4

ECOTHERM

Heat transfer solutions

®

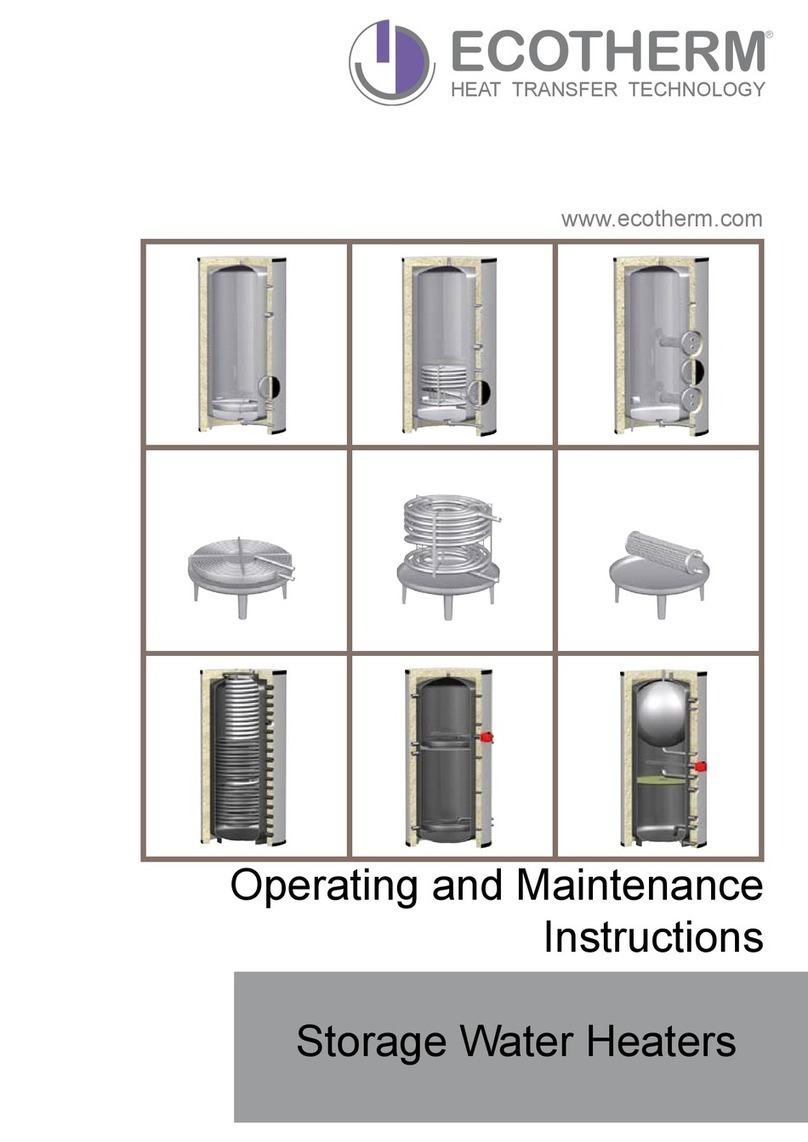

Operating Instructions High Capacity Water Heaters Models EHRE/EHPE & EDRE - ELC 11

Introduction

1. Introduction

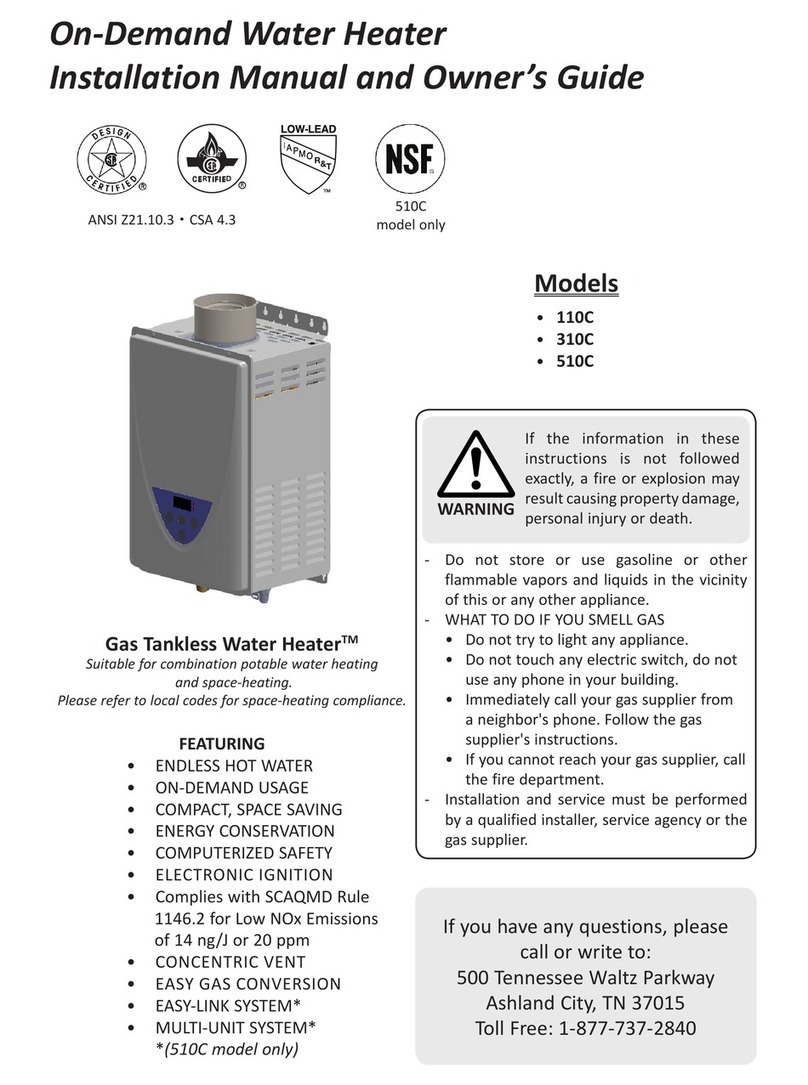

Congratulations!

With the purchase of your high

capacity water heater from

ECOTHERM you have opted for a

device incorporating the ultimate in

hygiene, economy, reliability and

functionality. We are convinced that

youruserswillenjoy thebenets of

your high capacity water heater for a

long time.

This manual contains vital information

on starting-up and service of your

ECOTHERM high capacity water

heater.

Please read this information carefully

before starting up and familiarise

yourself with the operating processes

required.

Compliance with all instructions is

the basis of smooth and trouble-

free operation of the ECOTHERM

high capacity water heater and

safeguards your rights in the event

of warranty claims.

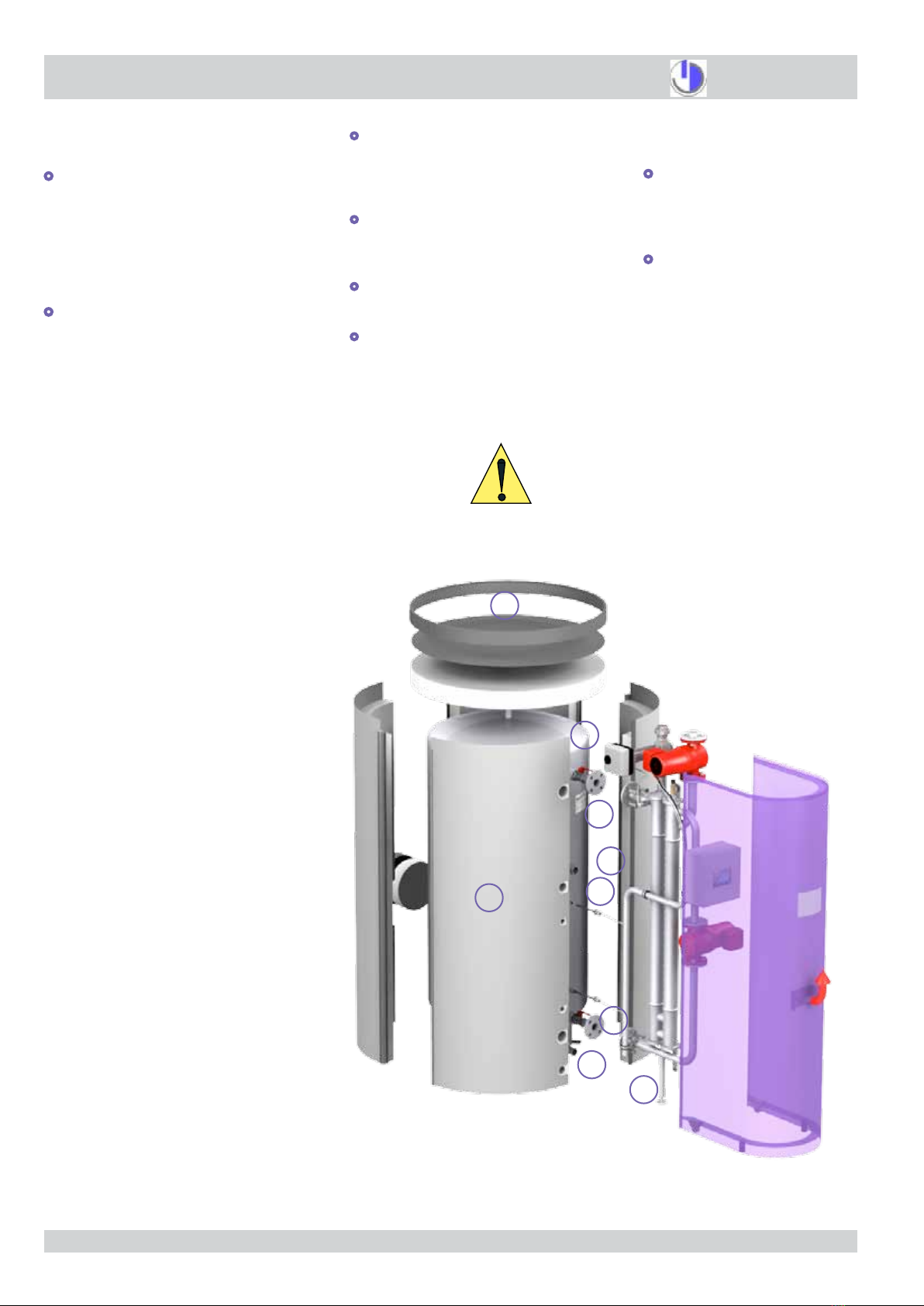

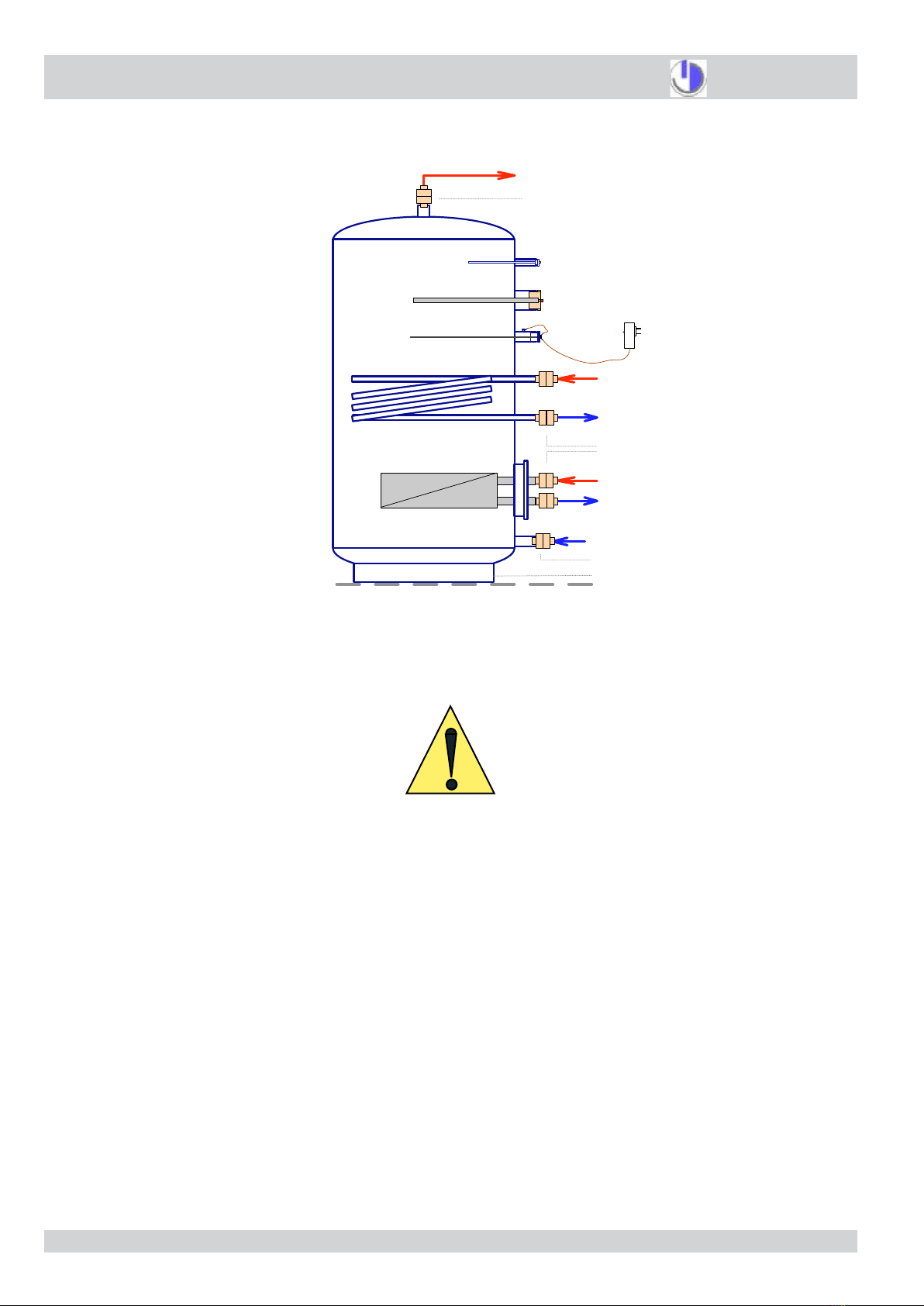

1.1 Preparing for installation

1.1.1 Unpacking storage tanks

Extreme care is required when un-

packing the pre-assembled compo-

nents from the casing. Some items

aretopheavy,andcertainparts(e.g.

microprocessorhousing)cannotbear

theweightofthepre-assemblywhen

laidsidewaysontheoor. When re-

moving storage tanks from a container,

care must be taken while clearing the

doorway not to damage or knock off

the air vent protruding from the top of

the tank.

1.1.2 Non-return valves for cold

water supply and circulation con-

nections

Non-return valves must be provided

for the secondary domestic cold water

supply and circulation connections, in

order to avoid possible convectional or

expansivebackowofheatedwater.

1.1.3 Filter recommendations

To avoid damage to pumps and fouling

of heat exchangers by intake of foreign

bodies, ECOTHERM recommends

that strainers be placed in front of sup-

ply connections as follows:

Primary circuit heating water supply:

Strainer mesh size 150 - 200 µm.

Secondary circuit cold water supply:

Strainermeshsize50-60µm

1.1.4 Primary circuit heating water

pressure from boiler

The heating water supply to the heat

exchanger has minimum pressure re-

quirement of 1.5 bar, and a maximum

of 10 bar. Failure to observe this re-

quirement may potentially expose the

primary circuit to negative pressure

aeration. ECOTHERM recommends

that a closed expansion vessel with

pressurisedll-upbettedtothepri-

mary circuit.

1.1.5 Secondary circuit expansion

vessel

An expansion vessel connected to

the domestic hot water supply line is

required to allow for the increase of

water volume during heating. Failure

to observe this requirement may result

in regular small losses of heated do-

mestic water through the ECOTHERM

product‘s own pressure safety valve

during heating.

1.1.6 Tank legs

Tank legs MUST NOT be screwed or

xed to the oor under any circum-

stances, otherwise expansion strain

will cause cracks, which may lead to

leakage. The tank must be placed on

theoor,supportedbyitslegs,which

must be able to move slightly as the

tankexpandsorcontracts.(Thescrew

holes in the base of the legs are for

transportationpurposesonly.)

1.1.7 Electronic control unit - maxi-

mum operating temperature

Damage to electronic components

may occur if the surrounding air

temperature in the immediate vicinity

rises above 40°C. The ambient air

temperature must be low enough to

enablesufcient heat radiationcool-

ing of the high temperature electronic

components.

1.1.8 Low power electrical supply

to control unit and electric anodes

Sufcient standard household plug

sockets are to be provided within the

area of the front covers of the ECO-

THERM control unit. Rating 230V

±5%, single phase, 2.5 kVA total

power for both sockets.

1.1.9 Copper piping and water borne

chloride ions

The following applies to installations

with copper piping and water borne

chlorideions(>100mg/litre):

1.1.9a Isolating connectors

All connections must be electrically

isolated from the copper piping using

the special isolating ange kits and

isolating screw connectors provided.

1.1.9bNon-sacricialelectricanode

Thenon-sacricialelectricanodesup-

plied must be connected to the mains

power supply and be operational at

all times, in order to inhibit galvanic

transport of material away from stain-

less steel surfaces.

1.1.9c Simple repair

Please note that in the unlikely event

of pitting occurring, affected stainless

steel areas can be quickly and cheaply

repaired to 100 % serviceability on site

by your local ECOTHERM Support

Centre using specialised techniques

developed by ECOTHERM. Stainless

steel therefore offers the best possible

choice for better hygiene, durability

and longer life.