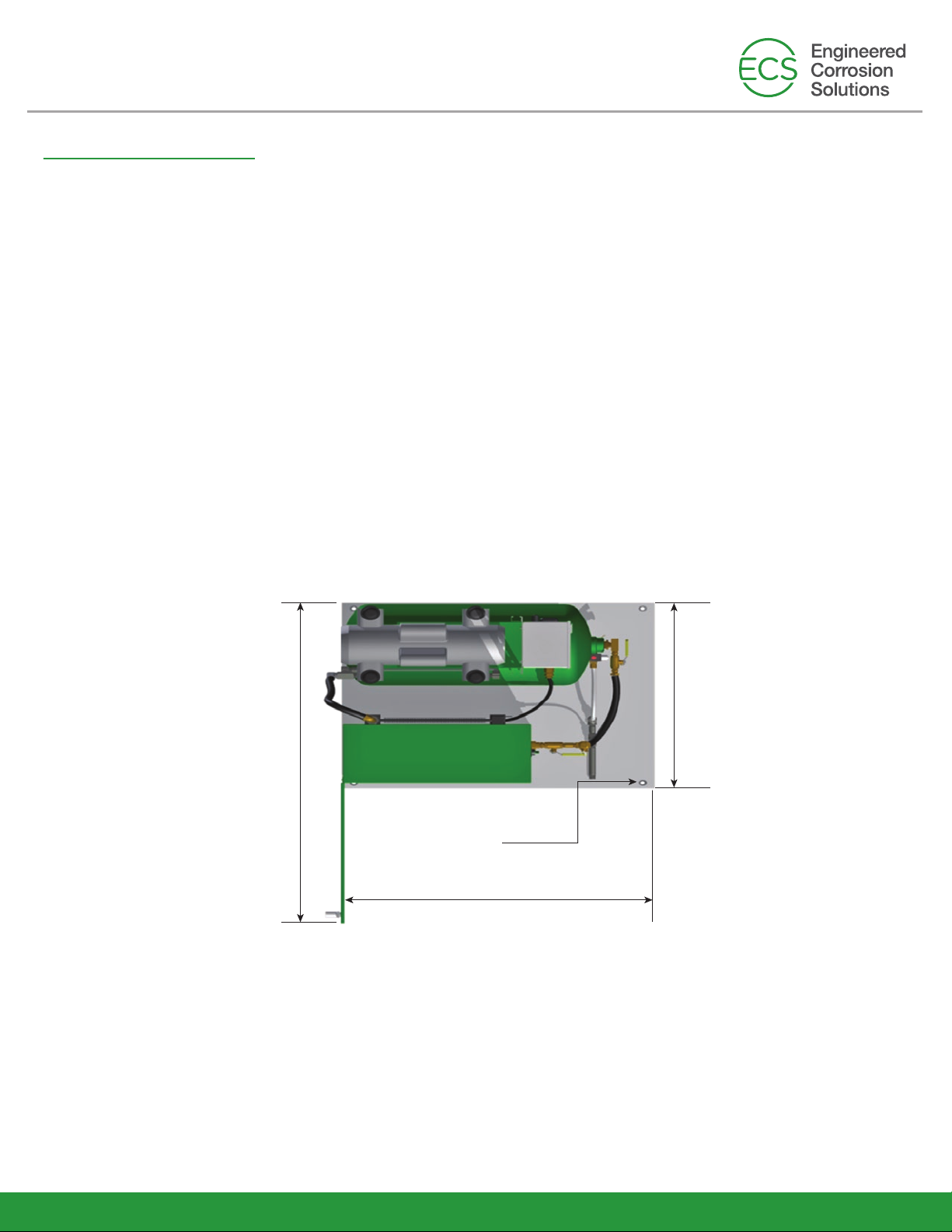

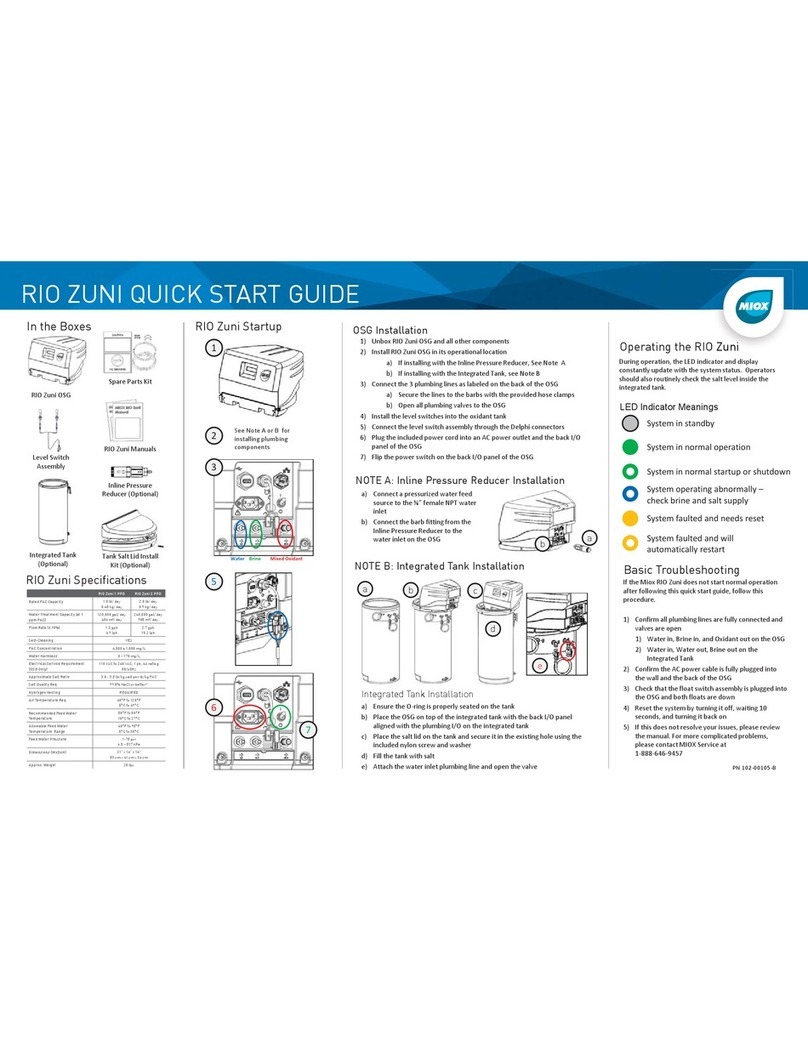

Step 3: Plumb the Nitrogen/Air Supply Line

The nitrogen/air discharge plumbing from the ECS Protector Nitrogen Generator is to be connected directly

to the sprinkler system valve trim using ½” to 1” black steel, galvanized steel, or copper piping. The size of

the nitrogen/air supply line shall be based on both the length of pipe between the nitrogen generator and

fire sprinkler systems and the total volume of fire sprinkler systems being supplied. The nitrogen generator

requires an in-line Air Maintenance Device (AMD) that is equipped with an on board field adjust able

pressure regulator for each zone being served. The preferred AMD is the Victaulic Series 757.

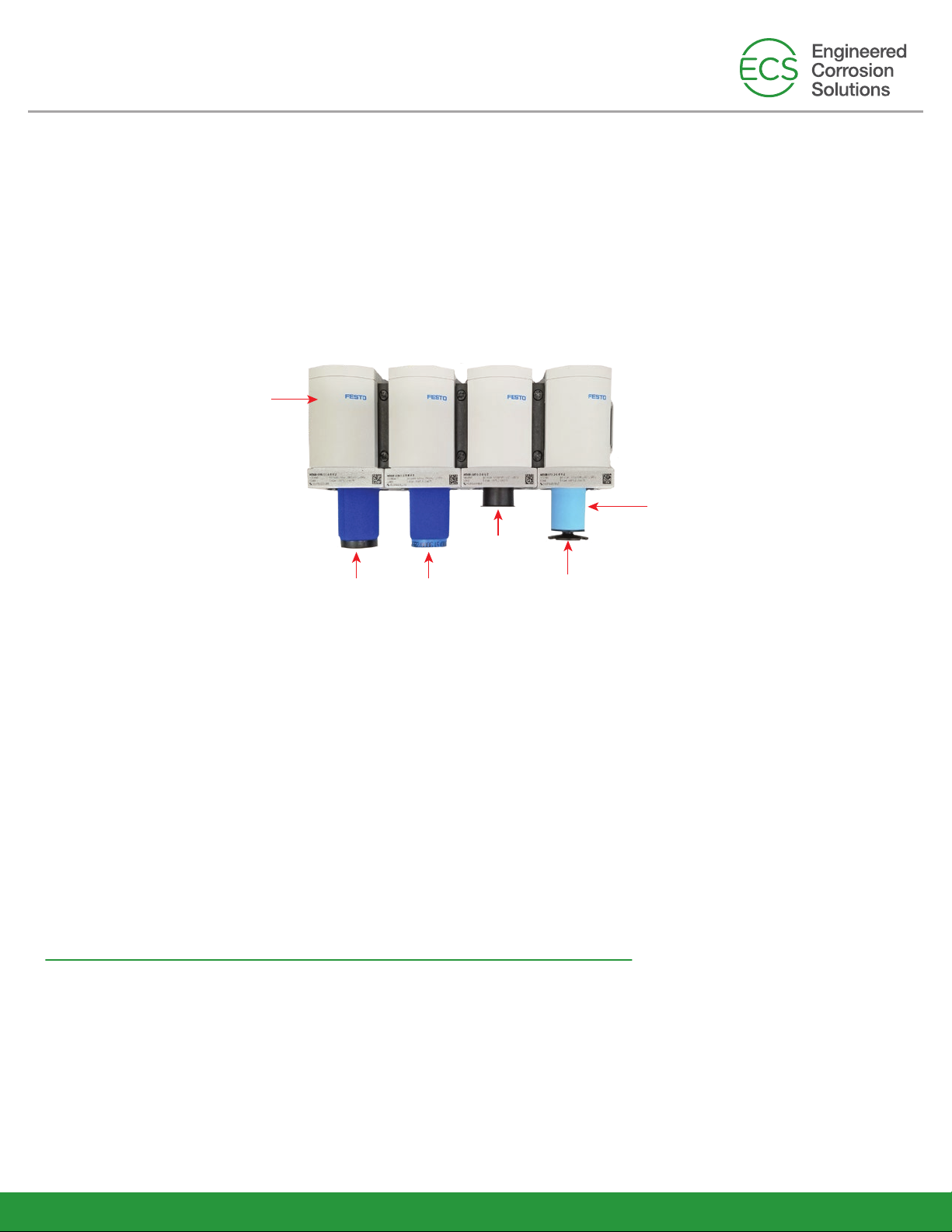

Step 4: Plumb the Condensate Drain Line

The ECS Protector Nitrogen Generator will occasionally discharge a small amount of condensate water

from the coalescing filters inside the cabinet and the air compressor tank. It is recommended that the ½”

drain connection be plumbed to a floor drain or building exterior. When plumbing to a drain is not feasible

an evaporative collection chamber can be used.

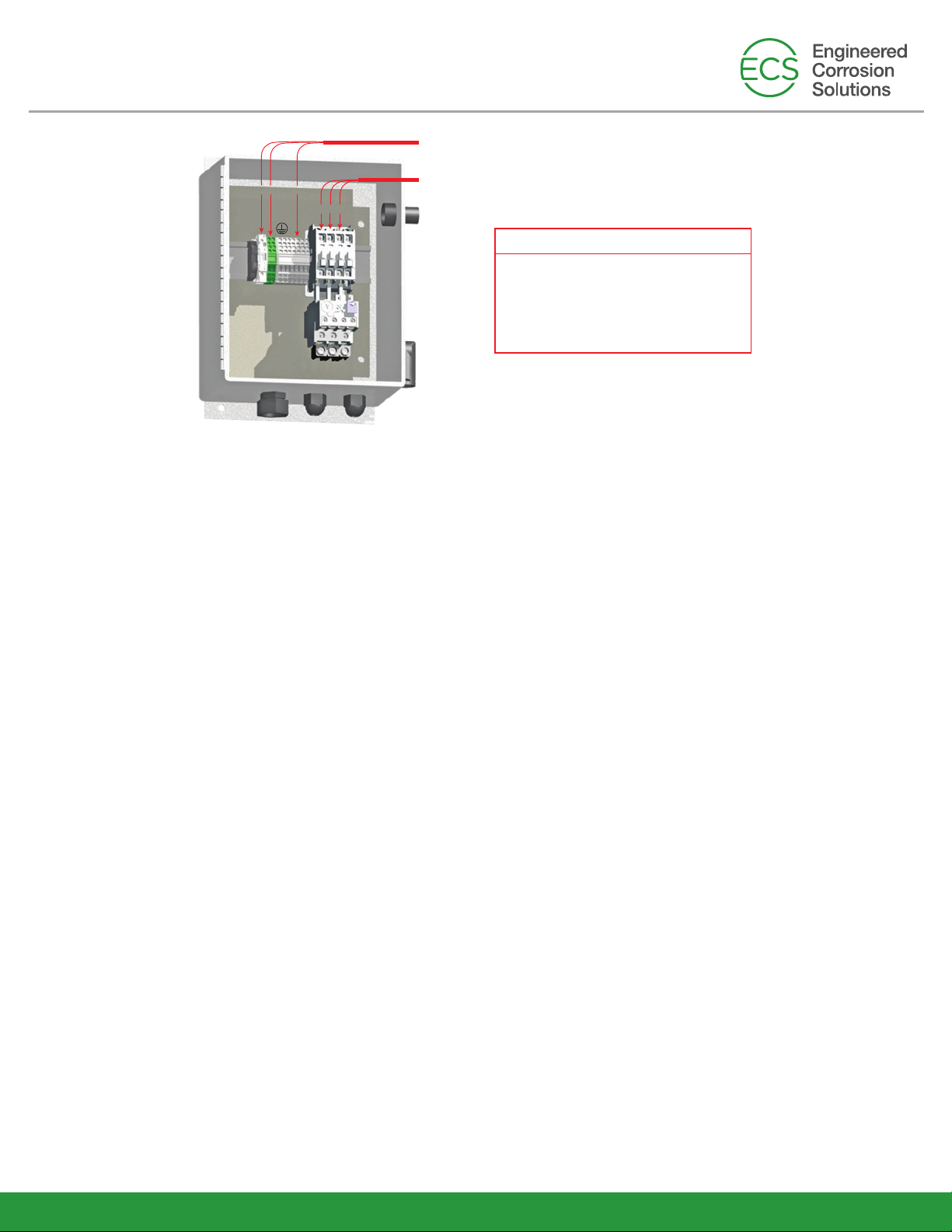

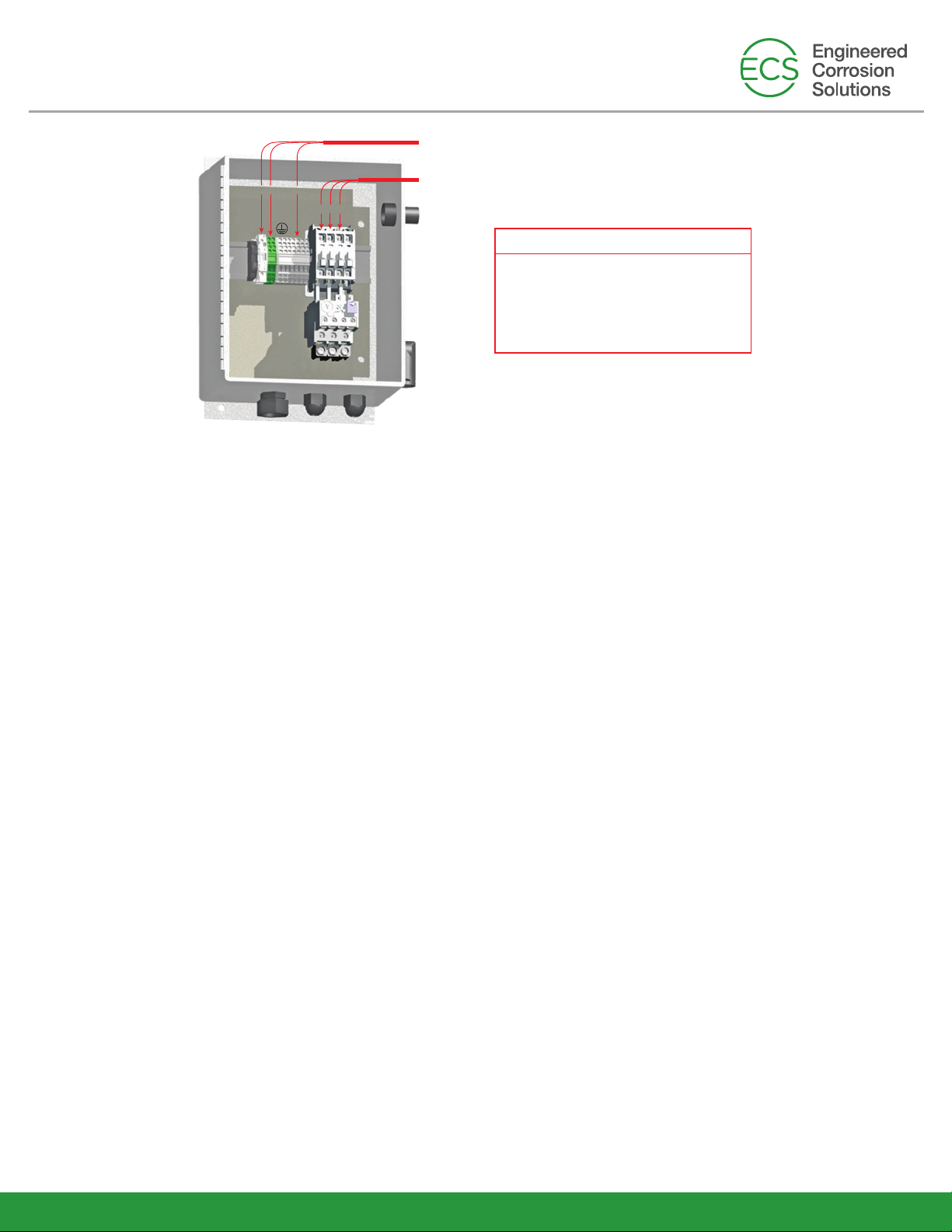

When providing 208VAC/3 phase/60Hz

to the control box, verify the

compressor and the motor starter have

been reconfigured for operating at

208VAC/3 phase/60Hz

NOTE:

L1 G N

120VAC/1 Phase 60Hz Connections

(220-240VAC/1 Phase 50Hz Connections)

480VAC/3 phase/60Hz Connections

208VAC/3 phase/60Hz Connections

(400VAC/3 phase/50Hz Connections)

L1 L2 L3

Rev 84

Engineered Corrosion Solutions •11336 Lackland Road St. Louis, MO 63146 •Phone: 314.432.1377 •www.ecscorrosion.com

NOTE: When both dry pipe and preaction fire sprinkler systems are connected to one nitrogen generator, additional

equipment may be required if the fire sprinkler systems operate at different supervisory gas pressures.

Step 5: System Signals and Monitoring, where used

The nitrogen generator cabinet has two (2) system signals and five (5) outputs that can be monitored by

the facility’s BMS or fire alarm system.

• Bypass Alarm - The nitrogen generator is operating in the bypass mode which is activated when

the bypass valve is in the “fast fill” position to fast fill the fire sprinkler system and the air supplied

directly from the air compressor has reached a pressure of 20 psig (1.4 bar).

(Flashing amber light)

• Leak Monitor - The nitrogen generator is equipped with a leak monitor audible signal which is

activated when the nitrogen generator runs excessively. (Audible signal)

The nitrogen generator cabinet includes system monitoring signals which can be monitored through a

building monitoring system, if desired:

• Nitrogen Generator Running - Form C contacts

• Bypass Mode Alarm - Form C contacts

• Nitrogen Generator Power Monitoring - Form C contacts

• Leak Monitoring - Form C contacts

• Nitrogen System Supply Line Pressure - Analog Signal

ECS Pre-Engineered Nitrogen Generator

PGEN-20 (20E)