EcoSpeed Electric Mid-Drive Guide

2

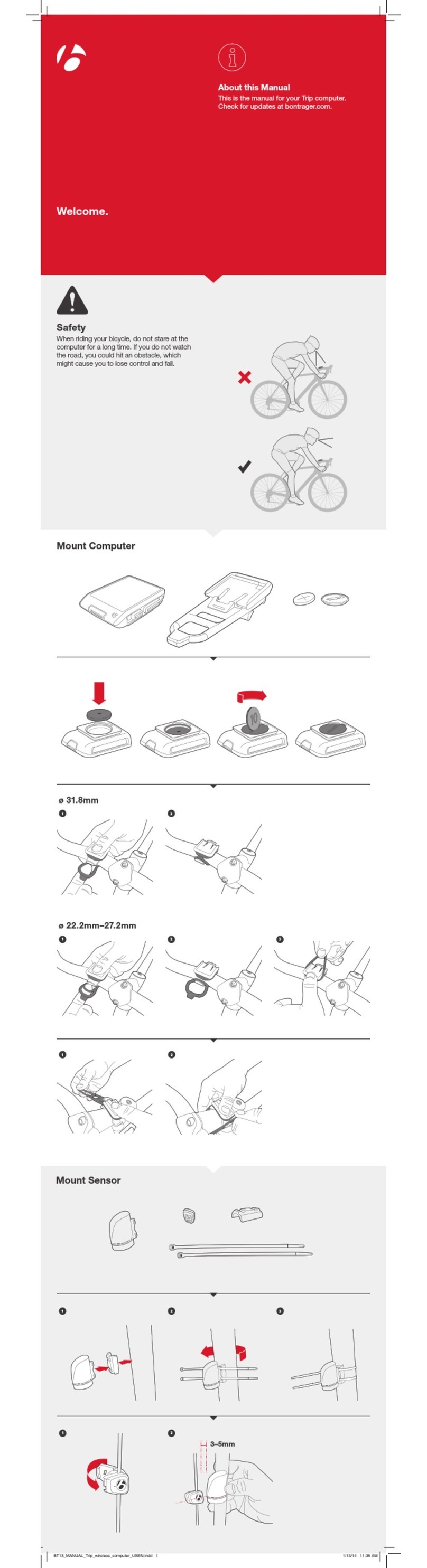

ElectricMid-DriveComponents

(600W.750Wisslightly different.)

3

Congratulations onyourpurchaseofEcoSpeed’s ElectricMid-DrivefortheEasyRacers TourEasyand

Gold Rushrecumbentbicycles.TheElectricMid-Driveis theworld’sbestmulti-speed,throttleoperated,

electric-assistconversionandtheonlyelectric-assistdesigned specificallytofita varietyofrecumbent

bicycles.

Theseinstructions will guideyoustepbystepthroughwhatwehopewill bea simpleand painless instal-

lationof yourEMD.Themechanicalskills involved are modestand,wegiveyouhints andtips atevery

stepthatreflectwhata professionalmechanicknows.Ifatanytimeyouhaveproblems,call us at1-866-

EcoSpeed (866-326-7733)forfriendlytechnicalassistanceore-mailus at support@ecospeed.net.

A word onhowtheseinstructions areorganized.Eachstepis under a majorheading–Step1:,Step2:,

etc.Ifyou’veinstalled anEMDbefore youcanjustread themajorheadings and ignore theexplanatory

text.Beloweachmajorheadingis a listof sub-steps.Theimportantinformationineachsub-stepis in

boldtext.Ifyou’re a competentbikemechanic,youcanjustreadthebold textand safelyignore therest.

Theremainingtextis there toclarifythings fornon-mechanics. We’vealsoincluded tips andhints in

Italics.

Beforegettingstartedcheckthatall thepiecesneededwereincludedinyourshipment:

Checkthepackinglistincludedwithyourshipment.

Youwill also needthefollowingtools:

1)Bicyclechainbreaker. Availablefromanybikeshop.

2)2.5mm,3mm,4mm and5mmhex(orAllen)wrenches. (Thestandard “L”shapedhex

wrenches sold atbikeshops andhardwarestoreswill probablywork but,theirshorthandlesmake

looseningand tighteningdifficult,especiallyinthelargersizes.A betteralternativeis a¼”ratchet

drivewrenchand hexsockets.Yourlocal hardwarestoremayhavethemortry www.snapon.com for

topquality.)

3)10mm boxoropenendwrench.

4)8mmnutdriver.

5)Wireclippersorscissors.

6)TorqueWrench(optional).

Onceyouhaveall theparts and toolsyouneed,it’stimetoclear a nicespacetowork,find severalof

hours time, and gettoit.

Step 0:Makesurethatyourbikeisingoodcondition.

Ifyouhaven’thad yourbiketunedupbyyourlocalbikeshopina while, nowwouldbea good time. In-

stallingtheEMDwill placeextra stress onyourbikesoit’s importantthatitbeintopcondition.

Step 1:Findawayto secureyourbikewhile working.

Theidealhereistomountyourbikeonaworkstandsuchasbikeshopsuse.Ifyouhaveac-

cess toonegreat,otherwisethere are other possibilities.

Ifyouhavea workarea where it’s OK toputhooks intheceiling, youcanhangthebikefromtheceiling

usingropes orstraps.

4

Putintwohooks about3 feet(1meter)

apartandhangtheseatcrossbracefrom

these. Putina thirdhookatthefrontof the

bikeandhangthefrontof thebikefrom

thishook.

Makesure thebikehangs levelwith all

wheels off theground.

Ifyoucan’tuseceilinghooks,youcanlean

thebikeagainsta wall with thefrontbrake

lockedtopreventrolling. Wrapseveral

tightrubber bands around thefrontbrake

lever untilthefrontwheelcannolonger

roll.

Step 2:Removeidlerandchain.

Removethemidmountedchain

idlerandall associatedpieces.

Usingyourchainbreaker tool,splitthe

chain,remove, and setaside.

Step 3):Install themotor plate

1)Insertthemotorplateintothe

frame. Itfits infromtheright sideof

thebike. Angletheplatesothatthe

chaintensioner springstopclears the

lower rightframetubeand slipthe

platebetweenthetwolower frame

tubes.Itshould beoriented sothatthe

chaintensioner armis towards the

frontofthebike.

MostGold Rushframeshavea cross tab

welded betweenthelower twintubes in

thevicinityof thechainidler mount.This

mayinterfere withinsertingthemotor

plateintotheframe. Ifso,youcansafely

cutoutthecross tabwitha hacksawor

other tool.Addingthemotorplateand

clamps will strengthentheframemuch

more thanremovingthetabweakens it.

2)Clampthemotorplateto the

frame. Fourclamp sets aresupplied with

thekit,a bottomfrontpair,a bottomrear

pair,and twosingleoffsetclamps forthe

topof themotorplate. Eachclamp setis

installed with a singleboltthreadedfrom

theleftsideofthebike.

2a)Bottom FrontClamp. See Photo1.Install clamphalvesonM6x70mmboltas shown.Usethe

9/16”spacer onrightsideofmotorplate. Usea flatwasher under thehead oftheboltand a flatandlock

(1)Bottom Front Clampset

(2)BottomRearClampSet

(3)Top FrontClampSet

5

washer under thenut.Useremaining

flatwashers as neededtofill ingaps

and adjustthemotorplateverticality.

Youdon’tneedtouseall thewashers.

2b)Bottom RearClamp. See Photos

2.Install clamp halves onM6x75 mm

boltas shown.Usethe5/16”long

spacer ontherightsideofthemotor

plateandthe9/16”longspacer onthe

leftside. Usea flatwasher under the

head oftheboltand a flatand lock

washer under thenut.Useremaining

flatwashers as neededtofill ingaps

and adjustthemotorplateverticality.

Youdon’tneedtouseall thewashers.

2b)TopFrontClamp. See Photos 3.

Thetopclamps haveasymmetric

halves.Usetheshallower halfontheleftsideofthe

bikeandthedeeper halfontherightside. This off-

sets themotorplateslightlytotheleftof thetop

frametubecenter line.

Attachthetopfrontclamp halvesoneither sideof

themotorplateusingtheM6x20mm bolt.Placea

flatwasher under thebolthead.Useother flat

washers betweenmotorplateand clamp oneither

sidetoadjustverticalityas needed.

2b)TopRearClamp.See Photos4.Attachthe

topfrontclamp halves oneither sideof themotor

plateusingtheM6x35 mm bolt.Placea flat

washer under thebolthead.Useother flatwashers

betweenmotorplateand clamp oneither sideto

adjustverticalityas needed.

Theboltshould protrudetotheright as shown

where itservestomountthechainguidetubeina

later step.

Tightenallclamps.Thelower clamps shouldbe

verytight.Becarefulnottoover tightentheupper

clamps though.Theyusealuminumthreads and so

canbeeasilystripped.

Step 4:Assemble theEMDunit

TheEMDfor theTourEasy/GoldRushis

shippedpartiallydisassembledso thatthemo-

tor platecan beinsertedbetween thetwin

frametubes.Inthisstep youwill reassemble

theEMDwiththemotorplateattachedto the

bike.

(5)GearboxOrientation

(6)Gearboxbolts,M5x12mmbutton

head

(4)Top RearClampSet

6

1)Attachthemotor/gearboxunittothe

motorplateusing4M5x 12mm button

headbolts.(photos5and6). Orientas

showninphoto5.Thearrowpointstohalfway

betweenthetwochainopenings inthegear-

box.

2)Threadchainthroughgearbox. Itgoes

ineasiestifyouinsertitfromthebottomand

usea finger torotatethesprocketinsidethe

gearbox.See photo7.

3)Jointheendsofthechainwithmas-

terlink. Refer tophotos 8fortheproper way

toinserttheincluded master link.Snapthe

springclipontothelinkusinga pairof needle

nosepliers.

NOTE: MostGold Rusheshavea

welded cross tabbetweenthelower

frametubes.This cross tabis nor-

mallylocated suchthatthechain

needs toencloseit.Ifnot,itmust

beremoved.

4)Removeboltsandretainer

platefrom SpindleAssembly

(photo9).

5)Leavethespacershowninphoto10inplace. This serves to

keepthespindleawayfromthemotorplatewhenitisbolted down.

6)Placethespindleagainst

themotorplatewiththechain

wrappedaroundthespindle

sprocket.(photo11)

7)Aligntheboltholesonthe

rearofthespindleassembly

withtheslotsinthemotor

plate(photo12).

8)Attachthespindleassem-

bly tothemotorplateusingthe

bolts,washers,andretainer

plateremovedinstep8.(photo

13) Donottightenboltsuntilstep9.

9)Adjustmotorchaintension. Gentlypull thespindleassemblytowards thefrontof themotor

platetotaketheslackoutof themotorchain(photo14).Lightlytightena coupleofthebolts.Rotatethe

spindle360 degrees lookingforanylocationwhere thechaingoestaut.Ifitdoesn't,tightenthe5 bolts to

55 inch-lbs (6.2N.m).Ifitdoes,loosenall bolts and movethespindleretainer a tinyamounttowards the

motorand repeatthis step.

10)Install thefront chaintensioner. Removetheslotted screwthatattaches thepivottube(black

cylinder)thetensioner notingtheorder of all ofthespacers and washers.Screwthepivottubeintothe

(7)Chain ThreadedthroughGearbox

(8)InstallingChain MasterLink(proceedclock-

wisestartinginupperleft)

7

motorplateas showninphoto15 placingthe3

mm spacer betweenthetubeand plate. Theflat

area onthetubecanbeturned bya 10mm wrench.

Tighten.

Placethespringover thepivottube. Inserttheslotted

screwand replacethespacers and washers.Attachthe

tensioner armtothescrewandtighten.

Finally,placethearmsof thespringas showninphoto

14sothatthetensioner is belowthemid-freewheeland

wantstorotateina clockwisedirection.

Step 5:Install thefrontchain.

1)Usethechainyouremovedinstep 2asthe

frontchain.(readwarningbelow)

(10)SpindleAssemblySpacer

(11)SpindleandChain

(12)SpindleandMotorPlate Alignment

(13)SpindleRetainer

(9)SpindleBoltsHoldingSpindleRe-

tainerPlate

8

2)

Set thefrontderailleurtothesmallest

gear. Threadthechainthroughthede-

railleurcage,aroundtheinnermost

frontsprocket,andthroughtheEMD

sprocketsasshowninphoto16.You can

useabentcoathangertohold theends ofthe

chainwhileyouadjustthelengthas shownin

thephoto.(notethatthephotoshows andif-

ferentbike.Thechainpath is thesame.)It’s

OK ifthetensionerswings moreto therear

when onthesmallestfrontringas longasthe

chaindoesn’tstrikethemid-freewheel.

Shortenthechainusingyourchainbreaker

and jointheends sothatitends uplooking

roughlylikephoto16with thechainonthe

smallestfrontring.

(Hint: ifyouneed anyinstructionintheuse

ofcommonbicycletools goto

http://www.parktool.com/repair_help/

FAQindex.shtml)

WARNING: Useonlydrylubricantsonall

chains.Ifyouhavebeenusingoiltolubricate

yourchain,youmusteither replaceitwitha

newchain,orcleanitthoroughlyand switch

lubricants.See Maintenancesection.

Step 6:Attachdrivesprocketandchain-

guardassembly.

Attachthedrivesprocketandchain-

guardassemblytothedrivespindleus-

ing5M6x 20mm buttonheadboltsas

showninphoto17.

Tightenall5 bolts securely.

(16)FrontChain Path

(17)DriveSprocket andChain Guard

(14)AdjustingMotorChain Tension (15)Chain TensionerInstalled

9

Step 7:Install thechainguidetube.

1) Attachthechainguidetubebracketto

the30mmboltthat goesthroughthe

middletopmotorplatemount.

Use2oftheincludedM6washersas

spacersbetweenthebracketandthetop

rearclamp.Finishwithanm6nutand

lockwasher.Photo18showsthebracket

minustheguidetube.Photo19shows

theguidetubeinstalled.

Youmaybetempted toleavethechainguide

tubeoff.Wedon’trecommend doingthis.Its

purposeis todamp chainshakewhichcan

causethechaintocomeoff themid-sprocket

under someconditions.

Step8: Install chainIdler.

1) Replacetheoriginaldoublechainidler

withtheincludedsingleidler. Attachthe

idler totheoriginalmountinglocationusingan

M6x16mmhex head bolt.PlacetheM8

washer betweentheidler and frame.

Step 9:Install therearchain.

Settherear derailleurtothelargestcog.

1)Usethesupplied76inchesofSRAM9-

speedchain.Ifyourbikehasan8-speed

rearcassette,it’susually OKto use9-

speedchain.

2)Threadthechainaroundthemid-

sprocket,throughthechainguidetube,

throughtheidler,aroundtherearcas-

sette,andthroughtherearderailleur

cageasshowninPhoto20.

Shortenthechain,ifneeded,usingyourchain

breaker tool.Withthechainaroundthelarg-

estrear cog, itshould lookapproximatelylike

photo21.

Jointheends ofthechainwiththeincluded

Powerlink™connector.

(19)ChainGuideTubeInstalled

(18)Chain GuideTubeBracket

(20)RearChainInstalled

10

Step 10:Adjust thechainguidetube.

1)Alignthechainguidetubesothattheflexible

attachmentishorizontalandthebracketisverti-

calasonphotos18and19.

2)Tighten thenut andboltholdingthebracket to

themotorplate.

Step 11:Install thethrottle

Yourkitusesa Hall-effectthumbthrottle. Hall

effectthrottles arenon-contactsolid statedevices that

relyona magnetmovingpastanintegrated circuittogen-

eratethevariablevoltageneeded tocontrolmotorpower

and speed.

Theplasticshellsof thesethrottles cansometimes stick

whennew.Ifthathappens,justruba droportwoof sili-

conelubricantintotheseamthatseparates thetwohalves

of thethrottle. Thatwill permanentlyfixtheproblem.

1)Thethrottleslidesontotheendofyourhandle-

barasshowninphoto 22.

Thehall-effectthrottleis designed tobemountedonthe

right side, butmaybemounted ontheleftas well.

Right sidemountingis theusualbut,lefthandmounting

allows youtoshifttherear cassetteand operatethethrot-

tlesimultaneously,whichsomeprefer. It’s alsopossibleon

mostbikes toswitchtheshifters tooppositesides to

achievesimultaneousthrottleand shiftoperationwith thethrottleontheright.

2)Routethethrottlewiresothatisdoesn’timpair turningthebars,won’tsnagonany-

thing,andreachesthethrottleconnectoronthemotor.

3)Connect thethrottletothemotor.

4)Don’tsecurethethrottlewirewithwiretiesyet. Waituntilyoutestthesystemandknowthat

everythingis workingthensecure all thewires totheframewiththeincluded wire ties.

Step 12:Install thebatterysystem.

1)See theincludedseparateinstructionsforyourtypeofbatterysystem.

2)Afterinstallingthebattery,secureloosewireswiththeincludedwireties.Makesure

thatthewiresarelocatedso asnot tointerferewiththemovementofanysuspension.

Step 13: FinishupandTest.

1)Withtherearwheelsuspendedoffoftheground,turnonthebatterypackswitchand

pressthethrottleto testthesystem.Runthebikethroughall ofthegearstomakesurethe

derailleurisproperly adjusted. Lookat themotorchainandverify that itisrunning

(22)MountingHall-EffectThrot-

(21)ProperlyAdjustedChain

11

smoothly.Makesurethatall wiresareout ofthewayofall movingparts.Makesureaxle

boltsorskewersaretight.

Proper adjustmentofthegears and makingsure thattherear cassetteandbearings areingood shapeis

especiallycriticalgiventheextra load thedrivetrainwillbesubjected to.Also,checkthattherear axle

skewer orbolts arefullytightened.Axlebolts shouldbetorqued toabout20ft-lbs (28Nm).Skewers

shouldbeas tight as youcancomfortablymakethem.Itis possibleforthemotortopull theaxleright

outof thedropouts iftheyare loose.

3)Roadtest. Runthroughall thegears makingsure theyare shiftingsmoothly.Usefull throttleineach

gear tocheckforskippingofthedrivechain.Keepspeeds lowatfirstuntilyou’re sure thateverythingis

functioningproperlyand youbecomefamiliar withridingwiththemotorassist.

Other manuals for Electric Mid-Drive

2

Other EcoSpeed Bicycle Accessories manuals