Fnirsi SG-004A User manual

Multi-functional Signal Generator

SG-004A

7.1 Fault Resolution 12

7.2 Equipment Maintenance 12

7.3 Firmware Upgrade 12

7、Fault Resolution & Equipment Maintenance

4.1 Switching Of Signal Types 05

4.3 V Voltage Signal 05

4.5 Hz Pulse Signal 06

07

4.7 24V Loop Detection

4.2 mA Current Signal 05

4.4 XMT Passive Current Signal 06

4.6 mV Millivolt Signal 07

08

4.8 Ohm Resistance Signal

4、Display & Signal Description

2.1 Specifications 01

2.3 Interface Terminal 02

2.2 Function Introduction 02

2.4 Power & Charge 03

2、Product Description

5.1 Engineering 08

5.3 Signal Conversion 08

5.5 Real-time Curve 10

10

5.7 Output Time

5.2 Preset Value 08

5.4 Program Output 09

5.6 History Record 10

10

5.8 Communication

5、Extensions

03

3、Button Panel Introduction

11

6、Wiring Instructions

01

1、Safety Instructions

13

8、Production information

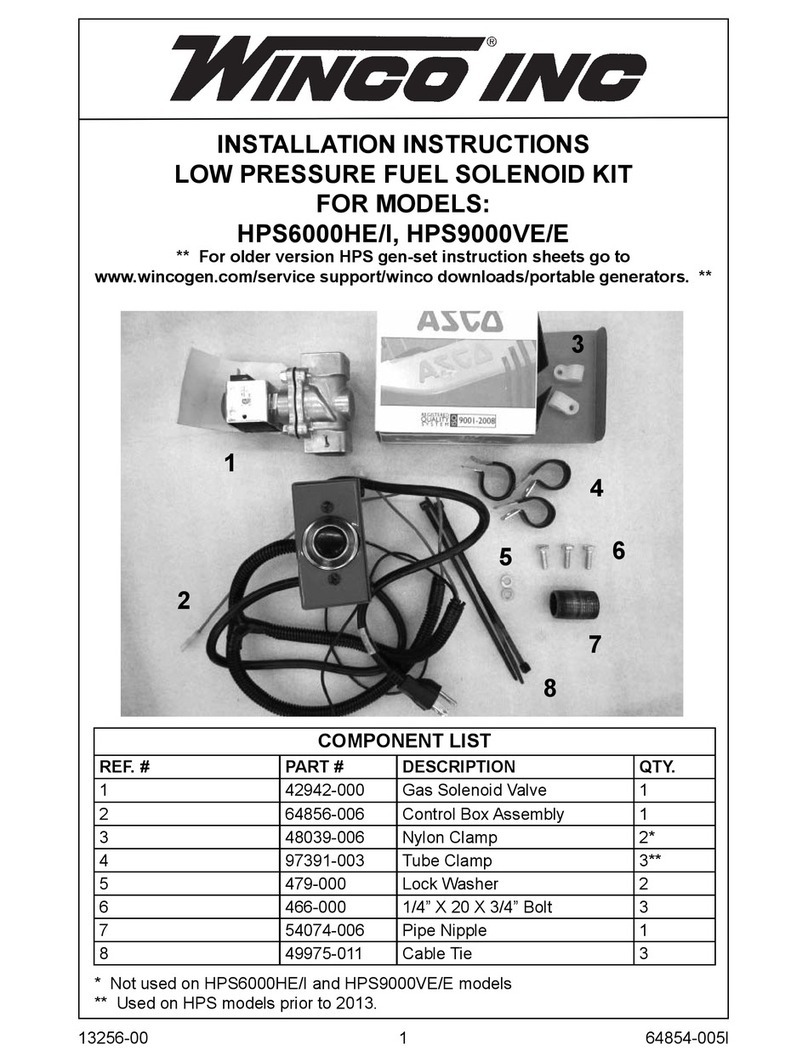

【 2.1 】 Specifications

Current(mA)

Voltage(V)

Passive(XMT)

24V loop

FRQ(Hz)

mV

TC(TC-S)

TC(TC-B)

TC(TC-E)

TC(TC-K)

TC(TC-R)

TC(TC-J)

TC(TC-T)

TC(TC-N)

TC(WRe3/25)

TC(WRe5/26)

RES(ohm)

Pt100

Cu50

0~24mA

0~24V

0~24mA

0~24mA

0~9999Hz

-10~100mV

0~1760℃

0~1810℃

0~990℃

0~1320℃

0~1760℃

0~1190℃

0~390℃

0~1290℃

0~2320℃

0~2320℃

0~390Ω

-200~650℃

-20~150℃

±(0.02%+0.003)

±(0.02%+0.003)

±(0.02%+0.003)

±(0.1%+0.005)

±2%

±(0.03%+0.03)

±(0.2%+1)

±(0.5%+1)

±(0.2%+1)

±(0.2%+1)

±(0.3%+1)

±(0.3%+1)

±(0.2%+1)

±(0.2%+1)

±(0.2%+1)

±(0.2%+1)

±(0.2%+1)

±(0.5%+1)

±(0.5%+1)

0.001mA

0.001V

0.001mA

0.01mA

5 digits

0.01mV

1℃

1℃

1℃

1℃

1℃

1℃

1℃

1℃

1℃

1℃

0.1Ω

0.1℃

0.1℃

100Ω

500K

100Ω

100Ω

1MK

2K

2K

2K

2K

2K

2K

2K

2K

2K

2K

2K

/

/

/

Signal Range Precision Resolution Impedance

PAGE

Plug the meter into the PC,and turn it on.Wait for the PC to recognize the USB drive

named "Bootloader"

Dont use the instrument in a flammable and explosive environment

Used batteries for instrument replacement and discarded instruments cannot be

disposed of with household waste.Please handle in accordance with relevant

national or local laws and regulations

When there is any quality problem with the instrument or when there is a question

about using the instrument.You can contact "Finiris" online customer service or the

manufacturer, we will solve it for you in the first time

【 2.2 】 Function Introduction

【 Conversion Of Engineering Quantity Display 】:Signals are displayed as physical

or engineering (ie pure quantity) values,The physical quantity corresponds linearly

with the engineering quantity.For example: the current signal of 4~20mA

corresponds to 0~100, that is, 4mA corresponds to 0, 12mA corresponds to 50, and

20mA corresponds to 100. This range can be modified by parameters

【 Preset Value 】: 4 groups of commonly used signal values can be preset to

facilitate quick adjustment of output

【 Signal Conversion 】: The input signal is converted into an output signal, which

can be converted between different physical quantities; for example: the input

frequency signal is converted into a current signal, and the input range is 0-1000hz

into 4-20mA

【 Programming Output 】: It has the output function of automatically and

continuously changing the size according to the setting parameters, and can

choose three modes: monotonous rise, monotonous fall and cycle

【 Real-time Curve 】: The change trend of input and output signals can be

displayed by drawing a curve, and the sampling time of the curve can be set.It can

also automatically adjust the display curve within the range of the maximum and

minimum values within a certain period of time

【 Modbus Slave 】: FNIRSI SG-004A can communicate with configuration software

or PLC via RS485, set the instrument

【 History Record 】: Record and view a certain amount of historical data

【 Firmware Upgrade 】: USB emulated U disk for firmware upgrade

【 2.3 】 Interface Terminal

Output-

Output+

Input+

Input-/(24V)

【 Interface 】

There are 4 inner diameter 4mm wiring ports on the top surface, which are

represented by different color rings

The blue port (IN-) is an alternate function, and it is also an input-, which can be

switched to a 24V independent test power supply.The (IN-) port is internally

shorted with the black (COM) port in the input state.When the (IN-) port is an

independent power supply, there is a 24V voltage between the (COM) port

Red (OUT) port and black (COM) port form an output port

Yellow (IN+) and blue (IN-) form the input port

PAGE

When the (IN-) port is an independent power supply, it can be called a (24V) port,

and it forms an output port pair with the (COM) port

The safety limit voltage of the input terminal cannot be greater

than 30Vpp, and the over limit will damage the equipment

NOTE!!!

All buttons are made of white translucent silicone material. The color LED backlight

is set under the Button, which can make the key surface change color with the

change of function and mode.Give more intuitive status indication

The keys are mainly divided into 【 3-Key area 】 and 【 5-Key area 】, and each key

has multiple functions.Among them, the 【 FN 】 Button and the 【 5-Key area 】 key

have the up/down function and the function marked on the key, which will be

changed according to the state of the 【 FN 】 key and the interface mode.Start-up

defaults to the upshift function

【 FN 】 key state is divided into: default white light state and red light state

【 5-Key area 】 The status is divided into:Button white light (Manual setting

mode);Button green light (Preset output mode);Button blue light (Programming

mode);No button light (Conversion mode)

Button Function Operation Description:

【 RUN 】 Light: The power on/on output is white light

【 IN 】Input key: Used to switch the input signal mode in the main

interface;When 【 FN 】 red light is on, click 【 IN 】 to enter the input setting

【 OUT 】 Output key: used to switch the output signal mode on the main

interface.When the 【 FN 】 red light is on, click 【 FN 】 to enter the output setting

【 FN 】Exit Return key:In the main interface, click 【 FN 】 , it will turn into a red

light to activate the downshift function of other keys (enter different modes,

etc.).In the setting interface, the function of 【 FN 】 is to return

【Main Interface】: Main display interface

1

2

3

5

4

PAGE

Built-in battery: 3000mA large capacity lithium battery

Battery display: Display the current battery

percentage in the upper right corner of the display

Charging interface: Type-C port (DC 5V-12V)

State of charge: (Up to 10W)When charging, the

power button will display a red light.When fully

charged, it will automatically stop charging and

display a blue light

【 2.4 】 Power & Charge

【 Bottom Display 】

Power Type-C port

6【 RCVK 】 Up function key: When the key is white, it is to add value or select upward

(when the output pulse is quantitative and the cursor is not in, it is the same as the

programming mode).In the history curve interface, it is a quick right shift of 100.

When the 【 FN 】 red light is on (the button is green), click 【 RCVK 】 to enter/exit

the preset output mode. At this time, the up, down, left and right buttons can

quickly recall the preset signal value

【 AUTO 】 Left function key: when the key is white, it is to select to the left (when

the output pulse is quantitative and the cursor is not present, it is the same as

the programming mode).

In the history curve interface, the cursor is moved to the left point by point.

When the 【 FN 】 red light, click 【 AUTO 】 to enter/exit the programming mode

(the button blue light), at this time, the up key-single output, the down

key-reset, the left key-end the output, the right key-pause/ continue

【 ON/OFF 】 confirmation button: when the main interface (turn on/off the

output); When the 【 FN 】 is red light (click to turn on/off the recording); when

setting the interface(Click for "OK")

【 CURVE 】 Right function key: When the key is white light (select to the right ~

when the output pulse is quantitative and the cursor is not in, it is the same as

the programming mode).In the history curve interface, the cursor is moved to

the right point by point.When 【 FN 】 is red light (click to switch curve

interface/character interface)

【 CONVRET 】 Down function key: When the key is white, it is to decrement the value

or select down (when the output pulse is quantitative and the cursor is not in, it is the

same as the programming mode; in the history curve interface, it is to move left

quickly by 100; When 【 FN 】 is red light (click to enter/exit the conversion mode)

7

8

9

10

【 Panel Display 】

1

2

7

10

6

9

8

5

3

【 3-key area 】

【 3-key area 】

4

PAGE

【 4.1 】 Switching Of Signal Types

Press 【 FN 】 on the main interface.After the 【 FN 】 button turns red, if you want to

switch the input signal type, press the 【 IN 】 button to enter the input setting

If you want to switch the output signal type, press 【 OUT 】 key to enter the output

setting.After entering the setting interface, you can directly select the desired signal

type from left to right.Press 【 FN 】 to exit to the main interface

There are also a variety of signal modes available for switching under various signal

types.Various signal types also have different parameters that can be set

【 4.2 】 mA Current Signal

【 Mode Switch 】: When the main interface 【 FN 】 is white, press 【 IN/OUT 】 to

switch the display of input/output actual value and engineering quantity

【 Output Open Circuit Detection 】: When the output is turned on, if the interface

displays open circuit and flashes, it means that the output signal is not connected

or the output is close to zero

【 Output Circuit Voltage 】:FNIRSI SG-004A can set current output no-load

voltage.The purpose of 12V is to save power.Some devices require a 24V drive

capability

【 Output Range 】:The limit range of the current output can be set

【 4.3 】 V Voltage Signal

【 Mode Switch 】: When the main interface 【 FN 】 is white.Press 【 IN/OUT 】 to switch

the display of actual value and engineering quantity of input/output

【 Overcurrent Protection 】: If the output voltage is shorted, the output will

automatically shut down

【 Output Range 】:The limit range of the voltage output can be set

PAGE

【 Input Signal Settings 】 【 Output Signal Settings 】

【 4.4 】 XMT Passive Current Signal

【 Mode Switch 】:When the main interface 【 FN 】 is white.Press 【 IN/OUT 】 to switch

the display of actual value and engineering quantity of input/output

【 Output Range 】: The limit range of passive current output can be set

【 4.5 】 Hz Pulse Signal

【 Mode 】: The pulse signal has four modes: frequency, PWM duty cycle, speed frequency,

pulse quantitative/counting. For input, when the main interface 【 FN 】 is white,

press 【 IN 】 to switch the mode directly. For output, long press 【 OUT 】 to switch mode

【 Range 】: Select the range of frequency output: 0~99.999Hz, 0~999.99Hz,

0~9999Hz, 0~200kHz

【 Method 】: Select level/open circuit according to the presence or absence of pull-up

【 Output Peak Value】: The level height of the output waveform, the highest is 24V

【 Input Counting Method 】: The rising edge means that the level rises from 0V to

the peak value of the pulse, and the counter is incremented by 1. A falling edge

indicates that the input level falls to the OV counter and increments by 1.Jump

means that as long as the input level jumps up and down, the counter is

incremented by 1. Long press 【 IN 】 to clear the count

【 Frequency Mode Operation Instructions 】: The input frequency range is

0~9999Hz, which cannot be selected, and the displayed decimal point is

automatically shifted.The output frequency range can be switched by

pressing 【 OUT 】 when the main interface 【 FN 】 is white

【 Operating Instructions In PWM Mode 】: PWM displays two parameters, the

frequency value (that is, the period value) and the duty cycle.The frequency value

will be displayed in the original engineering quantity position (no engineering

quantity display).Note that the maximum frequency does not exceed 9999Hz.The

frequency value/duty cycle parameters can be set when outputting.When the main

interface 【 FN 】 is white, press 【 OUT 】 to switch, there is a yellow cursor indication

【 Operating Instructions For Speed Mode 】:

(1) The speed mode is used to calculate the speed of the motor or gear. One

revolution of the motor or gear produces 1 pulse, one minute is 3000 revolutions, so 1

second is 50 pulses

(2)【 Time Unit 】: Frequency=RPS(per second)*number of pulses per revolution,

RPM(per minute)=RPS*60, RPH(per hour)=RPS*3600.In the speed setting selection,

note that the maximum frequency does not exceed 9999Hz

(3)【 Number Of Revolution Pulses 】: The number of pulses per revolution of the

motor or gear, which can be selected in the speed setting

(4)【 Tooth Missing 】: It is mainly used to simulate the engine speed, select it in the

speed setting

【 Quantitative/Counting Mode Operation Instructions 】: The main purpose of

pulse quantitative is to simulate the quantitative control sensor of flow, and the pulse

count is to simulate the flow of count.For inputs, the input frequency value will be

PAGE

【 4.6 】 mV Millivolt Signal

【 Mode 】: The millivolt signal is divided into three modes: 110mV, thermocouple, WR

thermocouple, in the main interface.When 【 FN 】 is white, press 【 IN/OUT 】 to switch

【 Type 】: Select the type of thermocouple TC-S, B, E, K, R, J, T, N

【 WR Type 】: Select the type of WR thermocouple WRE25, WRE26

【 Temperature Unit 】: Set to Celsius or Fahrenheit

【 Cold Junction Setting 】: Select the temperature detected by the meter or the

user-defined temperature

【 Cold End Temperature 】: Customized cold end temperature value

【 4.7 】 24V Loop Detection

Select the 24V label left and right in the OUT signal type interface to enter this

function state.In this state, displays the output 24V loop current on the main

interface.Unlimited input signal detection type

(1)Loop 1: After starting the output, 24V voltage is output between the (OUT) port

and (COM) port, and the loop current is detected at the same time, and the current

is displayed in the "output 24V loop" area.This function can be used to test, for

example, pneumatic control valves or two-wire transmitters, supply them with 24V

power supply and detect current

(2)Loop 2: After activating the independent 24V power supply.The (IN-) port

outputs 24V voltage between the (24V) port and the (COM) port.It does not affect

the detection type of the input signal by the (IN+) port.In this case, select mA for the

input signal type.Then the (IN-) port can be combined with the (IN+) port to form a

24V output,And at the same time detect the current loop.The function is similar to

the circuit one

(3)Port (IN-) can be switched to independent 24V power supply function.It outputs

a single DC24V voltage, which is the (24V) port at this time.(24V) port used with

(IN+) to test two-wire transmitters

PAGE

Notice!

①The difference between 24V loop detection and standalone 24V is:24V

loop detection output signal port to measure feedback current.

②Independent 24V port and output port can form 24V power supply,It

can also be combined with the input (+) to form a transmitter to supply

power and measure the feedback current of the transmitter

displayed in the original quantity position.For output, the cycle is displayed at the

original engineering position, and the unit is milliseconds.When the main interface

【 FN 】 is white, press 【 OUT 】 to switch between cycle and quantitative values, which

are distinguished by cursors.

The period value can be modified during quantitative output.In this mode, when the

cursor disappears after the output is turned on, the backlight of the up, down, left,

and right keys will turn blue.The function of the up, down, left, and right buttons will

also change, that is, the up is a single pulse sent.Down is program stop and reset, left

is no function, right is start/pause

【 Mode switch 】:When the main interface 【 FN 】 is white.Press 【 OUT 】 to switch

the display position of output actual loop current value and engineering quantity

【 Activate independent 24V 】: After this item is checked, the independent 24V

power supply starts to output from the (24V) port (IN-) port and the (COM) port, and

is not affected by input and output signal type switching

【 Activate Hold 】: After this item is checked, each time the machine is turned on,

the 24V state will remain in the state of the last turn-on.Otherwise, every time you

turn on the 24V, you need to turn it on manually

【 4.8 】 Ohm Resistance Signal

【 Temperature Unit 】: Set to Celsius or Fahrenheit

The resistance signal is divided into three types: Pt100, Cu50, and RES.When the

main interface 【 FN 】 is white, press 【 IN/OUT 】 to switch

【 Resistance Offset 】: Used to correct the resistance value of input/output

【 5.1 】 Engineering

When the signal value of analog quantity is used in the industrial field, it is

generally necessary to convert it into engineering quantity value.Therefore, in the

input and output settings of each signal, the instrument can set the upper and

lower limits of its engineering quantity and the upper and lower limits correspond-

ing to the signal value

【 5.2 】 Preset Value

【 Parameter Setting 】: You can set the signal value corresponding to the up, down,

left and right buttons

【 Operation Instructions 】: Start and Exit: When the main interface 【 FN 】 is red,

press the up key 【 RCVK 】 to Start/Exit the preset

【 Up, Down, Left And Right Keys 】: After starting the preset, the backlight of the

up, down, left and right keys will turn green, and the key function will also change

to "output the set value"

【 5.3 】 Signal Conversion

The input signal is converted into an output signal.For example: the input

frequency signal is converted into a current signal, and the input range is 0-1000hz

and converted into 4-20mA

PAGE

【 Parameter Settings 】:

(1) Input upper limit/input lower limit: the amplitude range of the input signal

(2) Output upper limit/output lower limit: the amplitude range of the output signal

(3) Overrun allowed: For example, 1-5V is converted into 4-20ma.If the user checks

this option, when the input is oV, the output will follow to OmA.If the user does not

check it, then the output is 4mA and the output is locked within the set range

(4) Automatic operation:After checking this option, the signal conversion will be

automatically started at the next power-on, and the signal conversion will be

automatically canceled when the signal conversion is exited

【 Instructions 】:

【 Start and Exit 】:When the main interface 【 FN 】 is red, press the key 【 CONVRET 】

to start/exit the signal conversion mode.After startup, the backlight of the up,

down, left and right keys will turn off and have no function

【 5.4 】 Program Output

The programming output can automatically complete N cycles of signal output

according to the parameters set by the user.This function is mainly used for the aging

test of electric valve or pneumatic valve,Or test work such as PLC program debugging

【 Parameter Settings 】:

(1)Mode: It is divided into three modes: single rise, single fall and cycle

(2)Number of loops: 0 is infinite, 30000 is the maximum

(3)Start value: The value at each start

(4)End value: The value at the end of each

(5)Increment step value: The value of each increment

(6)Increment step time: The time between each increment

(7)End stop: The time delay at the end value

(8)Decrement step value: The value to decrease each time

(9)Decrease step time: The time between each decrease

(10)Loop stop: Time delay at start value

【Supplementary Parameter Description】:

The start value and end value of single rise and single fall are selected according to

high and low,and does not automatically close

【 Instructions 】:

(1)Start and Exit:When the main interface 【 FN 】 is red, press the left key 【 AUTO 】

to start/exit the programming output mode

(2)Up, Down, Left and Right keys: After starting the programming output mode, the

backlight of the up, down, left and right keys will turn blue.The functions of the up,

down, left and right buttons will also change, that is, the top is a single run, the bottom

is a program reset, the left is a single-step run, and the right is a Stop/Continue

PAGE

【 5.5 】 Real-time Curve

【 Instructions 】:

When the main interface 【 FN 】 is red, press the right button 【 CURVE 】 to switch the

interface with/without curve

【 Parameter Description 】:

(1) Turn on the output curve: turn on the following display curve of the output

signal (Red line)

(2) Automatic output scaling: automatically adjust the scale range of the output

signal, and automatically adjust the scale range of the y-axis with the maximum

and minimum values of the curve

(3) Input automatic scaling: automatically adjust the scale range of the input signal,

and automatically adjust the scale range of the y-axis according to the maximum

and minimum values of the curve.

(4) Acquisition time: the refresh interval of the curve, and the time scale will also

change with it

PAGE

【 5.6 】 History Record

【 Enable/Close Recording 】: When the main interface【 FN 】 is red, press 【 ON/OFF 】

to enable/disable recording.When turned on, the top of the screen will flash to

display the record number

【 View Record 】: Select the record you want to view in the setting interface history

record,【 ON/OFF 】 confirm to enter the view.When entering the viewing record, the

backlight of the up, down, left, and right keys will turn yellow, and the functions of

the up, down, left, and right keys will also change; that is, up and down is to view

the 100 record values before and after the forward, and left and right is to view the

1 record value of the forward and backward

【 Delete Record 】: When viewing the record, press 【 ON/OFF 】 to choose whether to

delete this record

【 5.7 】 Output Time

【 Output Activation Output Time 】: When checked, each output will automatically

turn off the output after the output time expires

【 Output Time 】: Set output time

【 5.8 】 Communication

【 USB connection 】:Because the USB analog serial port is used for communica-

tion.Note that charging will slow down after checking the USB connection

【 Slave address 】: MODBUS slave address.(Please refer to the attached table 1, 2, 3

on page 14 for the address and description of the instrument register)

PAGE

Pneumatic

valves

Valve position

given

Valve position

feedback

Switch this input (-), the port to 24V,

as the power supply for the valve

feedback, the input and output are

carried out at the same time

Pneumatic

valves

Valve position

given

Valve position

feedback

This input (-), the port is closed to 24V,

as the negative pole of the input

signal, the input and output are

performed at the same time

PLC/Process

instrument, etc.

【 All switched by electronic switches 】

【 All-round Signal Output 】:

Current/Voltage/Millivolt/Frequency

/Resistance/Thermal Resistance/

Various Thermocouple Signals

PLC/Process

instrument, etc.

【 All switched by electronic switches 】

【 All-round Signal Output 】:

Current/Voltage/Millivolt/Frequency

/Resistance/Thermal Resistance/

Various Thermocouple Signals

PAGE

【 7.3 】 Firmware Upgrade

SG-004A uses USB emulated U disk for firmware upgrade.

【 Upgrade Steps 】:

(1)Plug the meter into the PC,and turn it on.Wait for the PC to recognize the USB

drive named "Bootloader"

(2)Copy the firmware to be upgraded to the U disk

(3)After a few seconds, the device is powered on normally and the upgrade is

successful

【 7.1 】 Fault Resolution

No response when SG-004A is turned on:

(1)Determine if the battery has power and if the indicator light is normal when charging

(2)Firmware upgrade error operation leads to system crash

Abnormal screen display:Check if the screen is connected properly.

Abnormal output value or measured value:

(1)Check the signal line

(2)Check the interface for signal selection

(3)The target parameter of the connection exceeds the range indicated by the

technical indicator?(It may cause the instrument to work abnormally or even

damage)

Error in input and output:It is normal that there may be errors in input and

output.Because the input and output are not isolated

【 7.2 】 Equipment Maintenance

The meter is powered by 3.7V rechargeable lithium battery, please use the power

adapter to extend battery life when using it for a long time

This instrument is not waterproof, please do not use it in a high humidity

environment

Do not place the unit in a place that is unstable or may be subject to strong

vibrations

Do not place this unit in places with high humidity, dust, direct sunlight, outdoors,

or near high temperatures

Notice:

①If the U disk cannot be recognized normally when connected to the

PC in the power-on state.At this point, please shut down and restart!

②USB firmware upgrade only supports WIN10.It is forbidden to drag

and drop files other than those officially released by FNIRSI.Other-

wise, it is very likely to cause irreversible consequences

PAGE

Product name: Multi-functional Signal Generator

Brand / Model: FNIRSI / SG-004A

Manufacturer: Shenzhen FNIRSI Technology Co., Ltd.

Website: www.fnirsi.cn

Address: Building C, Weihuada Industrial Park, Dalang Street, Longhua District,

Shenzhen, Guangdong, China

PAGE

40001

40002

40003

40004

40006

40008

40009

40010

40011

40012

40013

40014

uint16_t

uint16_t

uint16_t

float

float

uint16_t

uint16_t

uint16_t

uint16_t

uint16_t

uint16_t

uint16_t

read

RW

RW

read

RW

RW

RW

RW

RW

RW

RW

RW

Firmware version

Input signal

Output signal

Input value

Output value

Software output mode and output switch

Active current output value USER upper limit

Active current output value USER lower limit

Voltage output value USER upper limit

Voltage output value USER lower limit

Passive current output value USER upper limit

Passive current output value USER lower limit

Address Type of data

0X9C41

0X9C42

0X9C43

0X9C44

0X9C46

0X9c48

0X9C49

0X9C4A

0X9C4B

0X9C4C

0X9C4D

0X9C4E

Hexadecimal Attributes Illustrate

【 Schedule 2 】

Register upper 8 bits

Register lower 8 bits

01 is current; 02 is voltage; 03 is frequency; 04 is millivolt; 05 is resistance

The upper four bits are the type: 1-8 represent S, B, E, K, R, J, T, N in turn

Lower four-bit mode: 1 is mV, 2 is thermocouple, 3 is WR thermocouple

Enter

【 Schedule 3 】

100

101

102

103

0x64

0x65

0x66

0x67

read

write

read

write

Function code Hexadecimal

uint16_t

uint16_t

float

float

Type of data Attributes

【 Schedule 1 】

【Example 】

slave

address

function

code

register

address

register address

low byte

Register number

high byte

CRC high

byte

CRC low

byte

01 65 9C 42 04

Register number

low byte

62 40 AF

Write input millivolt signal, J thermocouple type

Illustrate:

01: Slave address set by the device; 65: Write function code, see Table 1; 9C42: Read and write

input signal address, see Table 2; 04: 01 is current, 02 is voltage, 03 is frequency, and 04 is

millivolt , 05 is the resistor; 62: the upper four bits are the type: 1 is S, 2 is B, 3 is E, 4 is K, 5 is R, 6

is J, 7 is T, 8 is N, the lower four bits mode: 1 is millivolt, 2 is thermocouple, 3 is WR

thermocouple; 40AF: CRC code (note! Send in hex)

Download Manuals

and Firmware

Manufacturer: Shenzhen FNIRSI Technology Co., Ltd.

Website: www.fnirsi.cn

Address: Building C, Weihuada Industrial Park, Dalang Street,

Longhua District,Shenzhen, Guangdong, China

Table of contents

Popular Portable Generator manuals by other brands

Clarke

Clarke FG2500 Operation & maintenance instructions

Lucid

Lucid SSG192 user guide

ITW

ITW SIMCO-ION D165 Installation and operating instructions

iPower

iPower 1492007 REV00 owner's manual

Winco

Winco HPS9000VE/E installation instructions

Generac Power Systems

Generac Power Systems EcoGen G0070340 Installation guidelines

Sportsman

Sportsman GEN4KDF instruction manual

Aremeca

Aremeca CO-800B operating instructions

Briggs & Stratton

Briggs & Stratton Kincrome KP10105 Operator's manual

Scheppach

Scheppach IGT2500 Translation of original instruction manual

Winco

Winco PSS60F4 1 Series Installation and operator's manual

Toyama

Toyama TDG7000EXP owner's manual