1 About These Instructions..................................... 21

1.1 Further applicable documents................................ 21

1.2 Warnings used ........................................................ 21

1.3 Definitions used ...................................................... 21

1.4 Symbols used ......................................................... 21

2 Safety instructions ....................................... 22

2.1 Intended use ........................................................... 22

2.2 Inappropriate use.................................................... 22

2.3 Fitter qualification ................................................... 22

2.4 Safety instructions for fitting, maintenance,

repairs and disassembly of the door system.......... 22

2.5 Safety instructions for fitting................................... 22

2.6 Safety instructions for initial

start-up and operation............................................ 23

2.7 Safety instructions for using

the hand transmitter................................................ 23

2.8 Approved safety equipment.................................... 23

3 Fitting ..................................................................... 23

3.1 Inspecting the door / door system .......................... 23

3.2 Clearance required ................................................. 23

3.3 Preparation on a sectional door.............................. 24

3.4 Preparation on an up-and-over door...................... 24

3.5 Fitting the operator boom....................................... 24

3.6 Fitting the garage door operator............................. 24

3.7 Determining the door end-of-travel positions......... 25

3.8 Emergency release.................................................. 25

3.9 Fixing the warning sign........................................... 25

4 Initial Start-Up / Connecting

Additional Components........................................ 25

4.1 Display and control elements ................................. 26

4.2 Teaching in the operator......................................... 26

4.3 Connecting additional

components / accessories ...................................... 26

4.4 DIL switch functions ............................................... 26

5 Radio...................................................................... 27

5.1 Hand transmitter RSC 2.......................................... 27

5.2 Excerpt from the declaration of conformity............ 27

5.3 Integral radio receiver ............................................. 27

5.4 Teaching in hand transmitters................................. 27

5.5 Operation ................................................................ 28

5.6 Deleting all memory spaces.................................... 28

Table of Contents

Dissemination as well as duplication of this document and the

use and communication of its content are prohibited unless

explicitly permitted. Noncompliance will result in damage

compensation obligations. All rights reserved in the event of

patent, utility model or design model registration. Subject to

changes.

6 Operation............................................................... 28

6.1 Instructing users ..................................................... 28

6.2 Function tests ......................................................... 28

6.3 Normal operation .................................................... 29

6.4 Behaviour during a power failure............................ 29

6.5 Behaviour following a power failure........................ 29

7 Inspection and Maintenance ............................... 29

7.1 Checking the tension of the toothed belt ............... 29

7.2 Checking safety reversal / reversing........................ 29

7.3 Exchanging the bulb............................................... 30

8 Displays for Operating

Conditions, Errors and Warnings ........................ 30

8.1 Operator light messages........................................ 30

8.2 Display of error and warning messages ................. 30

9 Deleting Door Data ............................................... 31

10 Dismantling and Disposal .................................... 31

11 Warranty Conditions............................................. 31

12 Excerpt from the Declaration of Incorporation.. 32

13 Technical Data....................................................... 32

A Articles supplied ..................................................... 2

B Tools needed for fitting the garage door

operator ................................................................... 2

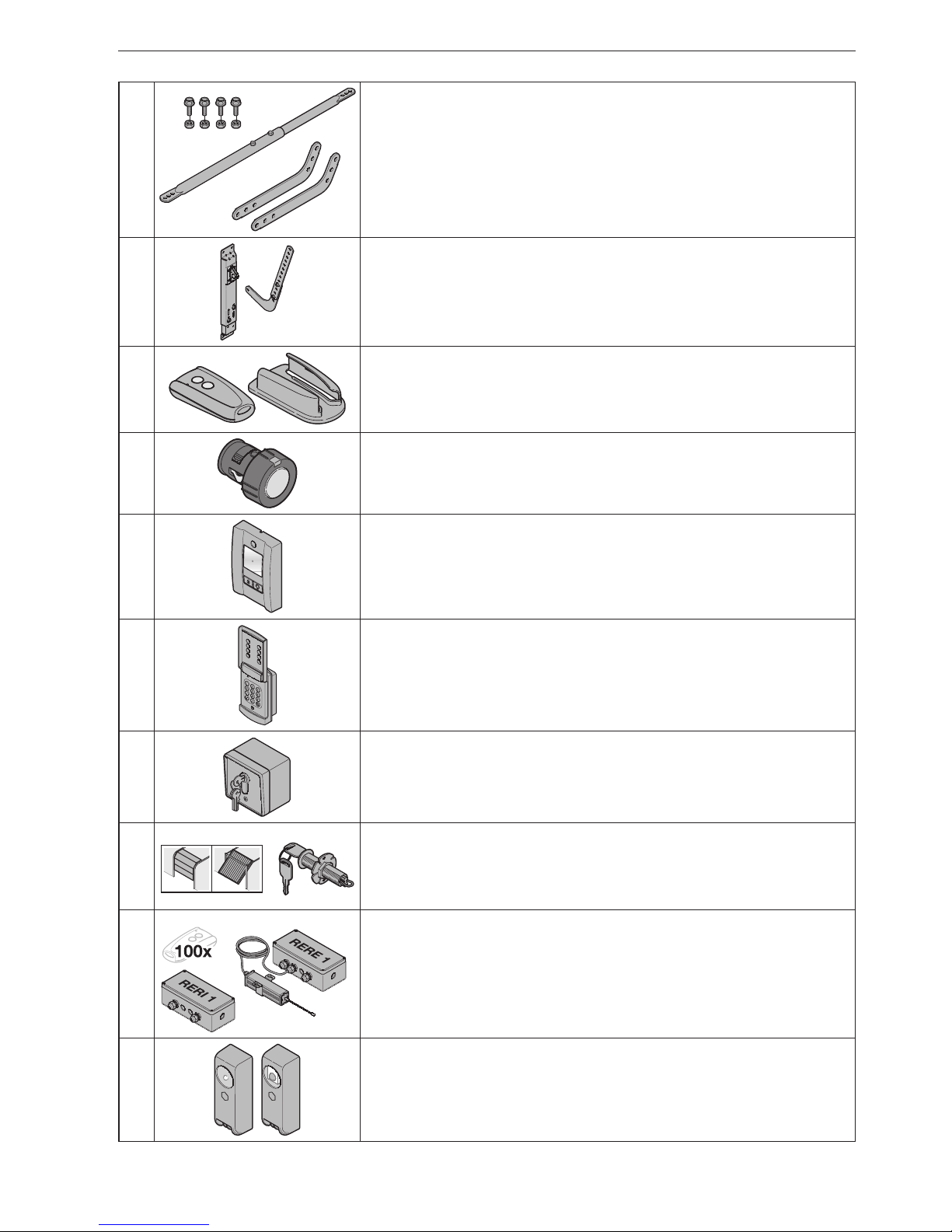

C Accessories for the garage door operator......... 19

D Spare parts .......................................................... 131

Drill stencil........................................................... 129

Illustrated section..................................... 108

20 TR10L003-B RE / 12.2013

ENGLISH