EcoSpeed Electric Mid-Drive Guide

1

ElectricMid-Drive™

InstallationandAssembly InstructionsforBurleyLWB(Koosah,

Sandpoint,Nasoke,Spider)

copyright2006,EcoSpeedLLC

http://www.ecospeed.com/docs/emd11_assy_rev1.01 Revision 1.01

2

ElectricMid-DriveComponents

(600W.750Wisslightly different.)

3

Congratulations onyourpurchaseofEcoSpeed’s ElectricMid-DrivefortheBurleylongwheelbasere-

cumbentbicycles.TheElectricMid-Driveis theworld’sbestmulti-speed,throttleoperated,electric-

assistconversionand theonlyelectric-assistdesigned specificallytofita varietyofrecumbentbicycles.

Theseinstructions will guideyoustepbystepthroughwhatwehopewill bea simpleand painless instal-

lationof yourEMD.Themechanicalskills involved are modestand,wegiveyouhints andtips atevery

stepthatreflectwhata professionalmechanicknows.Ifatanytimeyouhaveproblems,call us at1-866-

EcoSpeed (866-326-7733)forfriendlytechnicalassistanceore-mailus at support@ecospeed.net.

A word onhowtheseinstructions areorganized.Eachstepis under a majorheading–Step1:,Step2:,

etc.Ifyou’veinstalled anEMDbefore youcanjustread themajorheadings and ignore theexplanatory

text.Beloweachmajorheadingis a listof sub-steps.Theimportantinformationineachsub-stepis in

boldtext.Ifyou’re a competentbikemechanic,youcanjustreadthebold textand safelyignore therest.

Theremainingtextis there toclarifythings fornon-mechanics. We’vealsoincluded tips andhints in

Italics.

Beforegettingstartedcheckthatall thepiecesneededwereincludedinyourshipment:

Checkthepackinglistincludedwithyourshipment.

Youwill also needthefollowingtools:

1)Bicyclechainbreaker. Availablefromanybikeshop.

2)2.5mm,3mm,4mm and5mmhex(orAllen)wrenches. (Thestandard “L”shapedhex

wrenches sold atbikeshops andhardwarestoreswill probablywork but,theirshorthandlesmake

looseningand tighteningdifficult,especiallyinthelargersizes.A betteralternativeis a¼”ratchet

drivewrenchand hexsockets.Yourlocal hardwarestoremayhavethemortry www.snapon.com for

topquality.)

3)10mm boxoropenendwrench.

4)8mmnutdriver.

5)Wireclippersorscissors.

6)Rivet Nut (waterbottlemount)installationtool. (You canpurchasethistoolfromus,useit,

thenreturnitforafull refund.Or, keepit—yourchoice.)

7)Drill with3/32” (or2.5mm),3/16” (or5mm)and19/64” (or7.5mm) bits.

8)Machiniststransferpunch(includedinkit).

9)TorqueWrench(optional).

10)11/16”and7/8”wrenchesortwoadjustablewrenches(optional). Needed ifusingoptional

rivetnutinstallationtool.

Onceyouhaveall theparts and toolsyouneed,it’stimetoclear a nicespacetowork,find severalof

hours time, and gettoit.

Step 0:Makesurethatyourbikeisingoodcondition.

Ifyouhaven’thad yourbiketunedupbyyourlocalbikeshopina while, nowwouldbea good time. In-

stallingtheEMDwill placeextra stress onyourbikesoit’s importantthatitbeintopcondition.

4

Step 1:Findawayto secureyourbikewhile working.

Theidealhereistomountyourbikeonaworkstandsuchasbikeshopsuse.Ifyouhaveac-

cess toonegreat,otherwisethere are other possibilities.

Ifyouhavea workarea where it’s OK to

puthooks intheceiling, youcanhangthe

bikefromtheceilingusingropes or

straps.

Putintwohooks about3 feet(1meter)

apartandhangtheseatcrossbracefrom

these. Putina thirdhookatthefrontof

thebikeand hangthefrontof thebike

fromthis hook.

Makesure thebikehangs levelwith all

wheels off theground.

Ifyoucan’tuseceilinghooks,youcan

leanthebikeagainsta wall withthefront

brakelockedtopreventrolling. Wrap

severaltightrubber bands around the

frontbrakelever untilthefrontwheel

cannolonger roll.

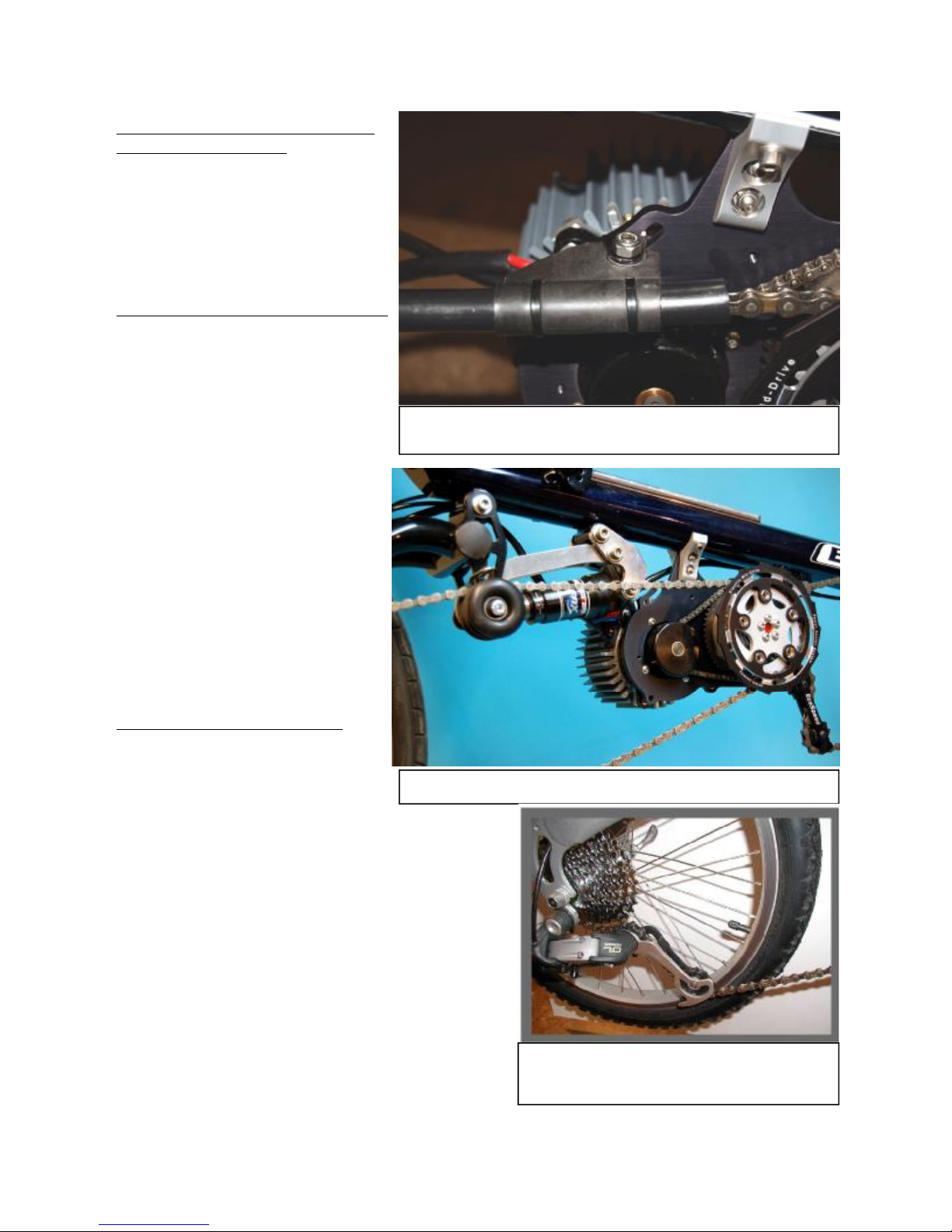

Step 2:Removeidlerandchain.

Removethefront chainidlerandall associated

pieces. Usingyourchainbreaker tool,splitthechain,

remove, and setaside. Removeonlythefrontchain

idler. Somemodels havea rear idler as well.

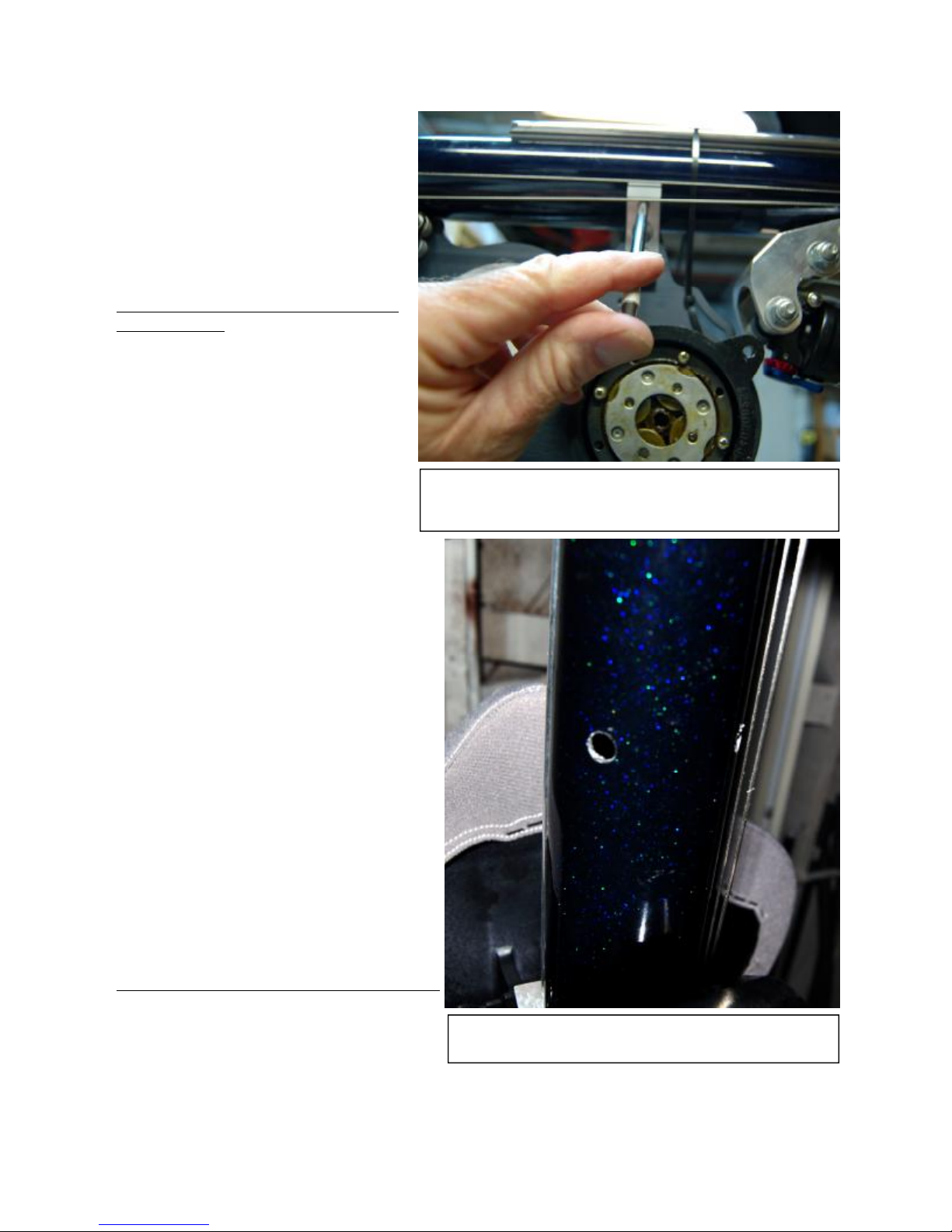

Step 3):Removethemotor fromthemotor unit.

1)RemovethemotorfromtheEMDunitbyre-

movingthe3bolts(photo 3)holdingitto the

gearbox.

Setasidethebolts and associated washers.Oncethe

bolts areremoved,themotorcanbepulled awayfrom

thegearbox.

Photo5 shows thegearboxwithmotorremoved.Be

carefulnottowipemuchof thewhiteheattransfer

grease fromthemotororgearboxhousing.

This stepmakestheunitlighter and easesthefollowing

steps.

Step 4:AttachtheT-Bracketsto youridlermount.

1)SlipthetwoT-Bracketsatthefrontofthemo-

torplatebetweenthetwotabsthatheldthe

chainidler.

(1)Front Idler Pulley

(2)T-BracketsAttachedto Idler

Mount

5

2)PlaceanM6fenderwasherunderthe

headofan M6x16mmbuttonheadbolt,

andslipit throughtheholeinone ofthe

idlermountingtabsasshowninPhoto2.

Dothesameontheoppositeside.

3)Placeafenderwasherovertheendof

eachboltandlooselythreadan

M6nylocknutonto eachbolt.

Theunitshould nowhangfree as

showninPhoto4.Notetheorientation.

Theunitshouldbeabletoswingup

and towards therear ofthebike.

Step 5:Swingmotor unitupagainst

theframeandadjust thepositionof

theT-Brackets andQuarterBrack-

ets.(photo 5)

1)Swingtheentiremotorunitup

andagainsttheframe.

2)Pushthefrontofthemotor

unitupwardssothatthereislittle

orno clearancebetween thetop

edgeofthemotorplateandthe

bottomoftheframetube.

3)Loosentheboltsholdingthe

quarterbracketsinplace.

WiththeEMDheldagainsttheframeso thatthereislittleorno clearancebetweenthe

motorplateandthebottom oftheframe,adjusttheplacementofthequarterbracketsso

thattheyarepressedflushagainsttheframe.

(4)MotorHangingfromFrame.Rear

of4Biketo Left

(5)EMDWith QuarterBracketsFlushwith

Frame.

(3)MotorBoltLocations

6

Whenyou’resatisfiedthatthey’re

properly aligned,tightenthetwo

boltsandnutsholdingthemtothe

motorplate.

Makingsure thebrackets areflushdistrib-

utes stresses evenlyontotheframeand

insures thattheboltsholdingthequarter

brackets inplacegoinstraight.

Step 6:Marktherearattachboltcen-

ters.(photo 6)

Therear of theunitisheld inplacewith

twoM5 x 20mm bolts.Thebolts thread

intowater bottlemountsthatare placed in

theframeforthatpurpose. Inthis stepyou

preciselymarktheplaces where the

mounts will beinstalled. (notethatifyou

everdecidetoremovetheEMD,you can

add asecond pairofthesemounts

2.5” (64mm)fromthefirstand placea

pairofwaterbottleholders underyour

seat.Also,ifyou wantto install awater

bottleholderortwoelsewhereonyourframe

whileyou havethetool,wecansupplyyou

with extrarivetnuts.)

1)Swingtheunit againsttheframeas

showninPhoto5.Besurethatthequar-

terbracketsareflushwiththesurfaceof

theframetube.

2)Sliptheincludedmachiniststransfer

punchintotheholeinthequarter

bracket withthepointedinagainstthe

frame. Thepunchis almosttheexactsame

sizeas theholeinthequarterbracket,soyou

mayhavetoplaywith itto getittogoin.

3)Taptheendofthepunchwithaham-

mertomakeasmall markontheframe.

You mayhavetotapitafewtimes togetan

easilyvisibleindentation.

4)Repeat1,2,and3forthequarter

bracketontheotherside.

Step 7:Install WaterBottle MountingNuts

Youcandothis stepyourselfor,takethebike

toanybikeshopandhavetheminstall thein-

cluded water bottlemountingnuts (knownas

RivetNuts).Doingityourselfis easywiththefollowinginstructions.

(6)MarkingHoleCenterwith Machinists

TransferPunch

(7)HolesDrilledinto FrameTube

7

1)Drill asmall pilotholeatthelo-

cationofeachmarkyoumadein

step 6.Useasmall bit (asmall bitis

easierto preciselyalignwith theinden-

tation) suchasa3/32”(2.5mm).

2)Expandtheholesizeusingabit

ofapproximately3/16”(5mm).

3)Expandtheholetoitsfinalsize

usinga19/64”(7.5mm)bit(photo

7). Gettingtothefinal holesizeintwo

steps allows thedrills topenetratemore

smoothlyreducingthechanceofpaint

chipping.

4)Install therivet nutsusingthe

instructionsthat camewithyour

tool.Photo 8showsinstallationus-

ingawrenchtyperivetnuttool.

Whenusingwrenchtypetool,besureto

notovertighten thetool.Doingsowill

stripthethreads frominsidetherivetnut.

Thewaytoavoid overtighteningis to

gripthewrenches closeto therivetnut

toolandcarefullynotetheeffortyou’re

exerting.Whentheeffortstartsto in-

crease,stopturningthetool.Thenutis

fullyinstalled atthatpoint.

5)ThreadoneoftheM5x 20mm

intoeachrivetnut afterinstallation.

Photo 9.Tightentheboltslightlyto

makesuretherivetnutdoesn’t

turn.

Ifitdoesturn,reattachtherivetnut

toolandtighten thetoolanother

eighthturn.Repeatuntiltherivet

nut doesn’tturnwhen theboltis

moderatelytightened.

Step 8: FinishInstallingtheEMD

unit.

1)Loosen thetwoboltsandcorre-

spondingnutsthatholdthequarterbracketstotheEMDunit.

2)SwingtheEMD unitupandslipthequarterbracketsovertherivetnuts.

3)Attachthequarterbracketstotherivetnutsusingthem5x 20mm bolts.Slip alock

washerandthenaflatwasherovertheheadofeachboltbeforeinstalling.

4)Makesurethatthetopedgeofthemotorplateisflush,ornearlyso,againsttheframe,

thentightentheboltsholdingthequarterclampsto themotorplate.

(8)InstallingRivet NutUsingWrenchType

Tool

(9)Rivet NutInstalled

8

5)Tightentheboltsholding

thequarterclampstothe

rivet nuts.Werecommend

thatyouuseatorque

wrenchandtorquethebolts

to 55inch-lbs(6.2N-m). If

you don’thaveafeelforhow

tight bolts should be,you should

useatorquewrench.You don’t

wanttostripoutthethreads of

therivetnuts and you don’t

wanttheboltstowork loose

whileyou’reriding.

6)Finally,reinstall themo-

tor.Notethatthemotorshaftis

“D”shaped and fits intothecor-

respondingopeninginthemid-

dleof thegearbox.

Youmayneed totwistthemotor

slightlytotheleftorright togettheshaftto

slipintothegearbox.

Oncethemotorslips intothegearbox,twistit

leftorright tomakethedecalupright and

insure thatthewires are towards therear of

thebike.

Install andtightenthemotorbolts.

Step 9:Install thefrontchain.

1)Usethechainyouremovedinstep 2

asthefrontifyourbikehasan8speed

rearcassette.Otherwise,usethechain

includedwiththekit.(read warningbe-

low)

2)Setthefront derailleurtothesmall-

estgear.Threadthechainthroughthe

derailleurcage,aroundtheinnermost

frontsprocket,andthroughtheEMD

sprocketsasshowninphoto10.You

canuseabentcoathangerto holdtheends

ofthechainwhileyou adjustthelengthas showninthephoto.

Shortenthechainusingyourchainbreaker and jointheends sothatitends uplookingroughlylike

photo10withthechainonthesmallestfrontring.

(Hint: ifyouneed anyinstructionintheuseofcommonbicycletools goto

http://www.parktool.com/repair_help/FAQindex.shtml)

WARNING: Useonlydrylubricantsonall chains.Ifyouhavebeenusingoiltolubricateyourchain,

youmusteither replaceitwith a newchain,orcleanitthoroughlyand switchlubricants.See Mainte-

nancesection.

(10)FrontChain Path

(11)DriveSprocket andChain Guard

9

Step 10:Attachdrivesprocketand

chain-guardassembly.

Attachthedrivesprocketand

chain-guardassemblytothedrive

spindleusing5M6x 20mmbutton

headboltsasshowninphoto11.

Tightenall5 bolts securely.

Step 11:Install thechainguidetube.

NOTE: Skip thisstepandstep13

ifyourbikehasarearchainidler

asshowninphoto13.

1)AttachusingM5x16mm boltto

theslot attherearofthemotor

plateasshowninphoto12.Use

an M5nylocknutandwasheron

themotorsideofthemotorplate.

2)Don’ttightentheboltyet,let

theguidetubehangfreeasshown

inthephoto.

Youmaybetempted toleavethechain

guidetubeoff.Wedon’t recommend

doingthis.Its purposeis todamp

chainshakewhichcancausethechain

tocomeoff themid-sprocketunder

someconditions.

Step 12:Install therearchain.

Settherear derailleurtothelargest

cog.

Usethesupplied68inchesof

SRAMPC-48chainifyourbikehasan 8-speed

rearcassette.Otherwiseusethechainyoure-

movedinstep2.

Threadthechainaroundthemid-sprocket,

throughthechainguidetube,aroundtherear

cassette,andthroughtherearderailleurcage.

Ifyourbikehasarearchainidler,threadthe

chainovertheidlerasshowninphoto13.

Shortenthechain,ifneeded,usingyourchainbreaker

tool.Withthechainaroundthelargestrear cog, itshould

lookapproximatelylikephoto14.

(13)RearChainInstalledon Bikewith RearIdler

(12)ChainGuideTube

(14)ProperlyAdjustedChain

10

Jointheends ofthechainwiththeincluded Powerlink™

connectorifusingthepC-48chain,otherwisejointhe

ends usingyourchainbreaker tool.

Step 13: Adjust thechainguidetube.

1)Alignthechainguidetubesothattheflexible

attachmentishorizontalandthebracketisverti-

calasonphoto12.

2)Tighten thenut andboltholdingthebracket

to themotorplate.

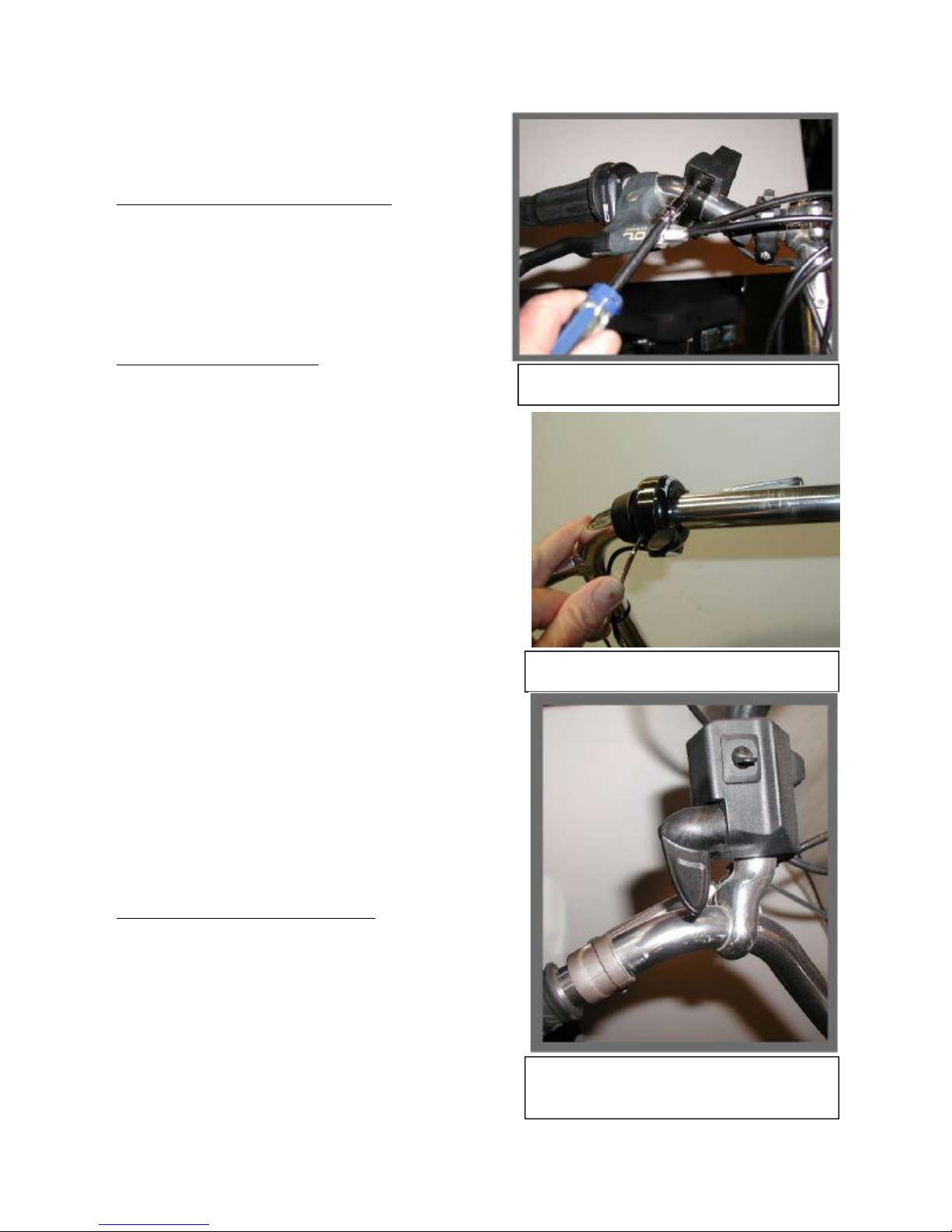

Step 14:Install thethrottle

Yourkit will haveoneoftwothrottletypes.

1a)The resistor throttlemountstoyourhandlebar

usingabracket asshowninphoto15,.

1b)The hall-effect throttleslidesontotheendof

yourhandlebarasshowninphoto16.

Thehall-effectthrottleis designed tobemountedonthe

right side, butmaybemounted ontheleftas well.

Tomounttheresistorthrottleontheleftyouwill needa

bar extensionas showninphoto17.

Right sidemountingistheusualbut,lefthandmounting

allows youtoshiftandoperatethethrottlesimultaneously,

whichsomeprefer.

2)Routethethrottlewiresothatisdoesn’timpair

turningthebars,won’tsnagonanything,and

reachesthethrottleconnectoronthemotor.

3)Connect thethrottletothemotor.

4)Don’tsecurethethrottlewirewithwiretiesyet.

Waituntilyoutestthesystemand knowthateverythingis

workingthensecure all thewires totheframewiththein-

cluded wire ties.

Step 15:Install thebatterysystem.

1)See theincludedseparateinstructionsforyour

typeofbatterysystem.

2)Afterinstallingthebattery,secureloosewires

withtheincludedwireties.Makesurethatthe

wiresarelocatedso asnotto interferewiththe

movementofthesuspension.

(15)MountingResistorThrottle

(16)MountingHall-EffectThrottle

(17)ResistorThrottleMountedon

LeftSideusingBarExtension

11

Step 16:FinishupandTest.

1)Withtherearwheelsuspendedoffoftheground,turnonthebatterypackswitchand

pressthethrottleto testthesystem.Runthebikethroughall ofthegearstomakesurethe

derailleurisproperly adjusted. Lookat themotorchainandverify that itisrunning

smoothly.Makesurethatall wiresareout ofthewayofall movingparts.Makesureaxle

boltsorskewersaretight.

Proper adjustmentofthegears and makingsure thattherear cassetteandbearings areingood shapeis

especiallycriticalgiventheextra load thedrivetrainwillbesubjected to.Also,checkthattherear axle

skewer orbolts arefullytightened.Axlebolts shouldbetorqued toabout20ft-lbs (28Nm).Skewers

shouldbeas tight as youcancomfortablymakethem.Itis possibleforthemotortopull theaxleright

outof thedropouts iftheyare loose.

3)Roadtest. Runthroughall thegears makingsure theyare shiftingsmoothly.Usefull throttleineach

gear tocheckforskippingofthedrivechain.Keepspeeds lowatfirstuntilyou’re sure thateverythingis

functioningproperlyand youbecomefamiliar withridingwiththemotorassist.

Other manuals for Electric Mid-Drive

2

Other EcoSpeed Bicycle Accessories manuals