................................................................8

ON/OFF Start Switch and Choke...............................................................................................................................8

Indicator Lights............................................................................................................................................................8

Engine Economy Control............................................................................................................................................9

Parallel Outlets...........................................................................................................................................................9

Fuel Cap Air Vent............................................................................................................................................................10

Ground Terminal.....................................................................................................................................................................10

Assembly..............................................................................................................................................................................11

Connecting Generator to an Electrical System . ................................................................................................. 11

Adding Fuel..............................................................................................................................................................11

Adding /Checking Oil...............................................................................................................................................12

Operation..............................................................................................................................................................................12

Grounding the Generator..........................................................................................................................................13

How to Start Engine.................................................................................................................................................13

How to Stop Engine..................................................................................................................................................14

Attaching Electronic Devices....................................................................................................................................14

AC Parallel Operation...............................................................................................................................................15

Don’t Overload Generator........................................................................................................................................16

Wattage Reference Guide........................................................................................................................................16

Maintenance.........................................................................................................................................................................17

Maintenance Schedule..............................................................................................................................................18

Checking Spark Plug.................................................................................................................................................18

Changing Oil .............................................................................................................................................................19

How to Clean Air Filter..............................................................................................................................................20

How to Clean Fuel Filter...........................................................................................................................................21

Transport /Storage...............................................................................................................................................................................21

Troubleshooting…………………………………………………………………………………………………………………………23

TABLE OF CONTENTS

.................................................................................................................................................................12