26

Congratulations...

......on an excellent choice. We thank you for the preference accorded to our products.

LAMBORGHINI CALORECLIMA has been actively present in Italy and throughout the world since

1959 with a widespread network of agents and concessionary agents to constantly guarantee the

presence of our product on the market.

Alongside this is the support of a technical service, “LAMBORGHINI SERVICE”, which is entrusted

with the qualified servicing of the product.

For the installation and positioning of the boiler:

CAREFULLY OBSERVE THE LOCAL REGULATIONS IN FORCE

INDEX PAGE

GENERAL INSTRUCTIONS ______________________________________________27

DESCRIPTION_________________________________________________________28

MAIN COMPONENTS _________________________________________________29

DIMENSIONS_________________________________________________________30

TECHNICAL FEATURES _________________________________________________30

GAS - NOZZLE CALIBRATION ___________________________________________31

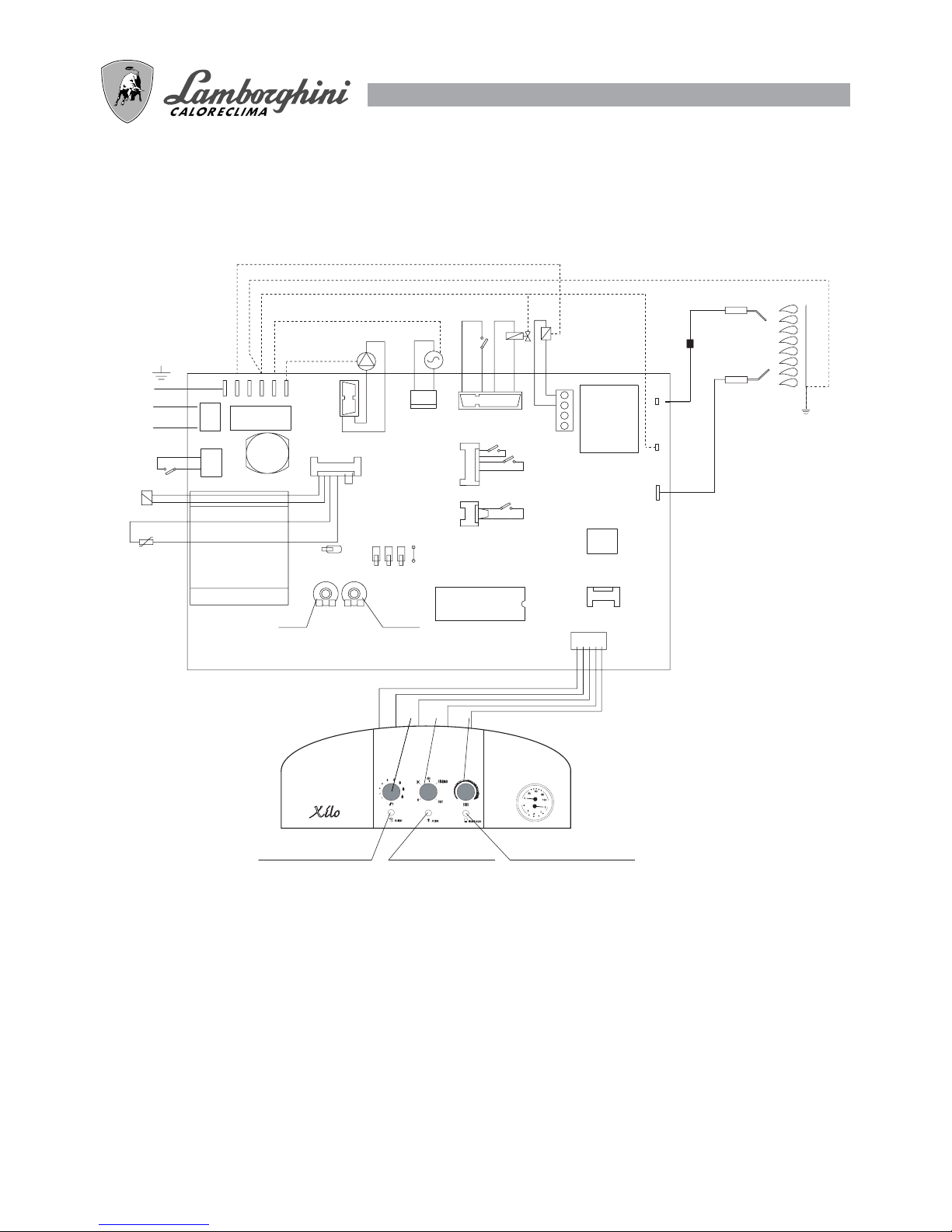

ELECTRICAL CONNECTIONS - WIRING DIAGRAMS ________________________32

MALFUNCTIONS AND ADJUSTMENTS ___________________________________36

WATER CONNECTION_________________________________________________37

WATER CIRCUIT _______________________________________________________38

INSTALLATION ________________________________________________________39

START-UP ____________________________________________________________39

FLUE EXHAUST CONNECTION __________________________________________40

FLUE EXHAUST INSTALLATION __________________________________________41

ADJUSTMENTS _______________________________________________________42

SWITCHING OFF______________________________________________________43

MAINTENANCE_______________________________________________________43

OPERATION WITH DIFFERENT TYPES OF GAS _____________________________45

FAULT-FINDING CHART ________________________________________________46